When dealing with intricate systems, it’s essential to have a clear understanding of the various elements that contribute to their functionality. These systems often consist of a range of interconnected elements, each playing a crucial role in ensuring seamless operation. This article delves into the structure and organization of such elements, helping to demystify how they work together to deliver reliable performance.

By exploring the detailed layout of essential components, you gain insight into how different modules are connected and interact with one another. This comprehensive overview aims to provide clarity, especially for those who want to understand the technical aspects behind each functional unit. Whether you’re troubleshooting or simply curious, this guide offers valuable knowledge to help you navigate these complex systems with confidence.

In the following sections, we will outline and describe the key units, explaining their roles and relationships within the overall configuration. This approach ensures that you not only identify each element but also appreciate its significance in the broader context of the system

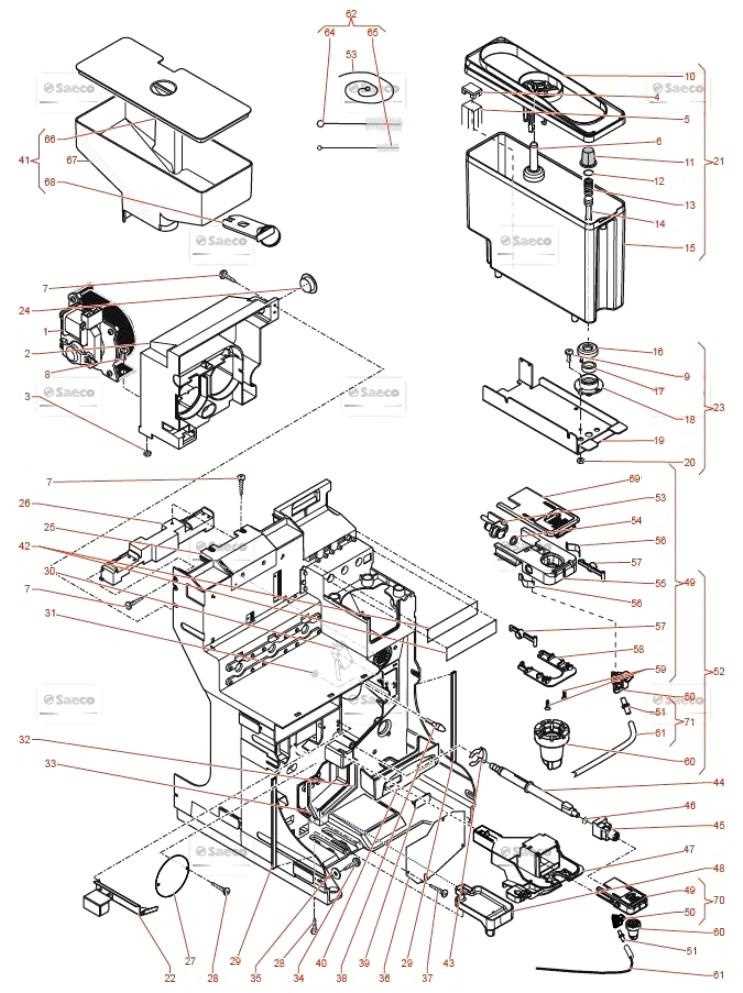

Saeco Xelsis Internal Component Overview

The internal layout of this advanced coffee machine is a blend of precision engineering and efficient design, ensuring smooth operation and high performance. The well-organized internal setup allows for easy access to essential elements, providing reliable performance over extended use. Understanding the structure can offer insights into how each section contributes to creating a seamless brewing process.

