When it comes to serving drinks efficiently, having a well-organized setup is crucial. This setup includes various essential elements that work together to ensure proper functionality and smooth operation. Knowing how each element contributes to the whole system can greatly enhance your understanding of the overall structure.

Each piece in the system plays a specific role, whether it’s handling the storage, controlling the pressure, or facilitating the flow of liquids. By identifying and recognizing the purpose of these individual components, you can ensure better maintenance and make informed decisions when upgrading or replacing parts.

Whether you’re setting up or troubleshooting, having a clear view of how everything fits together is essential. This guide will provide a detailed look into the core elements that make up the system, helping you achieve optimal performance.

Understanding the Components of a Keg

In beverage dispensing systems, it’s essential to understand the various elements involved in ensuring smooth and consistent flow. These elements work together to manage both the liquid and pressure, making sure everything functions efficiently. Each piece plays a unique role in maintaining the overall integrity of the system.

Valves are crucial for controlling the release of the beverage. They regulate the amount of liquid that flows out, ensuring that it is dispensed at the right rate. The design of these mechanisms allows for easy opening and closing, providing control over the flow.

The connectors act as bridges between different parts of the system, enabling the transfer of fluids. Their job is to create a secure and tight seal, preventing any unwanted leaks or spills

Exploring the Functionality of Keg Couplers

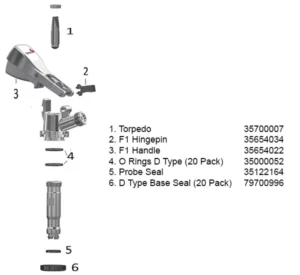

One of the critical components used in dispensing beverages is a connector that ensures a secure link between the dispensing system and the container. This connector plays a crucial role in enabling the transfer of liquid from the container to the tap, making it an essential element in the entire process.

Types of Connectors

There are various types of these connectors, each designed to match specific regional or brand requirements. Understanding the differences between them can help ensure compatibility with the dispensing setup. Some common types include:

- A-Type, often used in certain regions or for specific brands.

- D-Type, popular across different regions and brands.

Key Features of Keg Valves

Valves play a crucial role in maintaining the proper flow and control of liquids. These components are designed to regulate the movement of fluids, ensuring efficient operation and preventing any unnecessary leaks or spills. The features of these valves directly influence their performance and durability in various setups.

Durability and Material Composition

One of the essential characteristics of these valves is their durability, which is largely determined by the materials used in their construction. High-quality alloys or stainless steel are commonly chosen to ensure long-lasting resistance against wear, corrosion, and frequent handling. These materials also contribute to the overall safety and hygiene, making them suitable for long-term use.

Flow Control Mechanisms

Another key aspect is

Examining the Role of Pressure Regulators

The function of pressure regulators is essential in ensuring balanced control of airflow in a system. These components are specifically designed to manage the flow of gas, providing stability and preventing any fluctuations that could disrupt overall performance.

Maintaining Stability: A well-functioning pressure regulator helps maintain a consistent level, ensuring that the flow remains within the desired range. This prevents potential imbalances that could lead to operational issues or safety concerns.

Adjusting for Optimal Performance: Regulators allow fine-tuning of the gas flow to match specific needs. This ensures that the system operates smoothly, without any interruptions, and is adaptable to different conditions.

By understanding the critical role of these regulators, one

Anatomy of a Keg Faucet

Understanding the various components of a liquid dispensing handle is essential for efficient and smooth operation. Each piece works in harmony, ensuring a steady flow and precise control over the release of liquid. This section provides an overview of the main elements involved in this process.

Handle Mechanism

The top section is where the user interacts with the device. The lever allows for opening and closing the valve with ease. When pushed or pulled, it engages the internal components to release or stop the flow. The design ensures ergonomic handling and consistent control.

Valve and Spout

Located below the handle, the valve controls the release of the liquid. It connects to a tube that directs the flow into a spout. The precision of the valve ensures minimal dripping

How Gas Lines Support Dispensing

In the realm of beverage distribution systems, the effective transportation of carbon dioxide or other gases plays a crucial role in maintaining optimal performance. These conduits are integral to ensuring that the contents remain pressurized, allowing for a seamless flow from the storage vessel to the serving apparatus.

By creating a controlled environment, these flexible tubes enable the consistent delivery of the beverage while preserving its carbonation and freshness. The efficient functioning of these lines directly impacts the speed and quality of the pouring process, ensuring that the drink is served at the desired temperature and texture. Additionally, proper maintenance of these systems prevents leaks and potential waste, contributing to the overall efficiency of the dispensing setup.

The Importance of Liquid Lines in Kegs

Liquid channels play a crucial role in the efficient delivery of beverages from storage containers to dispensing systems. These conduits are designed to ensure that the contents flow smoothly while maintaining the desired temperature and carbonation levels. Understanding their significance can enhance the overall experience of beverage consumption.

Properly designed fluid pathways are essential for minimizing waste and preventing spoilage. By facilitating a consistent flow, they help preserve the quality and freshness of the beverage until it reaches the consumer. Additionally, well-maintained channels contribute to the efficiency of the dispensing system, allowing for quicker service and reducing downtime during peak usage times.

Moreover, the materials used in these lines can affect the taste and aroma of the drinks being served. Selecting high-quality, food-grade materials is vital to prevent contamination and ensure that the product’s integrity remains intact. Regular inspections and maintenance of these lines are equally important to avoid blockages and leaks, which can lead to costly repairs and decreased customer satisfaction.

