Understanding the internal and external elements of a renowned firearm model is crucial for both enthusiasts and professionals. Each mechanism is designed with precision to ensure optimal performance and reliability. This section will guide you through the main features, shedding light on the essential elements that contribute to the functionality of this well-regarded rifle.

With a focus on reliability and durability, the individual mechanisms work in harmony to deliver high-level accuracy and control. We will take a closer look at these mechanisms, highlighting their specific roles and how they contribute to the overall operation of this versatile model.

By breaking down the structure and function of each component, this guide provides valuable insights into how all the elements come together to form an efficient and effective firearm. Whether you’re a novice or an experienced user, this exploration will offer a deeper understanding of the key features that define this model.

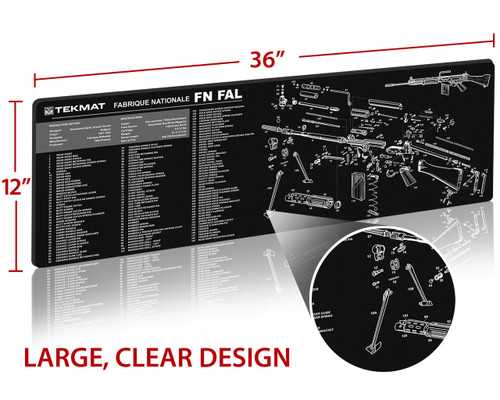

FN SCAR Components Breakdown

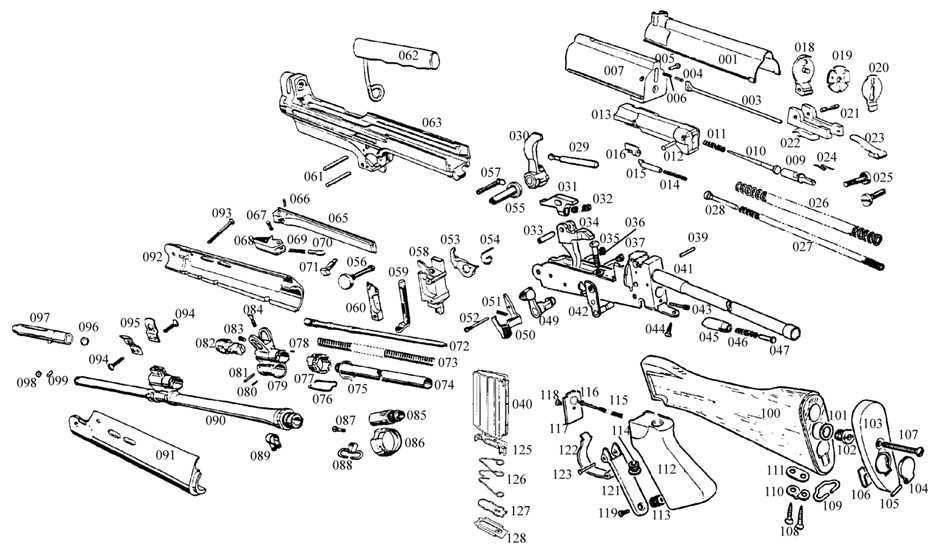

The breakdown of this advanced modular rifle focuses on its unique structure, which is designed for versatility and adaptability. Each element contributes to its reliability and effectiveness in various scenarios. By exploring the individual sections of this platform, we can better understand how it is engineered for precision and durability.

Upper Assembly Overview

The upper section incorporates key components responsible for the operation and accuracy of the firearm. It houses essential elements that ensure smooth performance, providing the foundation for proper function and targeting precision. This part of the weapon is crafted from high-strength materials to withstand rigorous conditions.

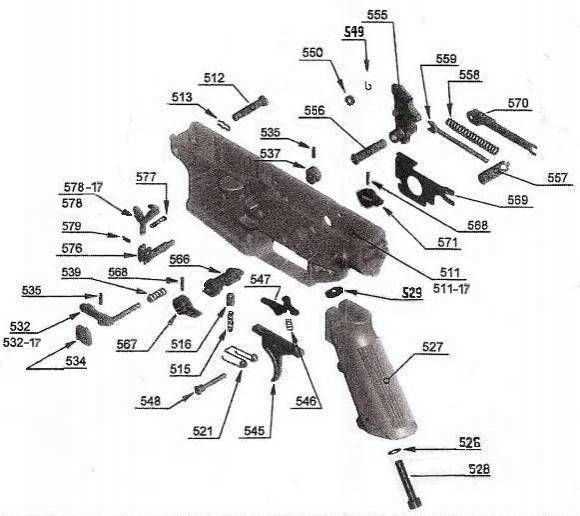

Lower Assembly Key Features

The lower section includes elements crucial for controlling the system and managing recoil. Designed for user comfort and control, it integrates various mechanisms that enhance stability and ease of use. This area also allows for customization, enabling the user to adjust settings based on mission requirements.

