The intricate layout of a vehicle’s frontal structure plays a crucial role in its overall performance and safety. This section aims to illuminate the various elements that constitute the frontal assembly, highlighting their interconnections and significance. A comprehensive understanding of these components can greatly enhance maintenance and repair processes.

Each element, from the chassis to the attachments, serves a distinct purpose, contributing to both functionality and aesthetics. Recognizing how these parts interact with one another not only aids in troubleshooting but also supports informed decisions when upgrading or replacing components. The assembly is designed to withstand external pressures while ensuring the vehicle operates efficiently under diverse conditions.

In this exploration, we will delve into the essential features of the frontal assembly, providing insights that can empower owners and enthusiasts alike. By understanding the layout and function of each component, one can appreciate the engineering that goes into creating a robust and reliable vehicle. Emphasizing clarity and accessibility, this guide serves as a valuable resource for those seeking to deepen their knowledge of automotive mechanics.

Understanding the Front End Components

The assembly at the vehicle’s foremost section plays a crucial role in its overall functionality and performance. This collection of components works in harmony to ensure stability, control, and safety during operation. Each element serves a specific purpose, contributing to the vehicle’s responsiveness and driving experience.

Main Structural Elements

At the core of this assembly are the structural elements that provide support and rigidity. These components not only absorb shocks from the road but also help maintain the vehicle’s alignment and balance. Their design is critical for ensuring that the vehicle can handle various driving conditions effectively.

The suspension and steering systems are vital for maneuverability and comfort. These systems work together to isolate the cabin from road irregularities while allowing for precise directional control. Proper maintenance of these mechanisms is essential for a safe and enjoyable driving experience.

