Understanding the intricate systems and the role of each mechanism is crucial when maintaining or repairing any large-scale machine. This guide offers a detailed breakdown of the essential elements, helping owners and operators ensure optimal performance and longevity. By familiarizing yourself with the layout and function of various assemblies, you can enhance your maintenance approach and troubleshoot issues more effectively.

In this article, we’ll delve into the primary systems that make up these machines, from the core mechanical structures to the auxiliary components. With a clear grasp of how these sections interact, you’ll be better equipped to handle routine inspections and adjustments, ensuring everything runs smoothly.

Whether you’re working on restoring an older model or simply keeping up with routine maintenance, having a clear visual reference of how everything is interconnected can significantly reduce the time spent on repairs. This overview will provide insights into the arrangement of critical systems, enabling more informed decisions when handling technical tasks.

Understanding the Ford 4500 Tractor Components

One of the key aspects to maintaining any machine is familiarizing yourself with its essential components. Knowing how various systems interact and function is crucial for both repair and upkeep. This guide provides a breakdown of key elements that make up the heart of the machine, offering insights into their roles and significance.

Engine and Powertrain

The engine is the powerhouse that drives the equipment, converting fuel into mechanical energy. Paired with the transmission, these elements work in harmony to ensure smooth operation across various terrains and tasks. Understanding how these systems operate will help you address any performance issues effectively.

Hydraulic System and Attachments

The hydraulic system plays a vital role in powering various implements, making tasks like lifting and loading easier. It is connected to different attachments that increase the machine’s versatility. Regular maintenance of the hydraulics ensures that the equipment remains efficient and capable of handling demanding tasks.

