Sensors are smaller components often found near control boards, responsible for detecting and regula

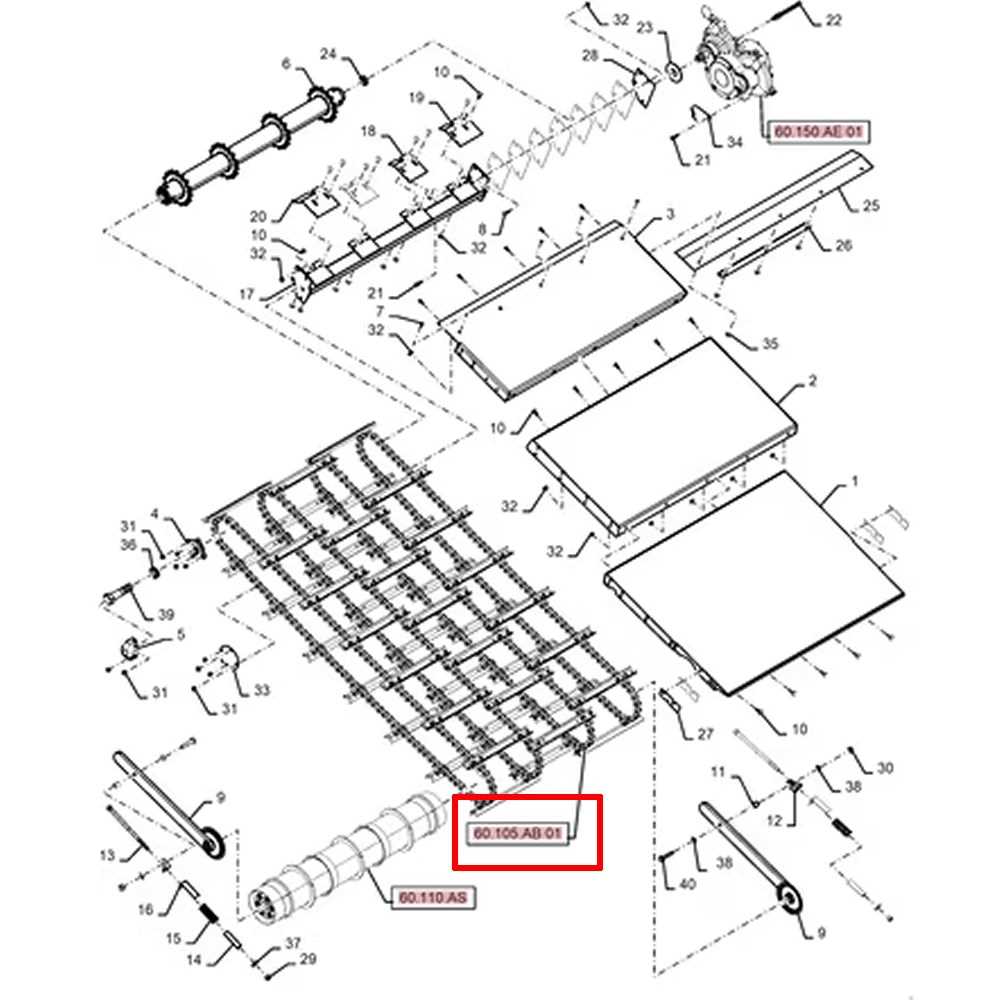

Repairing Critical Elements of the Mechanism

When addressing malfunctioning components in a complex system, it’s important to focus on key areas that ensure smooth operation. Identifying and fixing the essential elements can prevent further damage and maintain the overall functionality of the device.

Identifying Key Mechanical Issues

Before any repair can begin, it is crucial to assess which specific elements of the mechanism are causing the failure. This often involves a thorough inspection of various interconnected parts to pinpoint where the issue lies. Common causes of breakdowns may include wear, misalignment, or faulty connections.

- Check for visible damage on structural components.

- Ensure all moving parts are properly aligned.

