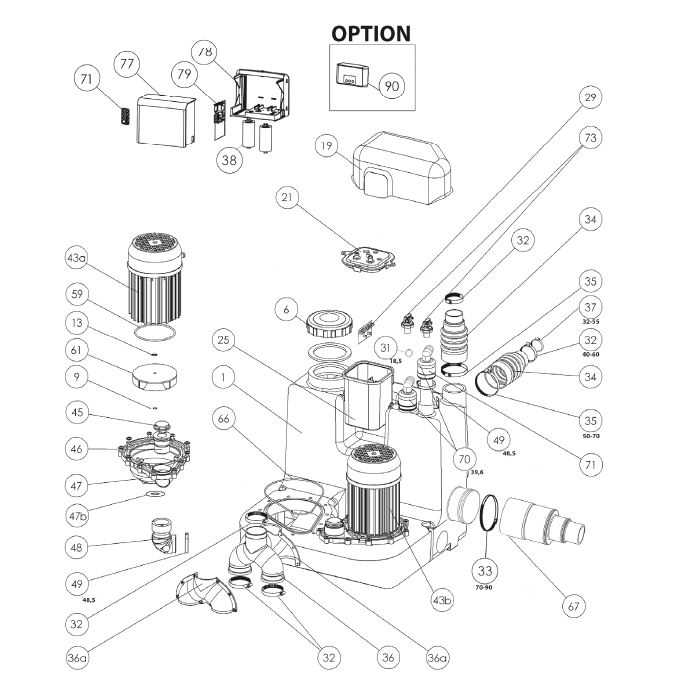

In any effective waste management system, comprehending the individual elements is crucial for optimal performance. Each component plays a specific role, contributing to the overall functionality and efficiency of the system. A thorough examination of these components allows for better maintenance and troubleshooting.

By analyzing the various elements, users can gain insights into how these mechanisms operate together. This understanding can aid in identifying potential issues before they escalate, ensuring that the system runs smoothly. Recognizing each component’s purpose and arrangement is essential for anyone looking to enhance their knowledge of waste management solutions.

Ultimately, an in-depth look at these features equips users with the necessary information to make informed decisions regarding installation, repair, and upgrades. This knowledge empowers individuals to address challenges proactively, leading to improved longevity and reliability of the system.

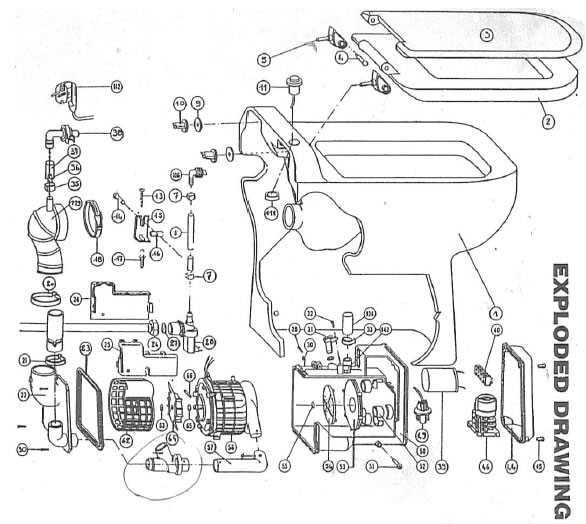

The innovative waste removal system provides a practical solution for areas lacking traditional plumbing. Its design allows for efficient management of wastewater, ensuring optimal functionality in various settings. This section will explore the essential components that contribute to the system’s effectiveness and reliability.

Understanding the key elements of this system is crucial for maintenance and troubleshooting. Below are the primary features that define its operational efficiency:

- Macreator: The unit’s core component responsible for breaking down waste.

- Discharge Pipe: A crucial element that transports waste to the main sewage line.

- Control Panel: The interface for managing the system’s operations and settings.

- Check Valve: Prevents backflow, ensuring that wastewater flows in the right direction.

- Inlet Ports: Points of entry for wastewater from various fixtures.

Each part plays a significant role in the overall performance of the system. Understanding these components aids in troubleshooting and ensures efficient operation. For those maintaining or installing the unit, familiarity with these features is essential for optimal performance.

Key Components of Saniplus Units

Understanding the essential elements of these units is crucial for effective operation and maintenance. Each component plays a significant role in ensuring optimal performance, allowing for efficient waste management in various settings. Below, we explore the primary elements that contribute to the functionality of these systems.

