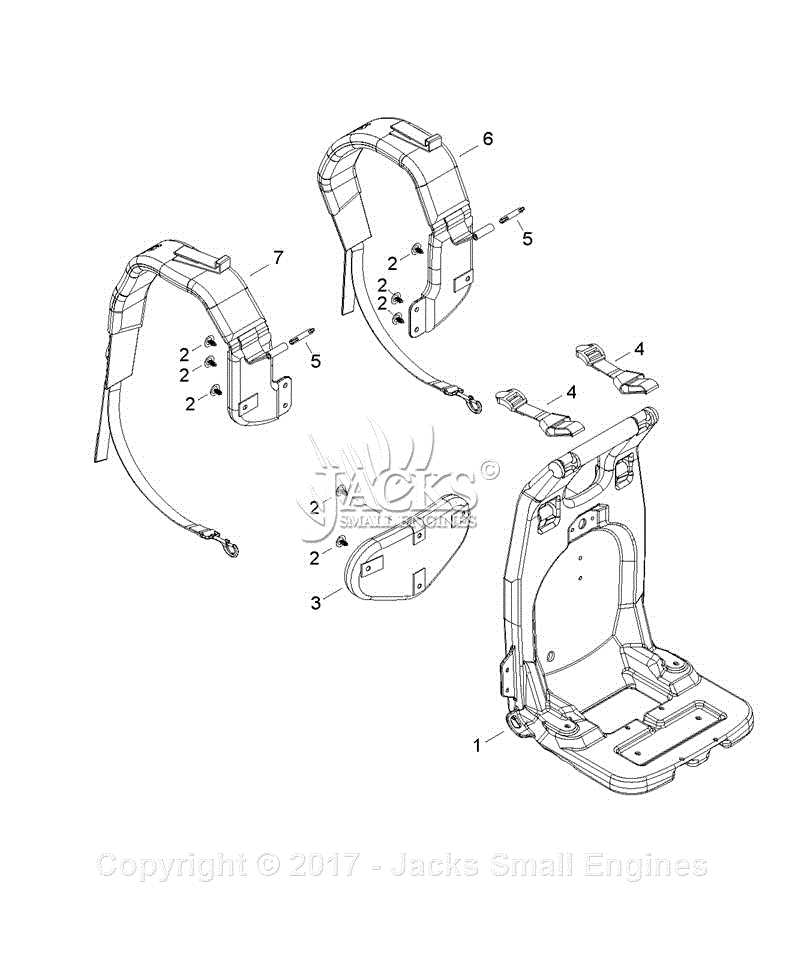

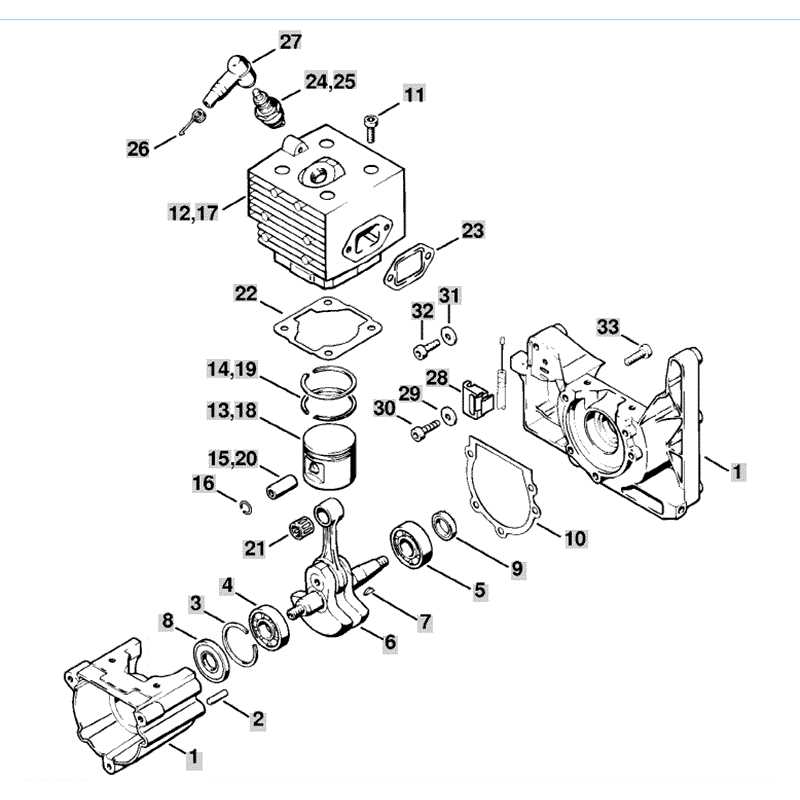

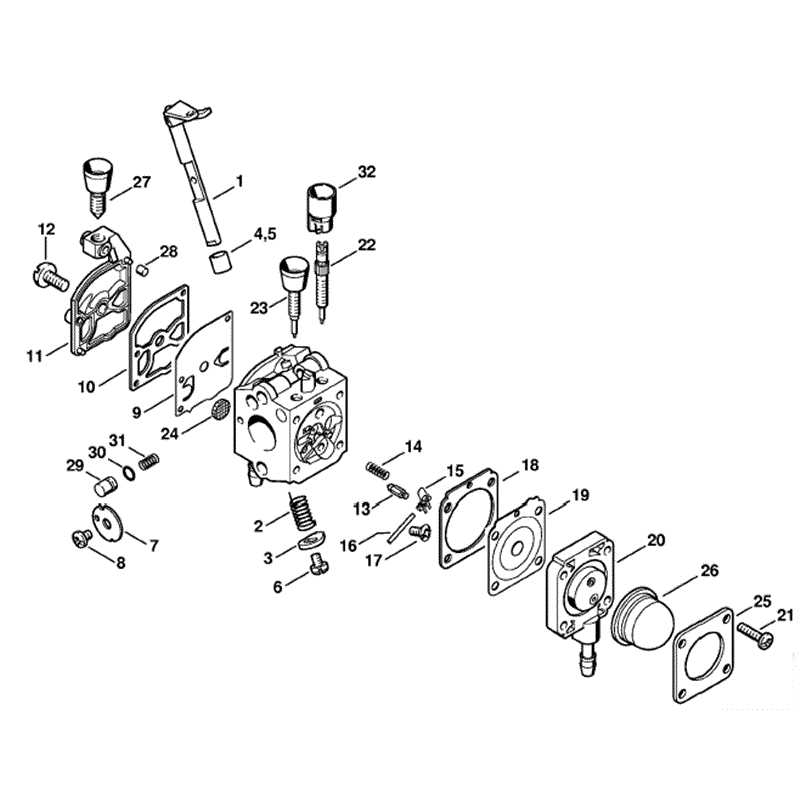

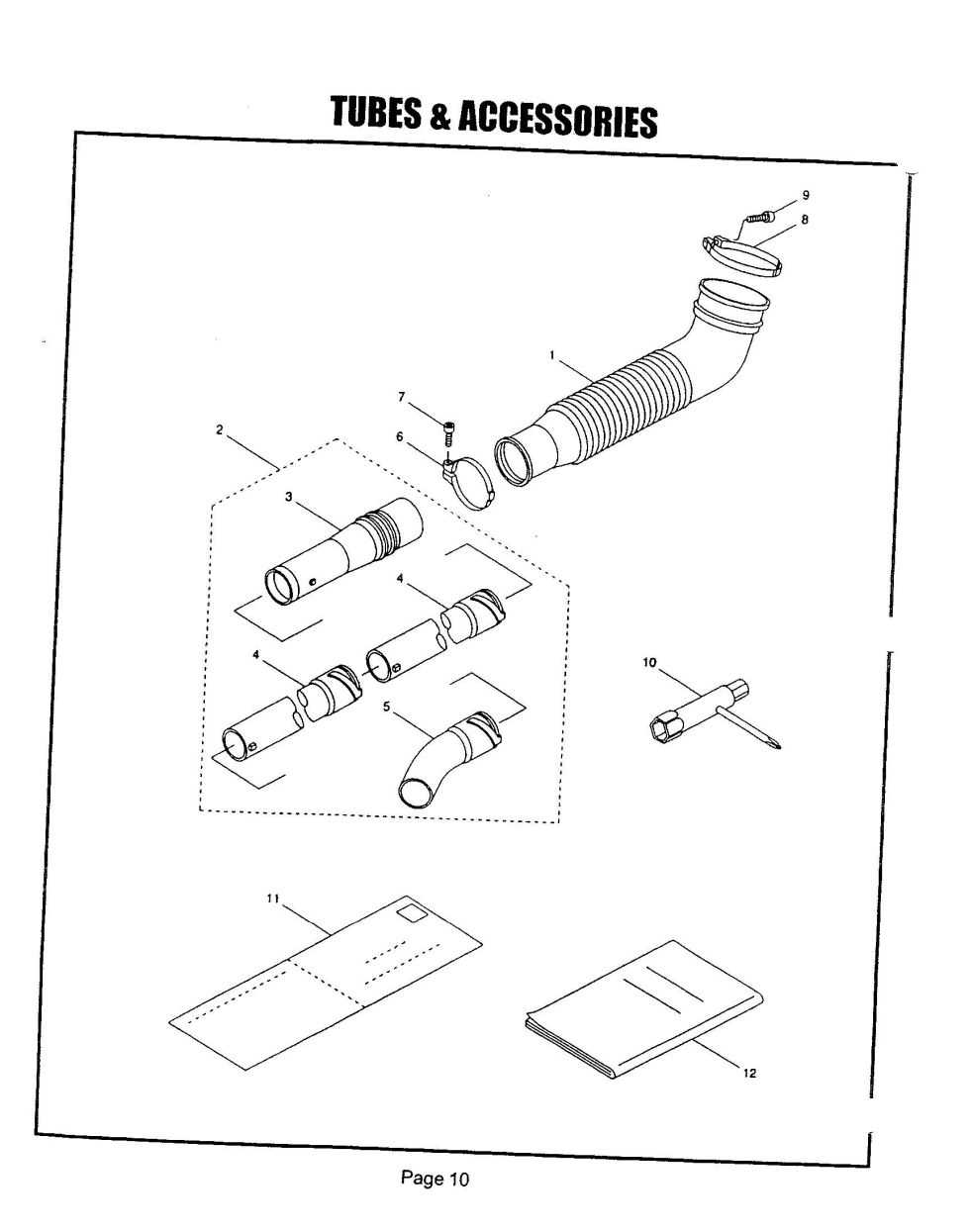

The exploration of intricate systems often reveals a wealth of interconnected elements that work harmoniously to achieve a common purpose. Understanding these elements enhances our appreciation for the engineering and design involved in their creation. This section delves into the various components of the Br 800 model, illustrating how each plays a vital role in the overall functionality.

By examining the structure and organization of these individual elements, users can gain insights into their respective functions and interactions. A clear representation of these components aids in troubleshooting, maintenance, and even upgrades, ensuring optimal performance. This overview serves as a comprehensive guide for anyone looking to familiarize themselves with the intricate workings of this model.

When dealing with equipment components, several recurring challenges can arise, affecting performance and reliability. Understanding these issues can help users maintain optimal functionality and prolong the lifespan of their machinery.