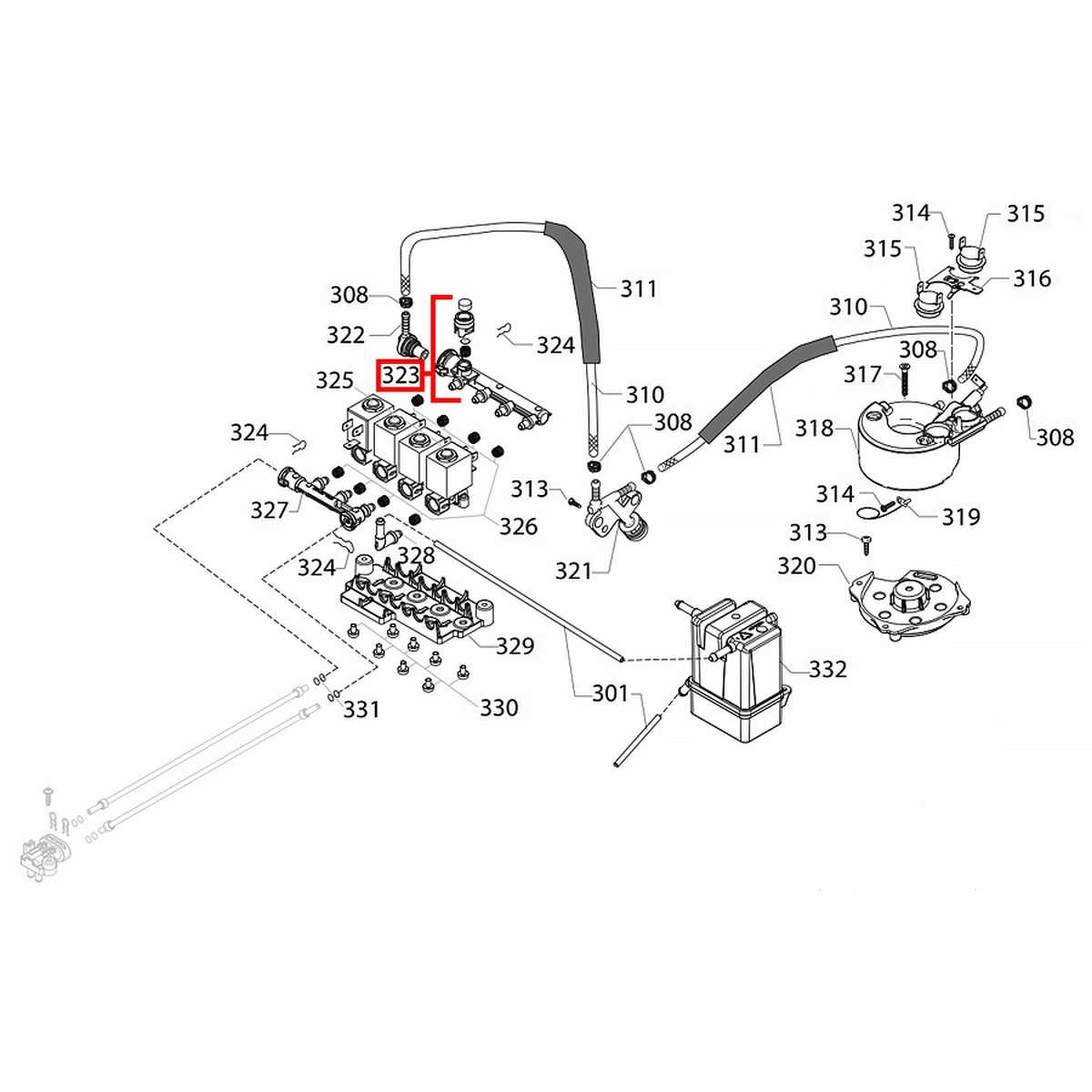

Key elements of the internal system include heating mechanisms, water management systems, and electronic control units. Each component plays a crucial role in the machine’s functionality, from temperature regulation to the precise handling of water pressure, ensuring a perfect cup every time.

The internal framework integrates a sophisticated combination of motors, pumps, and valves. These parts work together to drive the brewing and frothing processes, while sensors monitor every step to maintain optimal operation. The intricate coordination between the mechanical and electrical sections ensures both durability and high-quality output, making it a trusted choice for enthusiasts of freshly brewed beverages.

