In the realm of machinery, comprehending the intricate arrangement of essential elements is crucial for optimal performance and maintenance. Each section plays a vital role in ensuring that the overall system functions seamlessly, allowing for both efficiency and longevity. This exploration delves into the various components, highlighting their interconnections and individual responsibilities.

By visualizing the structure of these mechanisms, one can gain insight into their operational dynamics. Recognizing how each segment contributes to the collective operation fosters a deeper appreciation for the complexity involved in engineering design. Furthermore, such knowledge aids in troubleshooting and repair processes, making it an invaluable asset for enthusiasts and professionals alike.

As we navigate through the specifics of component arrangements, we will uncover key features and functionalities that define their effectiveness. This understanding not only enhances practical skills but also encourages informed decision-making when it comes to upgrades and modifications. Join us on this journey to unravel the essentials of mechanical layouts and elevate your expertise in the field.

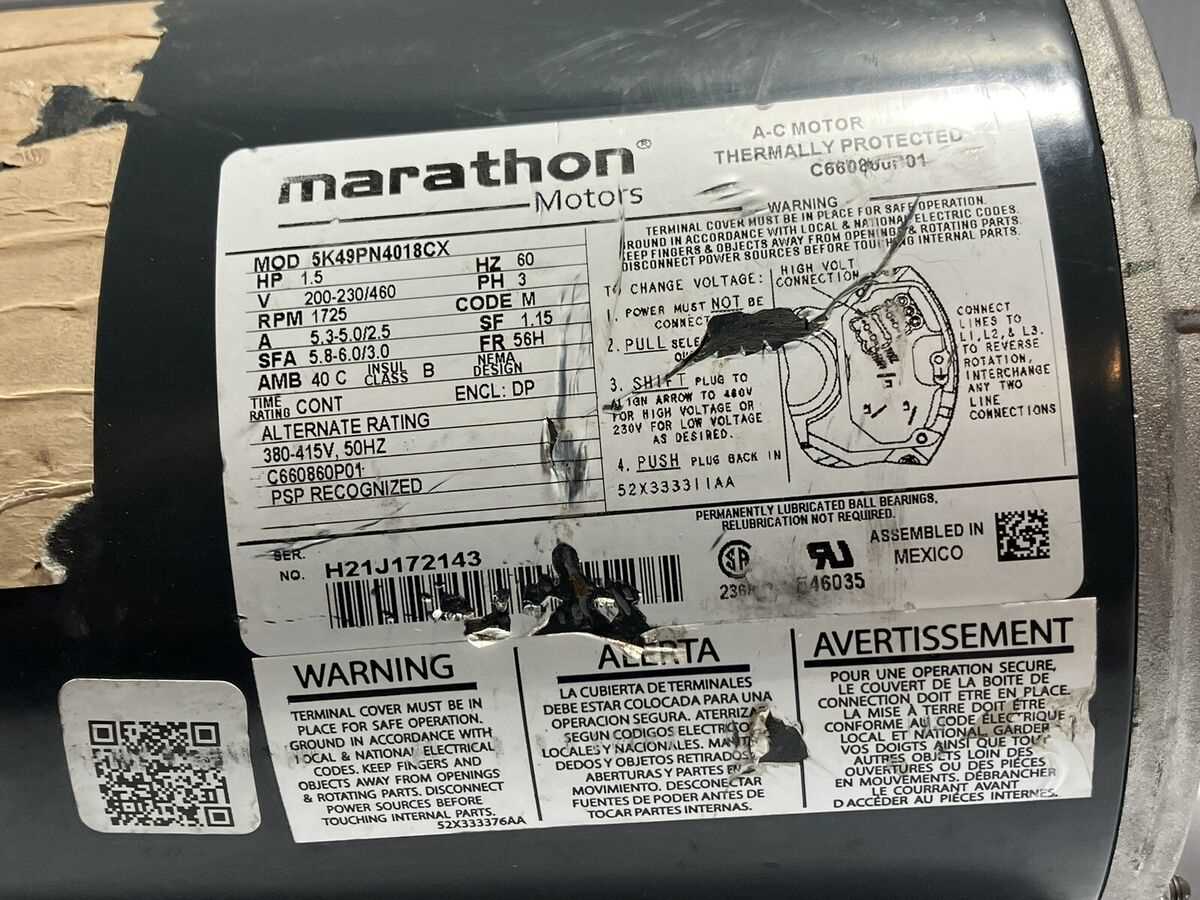

Understanding Marathon Motor Components

Gaining insight into the various elements that comprise a high-performance engine is crucial for anyone involved in maintenance or optimization. Each component plays a vital role in ensuring the overall functionality and efficiency of the unit. A thorough grasp of these individual sections allows for better troubleshooting and enhances operational longevity.