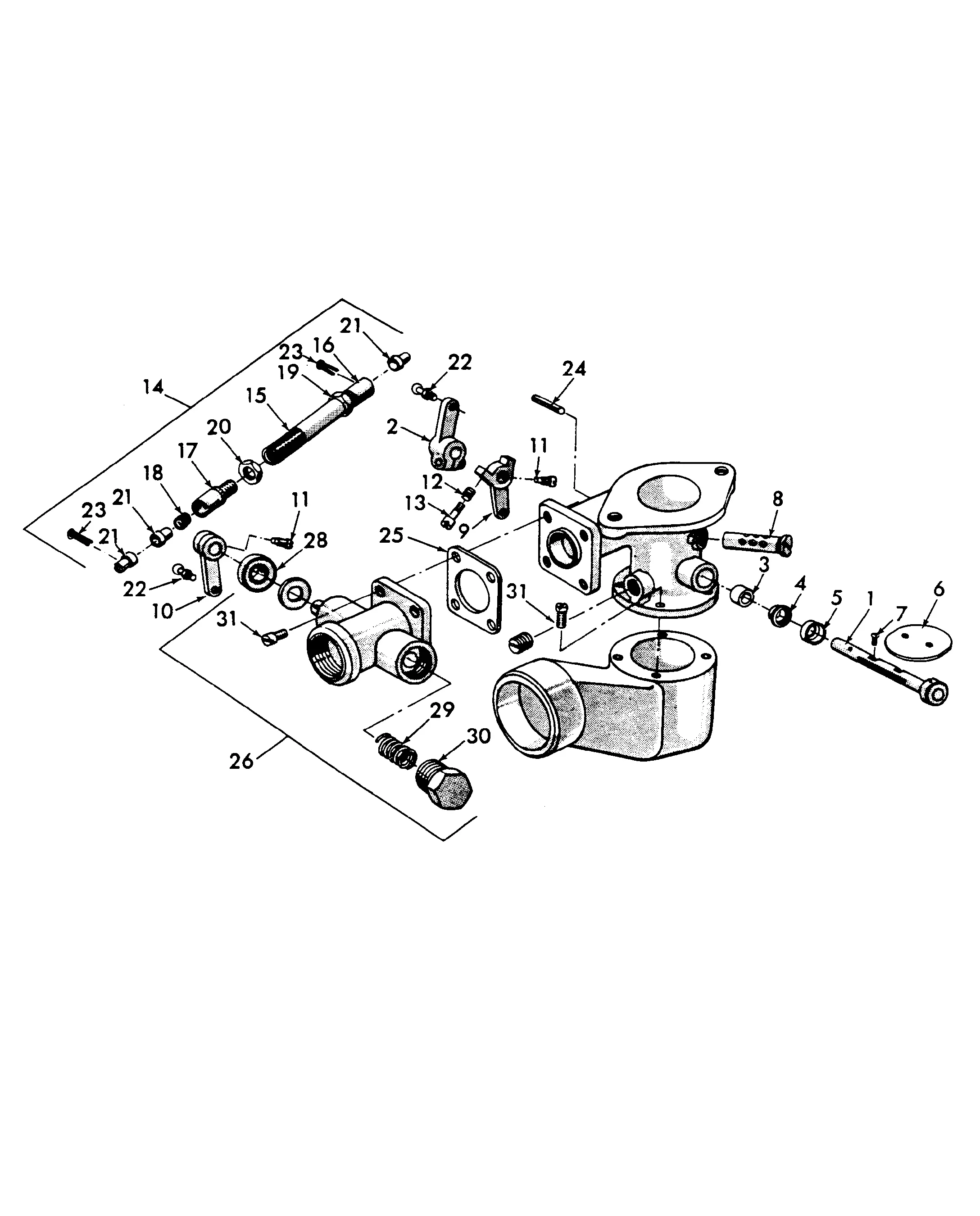

Key Diagrams for Tractor Engine Assembly

Understanding the detailed layout of the engine components is crucial for maintaining and repairing agricultural machinery. This section provides an overview of essential schematics that highlight the most important elements within the engine structure. By studying these illustrations, one can efficiently identify specific parts and their arrangement, ensuring proper assembly and functionality.

Piston and Cylinder Layout: The arrangement of pistons and cylinders plays a critical role in the engine’s power generation. The diagram showcases how these components are aligned and connected to other mechanisms within the system, allowing for smooth operation and optimal performance.

Crankshaft and Connecting Rods: The crankshaft, along with its connecting rods, forms the backbone of the engine’s motion. This diagram emphasizes the relationship between these parts, illustrating how rotational force is converted into linear motion, which drives the machine.

Valves and Timing Mechanism: Precise timing of the valve operation ensu

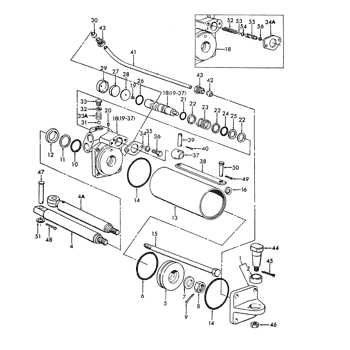

Exploring the Hydraulic System Layout

The hydraulic system is crucial for providing the necessary power to perform a range of tasks. Understanding the configuration and operation of this system is essential for ensuring optimal performance and efficiency. This section delves into the key components that work together to deliver fluid pressure, enabling various mechanical functions.

- Pumps: These are responsible for generating fluid flow and creating the necessary pressure to power hydraulic operations.

- Valves: These devices control the flow direction and pressure within the system, ensuring that different functions are carried out as intended.

- Hydraulic Cylinders: These components convert fluid pressure into mechanical force, enabling movement and lifting operations.

- Reservoirs: Storage units for hydraulic fluid, which are vital for maintaining proper fluid levels and ensu