- Look for loose or disconnected joints that may hinder functionality.

Steps to Repair Critical Components

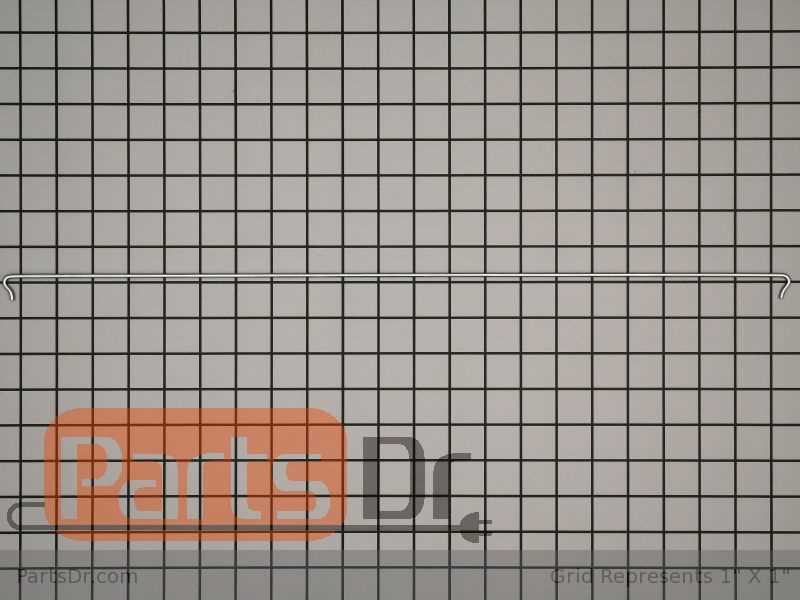

Locating Commonly Replaced Parts

Understanding how to find and identify frequently replaced components in household devices is essential for proper maintenance and repair. By knowing which elements are most prone to wear, users can anticipate potential issues and address them proactively.

Key areas to check often include moving mechanisms, electrical connections, and filters. These sections tend to experience the most stress during operation, making them common points of failure. Inspecting them regularly can prevent costly repairs.

Additionally, seals and gaskets should be examined periodically, as they can degrade over time, leading to performance issues or leaks. Replacing these parts when necessary ensures efficient operation and extends the life of your device.

