Understanding the internal structure of complex machinery can greatly simplify maintenance and troubleshooting. Visual representations of the various elements within such systems provide a clear overview of how each component functions and connects with others. These guides help in identifying the location and role of specific elements, making it easier to diagnose issues and ensure smooth operations.

In industrial equipment, it is crucial to know how different sections work together to achieve maximum efficiency. Detailed illustrations offer insight into the placement and purpose of each element, allowing users to quickly locate potential problem areas. With this knowledge, one can address operational concerns with greater precision and confidence.

Whether it’s for routine maintenance or repairs, having a structured layout of the machine’s various sections ensures that every part is accounted for, streamlining the process of keeping the equipment in optimal working

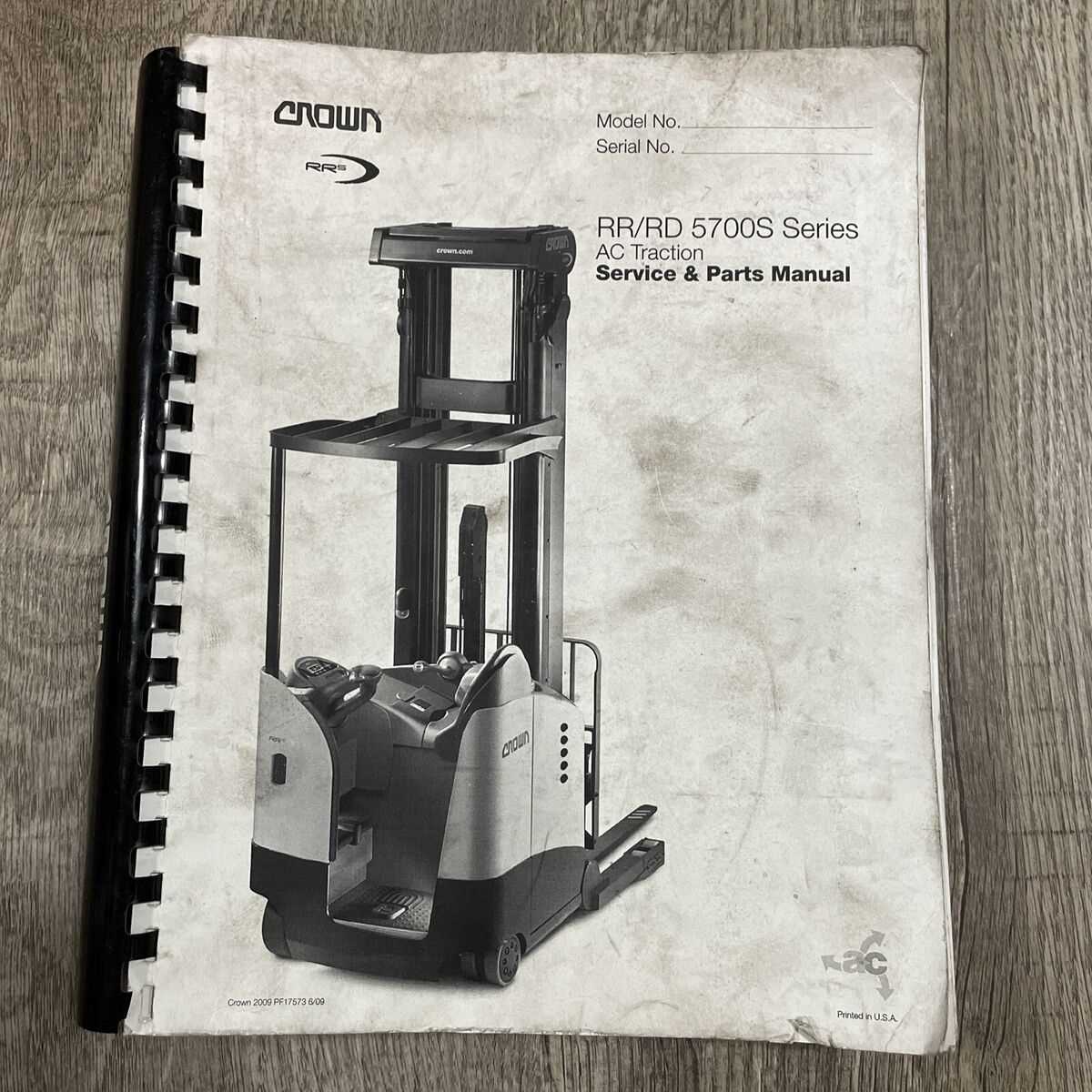

Understanding Crown Forklift Components

When analyzing the construction and functionality of industrial lifting equipment, it’s important to understand the key elements that ensure efficient operation. By focusing on the primary mechanisms, users can better maintain, troubleshoot, and optimize performance in daily tasks.

- Hydraulic System: This system enables smooth vertical movement of heavy loads, driven by fluid pressure that controls the lifting mechanism.

- Control Panel: Operators interact with this central hub, where different levers and buttons adjust movement, speed, and direction, ensuring precision in operation.

- Power Source: Equipment is powered either by electric batteries or internal combustion engines, each offering unique benefits depending on the environment and workload.