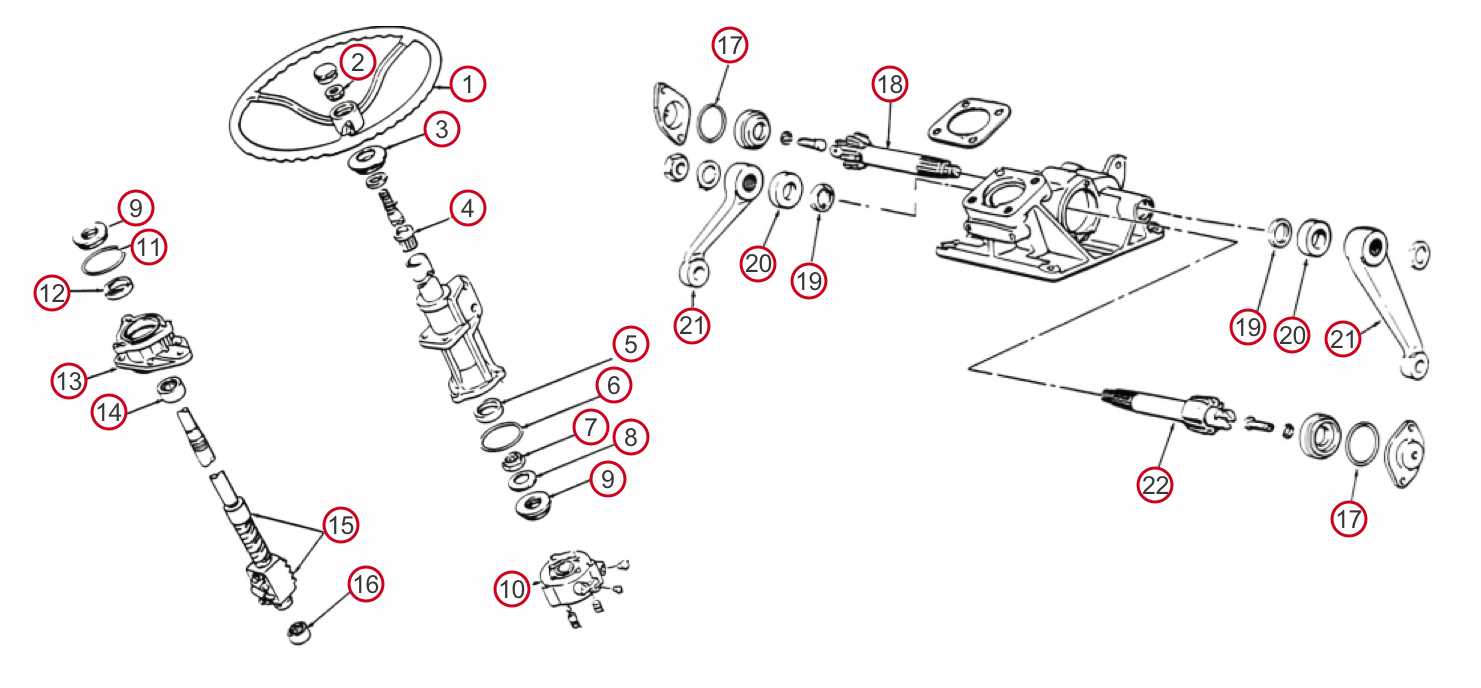

Front Axle and Steering Mechanism Breakdown

The front axle and steering components are crucial for ensuring smooth handling and control. Understanding how these parts work together allows for better maintenance and troubleshooting of issues that may arise with the vehicle’s maneuverability. This section provides a detailed overview of the assembly, including key elements and their interactions, contributing to the overall stability and direction control.

Main Components of the Front Axle

The axle consists of various elements, including the central beam, wheel hubs, and steering knuckles. These components are designed to handle significant loads while allowing the wheels to turn smoothly. The central beam provides structural support, while the hubs connect the wheels securely to the axle.

Steering Me

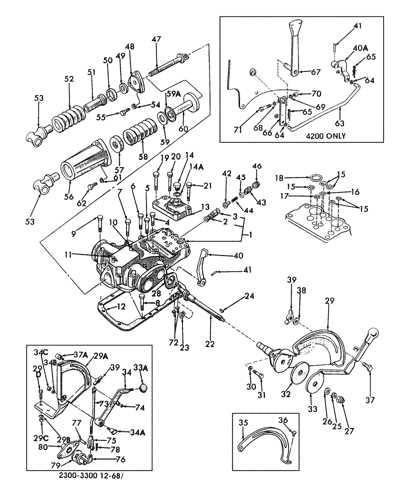

Transmission Parts Overview for Ford 4500

The gearbox of this equipment is a complex mechanism, ensuring the efficient transfer of power from the engine to the wheels. It plays a crucial role in enabling smooth movement across varying terrains and workloads. Understanding its individual components can assist in maintaining optimal functionality, enhancing performance, and extending the longevity of the machine.