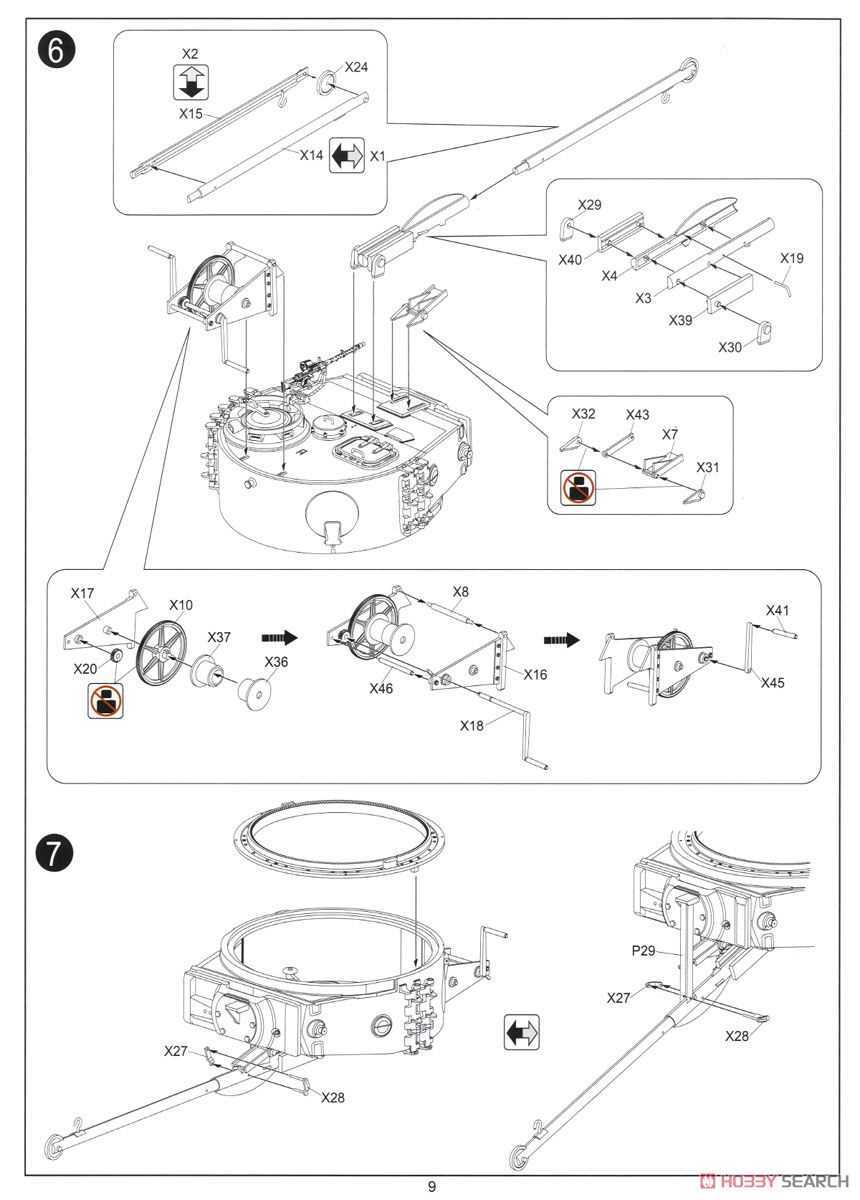

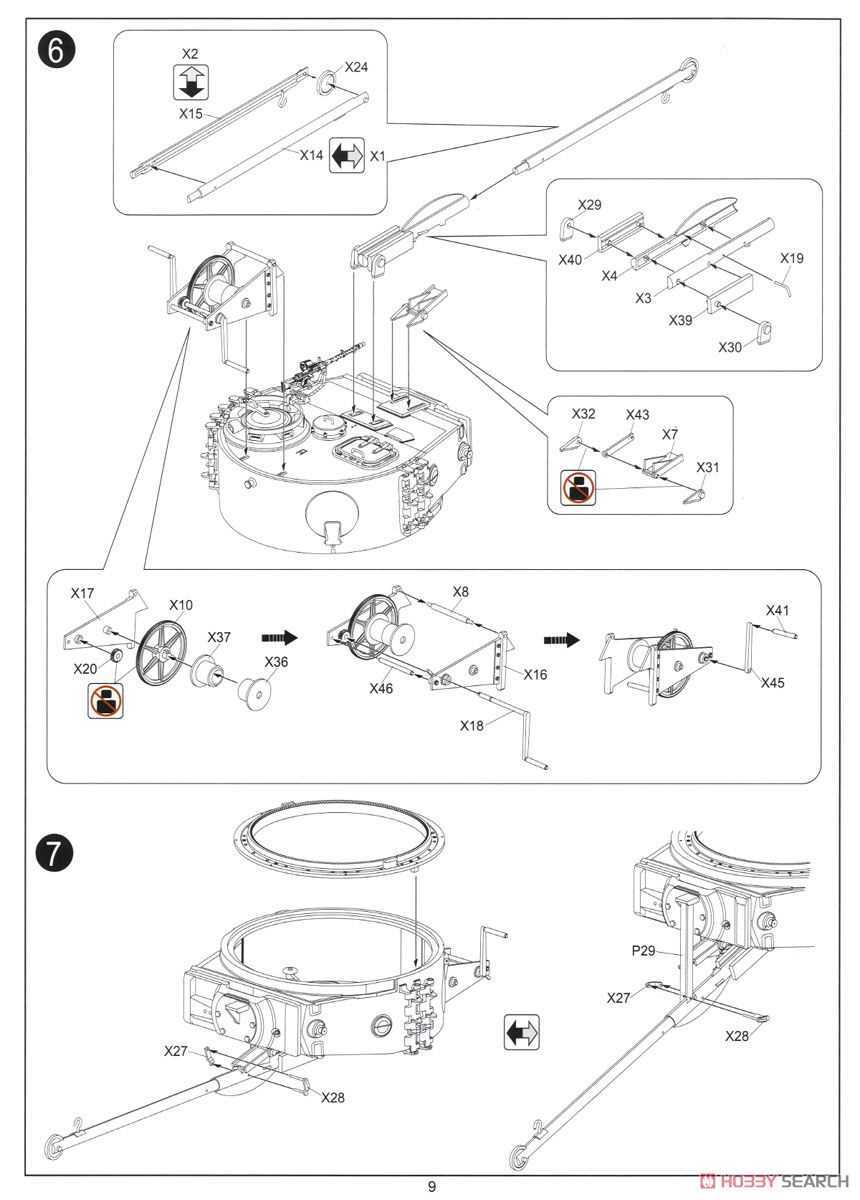

Guide to Troubleshooting Component Failures

Troubleshooting component malfunctions requires a systematic approach to identify and resolve issues effectively. Understanding the underlying principles and recognizing common signs of failure can significantly streamline the diagnostic process.

Start by examining the symptoms associated with the malfunction. Isolate the affected elements and assess their functionality. Utilize diagnostic tools to measure performance metrics, which can reveal inconsistencies or deviations from expected values.

Next, review the operational history and any recent changes made to the system. This may include modifications, maintenance, or environmental factors that could influence performance. Correlating these variables with the observed issues can provide valuable insights.

If initial assessments do not yield conclusive results, consult technical documentation and schematics. These resources often outline typical failure modes and corrective actions, assisting in narrowing down potential causes.

Finally, implement corrective measures based on the findings. Monitor the system closely after adjustments to ensure that the issues have been resolved and that no new problems arise.

Maintenance Tips for Long-lasting Performance