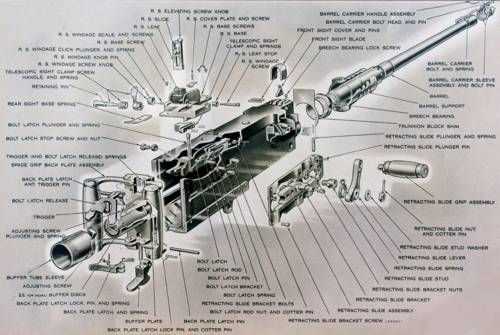

Main Internal Mechanisms Overview

The essential functioning of this equipment relies on several interconnected components that work in harmony. These internal elements are designed to ensure smooth performance, accuracy, and reliability during operation. Understanding how these systems interact provides valuable insights into maintaining and improving overall efficiency.

Core Functional Elements

At the heart of the device, the primary systems control key movements and responses. These elements handle the main operations, ensuring that the equipment reacts quickly and efficiently under various conditions. Precision engineering is crucial for these systems, as it determines the overall performance.

Supporting Mechanisms

The secondary mechanisms complement the core systems by managing auxiliary tasks. They help maintain balance, stability, and consistent operation, ensuring the entire setup functions as intended. By supporting the main processes, these parts contribute to long-term durability and smooth functioning.

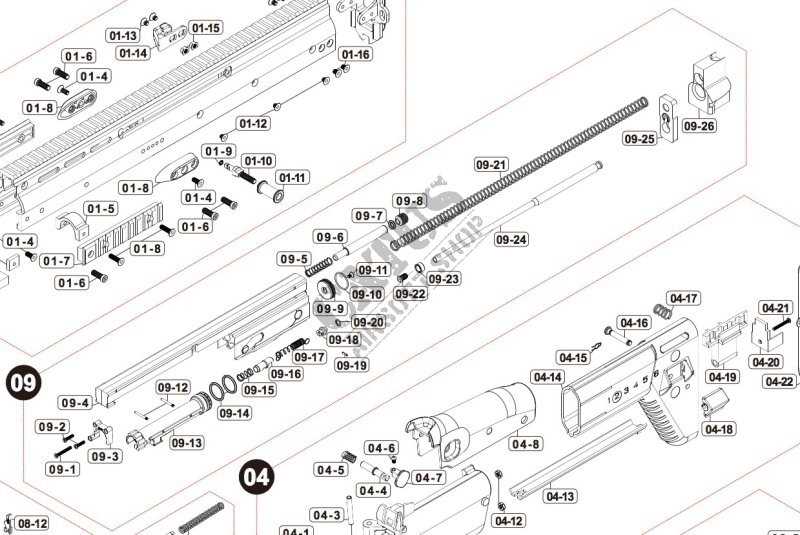

Barrel Assembly Structure and Details

The barrel assembly plays a crucial role in the overall functionality of any modern firearm. This section will cover its essential components and provide insights into the mechanisms that allow for effective operation and precision. By examining each element closely, we can understand how they contribute to performance and durability.

Key Components of the Barrel Assembly

Several elements are integrated into the barrel structure, each designed to serve a specific function. The chamber, designed for housing ammunition, works in unison with the rifling to ensure accuracy. Meanwhile, the exterior of the barrel is crafted to endure high temperatures and pressure, maintaining stability during repeated firing.

