When it comes to the operation of a floating lifting system, grasping the various elements involved is crucial for effective maintenance and functionality. This section aims to shed light on the intricate network of parts that work together to ensure seamless performance and reliability.

Familiarity with these components not only enhances the user experience but also empowers individuals to identify potential issues and address them promptly. By visualizing the arrangement and interconnection of these elements, one can appreciate the engineering that goes into creating a robust and efficient lifting mechanism.

Whether for routine upkeep or troubleshooting, having a clear understanding of how each segment contributes to the overall operation is invaluable. This knowledge ultimately aids in ensuring optimal performance and longevity of the equipment.

Key Elements of Hydrohoist Design

The construction of aquatic lifting systems involves various fundamental components that work in harmony to ensure efficient operation and reliability. Understanding these essential elements can enhance the effectiveness and longevity of such mechanisms.

- Framework: The sturdy structure provides the necessary support and stability, accommodating the weight and forces exerted during operation.

- Lifting Mechanism: This system is responsible for raising and lowering vessels, often utilizing hydraulic or mechanical methods to achieve smooth motion.

- Control System: An intuitive interface allows users to manage the lifting process, ensuring precision and safety throughout operations.

- Buoyancy Aids: Designed to provide flotation, these elements help maintain balance and stability while lifting or lowering objects.

- Safety Features: Integral to the design, these mechanisms prevent accidents and protect both the equipment and users during operation.

Each component plays a vital role in ensuring the overall effectiveness and safety of aquatic lifting systems. Proper attention to their design and maintenance can lead to enhanced performance and durability.

Visual Representation of Parts

This section focuses on the graphical illustration of components that make up the system, aiding users in understanding the layout and functionality of each element. By presenting a clear visual guide, individuals can easily identify and locate specific elements, enhancing their comprehension of the overall structure.

Benefits of Visual Guides

Utilizing graphical representations simplifies complex concepts, allowing for quicker learning and reference. A well-crafted visual guide offers the following advantages:

- Enhanced Clarity: Clear images provide immediate recognition of components.

- Improved Troubleshooting: Identifying specific areas becomes easier, facilitating effective problem-solving.

Interactive Elements

Incorporating interactive features within visual aids can further enrich the experience. By allowing users to click on or hover over parts, additional information can be displayed, promoting a deeper understanding of each component’s role. This interactivity fosters engagement and aids in retention of knowledge.

Functionality of Each Component

This section explores the essential roles played by various elements within the system, emphasizing their unique contributions to overall performance and efficiency.

- Framework: Provides structural integrity and support, ensuring stability during operation.

- Lift Mechanism: Enables vertical movement, allowing for smooth and controlled elevation of the platform.

- Control System: Facilitates user interaction, providing intuitive commands for operation and adjustments.

- Buoyancy Units: Enhance flotation capabilities, ensuring stability and safety in aquatic environments.

- Power Supply: Supplies the necessary energy for operation, enabling various functions to run seamlessly.

- Safety Features: Implement essential protective measures, preventing accidents and ensuring secure usage.

Understanding the function of each element aids in recognizing the importance of maintenance and potential upgrades, contributing to enhanced reliability and performance.

Assembly Instructions Overview

This section provides a comprehensive outline for the assembly process, emphasizing the essential steps required to effectively combine various components. Following these guidelines ensures a seamless integration of the elements, promoting functionality and stability.

Before commencing the assembly, it is crucial to gather all necessary components and tools. Familiarizing oneself with the layout and understanding the relationship between different parts will facilitate a smoother workflow. Below is a table summarizing the key steps involved in the assembly procedure.

| Step | Description |

|---|---|

| 1 | Collect all necessary elements and tools to prepare for assembly. |

| 2 | Review the layout and ensure a clear understanding of how components interact. |

| 3 | Begin the assembly by connecting the main structures securely. |

| 4 | Incorporate additional components as per the guidelines, checking for alignment. |

| 5 | Conduct a final inspection to verify that all connections are secure and functional. |

Maintenance Tips for Hydrohoist Parts

Proper upkeep of your equipment is essential for ensuring longevity and optimal performance. Regular attention to various components not only enhances efficiency but also minimizes the risk of unexpected failures. Here are some practical suggestions to help maintain your lifting apparatus effectively.