Pumping Mechanism: The core of any waste removal system, this mechanism is responsible for transporting waste away from its source. Its efficiency directly impacts the overall effectiveness of the unit.

Switching System: This element triggers the operation of the pump when necessary. A reliable switching system ensures that the pump activates only when needed, helping to conserve energy and prolong the lifespan of the equipment.

Inlet and Outlet Connections: These connections are vital for the proper flow of waste into and out of the system. Their design and placement are critical to prevent blockages and ensure smooth operation.

Collection Chamber: This component temporarily holds the waste before it is pumped out. A well-designed chamber minimizes odors and enhances efficiency by allowing for optimal waste storage.

Control Panel: Often overlooked, this interface allows users to monitor and manage the unit’s performance. A user-friendly control panel provides essential feedback and control options, contributing to overall ease of use.

Noise Reduction Features: These components are designed to minimize the sound produced during operation. Effective noise reduction enhances user comfort, making the system suitable for residential or commercial environments.

Functionality of Each Part

This section explores the roles and responsibilities of various components within the system, highlighting how they work together to ensure optimal performance. Understanding these functions is crucial for effective maintenance and troubleshooting.

- Motor: The motor is the driving force, responsible for activating the entire mechanism. It converts electrical energy into mechanical energy, enabling movement within the assembly.

- Pump: The pump facilitates the transportation of waste materials, ensuring efficient disposal. It creates pressure to push liquids through the system, minimizing blockages.

- Float Switch: This component monitors the water level within the unit. When the level rises beyond a certain point, the float switch activates the pump, preventing overflow.

- Check Valve: The check valve prevents backflow, ensuring that waste materials do not return to the basin. This component is essential for maintaining a one-way flow.

- Inlet and Outlet Ports: These ports serve as the entry and exit points for waste and water. They are strategically designed to facilitate smooth flow and easy connection to plumbing systems.

- Housing: The housing encases the entire system, providing protection and structural support. It is designed to withstand various environmental conditions while ensuring safety and stability.

Each component plays a vital role in the functionality of the assembly, and understanding their individual contributions can enhance the efficiency and reliability of the overall system.

Understanding the Pump Mechanism

The operation of a pumping system relies on the coordinated interaction of various components to ensure efficient fluid movement. Grasping the intricacies of how these elements work together is crucial for effective maintenance and troubleshooting. A thorough comprehension of the internal workings can enhance performance and longevity.

Key Components of the System

The functionality of the device hinges on several essential parts, each fulfilling a specific role in the overall mechanism. Recognizing these components can provide valuable insights into the device’s operation.

| Component | Function |

|---|---|

| Motor | Drives the pump to move fluids. |

| Impeller | Increases fluid velocity and pressure. |

| Housing | Encases and protects internal parts. |

| Check Valve | Prevents backflow of fluids. |

Operation Principles

The effectiveness of the pumping apparatus is attributed to its ability to create a pressure differential that facilitates fluid movement. When activated, the motor initiates the impeller’s rotation, generating a flow that pushes the liquid through the system. The arrangement of components ensures that the fluid flows in a controlled manner, promoting efficiency and reliability.

Common Issues with Saniplus Parts

When dealing with specific systems for waste management, users may encounter a range of common challenges. These complications can arise from various components that play crucial roles in ensuring efficient operation. Understanding these potential pitfalls is essential for effective troubleshooting and maintenance.

Frequent Complications

- Clogging: Obstructions often occur due to debris accumulation or inappropriate items being disposed of, leading to system inefficiency.

- Leakage: Poor seals or damaged connections can result in leaks, causing water damage and requiring prompt attention.

- Noise Issues: Unusual sounds may indicate underlying mechanical problems, which can disrupt normal operation.

- Poor Performance: Insufficient power or inadequate capacity can hinder the unit’s ability to handle waste effectively.

Preventative Measures

- Regular maintenance checks to identify wear and tear on components.

- Avoid flushing non-biodegradable materials to reduce clogging risks.

- Ensure proper installation of seals and connections to prevent leaks.

