The efficiency of ice maintenance machinery relies heavily on the intricate arrangement of its elements. Understanding the various components and their functions is crucial for anyone involved in the upkeep of skating rinks or similar facilities. Each segment plays a vital role in ensuring that the surface remains smooth and safe for users.

In this section, we will explore the key features and functionalities of these essential components. By delving into the specifics of how they interact, operators can enhance their knowledge and troubleshooting skills. This understanding not only aids in effective maintenance but also contributes to the longevity of the machinery.

Moreover, a comprehensive grasp of these mechanisms empowers users to perform necessary repairs and replacements. Familiarity with the equipment’s structure promotes confidence and competence, ultimately leading to better performance in ice management tasks.

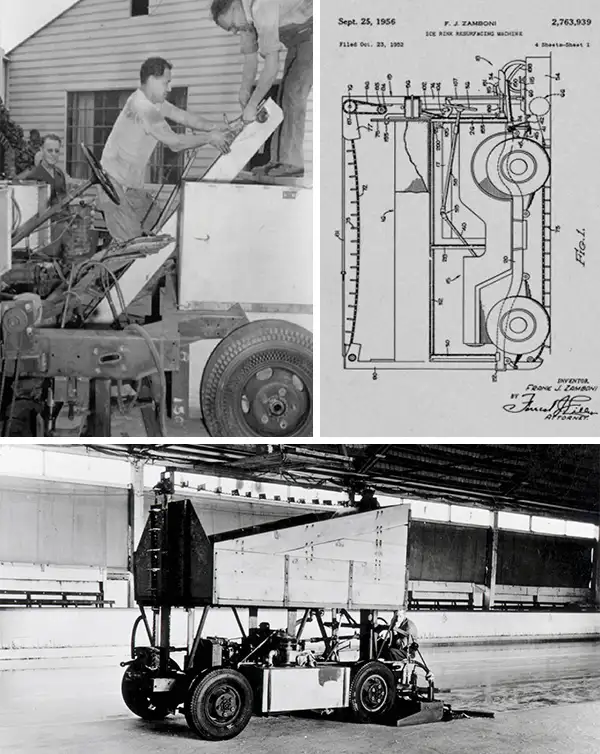

Understanding Zamboni Functionality

The operation of ice resurfacing machines involves a series of coordinated processes that ensure a smooth and safe surface for skating activities. These machines are designed to perform multiple tasks simultaneously, including cleaning, smoothing, and applying a fresh layer of water to create an ideal ice surface.

At the heart of the machinery is a powerful engine that drives the essential components, allowing for efficient operation. Key elements include a large blade that shaves the top layer of ice, removing imperfections and debris, while a water tank supplies liquid to fill in any gaps left behind. The entire system is engineered to maintain optimal performance under various conditions, providing consistent results for recreational and professional arenas alike.

Moreover, advanced features such as temperature control and automated systems enhance the usability of these machines. Operators can adjust settings to accommodate different ice conditions, ensuring the surface remains in top shape regardless of usage. This technology not only improves the quality of the ice but also contributes to the longevity of the machine itself, making maintenance more straightforward.

Key Components of Zamboni Machines

Understanding the essential elements of ice resurfacing equipment is crucial for optimal performance and maintenance. Each component plays a vital role in ensuring a smooth and even surface on ice rinks. This section will explore the fundamental features that contribute to the efficiency of these specialized machines.

Main Functional Parts

- Blade: This crucial element shaves the ice surface to create a smooth finish.

- Water Tank: Stores water used to wet the ice after shaving.

- Scraper: Removes excess ice shavings to prepare for resurfacing.

- Conveyor: Moves ice shavings from the blade to the collection area.

Supporting Systems

- Hydraulic System: Provides power for lifting and lowering the blade.

- Electrical System: Powers various components, including lights and controls.

- Cooling System: Maintains optimal operating temperature for efficient performance.

Importance of Maintenance for Zambonis

Regular upkeep is crucial for the optimal performance of ice resurfacing machines. Consistent attention to maintenance ensures that these machines operate efficiently and effectively, enhancing the quality of ice surfaces. Proper care not only prolongs the lifespan of the equipment but also prevents costly repairs and downtime.

Benefits of Regular Upkeep

Enhanced Performance: Frequent inspections and servicing lead to improved functionality. Well-maintained machinery performs better, providing a smoother and more consistent ice surface.

Cost-Effectiveness

Preventative maintenance can save significant amounts of money in the long run. Addressing minor issues before they escalate into major problems reduces repair costs and minimizes operational disruptions.

How to Identify Zamboni Parts

Recognizing the various components of an ice resurfacing machine is crucial for maintenance and repair. Understanding these elements ensures optimal performance and longevity of the equipment.