- Routine Inspections: Schedule regular assessments of all elements. Look for signs of wear, corrosion, or damage that may require immediate attention.

- Lubrication: Keep moving parts well-lubricated to reduce friction and prevent premature wear. Use the appropriate type of lubricant as recommended in your manual.

- Cleaning: Remove dirt, debris, and other contaminants from surfaces and mechanisms to ensure smooth operation. Regular cleaning helps avoid build-up that can impair functionality.

- Fastener Checks: Periodically examine all fasteners to ensure they are secure. Loose connections can lead to instability and operational hazards.

- Hydraulic System Maintenance: If applicable, regularly check the hydraulic fluid levels and look for leaks. Replace fluids according to the manufacturer’s guidelines.

By following these tips, you can prolong the life of your lifting equipment and ensure its safe and reliable operation.

Common Issues with Hydrohoist Components

When operating a lifting system, various challenges may arise that can hinder performance and safety. Recognizing these frequent concerns is essential for maintaining efficient functionality and extending the lifespan of the equipment. This section will outline some typical complications that users may encounter with their lifting apparatus.

Mechanical Failures

Mechanical components are prone to wear and tear over time. Issues such as rust or corrosion can lead to malfunctions, affecting the system’s ability to lift effectively. Regular inspections and timely replacements can mitigate these risks.

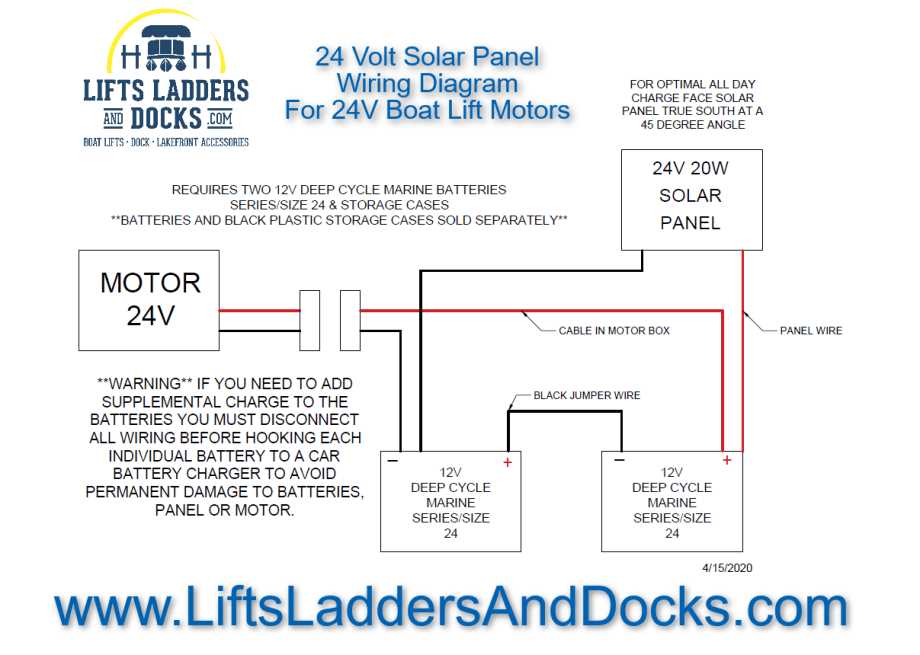

Electrical Problems

Electrical systems can also present challenges. Wiring faults, such as short circuits or loose connections, may result in power loss or erratic behavior. Ensuring proper maintenance and troubleshooting electrical issues promptly is crucial for smooth operation.

Upgrading Parts for Better Performance

Enhancing the components of your equipment can significantly improve its overall efficiency and functionality. By investing in superior alternatives, you can achieve a noticeable boost in performance, longevity, and reliability. This section discusses the advantages of upgrading various elements to ensure optimal operation.

Benefits of Component Enhancements

Upgrading elements can lead to several advantages, including:

- Increased operational efficiency

- Improved durability and lifespan

- Enhanced safety features

- Better adaptability to varying conditions

Key Areas for Improvement

When considering upgrades, focus on these critical areas:

- Drive Mechanism: Opt for more robust alternatives that can withstand heavier loads.

- Control Systems: Implement advanced controls for greater precision and ease of use.

- Structural Components: Utilize materials that offer better resistance to wear and environmental factors.