- Chassis Structure: The base frame supports the overall weight and houses various key systems, providing stability and durabil

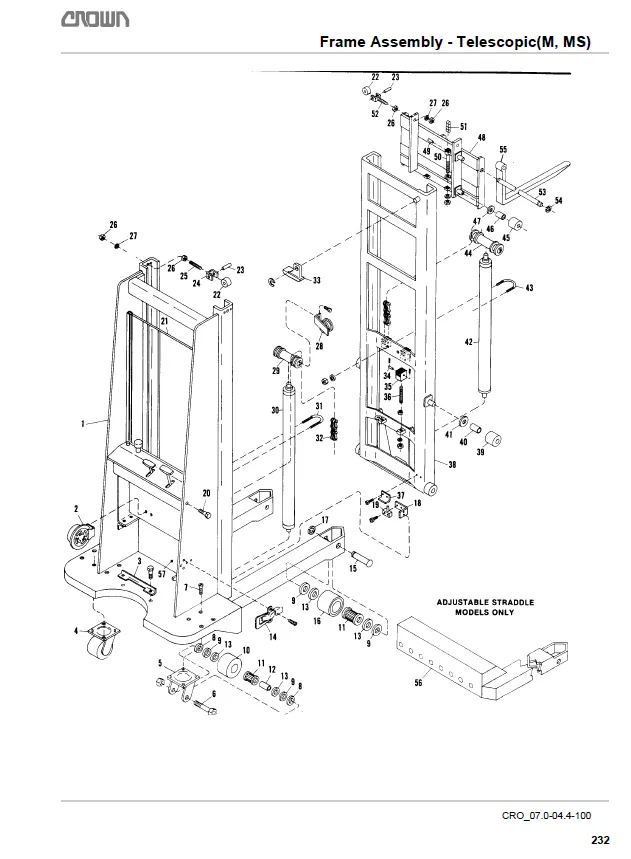

Key Diagrams for Crown Forklift Maintenance

Understanding various technical illustrations is essential for maintaining machinery efficiently. These visual guides offer a clear depiction of different mechanical and electrical systems, allowing for precise troubleshooting and proper upkeep. Regular reference to such diagrams can prevent missteps during repairs and ensure that equipment functions smoothly over time.

Each system is interconnected, and the visual breakdowns provide a detailed look into how different components work together. Whether addressing mechanical adjustments or electrical concerns, having an accurate visual aid is invaluable in identifying potential issues and implementing the necessary solutions effectively.

How to Identify Parts in Crown Forklifts

Understanding how to recognize the various components in these vehicles is essential for maintenance and repairs. Each element within the system has a specific function, and knowing how to spot them can save time and effort when diagnosing issues or performing routine checks. This guide will help clarify how to locate and distinguish the key sections within the machinery, ensuring that everything works smoothly and efficiently.

Recognizing Key Elements

To successfully find the correct items, it’s important to focus on the overall structure of the machine. Larger sections are often linked to specific operations, such as the movement of loads or the control mechanisms. Pay close attention to these areas when inspecting the equipment, as they will provide clues to the smaller components attached to them.

