In the world of agricultural equipment, the efficient functioning of machinery relies heavily on the intricate interplay of its various components. Knowing how these elements work together not only aids in maintenance but also enhances the overall performance of the equipment. This section aims to illuminate the relationships and functionalities of these essential parts.

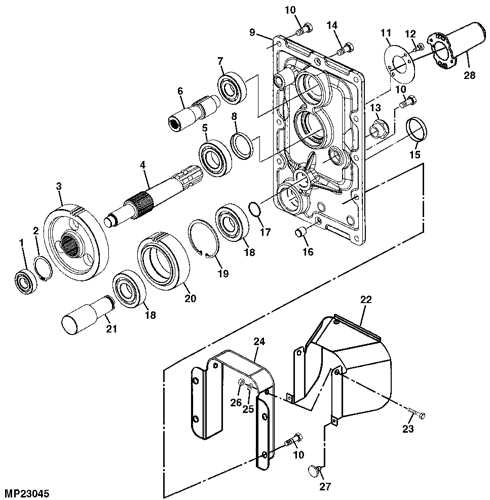

Visual aids play a crucial role in grasping the layout and connectivity of the different sections within a machine. By examining detailed representations, users can gain insights into assembly, disassembly, and troubleshooting processes. Understanding the configuration of these components is vital for anyone looking to optimize their machinery’s efficiency.

Moreover, having a clear understanding of individual elements contributes significantly to effective repairs and replacements. Whether it’s routine upkeep or addressing specific issues, familiarizing oneself with the layout can save time and resources. This guide will provide an overview that empowers operators and technicians alike in their endeavors.

Understanding John Deere 4400 Parts

Grasping the intricacies of machinery components is essential for effective maintenance and optimal performance. Knowing how various elements interact within agricultural equipment can significantly enhance efficiency and longevity. This section aims to illuminate the essential constituents that make up this specific model, offering insights into their functions and importance.

Key Components and Their Functions

Each unit consists of numerous vital elements, each serving a unique purpose. For instance, the engine assembly provides the necessary power, while the transmission system facilitates smooth operation across different terrains. Understanding these roles is crucial for troubleshooting and ensuring proper upkeep.

Maintenance and Replacement Considerations

Regular inspection and timely replacement of worn-out components can prevent unexpected breakdowns and costly repairs. Familiarity with the specific characteristics of each piece can aid in identifying issues early on. Moreover, utilizing quality substitutes when replacements are necessary can help maintain peak performance and reliability.

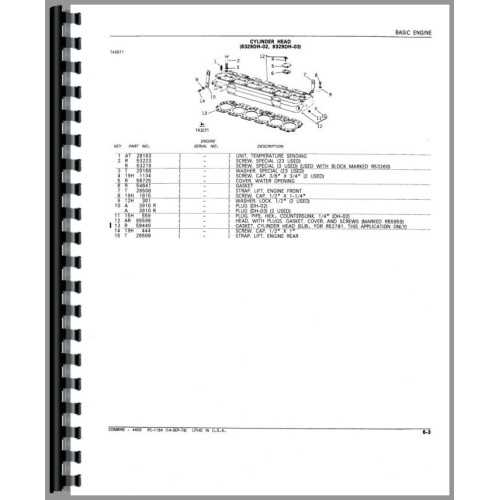

Importance of Parts Diagrams

Understanding the components of machinery is essential for effective maintenance and repair. Visual representations of various elements not only simplify identification but also enhance the efficiency of troubleshooting processes. By providing a clear overview, these illustrations help operators and technicians navigate complex assemblies with ease.

Having access to these visual aids facilitates informed decision-making regarding replacements and repairs. Users can quickly locate specific components, reducing downtime and minimizing the risk of errors. This ultimately contributes to the longevity and reliability of equipment.

Moreover, such illustrations serve as valuable educational tools. They help new users familiarize themselves with the machinery’s structure and function, enabling them to become more proficient in their roles. As a result, organizations benefit from improved operational efficiency and reduced training time.

Overview of John Deere 4400 Model

This section provides a comprehensive look at a popular agricultural machine renowned for its versatility and efficiency in farming tasks. It highlights the design, functionality, and key features that contribute to its reputation in the industry.

Key Features

The machine is equipped with advanced technology that enhances productivity. Its robust engine ensures reliable performance, while user-friendly controls allow for easy operation. The compact design makes it suitable for various farming environments.