Material and Design Considerations

Trigger Group and Functionality

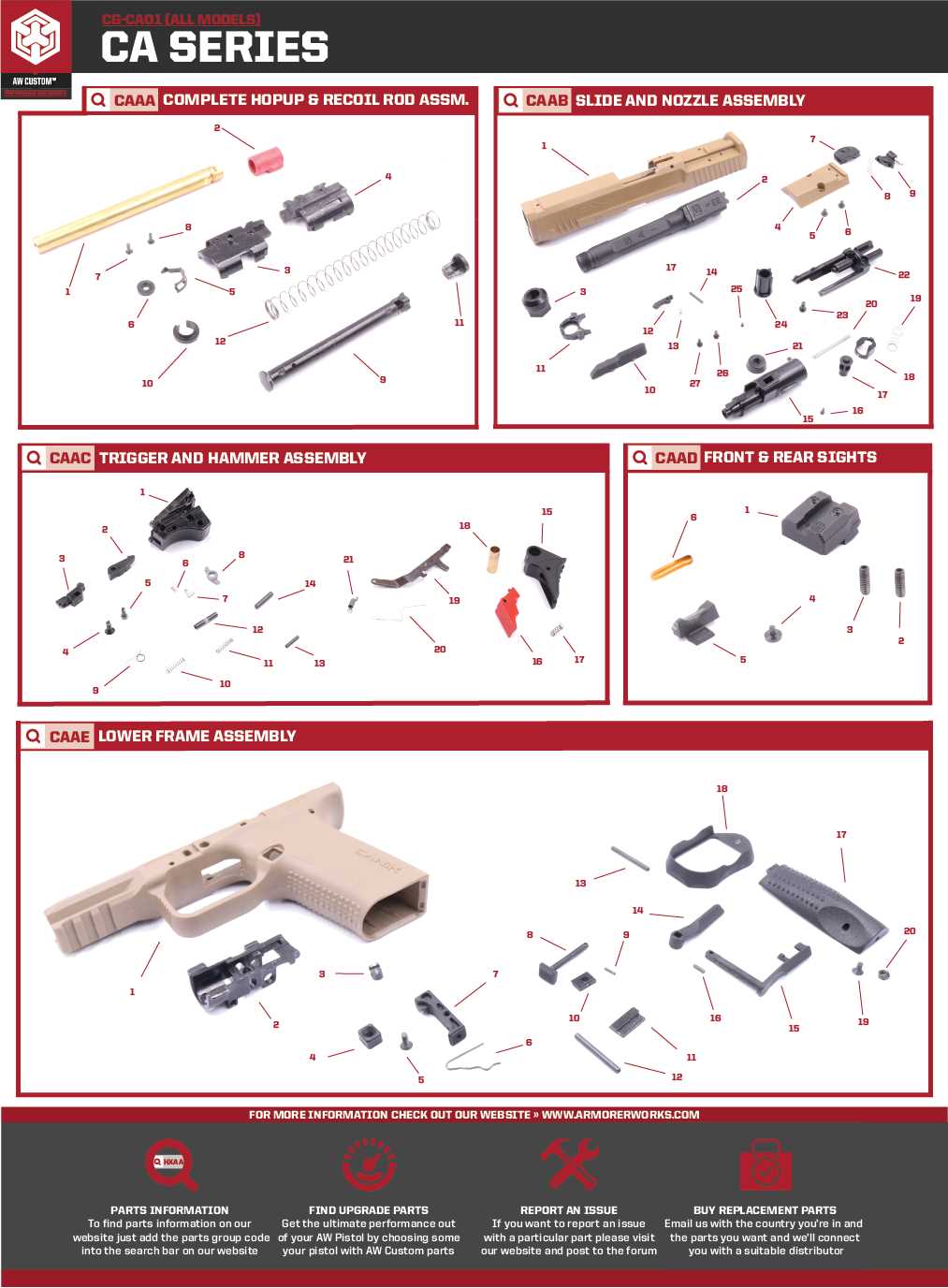

The trigger assembly is a critical component that ensures the proper firing sequence of the firearm. Its design plays a key role in delivering a reliable and smooth shooting experience. Each part within this mechanism contributes to the precise coordination required for the system to operate effectively.

The following list outlines the key components that interact within this system:

- Trigger lever – Initiates the firing process when engaged by the user.

- Sear – Holds and releases the hammer or striker when the trigger is pulled.

- Hammer or striker – Strikes the firing pin, causing ignition of the round.

- Disconnector – Ensures that the mechanism resets after each shot, preventing accidental discharge.

- Safety mechanism – Prevents unintentional firing by locking the trigger in place.