Main Components

Several key elements make up the transmission assembly. Each part is designed to work together, ensuring seamless operation. Here’s a breakdown of the essential units that comprise the transmission system:

Component Function Clutch Disconnects the engine from the transmission to allow for Detailed Look at Rear Axle Parts

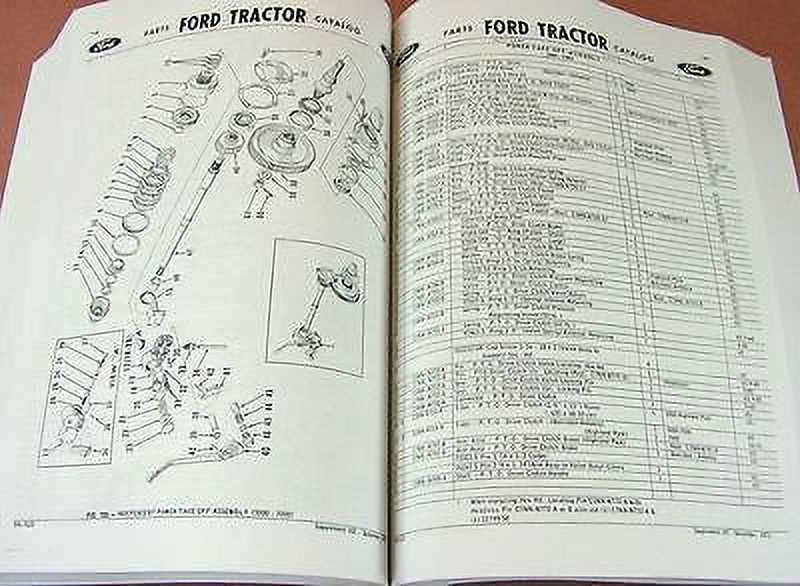

The rear axle assembly plays a crucial role in the overall functionality and performance of heavy machinery. This component is essential for transferring power from the engine to the wheels, ensuring efficient movement and stability. Understanding its individual elements can aid in maintenance and troubleshooting, enhancing the longevity and reliability of the equipment.

Key Components of the Rear Axle Assembly

Within the rear axle structure, several vital elements contribute to its effective operation. The housing serves as a protective casing, safeguarding internal mechanisms from environmental factors. Differential gears are pivotal for allowing smooth turns by enabling wheels to rotate at different speeds. Additionally, axle shafts are responsible for delivering torque, connecting the wheels to the power source.

Maintenance Considerations

Regular inspection of the rear axle assembly is essential for optimal performance. Lubrication of moving parts helps prevent wear and tear, while ensuring that the differential functions smoothly. Furthermore, checking for signs of leakage or damage can help identify potential issues before they escalate, ultimately preserving the integrity of the machinery.

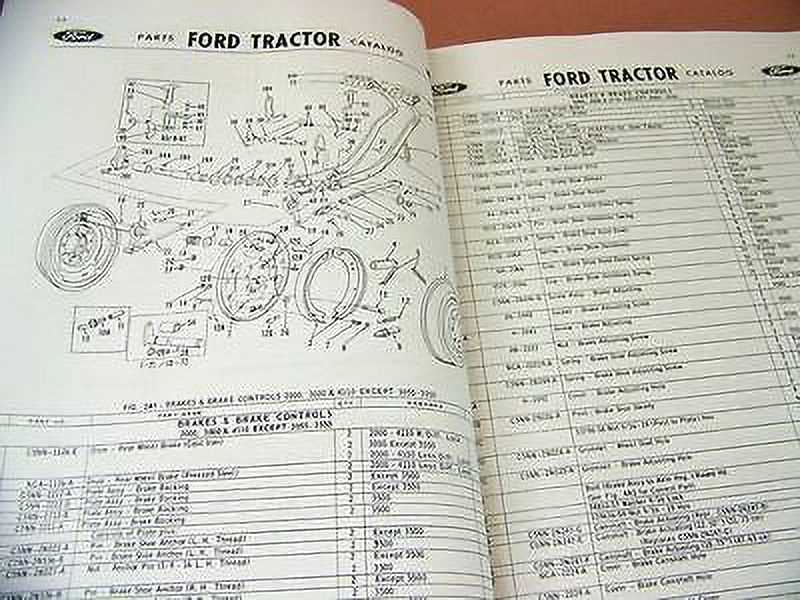

Braking System Components and Their Function

The braking system is a crucial aspect of any heavy machinery, ensuring safe operation and effective control during various tasks. Understanding the components that make up this system is essential for maintenance and troubleshooting. Each part plays a specific role in the overall function, contributing to the machine’s ability to slow down or come to a complete stop when necessary.

Main Components of the Braking System

This section outlines the key elements of the braking mechanism and their respective functions.