Specifications

| Feature | Description |

|---|---|

| Engine Type | Diesel |

| Horsepower | Approx. 60 HP |

| Transmission | Hydrostatic |

| Weight | About 3,200 lbs |

Main Components of the Tractor

The functionality of a modern agricultural machine relies on various essential elements working in harmony. Each component plays a pivotal role in ensuring efficiency and productivity in the field. Understanding these fundamental parts can enhance maintenance and operational practices, ultimately leading to better performance.

Powertrain System

The powertrain is the heart of any agricultural vehicle, consisting of the engine, transmission, and drive system. This system is responsible for converting fuel into mechanical power, allowing the tractor to perform heavy tasks with ease. The engine generates the necessary power, while the transmission efficiently transfers that power to the wheels, ensuring optimal speed and torque during operation.

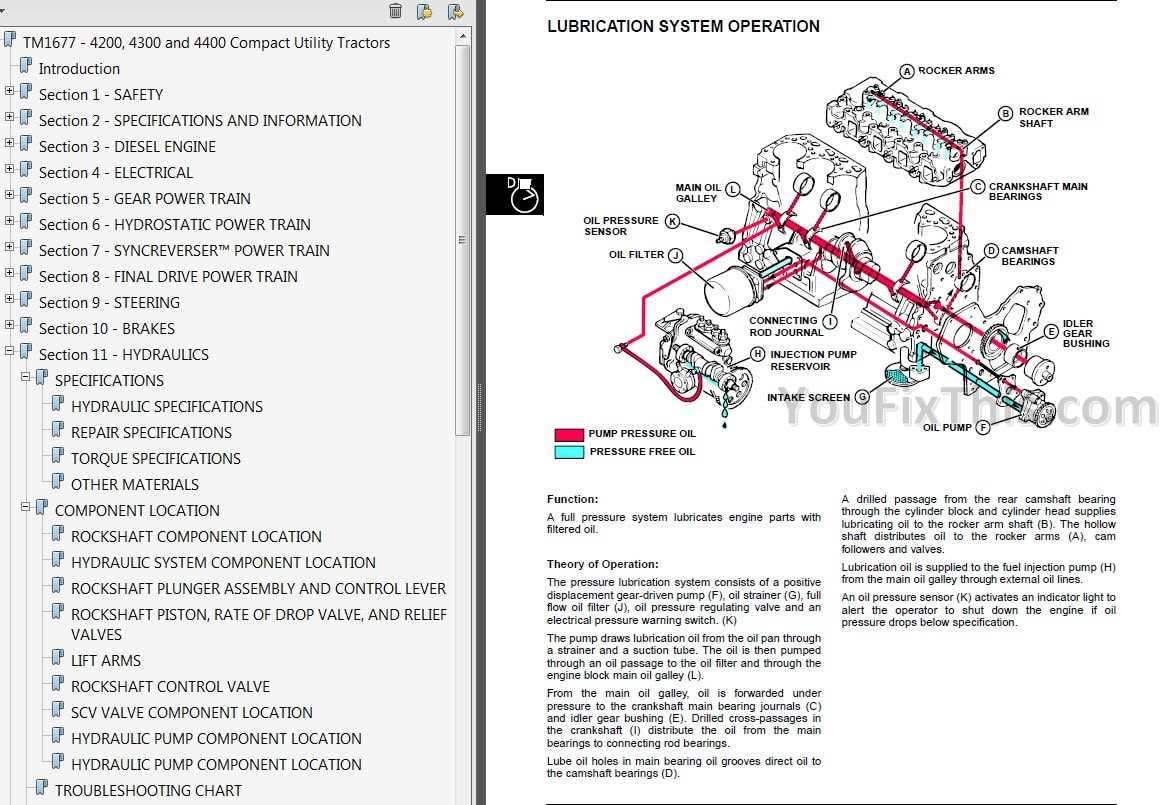

Hydraulic System

The hydraulic system is crucial for lifting and moving implements attached to the machine. It operates through a series of cylinders and pumps that generate the force needed to perform various tasks. This system enhances versatility by allowing the operator to control attachments with precision, making it easier to switch between different agricultural functions.

Locating the Parts Diagram Online

Finding the necessary illustrations for machinery components has become increasingly accessible due to the vast resources available on the internet. Users can efficiently locate visual references that outline specific elements, aiding in repairs and maintenance tasks. This process not only enhances understanding but also facilitates the ordering of replacement items.

Here are some useful resources to consider when searching for these visual guides:

| Resource Type | Description | Link |

|---|---|---|

| Manufacturer Website | Official sites often provide detailed schematics and documentation. | Visit Manufacturer |

| Online Retailers | Many sellers offer downloadable resources to assist customers with their purchases. | Browse Retailer |

| Forums and Communities | User-generated content can include shared diagrams and troubleshooting tips. | Join Community |

| Instructional Videos | Platforms like YouTube often feature guides that visually explain assembly and disassembly. | Watch Video |

Utilizing these sources will greatly enhance your ability to find accurate illustrations and ensure effective management of your equipment.