Main Brewing Unit Assembly Breakdown

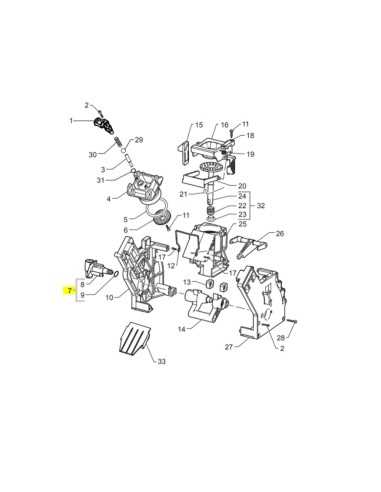

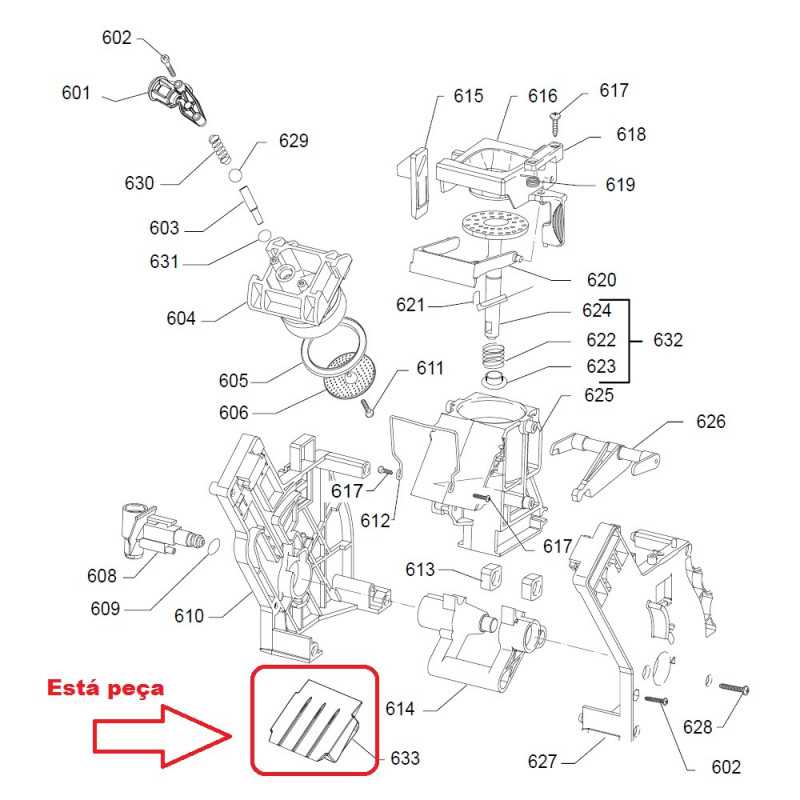

The central brewing component is responsible for the efficient transformation of water and ground elements into the desired beverage. This assembly consists of various interconnected pieces, each contributing to the overall operation and function. Understanding the breakdown of these elements helps ensure smooth operation and maintenance.

Key Components Overview

The brewing section is composed of several essential pieces, each with a distinct role. These include mechanisms for water distribution, grinding coordination, and beverage dispensing. Each segment is vital in ensuring that the entire system operates seamlessly from start to finish.

Component Breakdown

| Component | Function | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Water Inlet Valve | Regulates the flow of water into the brewing chamber. | |||||||||||||||

| Grinder Mechanism | Processes the beans into fine particles for extraction.

Understanding the Grinder MechanismThe grinder is an essential component in the coffee preparation process, responsible for transforming whole beans into fine grounds. This section explains how the system operates, converting raw materials into the right consistency for brewing. By understanding its functionality, you can ensure consistent performance and make adjustments when needed. Key Components of the GrinderThe system comprises several elements working together to break down coffee beans. The core components include burrs, a motor, and adjustment mechanisms. The burrs crush the beans, while the motor powers the grinding action. Fine-tuning options allow you to adjust the grind size to match different brewing preferences. How the Mechanism Works

When activated, the motor spins the burrs, creating friction that grinds the beans into smaller particles. The size of the grounds can be controlled through a calibration system Water Pump and Flow Control Parts

Ensuring the proper circulation of water is essential for maintaining smooth operation and reliable performance. The mechanism responsible for moving and regulating water flow plays a crucial role in delivering consistent results. Without an effective water management system, the functionality can suffer, leading to a decrease in efficiency and potential malfunctions.