Ensuring the durability and efficiency of your equipment requires regular care and attention. Implementing effective maintenance practices can significantly extend the lifespan and optimal functionality of your machinery. By following a few key strategies, you can prevent unexpected failures and enhance performance.

| Tip |

Description |

| Regular Cleaning |

Keep all components free from dirt and debris to prevent damage and ensure smooth operation. |

| Routine Inspections |

Conduct periodic checks for wear and tear, identifying potential issues before they escalate. |

| Lubrication |

Apply appropriate lubricants to moving parts to reduce friction and prevent overheating. |

| Replacement of Worn Parts |

Promptly replace any damaged or worn-out components to maintain optimal performance levels. |

| Correct Usage |

Follow the manufacturer’s guidelines to ensure proper operation and avoid unnecessary strain on the equipment. |

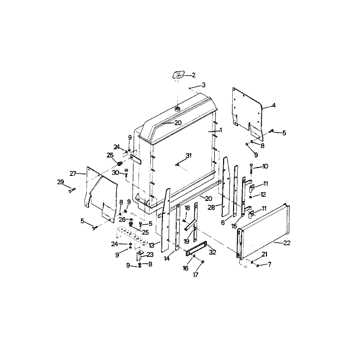

Replacing Electrical and Mechanical Elements

In the maintenance and repair of complex machinery, addressing both electrical and mechanical components is crucial for optimal performance. Ensuring these elements function correctly can prevent malfunctions and extend the lifespan of the equipment. Understanding the process for replacing these components can significantly enhance the reliability of the system.