Common Issues and Solutions

When operating machinery, various challenges may arise that can affect performance and efficiency. Understanding these common issues and their solutions can help ensure smooth operation and prolong the lifespan of the equipment.

-

Engine Problems:

- Issue: Difficulty starting or stalling.

- Solution: Check the fuel supply, inspect the battery, and ensure the ignition system is functioning properly.

-

Hydraulic Failures:

- Issue: Reduced power or responsiveness.

- Solution: Examine hydraulic fluid levels and look for leaks in the system.

-

Transmission Issues:

- Issue: Slipping gears or difficulty shifting.

- Solution: Inspect the transmission fluid and look for any signs of wear in components.

-

Electrical Failures:

- Issue: Malfunctioning lights or controls.

- Solution: Check wiring connections and fuses for any faults.

-

Cooling System Problems:

- Issue: Overheating during operation.

- Solution: Ensure the coolant levels are adequate and clean any debris from the radiator.

Addressing these common challenges proactively can lead to improved functionality and reduced downtime. Regular maintenance and timely troubleshooting are key to effective operation.

Aftermarket vs. Original Parts

The choice between replacement components from the manufacturer and those from third-party suppliers can significantly impact machinery performance and longevity. Each option presents its own set of advantages and drawbacks that require careful consideration.

Original components are designed specifically for the equipment, ensuring compatibility and adherence to the manufacturer’s standards. This often translates to enhanced reliability and performance, as these items are crafted with precision to meet specific specifications.

On the other hand, aftermarket alternatives can provide cost savings and a wider variety of options. Many of these components are engineered to match or even exceed the performance of their original counterparts. However, the quality can vary greatly, and buyers must conduct thorough research to identify reputable suppliers.

Ultimately, the decision hinges on factors such as budget, desired quality, and the specific needs of the machinery in question. Weighing the pros and cons of both options is essential for making an informed choice that best supports operational efficiency.

Maintenance Tips for Longevity

Ensuring the durability of any machinery requires consistent care and attention. Regular maintenance not only enhances performance but also extends the lifespan of the equipment. Implementing a few straightforward practices can make a significant difference in the overall functionality and reliability of your machinery.

Regular Inspection

Conducting routine inspections helps identify potential issues before they escalate. Look for signs of wear, loose components, or fluid leaks. Early detection can save time and money by preventing major repairs.

Scheduled Lubrication

Proper lubrication is essential for reducing friction and wear between moving parts. Establish a regular schedule for applying lubricants to ensure smooth operation and prevent damage from overheating.

| Maintenance Task | Frequency |

|---|---|

| Visual Inspection | Weekly |

| Fluid Check | Monthly |

| Lubrication | Every 50 hours of operation |

| Filter Replacement | Every 200 hours of operation |

By adhering to these maintenance practices, you can significantly enhance the reliability and efficiency of your equipment, ensuring it serves you well for years to come.