Stock Variants and Modifications

There are numerous configurations available for this platform, offering adaptability and versatility to meet different operational needs. Each option is designed to enhance specific performance aspects, allowing users to tailor their equipment according to their requirements.

Fixed and Adjustable Stocks

One of the most significant differences between configurations is the choice of fixed or adjustable stocks. Fixed options provide stability and robustness, often preferred for situations requiring consistent accuracy. In contrast, adjustable models offer flexibility, allowing the user to alter length and fit, enhancing comfort and control during varied operations.

Modular Designs

Modular stock designs are becoming increasingly popular due to their ability to support a wide range of accessories and enhancements. This allows for easy customization, making it possible to adapt the setup for different tasks or environments with minimal effort. Er

Magazine and Feed System Insights

The magazine and feed mechanism is a crucial element in the operation of firearms, enabling reliable ammunition delivery for optimal performance. Understanding its functionality and design intricacies is essential for enthusiasts and professionals alike. This section delves into the various components that contribute to the effective feeding and cycling of cartridges, ensuring seamless operation during use.

Key Components of the System

- Magazine: The container responsible for holding ammunition, designed for easy loading and accessibility.

- Follower: A critical component that pushes cartridges upward into the chamber as rounds are fired.

- Spring: Provides the necessary tension to ensure consistent feeding of ammunition from the magazine.

- Feed Lips: The part of the magazine that guides cartridges into the chamber, essential for proper alignment.

Operating Principles

- Upon firing, the spent cartridge is ejected, creating space for the next round.

- The follower rises due to the spring’s tension, pushing the next cartridge into the correct position.

- The feed lips guide the cartridge into the chamber, ensuring a smooth transition.

- This cycle repeats rapidly, allowing for continuous operation without interruption.

By mastering these elements, users can enhance their understanding of firearm mechanics and improve their maintenance practices. Regular inspections and proper handling of the magazine and feed system contribute significantly to reliability and overall performance.

Gas System Components Explained

The gas system within a firearm plays a critical role in its operation, facilitating the efficient use of gases produced during firing. Understanding the various elements of this mechanism is essential for both maintenance and enhancement of performance. Each component works in harmony to ensure reliable cycling and precision.

1. Gas Block: This component serves as a critical junction where the gas from the barrel is redirected into the system. Its design influences the amount of gas that enters the action, impacting the overall cycling of the firearm.

2. Gas Tube: This tube channels the redirected gases from the gas block to the bolt carrier group. Its length and diameter can affect the timing and pressure of the system, making it a vital factor in overall performance.

3. Bolt Carrier Group: Within this assembly, the gases push against the bolt carrier, initiating the cycling process. The design of this group is pivotal, as it influences how effectively the gases are harnessed to cycle the action.

4. Piston: In systems that utilize a piston, this component captures gas and utilizes it to drive the action. This design often leads to cleaner operation by keeping the operating mechanism separate from the combustion gases.

By comprehending these elements, enthusiasts and operators can better appreciate the intricacies of their firearm’s operation, facilitating informed choices regarding upgrades and maintenance.

Bolt Carrier Group Specifications

The bolt carrier group (BCG) plays a crucial role in the operation of semi-automatic and automatic firearms. This assembly ensures reliable cycling and functioning of the firearm by housing key components that work together to facilitate the firing process. Understanding the specifications of the BCG is essential for enthusiasts and professionals alike who seek to optimize their weapon’s performance.

The specifications of the bolt carrier group can vary depending on the design and intended use of the firearm. Below is a table summarizing the key specifications that should be considered when evaluating a BCG.

| Specification | Description |

|---|---|

| Material | Typically constructed from high-strength steel or aluminum alloy for durability and resistance to wear. |

| Finish | Common finishes include phosphate coating or nitride treatment, providing corrosion resistance and reduced friction. |

| Weight | Standard weight ranges from 8 to 10 ounces, influencing recoil and cycling speed. |

| Gas System Compatibility | Designed for use with direct impingement or piston systems, impacting the overall gas management of the firearm. |

| Operating System | Can be configured for semi-automatic or fully automatic firing modes, affecting the overall operation of the weapon. |

