In the world of power tools, having a clear understanding of their internal structure is essential for effective maintenance and repair. Knowing how each component interacts with one another can significantly enhance the tool’s performance and longevity. This section aims to provide a comprehensive overview of the essential elements that make up your equipment.

Visualization of the internal layout is crucial for anyone looking to troubleshoot or upgrade their device. By familiarizing yourself with the configuration of various elements, you can better diagnose issues and perform necessary replacements. A well-organized visual reference can simplify this process, allowing for efficient repairs and modifications.

Whether you’re a seasoned professional or a hobbyist, understanding these key elements can empower you to take control of your tool’s functionality. This guide will illuminate the various segments, enabling you to navigate through maintenance tasks with confidence and precision.

Dewalt DWFP12233 Overview

This section provides a comprehensive look at a specific model in the realm of pneumatic tools, focusing on its design and functionality. Understanding the various components and their roles is crucial for both maintenance and effective operation.

Key Features

This model boasts a range of features that enhance its usability and performance. The lightweight construction ensures easy handling, while the ergonomic design promotes comfort during extended use. Additionally, its reliable power source contributes to efficient operation, making it suitable for both professional and DIY applications.

Component Breakdown

A clear understanding of the main elements of this tool is essential for optimal performance. The following table outlines the primary components along with their respective functions:

| Component | Function |

|---|---|

| Motor | Powers the tool, providing the necessary force for various tasks. |

| Housing | Encases the internal components, ensuring durability and protection. |

| Trigger | Controls the activation of the tool, allowing for precise operation. |

| Pressure Gauge | Monitors the air pressure levels, aiding in maintaining optimal performance. |

Key Features of the Model

This section highlights the essential characteristics that set this model apart, emphasizing its design and functionality. Understanding these features can help users appreciate the tool’s capabilities and advantages in various applications.

Durability and Reliability

One of the standout attributes of this tool is its robust construction, designed to withstand rigorous use in demanding environments. High-quality materials ensure long-lasting performance, making it a reliable choice for both professionals and DIY enthusiasts.

Ease of Use

The design prioritizes user convenience, featuring ergonomic grips and intuitive controls. These elements enhance comfort during extended use, allowing users to operate the device with precision and ease, even in challenging positions.