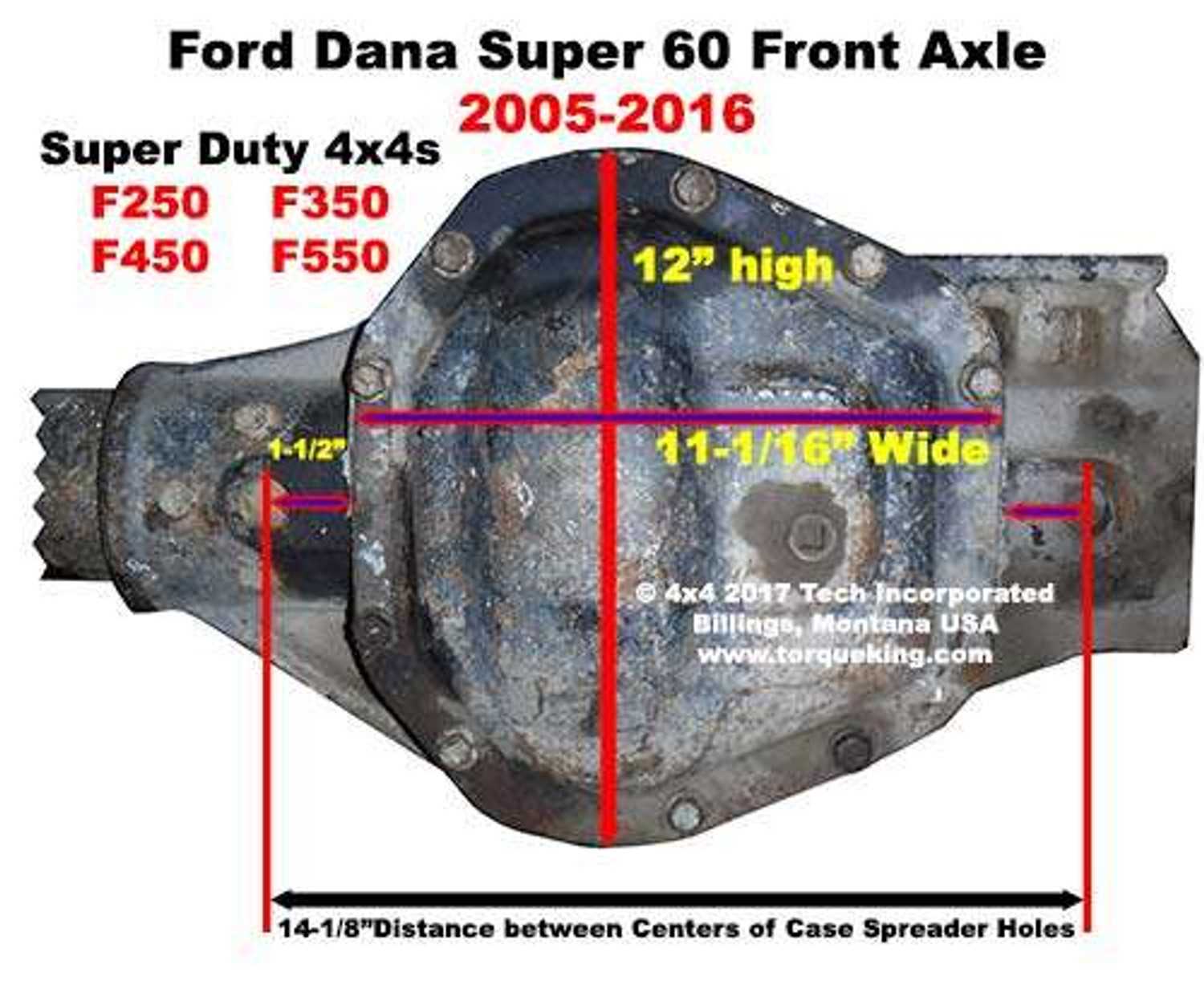

Overview of Ford F250 Front End

The assembly at the leading section of a vehicle plays a crucial role in its overall functionality and aesthetic appeal. This area is designed to house essential components that contribute to steering, suspension, and safety features. Understanding its structure can enhance maintenance practices and ensure optimal performance.

Key Components: Within this assembly, various elements work harmoniously to provide stability and control. These include the steering mechanisms, shock absorbers, and structural reinforcements that bear the weight and impact during operation.

Maintenance Considerations: Regular inspection of this section is vital for identifying wear and tear. Components such as bushings and joints may require periodic lubrication or replacement to maintain the integrity and responsiveness of the vehicle.

In summary, a well-maintained leading section is integral to ensuring safe and reliable vehicle operation. Understanding its composition aids in making informed decisions regarding care and potential upgrades.

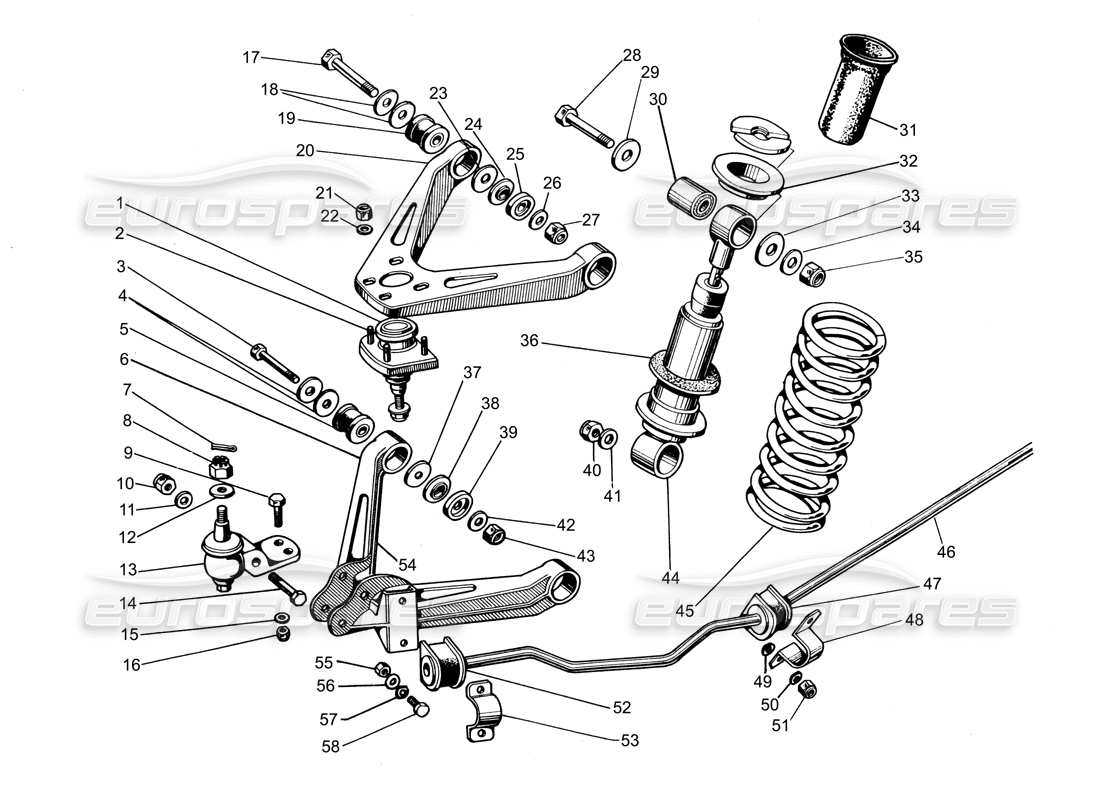

Key Parts in the Suspension System

The suspension framework plays a crucial role in ensuring a smooth ride and effective handling. This system is composed of various components that work together to absorb shocks and maintain vehicle stability during movement. Understanding these essential elements helps in diagnosing issues and enhancing performance.