Component Function Brake Pedal Initiates the braking process by applying pressure to the hydraulic system. Hydraulic Cylinder Converts the mechanical force from the pedal into hydraulic pressure to actuate the brakes. Brake Shoes Press against the brake drum to create friction, slowing the wheel’s rotation. Brake Drum Works in conjunction with brake shoes to provide resistance and halt motion. Master Cylinder Distributes hydraulic fluid to the brake system when the pedal is pressed. Importance of Regular Maintenance

Routine inspection and maintenance of these components are vital for optimal performance and safety. Neglecting any part of the braking system can lead to decreased efficiency and increased risk of accidents. Ensuring that all elements are functioning correctly not only prolongs the lifespan of the machinery but also enhances overall safety during operation.

Cooling System Parts Explained

The cooling mechanism of machinery plays a crucial role in maintaining optimal operating temperatures, preventing overheating, and ensuring efficient performance. Understanding the various components that make up this system can help in troubleshooting issues and performing maintenance effectively. This section delves into the key elements of the cooling assembly, highlighting their functions and importance.

Radiator

The radiator serves as the primary heat exchanger in the cooling system. It dissipates heat from the coolant, allowing it to cool down before recirculating back into the engine. Typically made of metal, it consists of multiple tubes and fins that enhance the heat transfer process. Regular inspection for clogs and leaks is vital to ensure proper functioning.

Water Pump

This component is essential for circulating coolant throughout the system. Driven by the engine, the water pump ensures that coolant moves efficiently between the engine, radiator, and other related components. A malfunctioning pump can lead to overheating and reduced efficiency, making timely replacement critical.

Understanding these essential components is key to maintaining a well-functioning cooling assembly, ultimately leading to improved longevity and reliability of the machinery.

Examining the Fuel System Diagram

The fuel delivery mechanism is crucial for optimal performance in any machinery. Understanding the layout of this system can provide insights into its functionality and maintenance. This section delves into the intricacies of the fuel network, highlighting key components and their roles in ensuring efficient operation.

Key Components of the Fuel Network

At the heart of the fuel system lies the pump, responsible for transporting fuel from the tank to the engine. Additionally, filters play an essential role in removing impurities, ensuring that only clean fuel reaches the combustion chamber. Injectors then precisely spray the fuel into the engine, optimizing the combustion process.

Maintenance and Troubleshooting Tips

Regular inspections of the fuel system can prevent potential issues. Checking for leaks, replacing filters, and ensuring the pump functions properly are vital steps in maintaining overall efficiency. Timely maintenance can significantly enhance the lifespan and reliability of the machinery.

Electrical Wiring Layout and Key Parts

The electrical system of heavy machinery plays a crucial role in ensuring optimal functionality and reliability. This section focuses on the layout of the wiring and essential components that contribute to the effective operation of the equipment. Understanding these elements is vital for troubleshooting and maintenance.

Wiring Configuration

The wiring configuration consists of various connections that facilitate the flow of electricity to different systems within the machinery. Proper routing of cables is essential to prevent short circuits and ensure safe operation. Each wire is designed to withstand specific electrical loads, and the arrangement typically includes both positive and negative terminals to create a complete circuit.

Essential Components

Key components of the electrical system include the battery, alternator, starter motor, and various sensors. The battery provides the initial power required to start the engine, while the alternator charges the battery during operation. The starter motor engages the engine, and sensors monitor performance metrics, ensuring that the machinery operates efficiently.

Attachments and Implement Connection Points

This section focuses on the various connectors and mounting areas available for tools and accessories that enhance functionality and performance. Understanding these connection points is crucial for optimizing the use of machinery and ensuring compatibility with a wide range of implements.

Different attachments can be utilized to improve productivity, and each type features specific connection points designed to facilitate secure and efficient integration. Below is a table that outlines common implement connection options and their respective characteristics.

Connection Type Description Compatibility Three-Point Hitch A standard mounting method allowing for easy attachment of implements. Compatible with various implements such as plows and harrows. Loader Attachments Quick-connect systems designed for front-mounted tools. Ideal for buckets, forks, and other front-end accessories. Hydraulic Connectors Interfaces for hydraulic-powered implements. Used with tools requiring hydraulic power like grapples and drills. PTO Shaft Power Take-Off connection for driving various attachments. Commonly used with mowers, tillers, and generators. Choosing the correct connection method is vital for maximizing efficiency and ensuring that implements function correctly. Always refer to the compatibility guidelines when selecting attachments to achieve the best performance from your equipment.