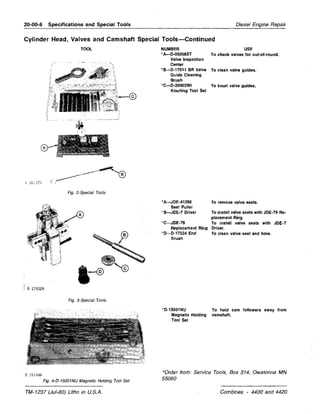

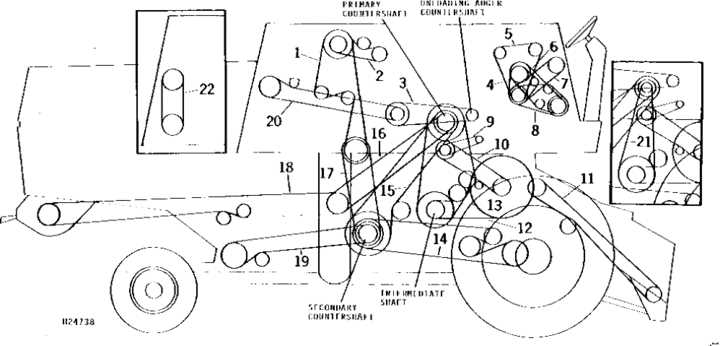

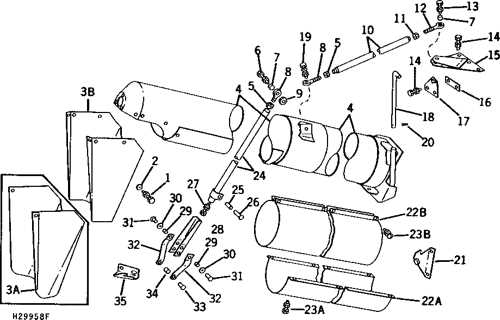

How to Interpret the Diagram

Understanding technical illustrations can greatly enhance your ability to maintain and repair machinery. These visual guides serve as a roadmap, helping you identify various components and their relationships within the system. Grasping the layout and symbols used is crucial for efficient troubleshooting and servicing.

Familiarizing with Symbols and Labels

Every illustration utilizes specific symbols and annotations to convey important information. Familiarize yourself with these markings to quickly understand what each part represents. Common symbols often denote moving parts, fixed components, and connections, ensuring you can easily navigate through the information presented.

Identifying Component Relationships

Each element in the illustration is positioned to reflect its relationship with other components. Pay attention to how parts are grouped or connected, as this can indicate their function and interactions. Understanding these relationships will aid you in diagnosing issues and performing necessary repairs effectively.

Ordering Replacement Parts Efficiently

Acquiring components for machinery can be streamlined with the right approach. Understanding the process can save time and reduce frustration, ensuring that you receive the necessary items promptly and accurately.

Steps to Follow

- Identify the Specific Component Needed

- Consult the Equipment Manual for Specifications

- Utilize Online Resources for Visual References

- Check Compatibility with Your Model

- Contact Authorized Dealers for Availability

Tips for Efficient Ordering

- Keep a Record of Previous Orders

- Join Loyalty Programs for Discounts

- Inquire About Bulk Purchase Options

- Review Customer Feedback for Reliable Suppliers

- Ask About Shipping Times and Return Policies

Benefits of Using Authentic Parts

Choosing original components for machinery maintenance is crucial for ensuring optimal performance and longevity. These genuine elements are designed to fit seamlessly and operate in harmony with the overall system, minimizing the risk of malfunctions and enhancing reliability. By investing in authentic replacements, users can experience a range of advantages that go beyond mere functionality.

Enhanced Reliability

Using original components significantly boosts the dependability of equipment. These items undergo rigorous testing to meet stringent quality standards, ensuring they can withstand the demands of heavy usage. This reliability translates to fewer breakdowns and a smoother operational experience, allowing users to focus on their tasks without unnecessary interruptions.

Long-Term Cost Savings

While the initial investment in genuine components may be higher, the long-term savings are substantial. Authentic parts are less likely to fail prematurely, reducing the need for frequent replacements and costly repairs. Additionally, their superior performance can lead to improved fuel efficiency and reduced wear on other machine elements, ultimately lowering overall operational costs.

Repair Procedures for Key Components

Maintaining the functionality of essential machinery elements is crucial for optimal performance. This section outlines systematic approaches to repairing key components, ensuring longevity and reliability in operations.

Engine Maintenance

Regular upkeep of the engine is vital for preventing breakdowns. Follow these steps for effective repairs:

- Inspect oil levels and change as needed.

- Check for any leaks around seals and gaskets.

- Replace the air filter to ensure proper airflow.

- Examine spark plugs for wear and replace if necessary.

Hydraulic System Repair

The hydraulic system is integral for efficient operation. Addressing issues promptly can prevent extensive damage:

- Assess hydraulic fluid levels regularly.

- Inspect hoses for cracks or wear.

- Replace any damaged seals to prevent leaks.

- Test the system’s pressure to ensure proper function.

By adhering to these procedures, you can ensure that key components remain in peak condition, enhancing the overall performance and lifespan of your machinery.

Resources for Further Information

This section aims to provide valuable sources for individuals seeking additional insights and details related to machinery components and maintenance. Whether you are a seasoned technician or a novice, these resources can enhance your understanding and assist you in your projects.

- Manufacturer Websites: Official sites often feature comprehensive manuals, specifications, and troubleshooting guides.

- Online Forums: Engaging with community forums can offer practical advice and shared experiences from fellow enthusiasts and professionals.

- Technical Manuals: Accessing detailed service manuals can provide in-depth information on assembly and disassembly procedures.

- Educational Videos: Platforms like YouTube host numerous tutorials that visually guide users through repair processes and maintenance tips.

- Local Dealerships: Visiting or contacting authorized dealers can yield expert knowledge and support tailored to specific models.

Utilizing these resources can empower users with the necessary tools to maintain and repair their equipment effectively.