To effectively identify the essential elements of this machinery, follow these guidelines:

- Familiarize Yourself with the Equipment: Study the overall structure and functions to grasp how each component works together.

- Refer to Manuals: Utilize user manuals or technical documentation that provides detailed descriptions and images of the individual elements.

- Seek Online Resources: Explore online forums, websites, or videos that showcase the different sections and their purposes.

- Engage with Experts: Consult with professionals or experienced operators who can provide insights and identify various components based on their experience.

By following these steps, you will enhance your ability to recognize and understand the different elements of the ice resurfacing machine.

Common Issues with Zamboni Parts

When maintaining ice resurfacing machines, operators often encounter various challenges that can impact performance. Understanding these issues is crucial for ensuring efficient operation and longevity of the equipment.

Here are some typical problems that may arise:

- Hydraulic Leaks: One of the most frequent issues is the presence of leaks in hydraulic systems, which can lead to reduced pressure and inefficient functioning.

- Electrical Failures: Malfunctions in the electrical system, including wiring issues or faulty components, can disrupt the machine’s operation.

- Blade Deterioration: Over time, the resurfacing blades can wear down, leading to uneven surfaces and poor ice quality.

- Cooling System Blockages: Accumulation of debris in the cooling system can hinder performance, causing overheating and inefficient operation.

- Drive System Malfunctions: Problems with the drive mechanism can result in power loss or uneven movement, affecting overall efficiency.

Regular inspections and maintenance can help identify these challenges early, ensuring that resurfacing machinery remains in optimal condition for ice maintenance tasks.

Replacing Zamboni Components Effectively

When it comes to maintaining your ice resurfacing machine, knowing how to replace various components can significantly enhance its performance. Understanding the essential steps and processes involved ensures that you keep your equipment running smoothly and efficiently.

Follow these guidelines to effectively replace machine components:

- Identify the specific component that needs replacement. Look for signs of wear, damage, or malfunction.

- Gather the necessary tools and new components required for the replacement process.

- Refer to the manufacturer’s manual for detailed instructions on the replacement procedure.

- Ensure that the machine is powered off and properly secured before beginning the replacement.

- Carefully remove the old component, taking note of how it is installed for reference during reinstallation.

- Install the new component, ensuring it is securely fitted and aligned correctly.

- Perform any required adjustments or calibrations to ensure optimal operation.

- Test the machine to verify that the new component functions as intended.

Regular maintenance and timely replacement of worn components can prolong the lifespan of your equipment, ensuring that it continues to deliver high-quality results on the ice.

Finding Quality Zamboni Parts

Locating reliable components for your ice resurfacing machine can significantly enhance its performance and longevity. Understanding where to search for high-quality supplies is crucial for maintaining optimal operation. This section explores effective strategies and resources to ensure you acquire the best materials available.

Research Trusted Suppliers

Start by investigating reputable vendors who specialize in ice rink machinery. Look for reviews and testimonials from other users to gauge the reliability of their offerings. Trusted suppliers often provide warranties and customer support, which can be beneficial when dealing with equipment-related issues.

Utilize Online Platforms

Online marketplaces can serve as excellent resources for finding a variety of components. Websites that focus on machinery often have user-friendly interfaces, allowing you to compare different options easily. Make sure to check for authenticity and reviews to avoid counterfeit products. Engaging with online communities dedicated to rink maintenance can also yield recommendations for dependable sources.