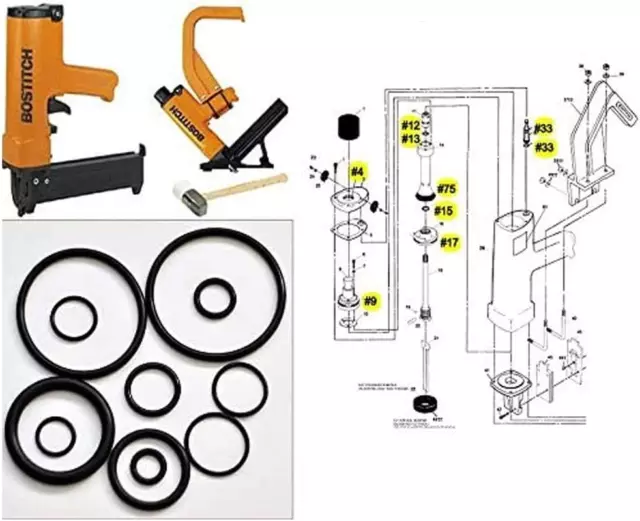

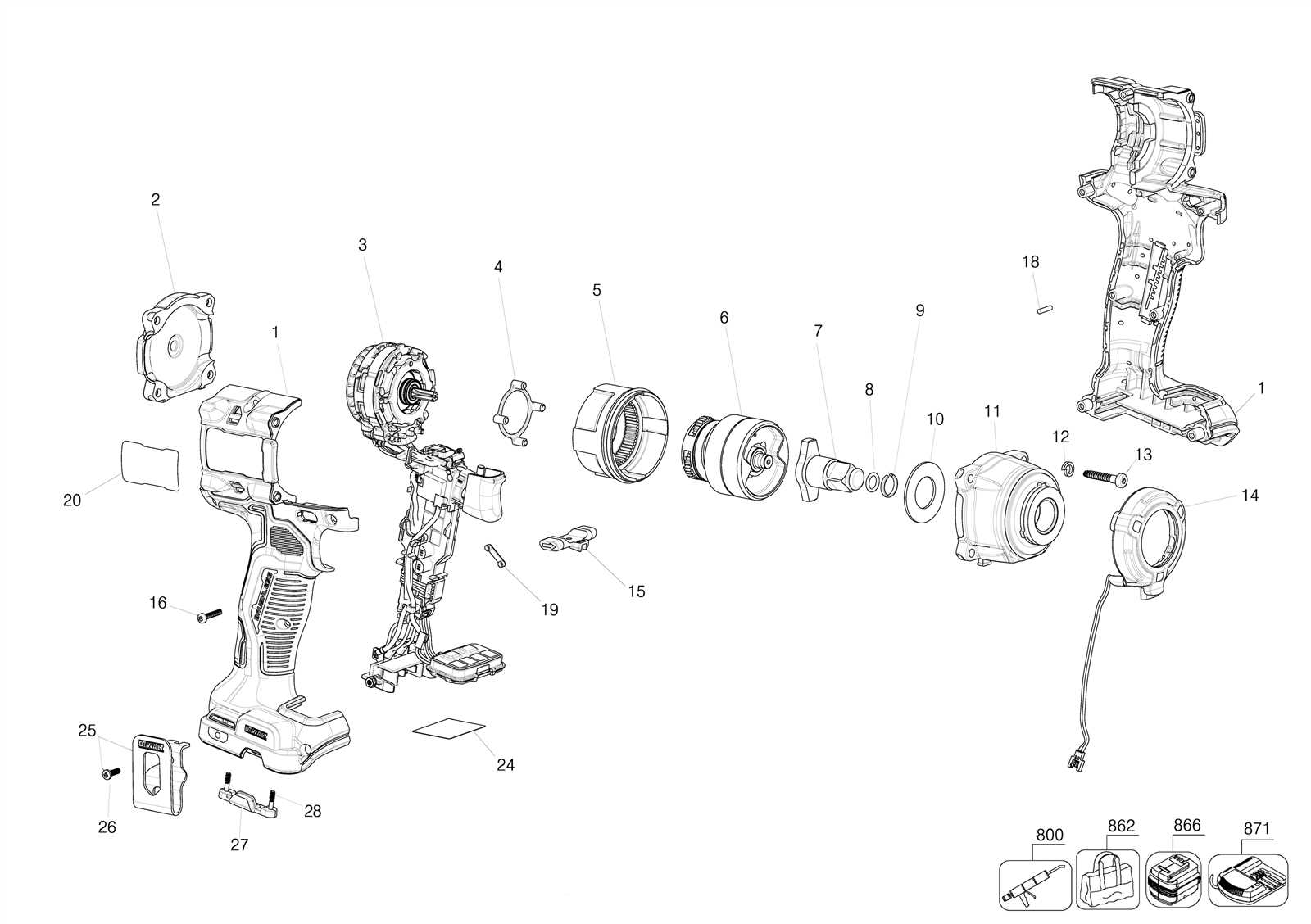

Understanding the Parts Diagram

Comprehending the assembly illustration is crucial for effective maintenance and repair of tools. This visual representation provides insight into the individual components, their arrangement, and how they interact within the mechanism. By familiarizing yourself with these elements, you can enhance your understanding of functionality and streamline troubleshooting processes.

Key Components Overview

The assembly illustration typically highlights essential components, categorizing them by function and location. This organization allows users to easily identify specific parts when needed for replacement or service. Familiarity with these elements not only aids in repairs but also fosters a deeper appreciation of the tool’s design and engineering.

Benefits of Utilizing the Illustration

Using this visual guide enhances the efficiency of repairs and maintenance. It allows for quick identification of worn or damaged parts, reducing downtime and improving overall performance. Moreover, understanding the layout can empower users to perform tasks with greater confidence and precision.

Main Components Explained

Understanding the key elements of any tool is essential for effective use and maintenance. Each component plays a specific role, contributing to the overall functionality and efficiency of the equipment.

Motor: The heart of the machine, responsible for generating power. It converts electrical energy into mechanical energy, enabling the device to perform its tasks.

Pressure Regulator: This crucial element maintains a consistent output pressure, ensuring optimal performance and preventing damage to the tool or the materials being worked on.

Air Tank: Serving as a reservoir, this component stores compressed air, providing a steady supply during operation. Its capacity can affect the duration of use before needing to recharge.

Fittings and Connectors: These elements facilitate the connection between the tool and its accessories. Proper fittings ensure a secure seal and prevent air leaks, which can diminish efficiency.

Trigger Mechanism: The user interface that controls the operation of the device. It allows for precise control over the tool’s activation and functionality, enhancing user experience.

By familiarizing oneself with these primary components, users can optimize their interaction with the tool, ensuring longevity and performance in various applications.

Assembly Instructions and Tips

When assembling your tool, it’s essential to follow a structured approach to ensure efficiency and safety. Proper organization of components and a clear understanding of the assembly process will greatly enhance your experience.

Preparation: Before you begin, gather all necessary components and tools. This will help prevent interruptions during assembly. Review any accompanying documentation for specific details on each part.

Step-by-Step Assembly: Start by laying out all items in a logical order. Begin with the base and gradually add components, ensuring each piece fits securely. Pay attention to any alignment indicators to avoid potential issues later.

Securing Connections: Use the recommended fasteners and ensure they are tightened adequately, but avoid overtightening, which can lead to damage. If applicable, apply lubricants to moving parts as specified in the instructions.

Final Checks: Once assembled, double-check all connections and moving parts. Make sure everything operates smoothly and adheres to safety standards before use. If any discrepancies arise, consult the documentation or seek assistance.

By following these guidelines, you will enhance the functionality and longevity of your tool while ensuring a seamless assembly process.

