Unveiling the inner workings of an advanced agricultural implement involves a meticulous breakdown of its intricate mechanisms. This section delves into the essential components that constitute a pivotal tool in modern farming practices. Understanding these elements is crucial for maintaining operational efficiency and ensuring optimal performance in agricultural settings.

Highlighted within this exploration are the critical parts that contribute to the seamless function of a cutting-edge equipment used in precision agriculture. Each component plays a pivotal role in enhancing productivity and precision, reflecting the synergy of engineering excellence and agricultural innovation.

New Idea 5212 Discbine Overview

This section provides a comprehensive look at a specific model of agricultural machinery designed for effective crop management. This implement is engineered to efficiently cut and condition forage, playing a crucial role in modern farming operations. Its innovative design combines functionality with durability, making it an essential tool for hay and silage production.

Key Features

The machinery is equipped with advanced cutting technology that ensures a clean and precise cut, promoting healthier regrowth. Its robust frame supports various field conditions, while the intuitive controls enhance usability for operators. Additionally, the integration of high-quality materials contributes to the longevity and reliability of the equipment.

Performance Benefits

Utilizing this implement significantly boosts operational efficiency, allowing farmers to cover larger areas in less time. The conditioning features facilitate faster drying times, improving the overall quality of the harvested material. As a result, this machine stands out as a valuable asset for enhancing productivity and profitability in agricultural practices.

Key Features of the Discbine

This section highlights the essential attributes that define the efficiency and effectiveness of this innovative agricultural implement. By examining its design and functionality, one can appreciate the unique advantages it offers to modern farming practices.

Enhanced Cutting Performance

The implement is designed to deliver superior cutting results, making it a valuable asset in haymaking and forage operations. Key aspects include:

- High-Quality Blades: Sharp, durable blades ensure clean cuts and minimize crop damage.

- Adjustable Cutting Height: Operators can easily modify the height to suit varying field conditions.

- Speed Control: Advanced mechanisms allow for optimal speed adjustments during operation, enhancing productivity.

Improved Durability and Maintenance

Built to withstand rigorous field conditions, this machine features several characteristics that promote longevity and ease of maintenance:

- Robust Frame Construction: A sturdy frame provides stability and reduces the risk of wear over time.

- Simple Maintenance Access: User-friendly design allows for quick access to essential components, making maintenance tasks straightforward.

- Weather-Resistant Materials: Components are crafted from materials that resist corrosion and wear, ensuring reliable performance in various climates.

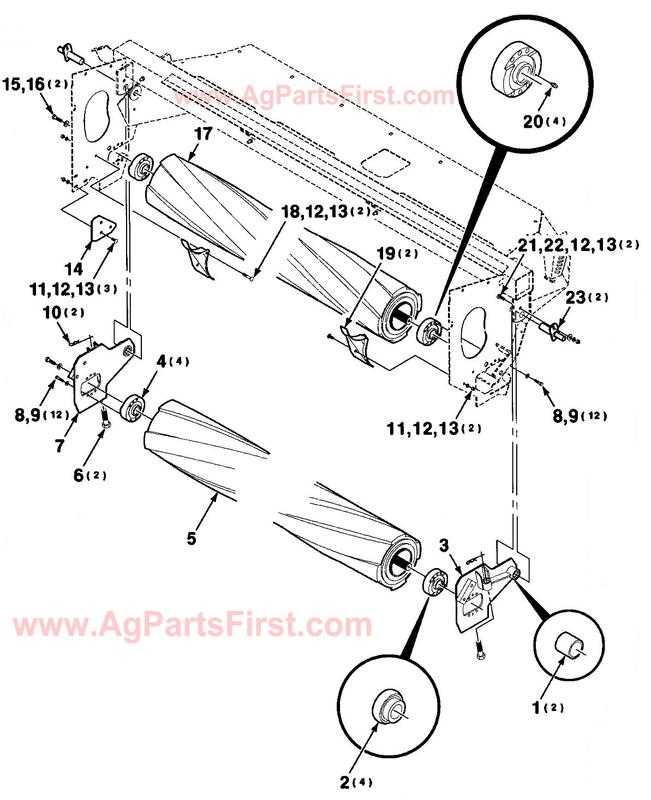

Understanding the Parts List

Grasping the components of agricultural machinery is essential for efficient operation and maintenance. Each element plays a crucial role in the overall functionality of the equipment, and recognizing their significance can enhance the user experience. Familiarity with the various components enables operators to troubleshoot issues, facilitate repairs, and ensure optimal performance.

