Understanding the intricate structure of a cleaning device is essential for maintaining its efficiency and longevity. By examining the various elements that constitute this equipment, users can gain insights into its functionality and troubleshooting methods. This exploration provides a valuable resource for those seeking to enhance their knowledge and skills in managing these machines.

Familiarity with each component not only aids in effective usage but also simplifies the repair process. Recognizing how each part interacts within the overall assembly allows for informed decisions when it comes to replacements or upgrades. Consequently, a well-rounded understanding of the unit’s makeup empowers users to optimize their cleaning experience.

Additionally, having access to detailed information about the assembly can prevent common mistakes during maintenance. Whether for routine upkeep or addressing specific issues, knowing the layout and functions of each part ensures that users can approach their tasks with confidence. This comprehensive guide aims to illuminate the essential features of the cleaning machine, making it easier for users to navigate their maintenance journeys.

Karcher K3 97: Key Components Overview

This section provides a comprehensive look at the essential elements that make up the K3 97 model, focusing on their functions and significance in ensuring optimal performance. Understanding these components is crucial for effective maintenance and operation.

| Component | Description | Function |

|---|---|---|

| Motor | The power source that drives the system. | Generates the necessary energy for operation. |

| Pump | A vital mechanism that moves water through the unit. | Creates pressure for effective cleaning. |

| Trigger Gun | The handheld device used to control water flow. | Enables user interaction for starting and stopping operations. |

| Hose | A flexible tube that transports water from the unit. | Connects the system to the cleaning area. |

| Nozzle | The attachment that adjusts the spray pattern. | Allows customization of water flow for different tasks. |

High-Pressure Hose Functionality and Maintenance

The high-pressure hose serves a critical role in power washing systems, acting as a conduit for delivering water at elevated pressures to effectively remove dirt and grime from various surfaces. Understanding its functionality is essential for ensuring optimal performance and longevity of the equipment.

Importance of Proper Maintenance

Regular upkeep of the high-pressure hose is vital to prevent wear and tear that can lead to leaks or bursts. Inspecting the hose for any signs of damage, such as cracks or abrasions, should be a routine practice. Additionally, keeping the hose clean from debris and contaminants helps maintain its integrity and efficiency.

Storage Tips for Longevity

To prolong the lifespan of the high-pressure hose, it is important to store it properly when not in use. Avoid kinking the hose, as this can cause internal damage. Instead, roll it up loosely and store it in a cool, dry place. This practice not only protects the hose but also ensures it remains ready for use when needed.

Water Inlet System and Its Role

The water inlet system serves as a crucial component in various cleaning devices, facilitating the flow of water essential for effective operation. Its primary function is to ensure a steady and reliable supply of water, which is necessary for the device to perform its intended tasks efficiently.

This system comprises several key elements that work together to maintain optimal water flow. Understanding these components helps in appreciating the overall functionality of the cleaning equipment.

- Water Filter: This element prevents debris and impurities from entering the system, protecting internal mechanisms from damage.

- Inlet Valve: Responsible for regulating water flow, the valve ensures that the right amount of water is supplied based on the operational needs.

- Hoses: These flexible tubes transport water from the source to the internal parts of the device, allowing for effective cleaning action.

- Connectors: Essential for linking different components, connectors ensure that the system is sealed and free from leaks.

In summary, the water inlet system is integral to the overall functionality of cleaning machinery. Each component plays a significant role in ensuring that water flows smoothly, ultimately enhancing performance and durability.

Trigger Gun Mechanism Explained

The trigger gun mechanism is a crucial component in pressure washing systems, playing a significant role in controlling water flow. Understanding its operation is essential for effective use and maintenance of these devices.

This mechanism typically consists of several key parts that work together to enable precise control. Below are the primary elements:

- Trigger: The part that initiates water flow when pressed.

- Valve: Regulates the pressure and volume of water released.

- Spring: Ensures the trigger returns to its original position when released.

- Body: Houses the internal components and provides structural integrity.

When the trigger is activated, it allows water to flow from the source through the valve, which adjusts to the desired pressure settings. The spring mechanism plays a vital role in ensuring that the trigger remains in a neutral position when not in use, preventing unintentional water discharge.