Maintenance Recommendations for Longevity

Proper upkeep is essential for extending the life of any tool. Regular maintenance not only enhances performance but also prevents premature wear and costly repairs. Adopting a few simple practices can significantly improve durability and efficiency.

1. Regular Cleaning: Ensure that all components are free from dust, debris, and other contaminants. Utilize a soft brush or compressed air to remove particles, particularly in tight spaces where buildup can occur.

2. Lubrication: Periodically apply appropriate lubricants to moving parts. This reduces friction and helps maintain smooth operation. Always refer to the manufacturer’s guidelines for recommended products and intervals.

3. Inspection: Conduct routine inspections to identify any signs of wear or damage. Look for cracks, rust, or loose connections that could compromise functionality. Address any issues promptly to prevent further damage.

4. Storage: Store tools in a dry, cool place to avoid exposure to moisture and extreme temperatures. Use protective cases or covers to safeguard against dust and physical damage when not in use.

5. Follow Usage Guidelines: Adhere to the operational guidelines provided by the manufacturer. Using the tool as intended minimizes the risk of misuse and prolongs its lifespan.

By implementing these recommendations, users can ensure optimal performance and longevity, making the most of their investment.

Common Issues and Solutions

Understanding potential problems that may arise with a specific tool can greatly enhance its performance and longevity. Identifying these issues early on allows for timely intervention, ensuring that operations remain smooth and efficient.

One frequent concern is the inconsistency in power delivery, which can stem from worn-out components or improper maintenance. Regular checks and timely replacements can help mitigate this issue. Another common challenge is air leaks, often caused by damaged seals or fittings. Inspecting these parts and ensuring proper sealing can effectively resolve this problem.

Additionally, overheating can occur due to excessive use or insufficient cooling. Allowing the device to rest and ensuring adequate airflow during operation are essential practices. Lastly, issues related to noise may indicate loose or damaged elements. Tightening or replacing these components can restore quiet functionality.

Where to Find Replacement Parts

When it comes to maintaining your equipment, locating the right components can be essential for optimal performance. There are several reliable sources where you can acquire these necessary elements, ensuring your tools remain functional and efficient.

Authorized Retailers

One of the most dependable options is to visit authorized dealers. These outlets often have a comprehensive selection of components that are specifically designed for your model. Purchasing from certified sellers guarantees that you are getting genuine replacements, which can enhance the longevity of your equipment.

Online Marketplaces

Another convenient choice is to explore online marketplaces. Websites dedicated to tool supplies often feature a vast inventory of components, making it easy to find what you need. Additionally, user reviews and ratings can guide you toward trustworthy options, ensuring you make informed decisions. Always verify the seller’s reputation before finalizing your purchase.

Comparing with Similar Models

This section focuses on evaluating and contrasting various tools within the same category to understand their strengths and weaknesses. By examining the features, specifications, and performance metrics of similar devices, users can make informed decisions tailored to their specific needs.

Performance and Features

When assessing comparable models, it’s essential to consider key performance indicators such as power output, air delivery rate, and durability. Some alternatives may offer advanced features like noise reduction technology or enhanced portability, which can significantly impact usability in various settings.

Cost-Effectiveness and Warranty

Price points often vary among similar tools, making it vital to analyze the cost-effectiveness of each option. Additionally, warranty offerings can provide insight into the manufacturer’s confidence in their product’s longevity, further influencing the purchasing decision.

User Reviews and Feedback

This section provides insights into the experiences of users with a specific tool, highlighting their opinions and evaluations. Feedback from various customers helps potential buyers make informed decisions based on real-world usage.

Users have expressed a range of opinions regarding performance and reliability:

- Many users appreciate the tool’s durability, noting its ability to withstand tough working conditions.

- Some reviews highlight the ease of use, making it suitable for both professionals and DIY enthusiasts.

- A few customers mentioned minor issues, such as weight and noise levels, but these did not significantly affect overall satisfaction.

Common themes from reviews include:

- High efficiency in completing tasks quickly.

- Comfortable handling, especially during extended use.

- Positive experiences with customer service regarding inquiries and support.

Overall, user feedback reflects a generally favorable view of the tool, emphasizing its practicality and performance in various applications.

Warranty and Customer Support

This section provides essential information regarding product assurance and assistance for users. Understanding the available options can significantly enhance the experience and ensure satisfaction with the equipment.

Warranty Information

The guarantee for your tool typically covers defects in materials and workmanship. Users should be aware of the duration and specific conditions of the warranty, which may include:

- Standard warranty period (usually 1-3 years).

- Exclusions for wear and tear items.

- Requirements for proof of purchase.

Customer Assistance

If you encounter issues or have inquiries, customer support is readily available. Here are the common methods to reach out:

- Phone support for immediate assistance.

- Email for detailed inquiries.

- Online resources including FAQs and troubleshooting guides.

Utilizing these resources can help resolve problems efficiently, ensuring that your equipment operates effectively for years to come.