Essential Components

| Component | Function |

|---|---|

| Shock Absorber | Dampens vibrations and maintains contact between tires and the road. |

| Spring | Supports vehicle weight and absorbs road impacts. |

| Control Arm | Connects the wheel hub to the chassis, allowing for vertical movement. |

| Ball Joint | Facilitates rotation and allows for smooth movement between components. |

| Stabilizer Bar | Reduces body roll during cornering, enhancing stability. |

Importance of Maintenance

Regular inspection and maintenance of these components are vital for ensuring optimal performance and safety. Worn or damaged elements can lead to decreased handling capabilities and increased wear on other systems. Proactive care can significantly extend the lifespan of the suspension setup.

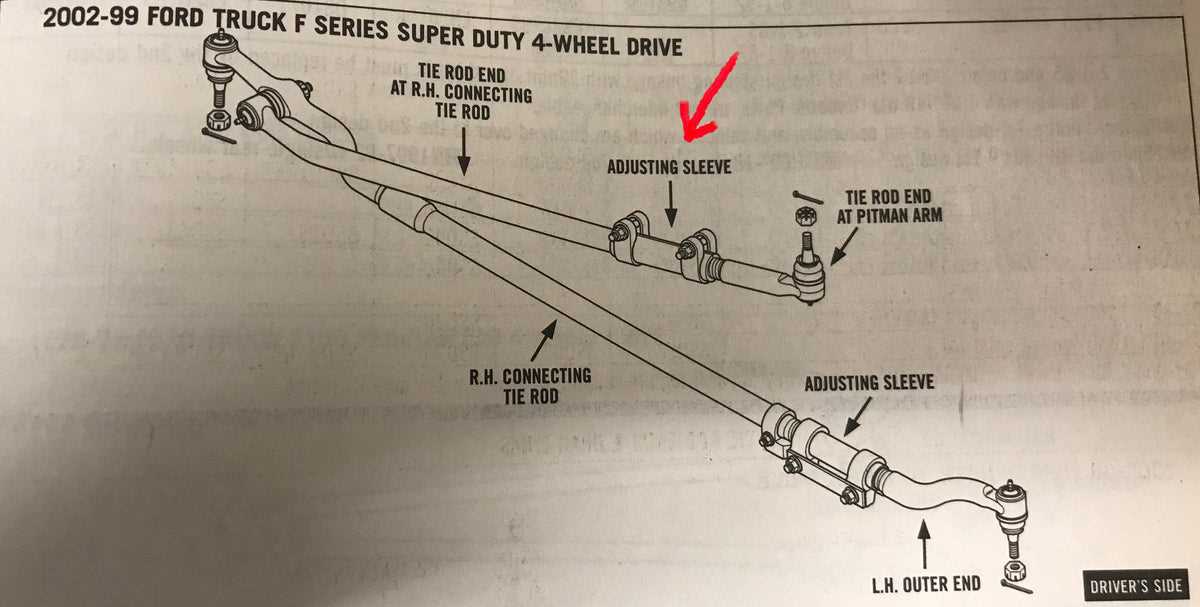

Steering Mechanisms Explained

Understanding the various components that contribute to vehicle navigation is crucial for ensuring optimal performance and safety. Steering systems play a vital role in guiding a vehicle, allowing for precise control and responsiveness during operation. This section delves into the fundamental mechanisms that facilitate steering and their significance in overall vehicle dynamics.

Key Components of Steering Systems

- Steering Wheel: The primary interface for the driver, enabling directional control.

- Steering Column: Connects the steering wheel to the mechanism, providing stability and support.

- Gearbox: Translates the rotational movement of the steering wheel into lateral motion.

- Linkage System: Transfers motion from the gearbox to the wheels, ensuring accurate steering.

- Wheel Assembly: Includes components that directly influence wheel alignment and handling.

Types of Steering Mechanisms

- Rack and Pinion: A common design that converts rotational motion into linear movement, offering precise steering control.

- Recirculating Ball: Utilizes a series of balls to reduce friction, commonly found in heavier vehicles for enhanced durability.

- Power Steering: Assists the driver by amplifying the force applied to the steering wheel, improving ease of maneuverability.