Identifying Smaller Components

Once you understand the main structures, it becomes easier to spot the smaller, often critical, elements. These could include the electrical connections, control switches, or hydraulic pieces that enable the system to function. Examining these parts

Overview of Crown Forklift Electrical System

The electrical system in this type of industrial machinery is vital for ensuring smooth operation, controlling key functions, and maintaining efficiency. The setup typically includes various components that work together to power the machine, manage energy flow, and operate critical systems like lighting, signaling, and motor functions. Understanding the layout and functionality of these electrical circuits is crucial for troubleshooting and maintenance.

Key elements of the electrical structure include power distribution, control circuits, and safety mechanisms. Each element plays a specific role in ensuring the machine operates correctly under different conditions. Below is an outline of the main areas of focus:

- Power Source: The primary energy provider, ensuring consistent performance.

- Control Units: Regulate various operational aspects such as steering and lifting functions.

- Wiring and Connectors: These components link different parts of the system to ensure uninterrupted electrical flow.

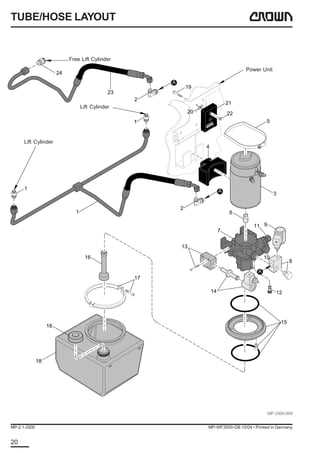

- Hydraulic Systems Explained

The hydraulic mechanism is essential for powering various movements in industrial machinery, providing the force required to lift, tilt, and transport heavy loads. By channeling fluid under pressure, these systems convert mechanical energy into motion, enabling smooth and efficient operations.

The core of this system includes several key components that work in unison to ensure optimal performance. Below is a breakdown of the main elements involved:

- Pumps: These are responsible for generating fluid flow, which drives the entire hydraulic operation.

- Valves: Used to control the direction, pressure, and flow of the fluid, ensuring precise maneuverability.

- Cylinders: These components receive the pressurized fluid and convert it into linear motion, enabling lifting and other actions.

- Hoses and Tubes: Fluid is transported through these pathways to various parts of the system.

- Familiarize Yourself with Terminology: Learn the common terms used in the documentation. This knowledge will help you navigate through the content more easily.

- Utilize Visual Aids: Pay close attention to illustrations and charts. These visuals can clarify complex information and assist in identifying specific items.

- Take Notes: Jot down important details or questions that arise while reading. This will help you retain information and facilitate future reference.

- Organize Information: Create a system for categorizing notes or highlights. Whether through digital tools or physical folders, keeping everything organized will streamline your process.

- Consult Multiple Resources: Cross-reference information with other manuals or online sources. This can provide a broader understanding and confirm accuracy.

- Practice Patience: Take your time to absorb the material. Understanding intricate details often requires careful reading and re-reading.

Replacing Crown Forklift Mechanical Parts

Maintenance and repair of industrial machinery is crucial for ensuring optimal performance and longevity. When it comes to mechanical components, timely replacement can prevent breakdowns and enhance operational efficiency. Understanding the process involved in swapping out these essential elements is vital for both safety and effectiveness.

Before commencing with the replacement, it is important to identify the specific components that require attention. This may involve inspecting for signs of wear, damage, or reduced functionality. Once the faulty elements are determined, gather the necessary tools and new components suitable for your model. Familiarizing yourself with the assembly layout will greatly aid in the disassembly and reassembly process.

When removing the defective components, take care to follow a systematic approach. Document each step to ensure proper reinstallation of the new elements. After securing the replacements, conduct thorough checks to confirm that all connections are tight and functioning as intended. Regular inspections following the replacement will help in maintaining peak operational standards.

Interpreting Crown Forklift Control Panel Layout

The control interface of a material handling vehicle plays a crucial role in ensuring efficient operation and safety. Understanding the arrangement and functionality of various controls is essential for users to operate the machine effectively. This section aims to provide insights into how to interpret the layout of the control panel, highlighting the significance of each component.