All these elements work together to form a cohesive water management structure that optimizes the system Milk Frother Components ExplainedThe milk frothing system is designed to transform liquid into a silky foam, providing a creamy texture for various beverages. This process relies on several key elements working together to ensure a smooth and consistent result. Understanding the individual elements and their roles can help identify any potential issues and improve the performance of the device. Main ComponentsThe frothing unit typically consists of a steam nozzle, an air intake valve, and a mixing chamber. The steam nozzle heats the milk, while the air intake introduces air into the milk, creating the foam. The mixing chamber ensures that steam, air, and milk are blended efficiently to form the perfect froth. Supporting Parts

Other important elements include tubing, seals, and connectors that ensure proper flow and prevent leakage. These components play a crucial role in maintaining the system’s integrity and ensuring optimal pressure for frothing. Regular cleaning and maintenance of these smaller elements can greatly enhance the durability and functionality of the Exploring the Steam Wand SystemThe steam wand is an essential component of many espresso-making machines, designed to create textured milk for a variety of beverages. This system allows users to froth and steam milk, enhancing the overall coffee experience by adding a rich and creamy texture. Understanding how this mechanism works can greatly improve your beverage preparation skills. Functionality of the Steam WandThe primary function of the steam wand is to introduce hot steam into the milk. When activated, it releases high-pressure steam, which incorporates air into the liquid. This process transforms regular milk into velvety foam, suitable for lattes, cappuccinos, and other specialty drinks. Mastering this technique can elevate your coffee artistry. Components of the System

Several key elements make up the steaming apparatus. The wand itself is usually made of stainless steel for durability and effective heat retention. It connects to a boiler that generates steam, ensuring that the wand produces consistent results. Additionally, a valve regulates steam flow, giving the user control over the frothing process. Understanding these components can assist in troubleshooting any issues that may arise during operation. Detachable Drip Tray and Waste Bin

The removable drip tray and waste container play a crucial role in maintaining the functionality and cleanliness of beverage preparation equipment. These components are designed to capture excess liquid and residue, ensuring that the surrounding area remains tidy and that the machine operates efficiently. Their design allows for easy removal and cleaning, contributing to the overall user experience. Functionality and Convenience

The detachable tray effectively collects spills and overflow, preventing messes during the brewing process. This feature not only simplifies maintenance but also enhances the longevity of the appliance. The waste bin complements this by holding used materials, making it easy to dispose of waste after each use. Maintenance Tips

Regular cleaning of the drip tray and waste bin is essential to prevent buildup and ensure optimal performance. It is advisable to wash these parts with warm, soapy water periodically, as well as to check for any signs of wear and tear. Keeping these components in good condition will enhance the reliability and efficiency of the entire system. Electronic Control Panel StructureThe electronic control panel serves as the brain of a coffee-making appliance, orchestrating various functions and processes. This sophisticated component integrates a range of elements that communicate with one another to ensure optimal performance and user experience. Understanding its structure is essential for effective troubleshooting and maintenance. At its core, the control panel comprises a microcontroller that processes user inputs and manages operational tasks. It typically features a display interface, allowing users to select settings, view statuses, and receive notifications. The interface is often complemented by tactile buttons or touch-sensitive areas, providing a user-friendly experience. Additionally, the control panel includes various connectors for linking with other components, such as heating elements, pumps, and sensors. These connections facilitate real-time monitoring and adjustments, enhancing the overall functionality of the appliance. Furthermore, a protective casing encases the internal circuitry, safeguarding it from environmental factors and ensuring longevity. In summary, the electronic control panel is a vital assembly that integrates multiple functions into a cohesive unit, enabling the seamless operation of a coffee-making system. Familiarity with its structure can significantly aid in diagnosing issues and performing necessary repairs. Water Reservoir and Filtration SystemThe water reservoir and its associated filtration mechanism play a crucial role in ensuring the quality and taste of beverages prepared with the machine. A well-designed storage solution not only holds the necessary liquid but also works to maintain its purity through effective filtration processes. The reservoir typically features a removable design for easy filling and cleaning. This accessibility helps in preventing the buildup of impurities that can affect the flavor and quality of the drinks. Additionally, many modern systems incorporate advanced filtration elements that eliminate contaminants, ensuring that only the cleanest water is used during preparation. Filtration technology varies, with some systems utilizing activated carbon filters that absorb impurities and odors, while others may employ multi-stage filtration methods for enhanced purity. These technologies are essential for removing chlorine, sediments, and other unwanted substances, which can compromise the beverage’s taste. Regular maintenance of the reservoir and filtration components is vital to uphold performance standards. Users are advised to periodically replace filters according to the manufacturer’s recommendations, as this will ensure optimal functionality and prolong the lifespan of the entire system. In summary, a well-maintained water storage and filtration system is integral to achieving the desired quality in beverages, contributing significantly to the overall user experience. Heating Element and Temperature Control