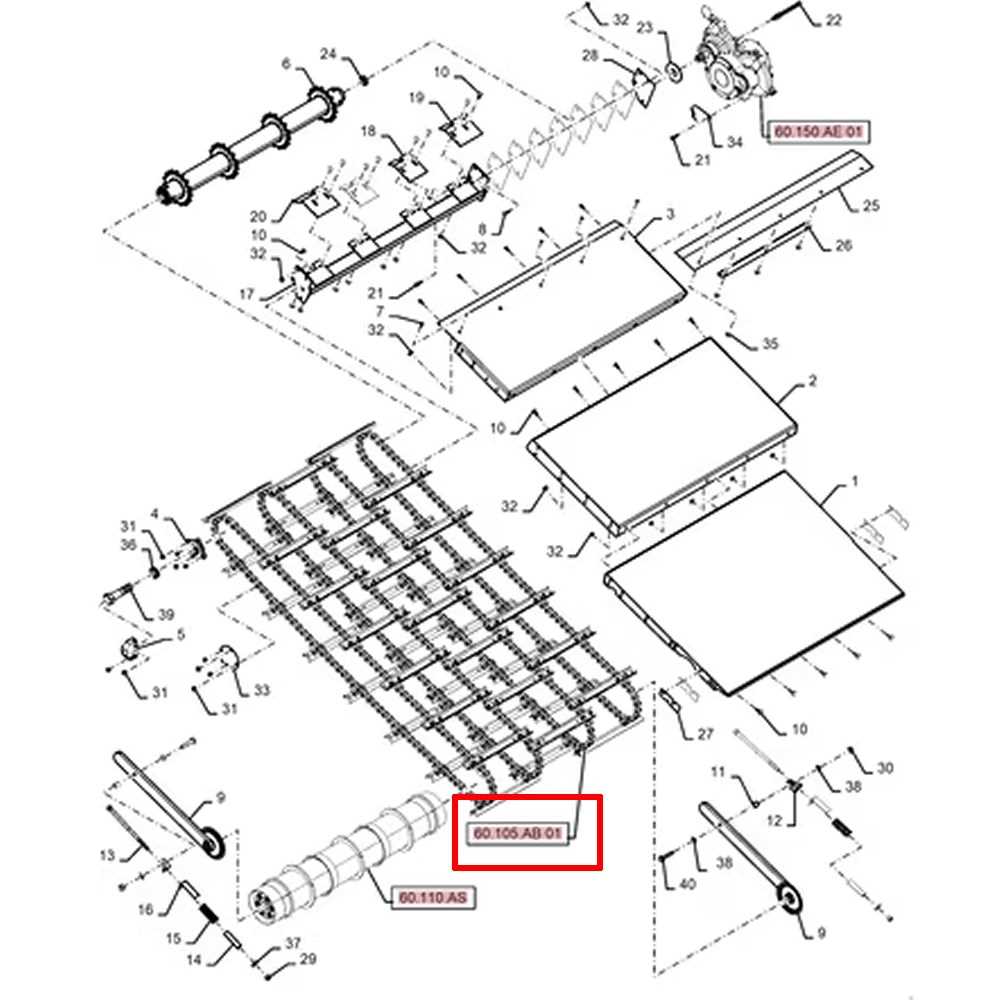

Identifying Components for Replacement

Before initiating the replacement process, it is essential to identify the faulty components accurately. This may involve thorough inspections and testing to determine which parts require attention. Utilizing a systematic approach will help in making informed decisions and minimize the risk of overlooking critical elements.

Steps for Effective Replacement

When replacing electrical and mechanical parts, follow a structured procedure:

- Power Down: Ensure that the machinery is powered off and disconnected from any electrical sources to prevent accidents.

- Remove the Faulty Part: Carefully detach the defective component, taking note of its connections and positioning for easier installation of the new element.

- Install the New Component: Position the replacement part correctly, ensuring all connections are secure and properly aligned.

- Test the System: After installation, power the machinery back on and conduct tests to confirm that the new component functions as intended.

By following these guidelines, the replacement of electrical and mechanical elements can be executed efficiently, ensuring the machinery operates smoothly and reliably.

Common Issues with the Drain System

The drainage system is crucial for maintaining proper water flow and preventing backups. However, various complications can arise, leading to inefficiencies and potential damage. Understanding these issues can help in identifying and addressing problems promptly.