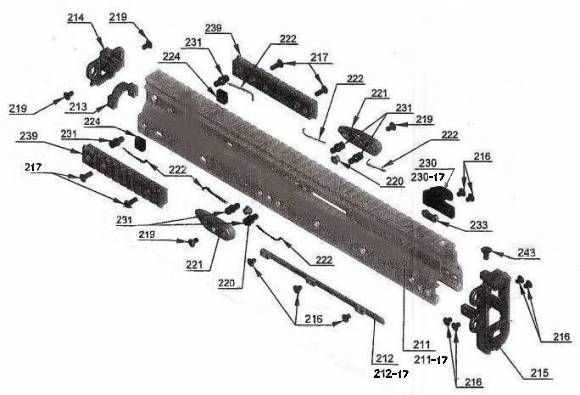

Optics Mounting and Rail Sections

This section explores the essential components for securely attaching optical devices to firearms. Proper alignment and stability are crucial for achieving accurate aiming and target acquisition. Understanding the various mounting systems and rail configurations allows users to customize their setup based on individual preferences and mission requirements.

Different rail systems, such as Picatinny and Weaver, provide versatile options for mounting scopes, red dot sights, and other accessories. Each system features specific dimensions and slots, ensuring compatibility with a range of attachments. Users should consider factors such as height, offset, and eye relief when selecting mounts to optimize their shooting experience.

Additionally, quality construction of both the rail and mounting hardware is vital to withstand recoil and environmental conditions. Selecting durable materials and reliable fastening mechanisms enhances the overall performance and longevity of the setup. Ensuring a secure fit not only improves accuracy but also contributes to the shooter’s confidence during operation.

Upper Receiver Design Elements

The upper receiver of a firearm plays a critical role in the overall functionality and performance of the weapon. It serves as the main structure housing various essential components that contribute to the firearm’s operation. Understanding its design elements is crucial for anyone interested in the mechanics of modern firearms.

Key Structural Features

The upper receiver incorporates several key features that enhance stability and precision. Its robust construction provides a solid foundation for mounting other critical elements, such as the barrel and sighting systems. The integration of a rail system allows for the attachment of various accessories, facilitating customization to meet specific user needs.

Material Considerations

Material selection is vital in the design of the upper receiver. Commonly crafted from aluminum or polymer, these materials ensure a balance between weight and durability. The choice of finish also impacts the receiver’s resistance to environmental factors, contributing to the longevity of the firearm in various conditions.

Pistol Grip Adjustments and Options

The grip of a firearm plays a crucial role in ensuring comfort, control, and accuracy during use. Customizing this component can significantly enhance the shooting experience, allowing for a better fit and improved handling. Various adjustments and options are available to tailor the grip to individual preferences.

When considering modifications, users can explore the following adjustments:

- Angle Adjustments: Altering the angle of the grip can provide a more natural wrist position, reducing fatigue during extended use.

- Height Modifications: Some grips offer adjustable height options, allowing shooters to find their optimal hand placement.

- Textured Surfaces: Different textures can enhance grip security, especially in adverse conditions, contributing to better handling.

In addition to adjustments, there are various options available for customization:

- Interchangeable Panels: Users can select from different panel designs to match their aesthetic preferences or functional needs.

- Padding Inserts: Adding padding can improve comfort during shooting sessions, especially for those who use their firearm frequently.

- Color Variations: Aesthetic choices, including colors and patterns, allow shooters to personalize their grip further.

Ultimately, the ability to modify the grip enhances both functionality and personal expression, ensuring a more satisfying shooting experience.

Maintenance and Replacement Parts Guide

This section provides essential information for ensuring the longevity and optimal performance of your firearm. Regular upkeep and timely substitutions of key components are vital for maintaining functionality and reliability. Understanding the appropriate actions to take can prevent potential issues and enhance your shooting experience.

To facilitate effective maintenance, consider the following recommendations:

- Conduct regular inspections to identify any wear or damage.

- Clean all components thoroughly after each use to prevent debris buildup.

- Lubricate moving parts as per the manufacturer’s guidelines to ensure smooth operation.

When it comes to replacing components, follow these guidelines:

- Refer to the specific model’s manual for compatibility and specifications.

- Utilize high-quality replacements to ensure optimal performance.

- Keep a stock of essential components to minimize downtime.

By adhering to these maintenance and replacement strategies, you can ensure your firearm remains in excellent condition, providing reliable service for years to come.