Key elements include the mechanisms that drive power generation, cooling systems that prevent overheating, and the control units that regulate performance. Each part, whether mechanical or electronic, interacts with others, creating a harmonious system designed for optimal output.

Identifying the function of each component is essential for effective diagnostics and repairs. Understanding how energy is converted, how lubrication is maintained, and how cooling is achieved enables technicians to pinpoint issues and implement solutions swiftly. Knowledge of these intricate relationships not only improves repair efficacy but also supports better decision-making during upgrades or replacements.

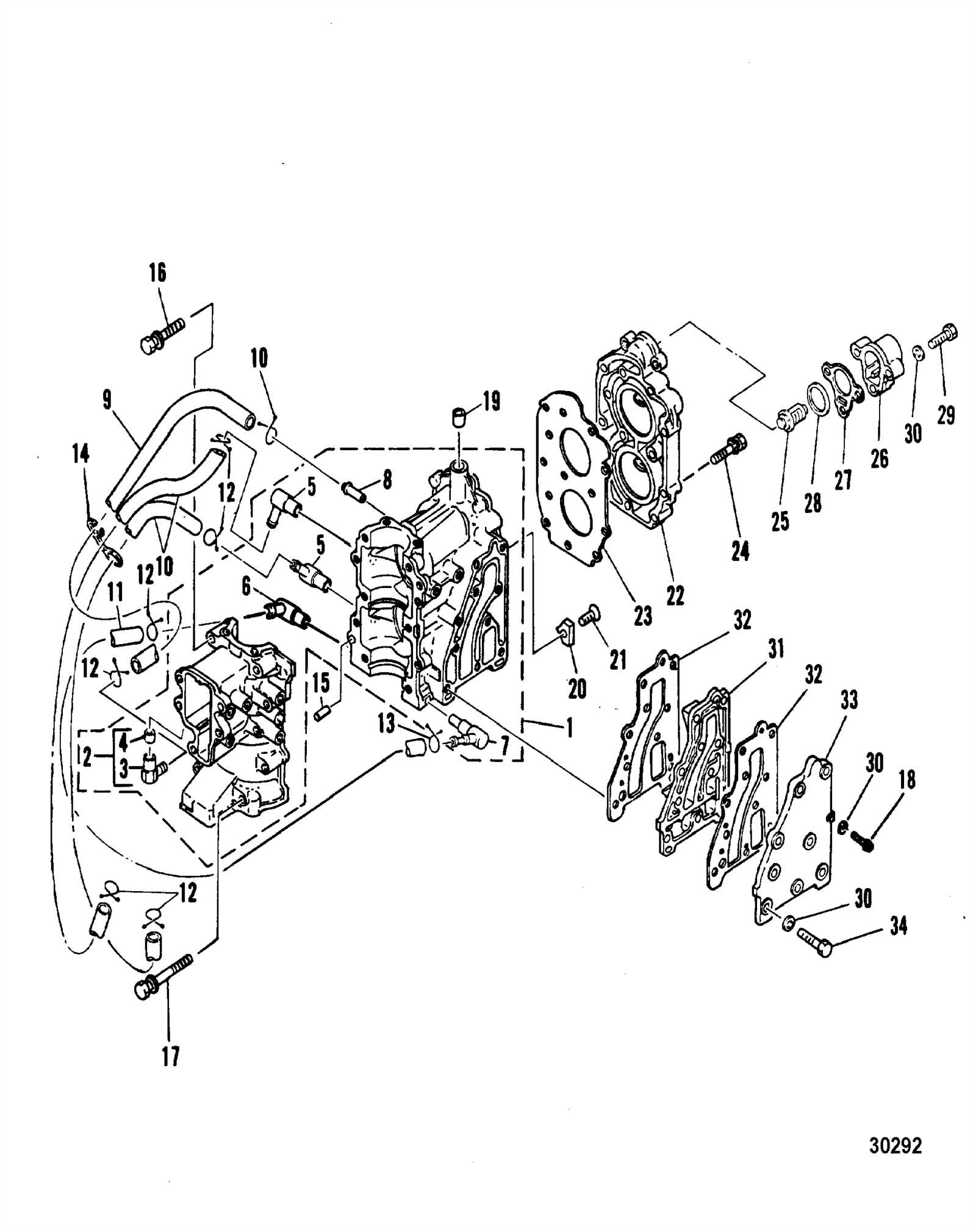

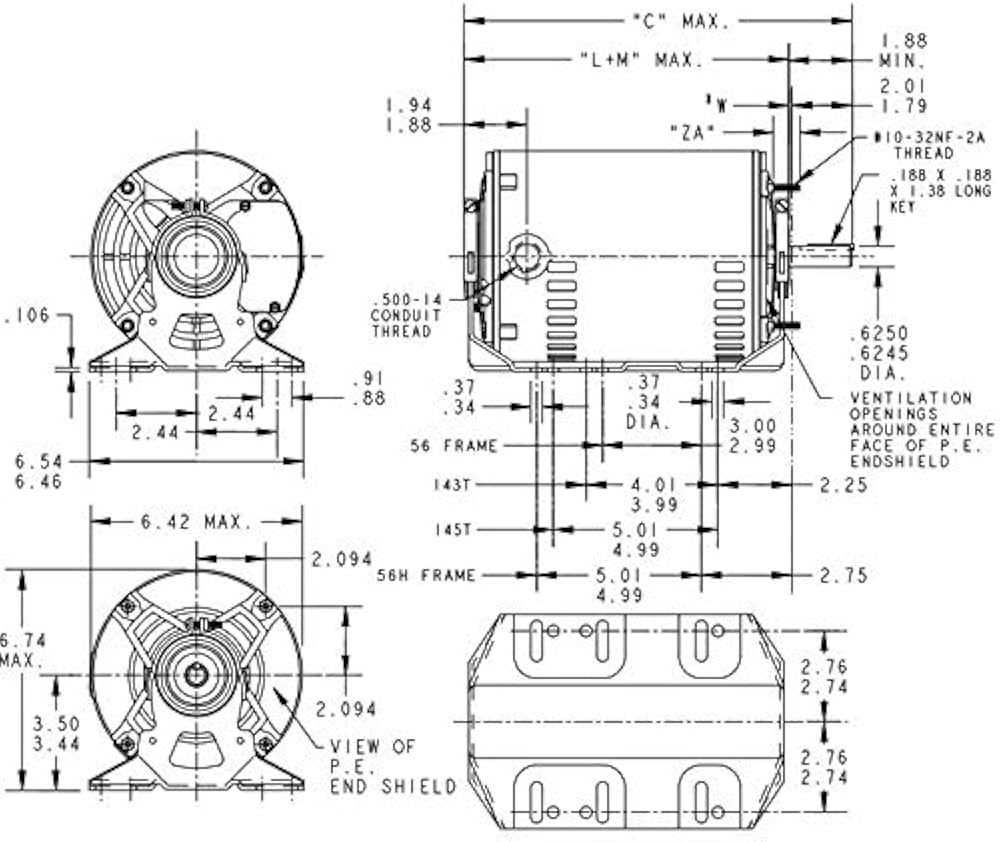

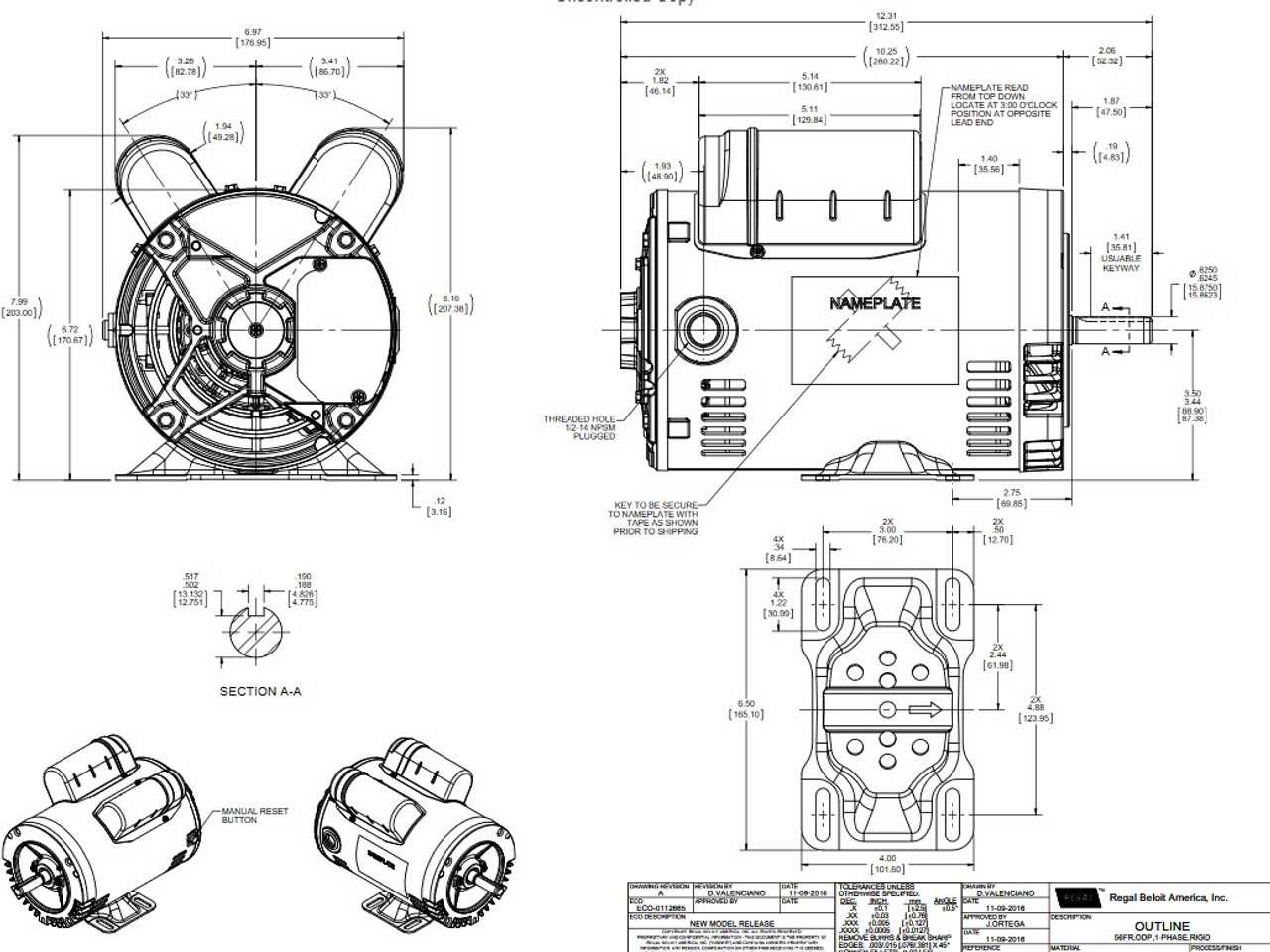

Importance of Motor Parts Diagrams

Understanding the intricate components of machinery is crucial for effective maintenance and troubleshooting. Visual representations of these elements serve as essential guides, enabling users to navigate complex systems with ease. Such illustrations not only enhance comprehension but also streamline repair processes by providing clear insights into how each segment interacts.