Components Overview

The list includes various elements, each contributing uniquely to the machine’s operation. From drive mechanisms to cutting systems, understanding these components helps users appreciate how they work together to achieve desired outcomes. Detailed knowledge allows for better decision-making when it comes to repairs or upgrades.

Maintenance and Replacement

Regular maintenance is vital for ensuring longevity and efficiency. Knowing which components require periodic inspection or replacement can save time and resources. This awareness not only helps in maintaining productivity but also reduces the likelihood of unexpected breakdowns during crucial operational periods.

Importance of Accurate Diagrams

Clear and precise visual representations play a crucial role in understanding the intricate components and assembly processes of complex machinery. Accurate diagrams serve as fundamental tools for technicians and engineers, facilitating efficient troubleshooting, maintenance, and repairs. They provide a visual roadmap, guiding professionals through intricate systems without ambiguity.

The Significance of Clarity

Clarity in diagrams ensures that every component and connection is distinctly outlined, eliminating confusion and minimizing errors during maintenance procedures. Engineers rely on these detailed visuals to swiftly identify parts, understand their interactions, and execute repairs effectively.

Enhancing Efficiency and Reliability

Accurate diagrams streamline workflow processes, reducing downtime and optimizing operational efficiency. By offering a comprehensive view of the machinery’s structure, these diagrams contribute to the reliability of repairs and enhance overall equipment performance.

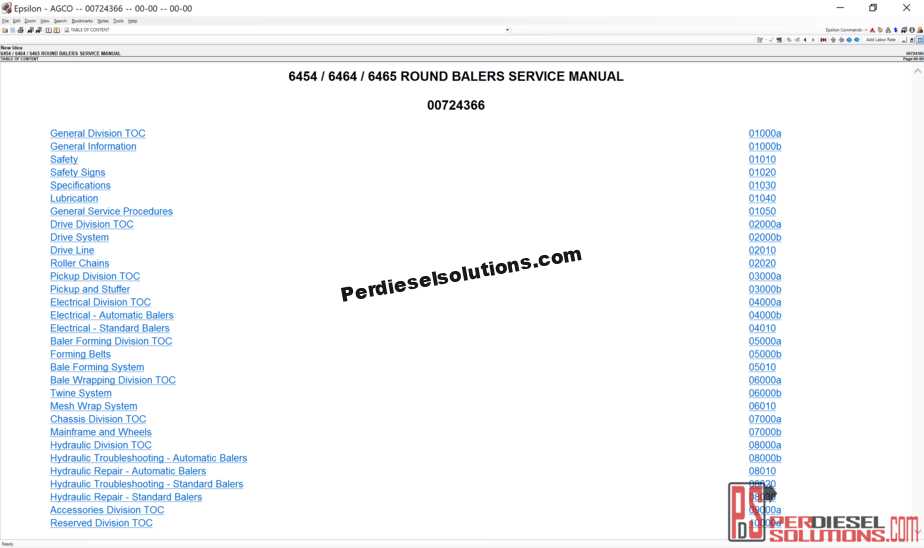

How to Read Parts Diagrams

Understanding schematic representations is crucial for effective maintenance and repair of machinery. These visual aids simplify complex assemblies by illustrating components and their interconnections. Grasping the basics of these illustrations can enhance your troubleshooting skills and streamline repair processes.

Key Elements to Identify

When examining a schematic, it’s important to recognize specific features that will guide you through the interpretation. Look for labels, numbers, and symbols that denote various elements within the system. Familiarity with these indicators can greatly improve your comprehension.