The heating component and its regulation are essential for achieving optimal beverage temperatures in coffee-making devices. These elements work together to ensure that water reaches the desired temperature before brewing, which significantly impacts the extraction process and the overall flavor profile of the drink. Proper functioning of the heating element is crucial for delivering consistent results, making it a vital aspect of any brewing system. Functionality of the Heating ElementThe heating element typically operates by converting electrical energy into thermal energy, which heats the water. This component is usually designed for rapid heating, allowing for quick preparation of beverages. Effective thermal insulation around the heating element minimizes energy loss, ensuring efficient operation and maintaining the desired water temperature throughout the brewing cycle. Temperature Regulation MechanismsTemperature control systems are integrated to monitor and adjust the heating process dynamically. Sensors detect the water temperature and relay this information to the control unit, which can modulate the heating element’s operation accordingly. This feedback loop enables precise adjustments, ensuring that the water is heated to the ideal temperature range for various types of drinks, enhancing the quality and consistency of the final product. Cleaning and Maintenance Tools OverviewProper upkeep of coffee-making equipment ensures optimal performance and longevity. Utilizing the right cleaning and maintenance tools is essential for preserving functionality and enhancing the quality of beverages. This section explores various implements that facilitate the care of your machine. Here are some common tools and their purposes:

Maintaining a regular cleaning schedule with these tools not only extends the life of your equipment but also guarantees a consistently enjoyable coffee experience. Coffee Dispenser and Nozzle LayoutThe configuration of the coffee delivery system plays a crucial role in the overall brewing experience. This assembly is designed to ensure that the beverage flows smoothly from the machine to the cup, providing a rich and flavorful drink. Understanding the layout and components involved can enhance the maintenance and operation of the coffee-making device. Key ComponentsAt the core of the coffee dispensing mechanism are several essential elements. The spout directs the brewed liquid into the cup, while the nozzle regulates the flow and ensures an even distribution of coffee. Additionally, there are often adjustable features that allow users to customize the height of the spout for different cup sizes, enhancing convenience and usability. Maintenance TipsTo maintain optimal performance, regular cleaning of the dispensing system is recommended. Residue buildup can lead to clogs or poor coffee quality. Utilizing appropriate cleaning solutions and tools can help preserve the functionality of the spout and nozzle, ensuring that each cup is brewed to perfection. Common Replacement Parts GuideMaintaining optimal performance in your coffee machine often involves replacing certain components over time. Understanding which elements may require attention can enhance both the functionality and longevity of your device. This guide highlights frequently needed components and their roles, ensuring you have a clear reference for keeping your machine in top condition. Essential Components

Several key elements may need replacement due to regular wear and tear. Familiarizing yourself with these components can help in troubleshooting issues and improving the efficiency of your coffee maker.

Replacement Tips

When considering replacements, ensure to use quality components that match your device specifications. Regular maintenance checks can help identify potential issues before they escalate, allowing for a smoother brewing experience. |