In summary, the effective functioning of steering systems is essential for a vehicle’s operational integrity. Each component plays a unique role in ensuring a seamless driving experience, highlighting the importance of maintenance and understanding of these mechanisms for all vehicle owners.

Importance of the Frame Structure

The frame structure serves as the backbone of any vehicle, playing a crucial role in ensuring stability and safety. This foundational component supports the entire weight of the machine, distributing forces and absorbing impacts during operation. Its design directly influences handling, ride quality, and overall performance.

Moreover, a robust frame contributes significantly to the vehicle’s durability, resisting wear and tear from various driving conditions. It is engineered to withstand stress and maintain integrity over time, which is essential for long-term reliability. Proper frame alignment and strength are vital for enhancing safety features and minimizing the risk of structural failure.

Additionally, the frame’s layout affects the ease of access to other components, influencing maintenance and repair processes. A well-designed structure facilitates efficient servicing, ultimately saving time and costs for owners. Overall, understanding the importance of the frame structure is fundamental for appreciating the vehicle’s overall engineering and functionality.

Common Issues with Front End Parts

The components responsible for steering and suspension systems are crucial for maintaining vehicle stability and performance. Over time, these elements can develop various problems that affect driving safety and comfort. Understanding these common issues can help in timely maintenance and repairs.

| Issue | Description | Symptoms |

|---|---|---|

| Worn Ball Joints | Ball joints connect the steering knuckles to the control arms and can wear out due to friction and age. | Clunking noise when turning, uneven tire wear, and steering wheel vibration. |

| Damaged Tie Rod Ends | These components link the steering gear to the wheels and can become loose or broken. | Loose steering feel, misaligned wheels, and excessive play in the steering wheel. |

| Worn Bushings | Bushings are rubber or polyurethane components that provide cushioning and support in various suspension setups. | Noise when going over bumps, reduced handling stability, and uneven tire wear. |

| Leaking Shock Absorbers | Shock absorbers control the impact and rebound of the vehicle’s springs, and leaks can diminish their effectiveness. | Bouncy ride, excessive body roll, and visible fluid leakage. |

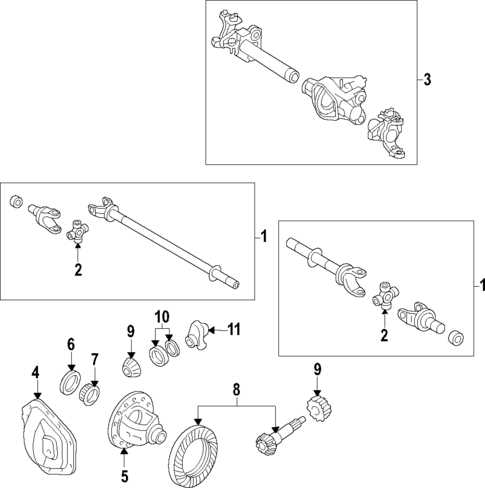

Diagram Analysis: Component Layout

This section delves into the arrangement and organization of key elements found in the vehicle’s front assembly. Understanding the layout is crucial for diagnosing issues and facilitating maintenance, ensuring optimal performance and longevity.

The main elements of the assembly can be categorized as follows:

- Structural Components:

- Frame supports

- Cross members

- Mounting brackets

- Suspension Elements:

- Control arms

- Shock absorbers

- Springs

- Steering Mechanisms:

- Steering knuckles

- Racks and pinions

- Linkages

- Braking System:

- Calipers

- Rotors

- Brake lines

Each element plays a vital role in ensuring the vehicle operates smoothly. A comprehensive understanding of their placement and interrelation aids in effective troubleshooting and repair strategies.

Regular inspection and familiarity with the configuration can enhance overall performance and safety, ultimately leading to a more reliable driving experience.

Replacing Worn Suspension Parts

Maintaining optimal performance and safety in your vehicle involves regularly assessing and renewing components that bear the brunt of road impacts. Over time, certain elements can degrade, leading to issues such as decreased handling and increased tire wear. Addressing these concerns through timely replacements is crucial for restoring stability and comfort.

Identifying Signs of Wear

Before undertaking replacements, it’s essential to recognize the indicators of deterioration. Common symptoms include excessive noise during bumps, noticeable steering play, and uneven tire wear. A thorough inspection can help pinpoint the affected components, ensuring a targeted approach to maintenance.