At first glance, the control interface may appear complex, featuring an array of buttons, levers, and indicators. Each element serves a specific purpose, facilitating the operator’s interaction with the machinery. Familiarizing oneself with these components allows for smoother operation and reduces the likelihood of errors.

Typically, the control panel includes essential functions such as power activation, speed regulation, and direction control. It is vital to identify the location of these controls to ensure a quick response during operation. Additionally, visual indicators and warning lights are strategically placed to inform the operator about the machine’s status, enhancing overall situational awareness.

Moreover, some models may feature advanced controls for additional functionalities, such as lifting and lowering mechanisms or tilt adjustments. Understanding these advanced features can improve operational efficiency and enhance the user experience. Therefore, taking the time to learn the control panel’s layout is an investment in safety and effectiveness.

Common Wear and Tear Parts in Forklifts

In the world of material handling, certain components are more susceptible to degradation over time due to the demands of frequent usage. Understanding these elements is essential for maintaining operational efficiency and ensuring safety. Regular inspection and timely replacement of these items can prevent costly downtime and enhance the lifespan of the equipment.

1. Tires and Wheels

The contact points with the ground endure significant stress, leading to wear that affects stability and maneuverability. Proper maintenance and timely replacement of tires are crucial for ensuring optimal performance.

2. Brake System

This essential mechanism experiences considerable strain with each operation. Regular checks and maintenance of brake components help ensure safe stopping power and prevent potential hazards.

In summary, focusing on these critical components can significantly reduce the likelihood of unexpected breakdowns and enhance overall functionality.

Efficient Troubleshooting Using Parts Diagrams

Utilizing schematics can significantly enhance the process of diagnosing issues in machinery. By visualizing the arrangement and connections of various components, technicians can pinpoint problems more effectively. These representations serve as valuable references, guiding users in identifying faulty elements and understanding how each piece interacts within the overall system.

When faced with malfunctions, consulting these visual aids enables quicker assessments and targeted solutions. Technicians can trace connections and verify the functionality of individual components, reducing the time spent on trial-and-error methods. Furthermore, having a clear layout allows for organized maintenance procedures, ensuring that all areas are thoroughly examined.

In addition to aiding in the identification of existing issues, these illustrations facilitate preventive measures. Regularly referencing these visuals during maintenance routines helps technicians anticipate potential failures and address them proactively. By fostering a deeper understanding of the machinery’s design, users can enhance their overall efficiency and reliability.

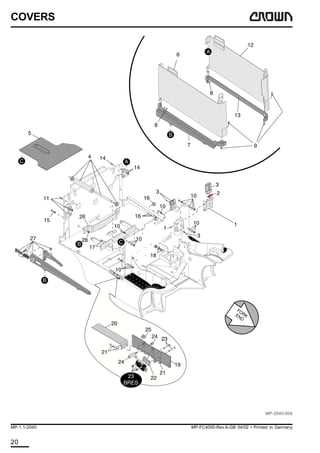

Visual Guide to Crown Forklift Assembly

This section provides an insightful overview of the various components involved in the construction of a well-known material handling vehicle. Understanding the configuration and arrangement of these elements is crucial for effective operation and maintenance. Each section highlights key assemblies and their functions, offering a clearer perspective on the entire structure.

Key Components Overview

The essential units of this machinery work in harmony to ensure optimal performance. From the power source to the lifting mechanism, each assembly plays a significant role. Recognizing how these units interact enhances the overall efficiency and safety of the equipment.

Assembly Insights

When examining the construction layout, it becomes evident that precision is vital. Each part must fit seamlessly with its counterparts to achieve the desired functionality. Regular checks and maintenance of these connections can prevent malfunctions and extend the lifespan of the equipment.

Tips for Reading Forklift Parts Manuals

Understanding maintenance and repair literature is crucial for effective equipment management. These guides provide essential information about components, ensuring that users can identify, source, and replace necessary elements efficiently. Here are some practical tips to enhance your experience with these manuals.

By applying these strategies, you can effectively interpret and utilize maintenance guides, ensuring better operational efficiency and equipment longevity.