1. Clogs and Blockages

One of the most frequent problems faced by drainage systems is clogs. These can be caused by:

- Accumulation of debris and waste materials

- Fat and grease buildup from kitchen waste

- Foreign objects lodged in the pipes

2. Leaks and Water Damage

Another significant concern is leaks, which can result from:

- Worn-out seals or gaskets

- Pipes that have corroded over time

- Improper installation or damaged connections

Addressing these issues promptly is essential to prevent further complications and ensure the efficient operation of the drainage system.

Proper Care of Sensitive Parts

Ensuring the longevity and optimal performance of delicate components requires attentive maintenance and handling practices. These elements often demand a higher level of care due to their fragility and susceptibility to damage. By implementing appropriate measures, one can significantly reduce the risk of wear and prolong the lifespan of these essential elements.

Cleaning Techniques

Regular cleaning is crucial for maintaining the integrity of sensitive components. Use a soft, lint-free cloth to gently wipe surfaces, avoiding harsh chemicals that may cause deterioration. For intricate areas, consider using compressed air to dislodge dust and debris without causing abrasion.

Storage Recommendations

Proper storage conditions play a vital role in protecting delicate items. Store them in a cool, dry place away from direct sunlight to prevent fading or warping. Utilizing protective cases or bags can provide an additional layer of security against environmental factors and accidental impacts.