- Support Accessories: Enhance stability and functionality with upgraded support systems.

By prioritizing these areas, you can maximize the potential of your equipment and ensure it meets the demands of modern usage.

Safety Precautions When Handling Components

When working with various mechanical elements, it is essential to prioritize safety to prevent accidents and ensure effective operations. Adhering to recommended practices and using appropriate protective measures can significantly reduce risks associated with handling these items.

Personal Protective Equipment

Before beginning any task, ensure you are equipped with suitable protective gear. This may include gloves, safety glasses, and steel-toed boots. Such equipment is vital for safeguarding against potential injuries, including cuts, abrasions, and impacts from falling or heavy objects.

Proper Lifting Techniques

When moving items, always use correct lifting techniques to avoid strain or injury. Bend at the knees rather than the waist, keep your back straight, and hold the load close to your body. If an object is too heavy or awkward to lift alone, seek assistance or use mechanical aids to facilitate safe handling.

Identifying Genuine Hydrohoist Components

Ensuring the authenticity of essential elements is crucial for optimal performance and safety. Recognizing original components not only enhances reliability but also extends the lifespan of your equipment. This section will explore key indicators to help differentiate genuine parts from imitations.

Key Features to Look For

- Examine Branding: Authentic components often feature distinct branding or logos. Check for clarity and consistency.

- Quality of Materials: Genuine items are made from high-quality materials. Feel for sturdiness and weight.

- Packaging: Original products typically come in professional packaging with clear labeling.

Verification Methods

- Consult Documentation: Review any manuals or official guides for information on recognized suppliers and specifications.

- Seek Expert Advice: Reach out to professionals or authorized dealers for their insights on authenticity.

- Online Resources: Utilize reputable websites to cross-reference component details and verify claims.

Replacement Parts: What You Need to Know

When maintaining or upgrading your equipment, understanding the components you may need is crucial. This section provides essential insights into sourcing and selecting suitable alternatives for effective replacements, ensuring optimal performance and longevity.

Identifying Necessary Components

Before proceeding with any replacements, it’s vital to accurately identify which items are essential for your specific application. Regular inspection and awareness of common wear indicators will aid in making informed decisions, reducing downtime and enhancing overall functionality.

Quality Considerations

Opting for high-quality substitutes can significantly impact the reliability of your machinery. Look for reputable manufacturers and ensure that the specifications align with your original equipment. Investing in durable alternatives not only enhances performance but also minimizes future maintenance costs.

Tools Required for Assembly and Repair

When undertaking the assembly and maintenance of lifting equipment, having the right tools is essential for ensuring efficiency and effectiveness. The proper instruments not only facilitate the repair process but also enhance safety during operations. This section outlines the necessary tools that are commonly needed for these tasks.

Essential Tools

Various tools play a critical role in the assembly and repair of lifting mechanisms. Here is a list of some essential instruments that every technician should have on hand:

| Tool | Purpose |

|---|---|

| Wrenches | Used for tightening or loosening bolts and nuts. |

| Screwdrivers | Essential for fastening screws in place. |

| Pliers | Helpful for gripping and bending materials. |

| Torque Wrench | Ensures fasteners are tightened to the correct specifications. |

| Measuring Tape | For precise measurements during assembly. |

Safety Equipment

In addition to standard tools, safety equipment is paramount to protect individuals during repair and assembly work. Some recommended items include:

| Equipment | Function |

|---|---|

| Safety Glasses | Protects eyes from debris and harmful substances. |

| Gloves | Offers hand protection against sharp edges and chemicals. |

| Hard Hats | Protects the head from falling objects. |

Resources for Hydrohoist Parts Information

For those seeking detailed insights and guidance on various components, a wealth of resources is available to assist in understanding and sourcing essential items. These resources can enhance knowledge, facilitate repairs, and ensure proper maintenance of equipment.

Online Forums and Communities

Participating in online discussions and communities can provide valuable information. Enthusiasts and experts share their experiences, offer advice, and discuss common challenges, making these platforms an excellent source of knowledge.

Manufacturer Manuals and Documentation

Consulting official manuals and documentation from manufacturers is crucial. These resources typically include comprehensive details on specifications, maintenance recommendations, and troubleshooting steps, ensuring users have the correct information at their fingertips.