Steps for Replacement

Once you have identified the worn components, the next step involves gathering necessary tools and new parts. Begin by safely lifting the vehicle and securing it on jack stands. Remove the old components, taking care to note the order of disassembly for easier installation of the new items. After securing the new pieces, lower the vehicle and perform a test drive to ensure everything functions correctly.

Upgrading Steering Components

Enhancing the steering elements of a vehicle can significantly improve handling, stability, and overall driving experience. This process often involves replacing outdated or worn components with advanced alternatives designed for improved performance and durability. Upgrading these components can lead to a more responsive and precise steering feel, contributing to a more enjoyable ride.

When considering an upgrade, it’s essential to evaluate the specific components that may require attention. Steering gears, linkages, and related elements can wear down over time, affecting the vehicle’s response and control. By opting for high-quality replacements or performance upgrades, drivers can achieve a noticeable difference in their vehicle’s handling characteristics.

Additionally, exploring options such as adjustable systems can provide further customization to suit individual driving styles and preferences. These enhancements not only improve functionality but also contribute to the longevity of the steering system. Investing in superior steering components ultimately leads to a safer and more enjoyable driving experience.

Maintenance Tips for Longevity

Ensuring the durability and optimal performance of your vehicle requires regular attention and care. Implementing a few essential practices can greatly extend the lifespan of key components, ultimately enhancing your driving experience.

- Regular Inspections: Periodically check critical systems for wear and tear, including suspension, steering, and braking mechanisms.

- Routine Lubrication: Keep moving parts well-lubricated to prevent friction and prolong their functionality.

- Proper Alignment: Ensure that wheel alignment is correctly adjusted to avoid uneven tire wear and improve handling.

- Quality Fluids: Use high-quality lubricants and fluids that meet or exceed manufacturer specifications.

- Timely Repairs: Address any issues promptly to prevent further damage and maintain system integrity.

Incorporating these practices into your maintenance routine will significantly enhance the longevity and reliability of your vehicle.

Tools Required for Front End Repairs

Effective maintenance and restoration of vehicle components necessitate a specific set of tools. Having the right equipment can significantly enhance efficiency and ensure precision in the repair process. Understanding which tools are essential will prepare you for a successful undertaking, minimizing potential setbacks.

Firstly, a comprehensive socket set is crucial, providing various sizes to accommodate different fasteners. Additionally, wrenches, both open-end and box-end, are vital for accessing hard-to-reach areas. Pliers, particularly needle-nose and locking types, are indispensable for gripping and manipulating small components.

A jack and jack stands are essential for safely elevating the vehicle, allowing for easier access to lower sections. A torque wrench is also necessary for applying the correct force when fastening bolts, preventing damage or wear. Finally, a set of screwdrivers, including flathead and Phillips, rounds out the basic toolkit needed for thorough repairs.

How to Read the Diagram

Understanding a schematic representation of components is essential for effective maintenance and repair. These visual guides illustrate how different elements interact within a system, making it easier to identify connections and functionalities.

Start by Familiarizing Yourself with the layout and symbols used in the illustration. Each symbol typically represents a specific component or function. Take the time to learn what each icon means to avoid confusion during troubleshooting.

Follow the Flow of the connections. Many schematics are designed to show the flow of information or power, which can help you understand how each part influences the overall operation. Look for arrows or lines that indicate the direction of flow.

Cross-Reference with Specifications if available. Comparing the visual representation with detailed specifications or a list of components will provide additional clarity and ensure accuracy when interpreting the schematic.

Practice Patience and take your time to analyze the information thoroughly. Familiarity with these representations improves with experience, enabling more efficient troubleshooting and repairs.

Consulting Professional Mechanics

When tackling vehicle maintenance and repairs, seeking the expertise of skilled technicians can be invaluable. Their extensive knowledge and experience ensure that complex issues are addressed effectively, providing peace of mind to vehicle owners. Relying on professionals not only enhances the quality of repairs but also prolongs the lifespan of essential components.

The Benefits of Professional Consultation

Engaging with seasoned mechanics offers numerous advantages, including accurate diagnostics, access to specialized tools, and a comprehensive understanding of vehicle systems. Professionals can identify underlying problems that may not be immediately visible, preventing future complications.

Choosing the Right Expert

It’s crucial to select the right technician for your needs. Consider factors such as certifications, experience, and customer reviews when making your choice. Here’s a helpful comparison table to guide your decision:

| Criteria | Importance |

|---|---|

| Certifications | High |

| Years of Experience | Medium |

| Customer Reviews | High |

| Specialized Tools | Medium |

Investing time in finding a reliable expert will ultimately enhance the performance and safety of your vehicle, making the consultation a worthwhile endeavor.