Here are some frequently encountered problems and their potential causes:

| Issue | Description | Possible Solution |

|---|---|---|

| Worn components | Over time, certain elements may wear down due to regular usage, leading to decreased efficiency. | Regular inspection and timely replacement can mitigate this issue. |

| Improper assembly | Incorrectly fitted parts can result in operational failures or reduced effectiveness. | Following the manufacturer’s assembly instructions closely is crucial. |

| Clogging | Debris accumulation can hinder performance and cause overheating. | Frequent cleaning and maintenance should be conducted to prevent this problem. |

| Corrosion | Exposure to moisture or chemicals can lead to rust and deterioration. | Using protective coatings can help safeguard against corrosion. |

Maintenance Tips for Longevity

Ensuring the extended lifespan of your equipment involves regular care and attention. Adopting proactive maintenance practices can significantly enhance performance and reduce the risk of unexpected failures.

First, routinely check for signs of wear and tear. Regular inspections can help identify potential issues before they escalate into more significant problems. Pay close attention to components that experience frequent movement or contact.

Additionally, keep your device clean and free from debris. Accumulated dirt can impede functionality and lead to premature deterioration. Use appropriate cleaning solutions and tools to maintain optimal condition.

Moreover, ensure all moving parts are adequately lubricated. This reduces friction and minimizes wear, contributing to smoother operation. Follow manufacturer guidelines for the correct type of lubricant to use.

Lastly, store your equipment in a suitable environment. Protect it from extreme temperatures and humidity levels, which can adversely affect its integrity. Proper storage practices are crucial for preserving quality over time.

Tools Required for Assembly

Proper assembly of the equipment requires a selection of essential instruments to ensure efficiency and precision. Each tool serves a specific purpose, contributing to a smooth workflow and enhancing the overall quality of the assembly process.