Maintaining this mechanism is essential for optimal performance. Regular inspections for wear and tear, as well as cleaning any blockages, can help prolong the lifespan of the device and ensure efficient operation.

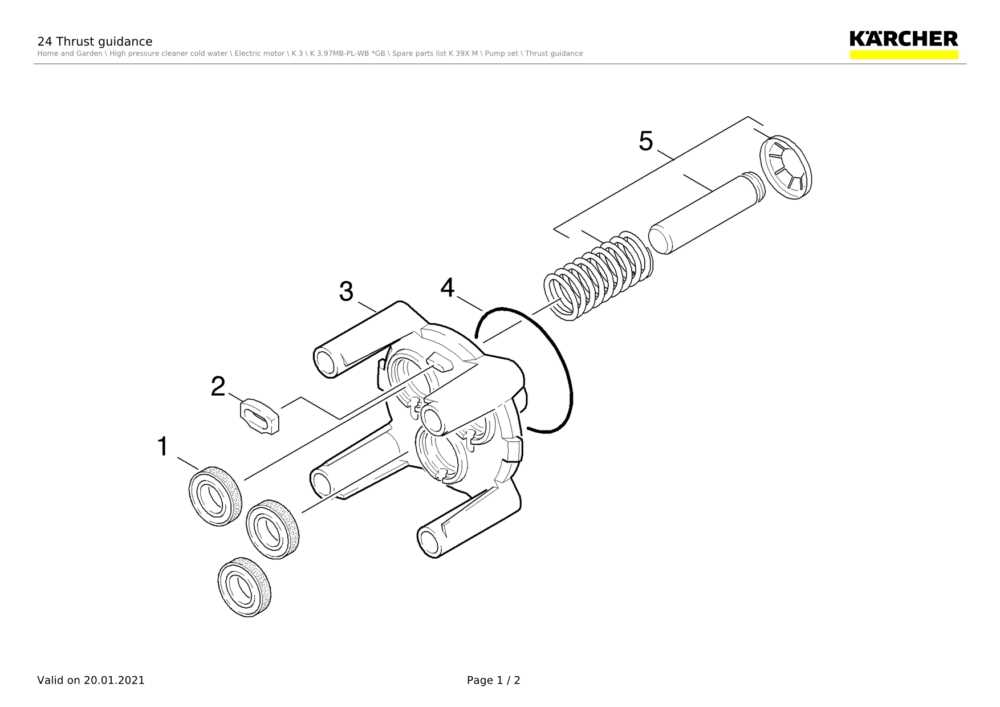

Pump Assembly Breakdown

This section provides a comprehensive overview of the components involved in the water pump assembly, essential for understanding its functionality and maintenance. Each part plays a crucial role in ensuring efficient operation and reliability.

| Component | Description |

|---|---|

| Pump Housing | The outer shell that encloses and protects the internal components of the pump. |

| Impeller | A rotating element that increases the velocity of the fluid, facilitating movement through the system. |

| Seal | A component that prevents leakage of fluids from the assembly, maintaining pressure and efficiency. |

| Drive Shaft | The shaft that transmits power from the motor to the impeller, enabling rotation. |

| Pressure Regulator | A mechanism that maintains optimal pressure levels within the system to prevent damage. |

Electric Motor in Karcher K3 97

The electric motor serves as a vital component, providing the necessary power to operate various functions of the device. Its efficient design ensures optimal performance, contributing to the overall effectiveness of the equipment.

Key Features: The motor is engineered to deliver reliable energy while maintaining a compact size, allowing for easy integration within the unit. Its construction emphasizes durability, ensuring a long service life under demanding conditions.

Maintenance Considerations: Regular inspections and upkeep of the motor are crucial for sustaining performance levels. Users are encouraged to keep the motor clean and free from debris, as this can significantly enhance its efficiency and longevity.

How the Spray Lance Operates

The spray lance is a crucial component that enhances the functionality of a pressure cleaning system. Its design allows for the effective dispersion of water or cleaning solutions, facilitating a thorough and efficient cleaning process. By adjusting the angle and pressure, users can tailor the spray to suit various surfaces and tasks.