Utilizing Reference Tables

Many schematics include accompanying tables that provide detailed descriptions and specifications for each component. These tables serve as valuable tools for identifying parts and understanding their functions.

| Symbol | Description |

|---|---|

| A | Hydraulic pump |

| B | Drive belt |

| C | Control lever |

| D | Frame assembly |

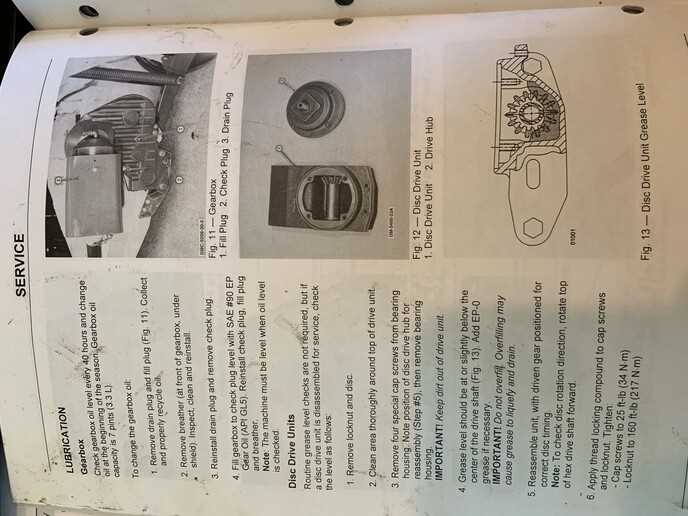

Common Maintenance Practices

Regular upkeep is essential for ensuring optimal performance and longevity of machinery. Implementing consistent maintenance routines can prevent unexpected breakdowns and enhance operational efficiency. Understanding fundamental practices will aid in prolonging the life of equipment and ensuring its reliability during use.

Routine Inspections

Conducting periodic assessments is crucial for identifying potential issues before they escalate. Inspections should include checking for wear and tear, ensuring all components are securely fastened, and verifying fluid levels. Addressing minor concerns promptly can save time and resources in the long run.

Lubrication and Cleaning

Maintaining proper lubrication levels is vital for reducing friction and preventing damage to moving parts. Regular cleaning helps remove debris and contaminants that could hinder performance. Establishing a schedule for both lubrication and cleaning can contribute significantly to the overall functionality and efficiency of the equipment.

Identifying Worn Components

Recognizing the signs of deterioration in machinery is crucial for maintaining optimal performance and preventing unexpected breakdowns. Regular inspections help in identifying components that may have lost their functionality due to wear and tear. This proactive approach not only extends the life of the equipment but also enhances operational efficiency.

Visual Inspection Techniques

One effective method for assessing component condition is through visual inspection. Look for signs of damage such as cracks, excessive rust, or unusual wear patterns. Frequent observations can reveal underlying issues that may not be immediately apparent, allowing for timely repairs or replacements.

Testing and Measurement

In addition to visual checks, employing testing methods such as measuring dimensions or performance can provide valuable insights. Components that fall outside acceptable tolerances may require immediate attention. Utilizing appropriate tools ensures accuracy and aids in making informed decisions regarding maintenance or replacement.

Replacement Parts Availability

When it comes to maintaining agricultural equipment, ensuring access to essential components is crucial for optimal performance. Availability of these necessary elements can greatly affect the efficiency and longevity of machinery. Understanding where to find reliable sources for replacements can simplify the repair process and minimize downtime.

Sources for Components

There are several options available for sourcing necessary components. Authorized dealers often provide original equipment options, while aftermarket suppliers may offer alternatives that are compatible and cost-effective. Additionally, online platforms have become increasingly popular, allowing for easy comparison of prices and availability.

Considerations for Selection

When selecting components, it’s important to consider factors such as quality, compatibility, and warranty. Original components typically offer the assurance of reliability, while aftermarket options may provide savings. Always check reviews and seek recommendations to ensure the best choice for your equipment.

| Supplier Type | Description |

|---|---|

| Authorized Dealers | Provide original equipment components with guaranteed compatibility and quality. |

| Aftermarket Suppliers | Offer alternative components that may be more affordable but should be evaluated for quality. |

| Online Platforms | Facilitate easy comparison shopping, allowing users to find the best prices and availability. |

Assembly Instructions for Discbine

This section provides comprehensive guidance on the proper assembly process for the cutting equipment. By following these steps, users can ensure that the machinery operates efficiently and effectively. Each stage of the assembly is outlined in detail, focusing on key components and their interconnections.