Essential Instruments

- Screwdriver set

- Wrench or socket set

- Measuring tape

- Pliers

- Utility knife

Additional Supplies

- Lubricants for smooth operation

- Cleaning cloths for maintenance

- Safety goggles for protection

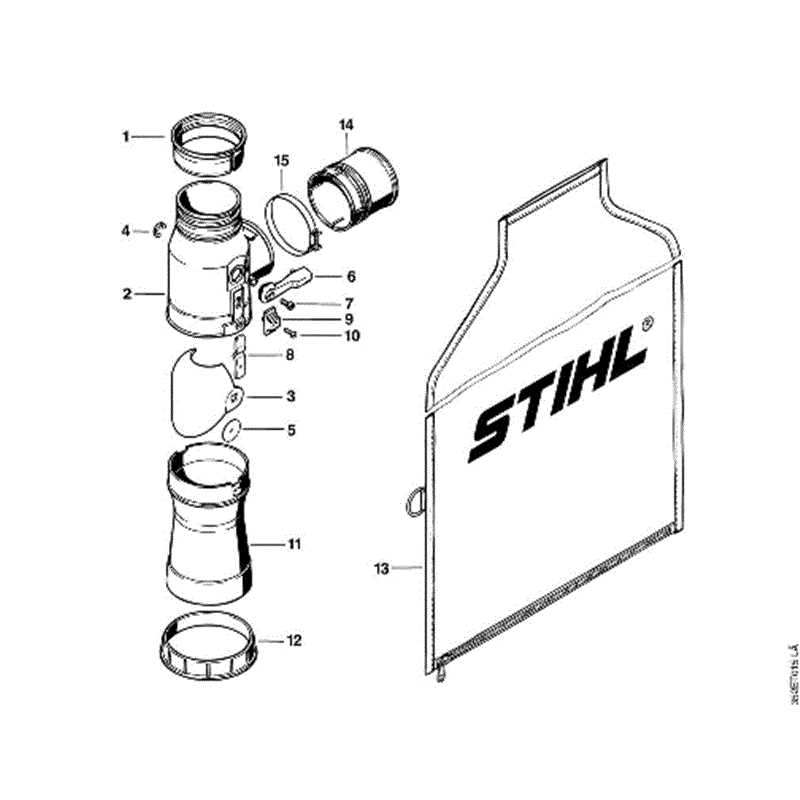

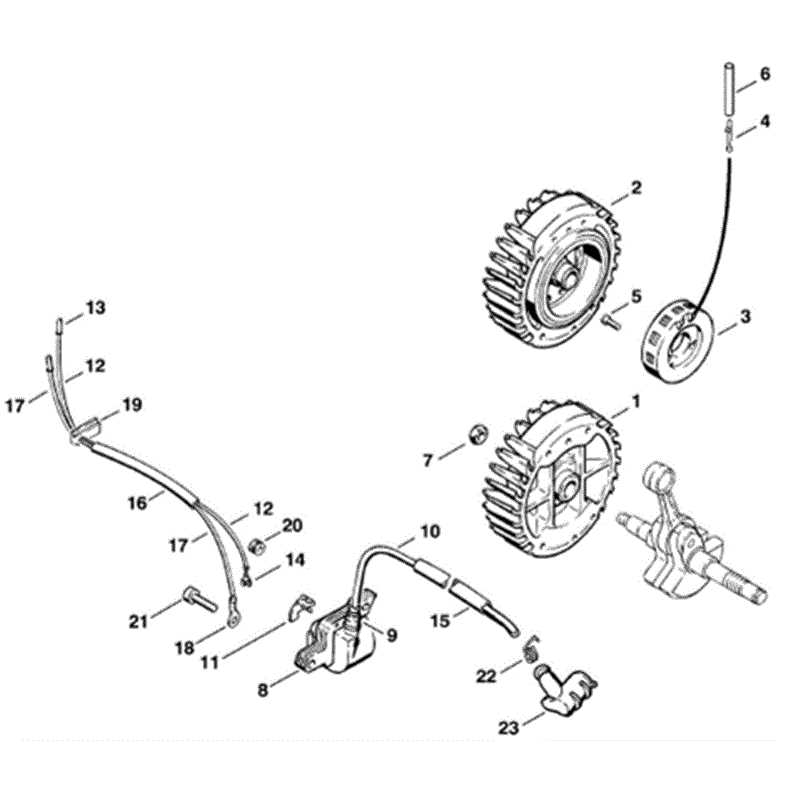

How to Read the Parts Diagram

Understanding the visual representation of components is essential for efficient maintenance and repair. By familiarizing yourself with this illustration, you can quickly identify each element’s location and function, which simplifies the troubleshooting process. This guide will help you interpret the information conveyed through the schematic.

Identifying Key Elements

Start by examining the legend or key that typically accompanies the illustration. This section often includes symbols and notations that correspond to various components. By recognizing these symbols, you can gain insight into the roles of individual pieces and their interconnections.

Following the Flow

Next, trace the connections and pathways indicated in the schematic. Understanding how different elements interact can provide a clearer picture of the overall system functionality. Pay attention to any annotations or reference numbers that may indicate specific installation instructions or part specifications, ensuring you have the necessary details for your tasks.