Mechanism of Action

The operation of the spray lance relies on a simple yet effective mechanism. When the trigger is pressed, water flows from the source through the lance. This flow is then directed through a nozzle, which can be adjusted to alter the spray pattern. The ability to change the nozzle size allows for a fine mist or a concentrated jet, providing versatility in cleaning applications.

Importance of Maintenance

Regular maintenance of the spray lance is essential for optimal performance. Ensuring that the nozzle is clean and free from debris prevents blockages that can affect water flow and pressure. Additionally, checking for any wear or damage will prolong the life of this vital tool, ensuring it operates efficiently and effectively.

Cleaning Nozzle Variations

Different types of cleaning nozzles play a significant role in enhancing the efficiency and effectiveness of pressure washing. These attachments can significantly impact the cleaning process, allowing users to tackle various surfaces and levels of grime with ease. Understanding the unique characteristics and functionalities of each nozzle type helps in selecting the right tool for specific tasks.

Here are some common variations of cleaning nozzles:

| Nozzle Type | Application | Pressure Rating |

|---|---|---|

| Turbo Nozzle | Ideal for tough stains on hard surfaces | High pressure |

| Fan Nozzle | Great for broad cleaning areas | Medium pressure |

| Soap Nozzle | Best for applying detergents | Low pressure |

| Rotary Nozzle | Effective for intricate cleaning | Variable pressure |

Choosing the appropriate nozzle can make a considerable difference in achieving desired cleaning results while ensuring efficiency and safety during use.

Internal Seals and Gaskets in Detail

Understanding the significance of internal seals and gaskets is crucial for maintaining the efficiency and longevity of various machinery. These components play a vital role in preventing leaks and ensuring proper functioning by providing a tight barrier between different parts.

Seals and gaskets are designed to withstand varying pressures and temperatures, making them essential for optimal performance. Here are some key aspects to consider:

- Material Types: Seals and gaskets are made from a variety of materials, including rubber, silicone, and foam, each chosen for specific applications based on durability and resistance to environmental factors.

- Functionality: Their primary purpose is to prevent fluid or air leakage, which can lead to inefficiency or damage to the equipment.

- Installation: Proper installation is essential for effectiveness. Ensuring a snug fit is necessary to avoid future issues.

- Maintenance: Regular inspection of these components can help identify wear and tear, enabling timely replacements and reducing downtime.

In summary, internal seals and gaskets are fundamental components that enhance the reliability and functionality of machinery. Understanding their role can lead to better maintenance practices and improved overall performance.

Importance of Regular Filter Cleaning

Maintaining a clean filtration system is crucial for optimal performance and longevity of your cleaning equipment. Over time, dirt, debris, and contaminants can accumulate, leading to reduced efficiency and potential damage. Regular maintenance helps ensure that your equipment operates smoothly and effectively.

Effective Operation: A clean filter allows for better airflow and improved suction power. This enhances the cleaning process, making it more efficient and thorough.

Preventing Damage: Neglecting filter maintenance can result in strain on the machine’s components. Accumulated dirt can block airflow, causing overheating and possible breakdowns, which can be costly to repair.

Extending Lifespan: Regularly cleaning or replacing filters not only maintains performance but also extends the overall lifespan of the equipment. Investing a little time in upkeep can lead to significant savings in the long run.

In summary, prioritizing filter maintenance is essential for ensuring efficient operation, preventing potential damage, and prolonging the life of your cleaning apparatus.

Replacement Parts and Where to Find Them

When it comes to maintaining your equipment, sourcing quality components is essential for optimal performance. Understanding the various elements that require occasional replacement can significantly enhance the longevity of your device. Identifying reliable sources for these items ensures that you have access to everything needed for seamless operation.

Several avenues exist for procuring necessary components. Local retailers often carry a selection of items suited for common devices, making it convenient to find what you need. Additionally, authorized distributors provide specific replacements tailored for particular models, ensuring compatibility and reliability.

Online marketplaces have become increasingly popular, offering a vast array of options at competitive prices. Searching through reputable websites allows you to compare features and prices easily. It is advisable to check customer reviews and ratings to gauge the quality of the offerings.

Furthermore, consider reaching out to community forums or user groups dedicated to similar equipment. Members often share valuable insights regarding sourcing components and may even offer recommendations for trusted suppliers. Utilizing these resources can save time and enhance your overall experience.