Maintenance Tips for Longevity

Ensuring the extended functionality of your waste management system requires regular care and attention. Proper upkeep can prevent premature wear and enhance the overall efficiency of the unit. Below are essential recommendations to help maintain your system effectively.

| Maintenance Task | Frequency | Details |

|---|---|---|

| Inspect for Leaks | Monthly | Check all connections and components for any signs of moisture or leaks to prevent water damage and inefficiency. |

| Clean Filters | Every 3 Months | Remove and clean filters to ensure optimal flow and prevent blockages, which can hinder performance. |

| Check Electrical Connections | Every 6 Months | Inspect wiring and connections for any wear or damage, ensuring all components are secure and functioning properly. |

| Flush System | Annually | Run a thorough flush with a suitable cleaning solution to remove buildup and maintain smooth operation. |

| Monitor Sounds | Regularly | Pay attention to unusual noises during operation, which may indicate underlying issues that require immediate attention. |

By adhering to these maintenance practices, you can significantly extend the lifespan of your system while ensuring reliable performance throughout its use.

Identifying Replacement Parts Easily

Understanding the various components of a drainage system is essential for effective maintenance and timely repairs. When issues arise, knowing how to locate the necessary elements can save both time and money. This section aims to simplify the process of recognizing and sourcing the right components for your system.

Common Components Overview

Familiarity with the typical elements found in these systems can significantly ease the identification process. Each unit comprises essential components such as the pump, macerator, and inlet connections. By understanding the function of each item, users can pinpoint potential replacements when issues occur.

Utilizing Resources for Assistance

To enhance the search for the correct replacements, leverage online resources and manuals. Many manufacturers provide detailed guides and illustrations, which can serve as valuable references. Additionally, reaching out to support teams or forums can offer insights from experienced users, ensuring you find the precise replacements needed for optimal functionality.

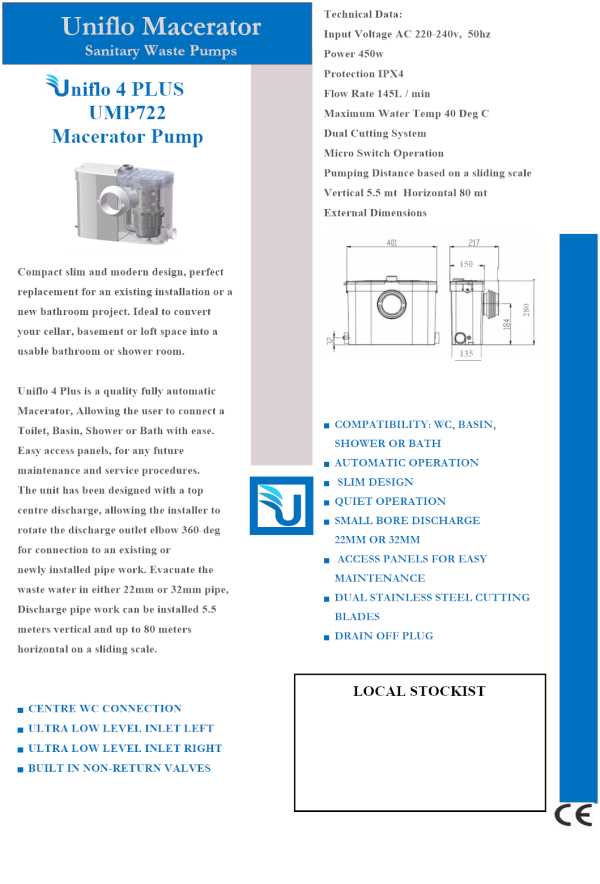

Installation Guidelines for Saniplus

Setting up a waste removal system can significantly enhance the functionality of any space, particularly in areas where traditional plumbing is not feasible. This section provides essential recommendations to ensure a successful installation process, focusing on the key components and procedures that facilitate optimal operation.

Preparation Steps

Before commencing installation, it is crucial to assess the intended location thoroughly. Ensure that the surface is level and capable of supporting the unit’s weight. Gather all necessary tools and materials, including connectors and fasteners, to streamline the process. Familiarize yourself with the manufacturer’s specifications to adhere to guidelines for placement and assembly.

Connection and Setup

Begin by connecting the drainage pipes securely, ensuring that all joints are watertight. Follow the manufacturer’s instructions regarding the orientation and positioning of each element. After all connections are made, conduct a thorough inspection to identify any potential leaks. Testing the system before finalizing the setup is essential for verifying functionality and performance.

Differences Between Saniplus Models

When exploring the various versions of a specific macerating system, it’s essential to understand the nuances that set each variant apart. These differences can significantly impact functionality, installation, and user experience. Below are the key aspects that distinguish the models available in this category.