Differences Between BR 800 Models

The variations among different iterations of the BR series present unique features and specifications that cater to distinct user needs. Understanding these differences is essential for choosing the right model for specific applications.

Performance Features

Each iteration in the series offers varying performance capabilities. These differences may include engine power, fuel efficiency, and airflow rates, which are crucial for tasks ranging from light-duty to heavy-duty applications.

Design Elements

The design aspects of the models also exhibit diversity, affecting usability and comfort during operation. Key elements like weight distribution, handle ergonomics, and vibration reduction technologies are noteworthy considerations.

| Model | Engine Power (HP) | Airflow Rate (CFM) | Weight (lbs) |

|---|---|---|---|

| BR Model A | 2.5 | 450 | 12 |

| BR Model B | 3.0 | 600 | 14 |

| BR Model C | 3.5 | 750 | 15 |

Where to Find Replacement Parts

When it comes to sourcing components for your equipment, there are several reliable avenues to explore. Whether you’re looking for official resources or aftermarket options, having access to the right information can save you time and effort.

Official Manufacturer Websites often provide a comprehensive list of available components, including specifications and ordering information. Checking the manufacturer’s site ensures that you are purchasing genuine items designed specifically for your model.

Authorized Dealers are another excellent source for obtaining authentic components. They usually have a stock of necessary items and can offer expert advice on compatibility and installation.

Online Marketplaces can also be beneficial for finding both new and used components. Websites that specialize in aftermarket supplies may offer a wider variety of options, often at competitive prices. However, it’s crucial to read reviews and verify seller credibility to ensure quality.

Local Repair Shops can be valuable resources as well. Many technicians have access to a network of suppliers and may even stock essential items themselves. Additionally, they can provide guidance on what you need for your specific situation.

Exploring these channels will help you locate the necessary components efficiently, ensuring your equipment remains in optimal condition.

Step-by-Step Assembly Guide

This section provides a comprehensive guide for assembling your equipment efficiently and accurately. Following the outlined steps will help ensure that every component is correctly positioned and secured, leading to optimal performance.

Preparation Before Assembly

Before you begin the assembly process, ensure that you have the following tools and components ready:

- Screwdriver set

- Wrench

- Operating manual

- All necessary components

- Work surface

Assembly Steps

- Start by laying out all components on a flat surface for easy access.

- Refer to the operating manual to familiarize yourself with each element and its purpose.

- Begin by attaching the main frame components using the screws provided, ensuring they are tightened securely.

- Next, connect any additional sections, paying attention to alignment as specified in the manual.

- Once all parts are connected, double-check for any loose fittings and tighten as necessary.

- Finally, perform a thorough inspection to ensure everything is in place and functioning properly.

Following these instructions carefully will lead to a successful assembly and reliable operation of your device.

Safety Precautions During Repairs

Ensuring safety during maintenance tasks is crucial for preventing accidents and injuries. By following proper procedures and guidelines, individuals can create a secure environment that minimizes risks while working on equipment.

- Wear Protective Gear: Always use appropriate personal protective equipment, such as gloves, goggles, and masks, to shield yourself from potential hazards.

- Disconnect Power Sources: Before starting any repair work, ensure that all power supplies are turned off and disconnected to prevent electrical shocks.

- Work in a Well-Ventilated Area: If using chemicals or working with fuel, ensure the workspace is adequately ventilated to avoid inhaling harmful fumes.

- Use Proper Tools: Employ the correct tools for the job to ensure efficiency and reduce the risk of accidents.

- Follow Manufacturer Guidelines: Adhere to the recommendations and instructions provided by the manufacturer to maintain safety standards.

By taking these precautions, individuals can significantly reduce the likelihood of accidents and ensure a safer working environment while performing maintenance tasks.

FAQs About BR 800 Components

This section addresses common inquiries related to the various elements of the BR 800 model. Understanding the functions and characteristics of these components can help users maintain and operate their equipment effectively.

Common Questions

Many users seek clarity on specific aspects of the components used in the BR 800. Below are frequently asked questions that may assist you in gaining a better understanding.

| Question | Answer |

|---|---|

| What types of components are included? | The model consists of various essential elements that contribute to its overall functionality and performance. |

| How can I identify damaged components? | Regular inspections can help detect wear and tear. Look for signs such as unusual noises or decreased efficiency. |

| Where can I find replacement components? | Replacement parts are typically available through authorized dealers or specialized retailers. |

Maintenance Tips

Proper care of the individual elements can prolong the life of your equipment. Here are a few recommendations:

- Regularly clean components to prevent dirt accumulation.

- Check for loose fittings and tighten as needed.

- Follow the manufacturer’s guidelines for servicing.