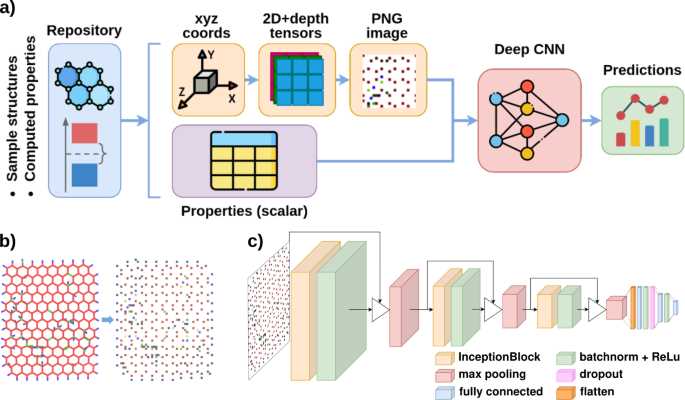

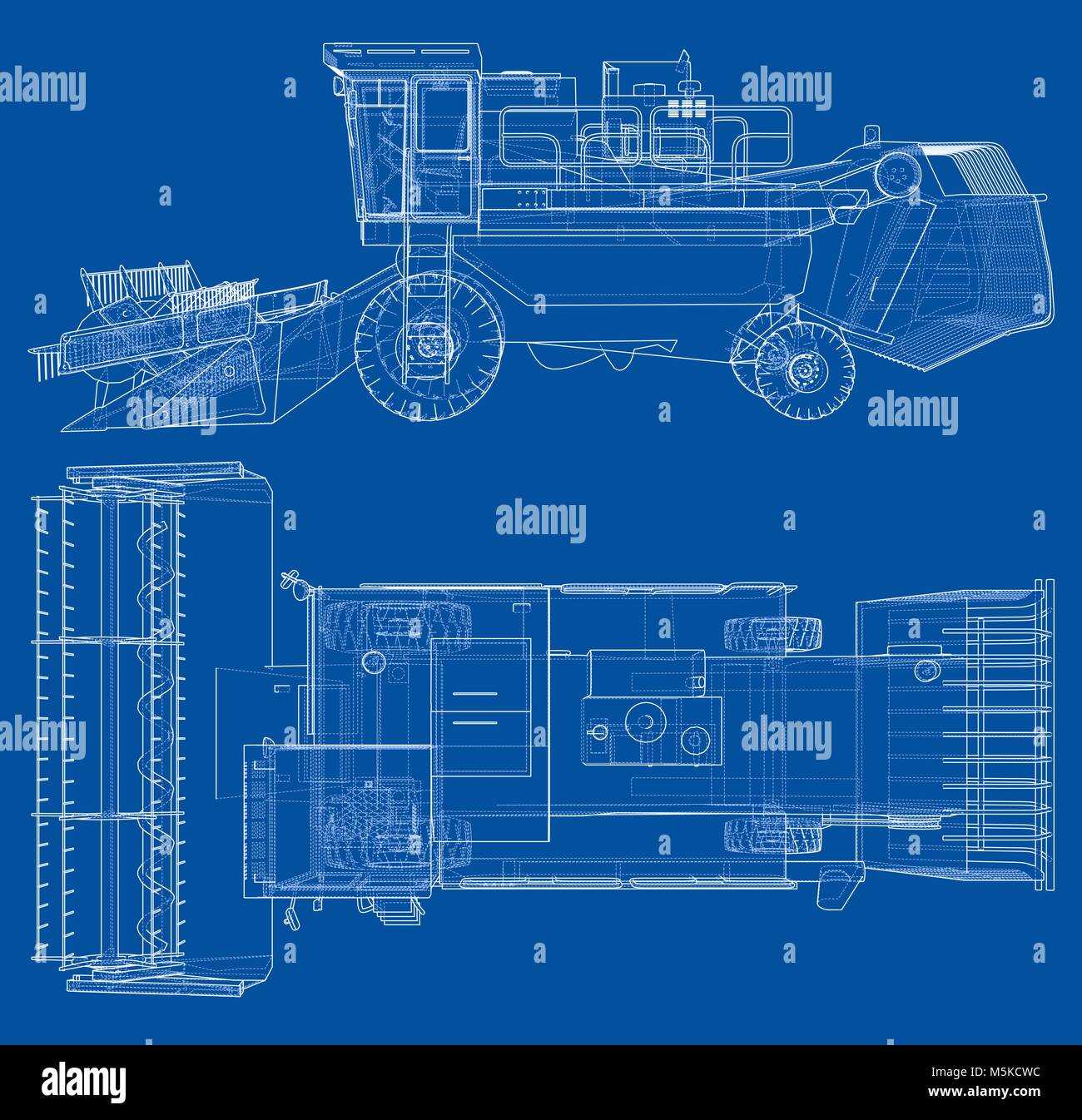

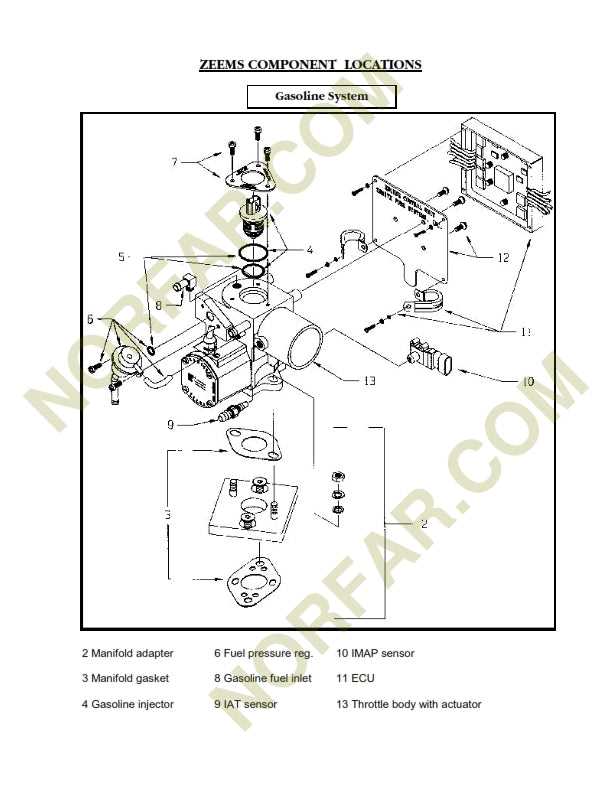

Parts Diagram Interpretation Guide

This section aims to provide clarity on understanding the visual representations of equipment components. These illustrations serve as essential references for identifying and locating various elements within the machinery. By mastering the interpretation of these visuals, users can enhance their maintenance and operational skills.

Understanding Symbols and Labels

Each illustration is accompanied by symbols and labels that denote specific elements. Familiarity with these can streamline the troubleshooting process. Here are some common symbols:

- Circle: Indicates a movable component.

- Square: Represents a fixed part.

- Arrow: Shows direction of movement or flow.

Reading the Visuals Effectively

To interpret these visuals accurately, follow these steps:

- Identify the primary sections of the machinery.

- Locate the corresponding labels for each component.

- Use a reference guide to understand any unfamiliar symbols.

- Cross-check with the operational manual for context.

By applying these strategies, users can gain a comprehensive understanding of the machinery layout, facilitating better maintenance and effective repairs.

Enhancements for Zamboni Performance

Improving the efficiency and functionality of ice resurfacing machines is essential for maintaining optimal ice quality. By focusing on specific modifications and upgrades, operators can enhance performance, prolong the lifespan of equipment, and ultimately provide better conditions for ice sports.

Regular Maintenance: Consistent upkeep is critical for maximizing performance. Routine checks of mechanical components, fluid levels, and electrical systems can prevent unexpected breakdowns and ensure the machine operates at peak efficiency.