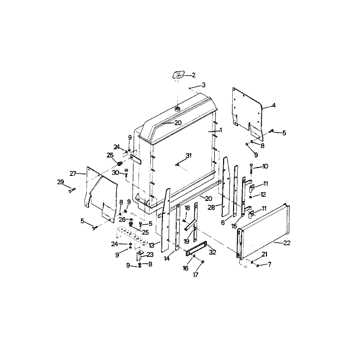

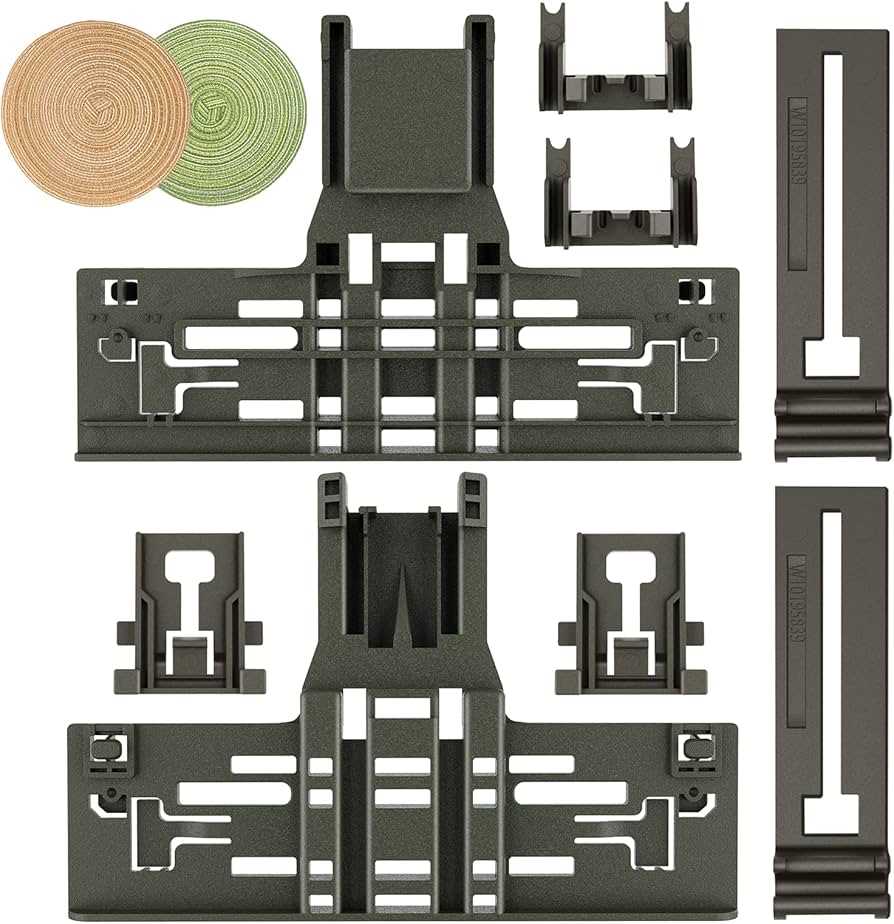

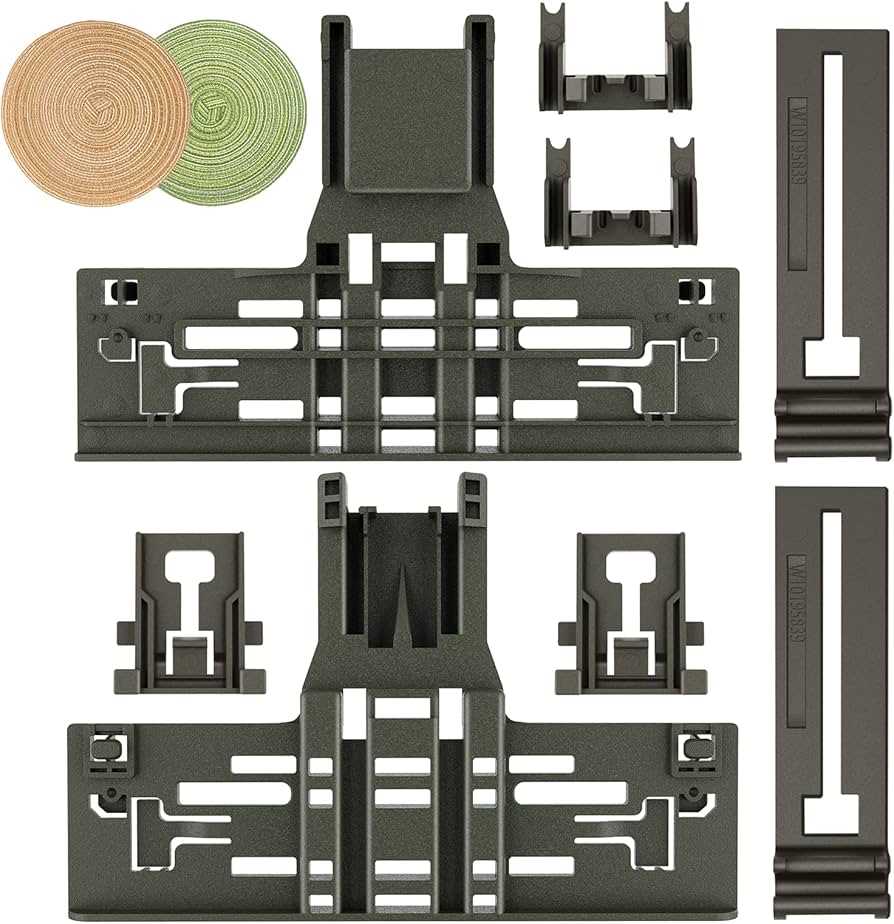

Exploring Installation and Mounting Components

This section delves into the various methods and techniques for effectively positioning and securing essential elements in a system. Understanding the proper approach to installation ensures optimal performance and longevity of the components involved.

Proper mounting techniques are crucial for maintaining stability and functionality. Utilizing the right tools and following recommended guidelines can significantly impact the overall success of the installation process. Below is a summary of key mounting practices.

| Component |

Recommended Mounting Method |

Key Considerations |

| Bracket |

Secure with screws |

Ensure alignment and stability |

| Panel |

Use adhesive pads |

Check for surface compatibility |

| Base |

Bolting to foundation |

Verify load capacity |

| Connector |

Clamp securely |

Inspect for tightness and fit |

Adhering to these practices will enhance the reliability and effectiveness of the installation, paving the way for successful operation.