Performance and Capacity

- Different models feature varying motor power, affecting the ability to handle waste.

- Some versions have a higher capacity for wastewater, making them suitable for larger installations.

- Efficiency ratings may vary, influencing the overall energy consumption of each unit.

Design and Features

- Certain versions offer compact designs, ideal for restricted spaces, while others are bulkier.

- Additional features, such as noise reduction technology, may be present in specific models.

- Variations in discharge options can impact installation flexibility and plumbing compatibility.

Connecting Saniplus to Drainage System

Establishing a link between a macerator pump and a waste disposal system is essential for efficient operation. This process involves ensuring proper alignment and connection with existing plumbing. The setup aims to facilitate the seamless removal of wastewater while preventing backflow and leaks.

Preparation is Key to a successful installation. Begin by gathering all necessary tools and materials, including the pump unit, fittings, and plumbing pipes. It is crucial to assess the layout of the area to determine the best routing for the discharge line, ensuring minimal bends and obstructions.

Installation Steps typically involve positioning the pump near the source of waste, connecting the inlet pipe from the fixtures to the pump, and then routing the outlet pipe to the drainage system. Proper sealing and secure connections will help maintain the integrity of the system. Additionally, following the manufacturer’s guidelines during this process will enhance overall functionality and longevity.

Regular maintenance and checks will ensure that the connections remain effective, preventing potential issues in the future. This proactive approach not only preserves the system but also promotes a hygienic environment.

Compatible Accessories for Saniplus

When it comes to enhancing the functionality of specific drainage systems, a variety of complementary components are available. These accessories can significantly improve performance, ensure optimal operation, and provide greater flexibility in installation. Understanding the options can help users make informed decisions about the best enhancements for their needs.

Types of Compatible Components

- Pumps: Essential for moving wastewater efficiently, various models cater to different requirements.

- Hoses: Durable and flexible options help facilitate the transport of waste to the main sewer line.

- Valves: Automatic or manual systems prevent backflow and maintain system integrity.

- Fittings: Various connectors and couplings allow for secure and leak-free installations.

Benefits of Accessory Integration

- Enhanced Efficiency: Proper components can improve the overall performance of the drainage system.

- Increased Durability: Quality accessories contribute to the longevity of the entire setup.

- Greater Versatility: A range of options allows for customization based on specific needs.

- Simplified Maintenance: The right tools can make upkeep and repairs more straightforward.

Usage Scenarios for Saniflo Systems

These innovative systems offer flexible solutions for enhancing plumbing configurations, making them ideal for various situations where traditional drainage methods may not be feasible. Their ability to manage waste efficiently from multiple sources allows for creative applications in both residential and commercial environments.

Installation in Basements: Many homeowners find themselves in need of additional bathroom facilities in basements, where standard plumbing may be difficult to implement. Utilizing these systems enables the installation of bathrooms in lower levels without extensive renovation work, providing comfort and convenience.

Remote Locations: In situations where access to conventional sewage systems is limited, such systems can transport waste over considerable distances. This feature is particularly beneficial for cabins, garden houses, or remote offices, ensuring functionality in less accessible areas.

Additional Bathrooms: Expanding a property often leads to the desire for extra restroom facilities. These systems facilitate the addition of bathrooms or powder rooms, catering to growing family needs or increased visitor traffic, enhancing overall property value.

Commercial Applications: Business owners can benefit significantly from these versatile systems. Restaurants, cafes, or retail spaces can install restrooms without major plumbing alterations, promoting a seamless customer experience while maximizing available space.

Troubleshooting Common Problems

When dealing with common issues in waste management systems, understanding the potential malfunctions is crucial for effective resolution. Various symptoms can indicate underlying problems, and timely identification can prevent further complications and ensure optimal performance.

Identifying Blockages

One of the most frequent challenges encountered is blockage within the system. This can manifest as slow drainage or complete stoppage. To address this, inspect the discharge pipes for any obstructions or debris. Using a plumbing snake can be an effective method for clearing minor blockages. If the issue persists, consider checking the venting to ensure proper airflow.

Examining Power Supply Issues

Power supply malfunctions can also lead to operational failures. If the unit does not activate, verify that the electrical connections are secure and that the circuit is functioning correctly. It’s advisable to check the fuse or circuit breaker to ensure power is reaching the device. In case of consistent issues, consulting a qualified electrician is recommended for a thorough assessment.