Upgraded Components: Investing in high-quality replacement parts can significantly impact overall performance. Enhanced blades, improved heating elements, and advanced hydraulic systems contribute to more effective ice treatment and reduced energy consumption.

Innovative Technologies: Implementing the latest advancements in technology can streamline operations. Features like automated controls and advanced monitoring systems allow for precise adjustments, making the resurfacing process more efficient and consistent.

Operator Training: Ensuring that operators are well-trained can lead to better performance outcomes. Comprehensive training programs focused on the proper use of equipment, maintenance procedures, and troubleshooting techniques empower operators to maximize the potential of their machines.

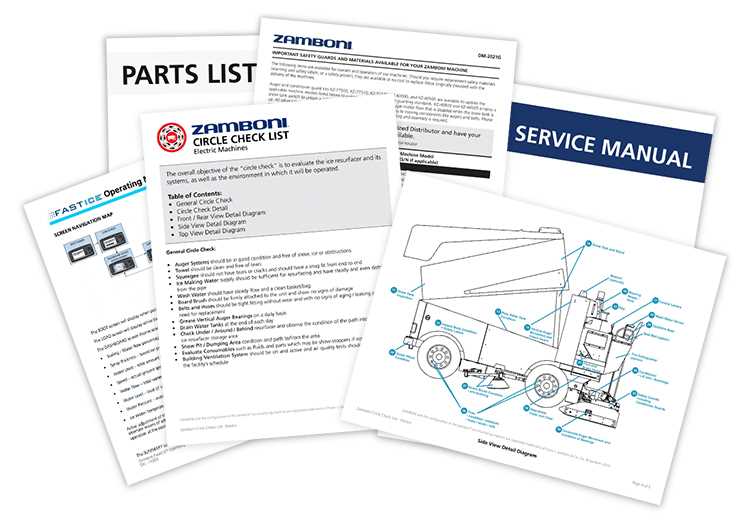

Resources for Zamboni Owners

Owning an ice resurfacing machine comes with the responsibility of maintaining its functionality and efficiency. Whether you’re an operator or a manager, having access to reliable information and resources can greatly enhance your experience and ensure the longevity of your equipment.

Essential Guides and Manuals

- Operational Manuals: Detailed guides on the operation and maintenance of the machine.

- Maintenance Checklists: Handy lists to help you keep track of essential maintenance tasks.

- Troubleshooting Guides: Resources to assist in diagnosing common issues and providing solutions.

Community and Support Networks

- Online Forums: Join discussions with other operators to share experiences and advice.

- Social Media Groups: Engage with a community of enthusiasts and professionals.

- Local Workshops: Attend events to learn more about machine care and meet fellow owners.