Preparation Steps

Before beginning the assembly, it is essential to gather all necessary tools and components. A well-organized workspace will facilitate a smoother assembly process. Ensure that all items are clean and free from debris to avoid complications during installation.

Assembly Process

The assembly consists of several stages, which are detailed in the following table:

| Step | Description |

|---|---|

| 1 | Secure the frame components using the specified fasteners. Ensure each connection is tight. |

| 2 | Attach the cutting blades to the designated brackets. Ensure alignment is precise for optimal performance. |

| 3 | Install the drive mechanism and connect it to the power source, ensuring safety precautions are followed. |

| 4 | Conduct a thorough inspection of all connections and components before the initial operation. |

By adhering to these assembly instructions, users can achieve a well-functioning system ready for efficient operation.

Troubleshooting Common Issues

When operating agricultural machinery, encountering problems is not uncommon. Understanding potential difficulties and their solutions can significantly enhance productivity and reduce downtime. This section will focus on typical challenges faced during operation and maintenance, providing guidance on how to effectively address them.

1. Poor Cutting Performance: If the cutting mechanism fails to perform optimally, it may lead to uneven cuts. Check for dull blades or obstructions in the cutting area. Regular sharpening and cleaning can prevent these issues.

2. Hydraulic System Malfunctions: Issues in the hydraulic system can cause a loss of power or responsiveness. Inspect hoses and connections for leaks or damage. Ensuring that the hydraulic fluid is at the correct level and in good condition is essential.

3. Uneven Crop Distribution: If crops are not being distributed evenly, it could be a sign of a blockage or misalignment. Examine the flow paths and make adjustments as needed to ensure proper functionality.

4. Excessive Wear and Tear: Frequent operation can lead to accelerated wear on various components. Regular inspections and timely replacements of worn parts can help maintain the machinery’s performance and longevity.

5. Electrical Issues: Problems with the electrical system can affect functionality. Inspect wiring for frays or loose connections, and ensure that all fuses are intact. A systematic approach to diagnosing electrical faults can save time and resources.

By recognizing and addressing these common challenges, operators can ensure smoother operation and enhance the efficiency of their equipment.

Upgrading Your Discbine Equipment

Enhancing your mowing machinery can significantly improve efficiency and performance. By integrating advanced components and modern technology, you can ensure that your equipment operates at its best, reducing downtime and increasing productivity. Regular updates not only prolong the lifespan of your machinery but also provide you with the latest features that can transform your mowing experience.

Benefits of Modernization

Investing in the latest enhancements allows operators to experience superior functionality. Upgrading can lead to improved cutting precision, better fuel efficiency, and enhanced comfort during operation. Furthermore, incorporating advanced systems may facilitate easier maintenance and diagnostics, ultimately saving time and resources in the long run.

Choosing the Right Components

When considering enhancements, it’s essential to select components that are compatible with your existing setup. Researching different manufacturers and understanding the specifications of various parts can help you make informed decisions. Additionally, consulting with experts or fellow operators can provide valuable insights into the best options available for your specific requirements.

Expert Tips for Efficient Use

Maximizing performance and longevity of your equipment requires strategic approaches and best practices. By implementing proven techniques, users can enhance productivity while minimizing downtime and maintenance costs.

Regular Maintenance Routines

Establishing a consistent maintenance schedule is crucial for optimal operation. Here are some essential tasks to include:

- Inspect all components for wear and tear.

- Clean machinery thoroughly after each use.

- Lubricate moving parts as per manufacturer recommendations.

- Check fluid levels and replace as needed.

Operating Techniques for Efficiency

Employing the right operating methods can significantly impact overall efficiency. Consider the following tips:

- Utilize proper speed settings for various tasks.

- Avoid overloading the equipment to ensure safe operation.

- Monitor environmental conditions to adapt practices accordingly.

- Stay updated on the latest technologies and improvements in machinery.