Maintenance Tips for Keg Seals and O-Rings

Ensuring optimal performance of your brewing equipment involves regular attention to essential components that help maintain pressure and prevent leaks. The longevity and effectiveness of these crucial elements significantly affect the overall functionality of the system.

1. Regular Inspection: Periodically examine the integrity of the seals and O-rings. Look for signs of wear, cracks, or deformation that may compromise their ability to create a secure fit.

2. Clean Thoroughly: Keep these components free from debris and residue. Use warm, soapy water to clean them, and rinse thoroughly to remove any soap residue, as it can degrade the material over time.

3. Proper Lubrication: Apply a suitable lubricant specifically designed for rubber or silicone. This can enhance the elasticity and help prevent cracking while ensuring a snug fit during assembly.

4. Replace as Needed: Don’t hesitate to replace seals and O-rings at the first sign of wear. Using damaged components can lead to leaks and pressure loss, affecting the quality of your product.

5. Store Properly: When not in use, store these parts in a cool, dry place away from direct sunlight. This helps preserve their material integrity and prolongs their lifespan.

Identifying Parts of a Keg Shell

The structure that holds and preserves beverages is composed of several essential components, each serving a unique function in ensuring optimal storage and dispensing. Understanding these elements is crucial for effective maintenance and operation, allowing for a seamless experience in beverage management.

Understanding the Outer Shell

The outer shell provides the necessary strength and durability to withstand internal pressure. Typically constructed from stainless steel or aluminum, this robust layer is designed to prevent leaks and maintain the integrity of the contents inside. It is often cylindrical in shape, facilitating easy handling and stacking.

Exploring the Opening Mechanism

At the top of the structure, an opening mechanism is present, which allows for filling and dispensing. This area usually features a sealing element that ensures airtight closure, preventing contamination and preserving freshness. Recognizing this component is vital for ensuring proper operation during both filling and serving processes.

Best Practices for Keg Handles

Proper management and maintenance of the handles used for dispensing beverages can significantly enhance user experience and operational efficiency. Adhering to best practices ensures longevity and functionality while also prioritizing safety.

- Regular Cleaning: Consistent sanitation of handles prevents the buildup of residue and ensures hygienic operation.

- Secure Attachment: Ensure that handles are tightly fastened to avoid accidents or spillage during use.

- Inspection for Wear: Periodically check for any signs of wear or damage to prevent malfunction during service.

- Comfortable Grip: Select handles designed for ease of use, allowing for a comfortable grip to minimize strain during operation.

- Color-Coding: Utilize distinct colors for different beverage types to reduce confusion and enhance workflow.

Implementing these strategies not only improves functionality but also contributes to a safer and more enjoyable environment for all users.

Temperature Control with Keg Insulators

Maintaining the ideal temperature for beverages is crucial for flavor preservation and overall enjoyment. Using specialized insulating materials can significantly enhance temperature regulation by minimizing heat exchange with the surrounding environment. This approach ensures that drinks remain chilled or at a desired warmth for extended periods.

Insulating solutions serve as a barrier against external temperature fluctuations, which can adversely affect the contents. These solutions not only help in retaining cold or warm temperatures but also promote energy efficiency by reducing the need for constant cooling or heating. Additionally, they can protect the container from condensation, which can lead to moisture-related issues.

Implementing such insulating materials can be particularly beneficial in various settings, from home gatherings to professional environments. With proper insulation, one can enjoy beverages at their peak quality, enhancing the overall experience for guests or customers.

How Keg Caps Protect Your Beverage

Caps play a vital role in ensuring the freshness and quality of your drink. By creating a secure seal, they prevent contaminants from entering and maintain the ideal conditions for storage. Understanding their importance can enhance your overall beverage experience.

These protective covers offer several key benefits:

- Prevention of Contamination: Caps help block dust, dirt, and other foreign particles from spoiling the liquid.

- Pressure Maintenance: They assist in retaining the carbonation, ensuring that your beverage remains fizzy and enjoyable for a longer time.

- Flavor Preservation: By keeping air out, caps help maintain the intended taste and aroma, safeguarding against oxidation.

- Safety Assurance: Properly fitted caps prevent accidental spills and leaks, ensuring safe handling and transport.

In conclusion, these essential components are crucial for maintaining the integrity and enjoyment of your drink. Their functionality extends beyond mere convenience, providing a reliable barrier against various external factors that could compromise quality.

The Impact of Keg Dip Tubes on Pour Quality

The design and functionality of the delivery components within a beverage container play a crucial role in ensuring the optimal serving of drinks. These elements directly influence the taste, presentation, and overall experience for the consumer. Understanding their significance can lead to improvements in beverage serving methods and enhance customer satisfaction.

Flow Efficiency and Consistency

One of the primary functions of these delivery components is to facilitate a smooth flow of liquid from the container to the glass. When properly designed, they minimize turbulence and maintain a consistent pour rate, ensuring that each serving is uniform. This efficiency is vital for maintaining the integrity of the beverage, as it helps preserve carbonation levels and flavor profiles.

Minimizing Contamination

Another important aspect is the role these components play in preventing contamination. Well-engineered systems reduce the risk of unwanted elements entering the beverage, which can negatively impact taste and quality. Ensuring cleanliness and proper functionality is essential to providing a safe and enjoyable drinking experience.