Efficiency is significantly improved when one can quickly identify specific elements and their functions. These visual aids eliminate ambiguity, making it easier to locate issues and apply solutions promptly. Furthermore, they contribute to the longevity of equipment by ensuring that all components are correctly assembled and maintained according to manufacturer specifications.

In addition, these resources promote safety. By clearly outlining where each element is situated and how it operates, users can minimize the risk of accidents during maintenance tasks. Overall, having access to detailed illustrations is invaluable for anyone working with complex mechanical systems.

Key Components of Marathon Motors

This section explores the essential elements that contribute to the efficient operation of industrial machines. Understanding these components is crucial for optimal performance and maintenance.

- Stator: The stationary part that generates a magnetic field, crucial for energy conversion.

- Rotor: The rotating element that interacts with the magnetic field to produce motion.

- Bearings: Support the rotor, reducing friction and ensuring smooth operation.

- Windings: Copper coils that create magnetic fields when electricity flows through them.

- Cooling System: Essential for preventing overheating, often utilizing air or liquid cooling methods.

Each of these components plays a significant role in the overall functionality and longevity of the equipment.

How to Read a Motor Diagram

Understanding the layout of components within a mechanical system is essential for effective troubleshooting and maintenance. This guide will help you navigate the visual representations of various elements and their connections.

| Symbol | Description |

|---|---|

| Circle | Typically represents a unit or assembly. |

| Line | Indicates the relationship or pathway between components. |

| Arrow | Shows the direction of flow or operation. |

| Rectangle | Usually denotes a control or interface element. |

By familiarizing yourself with these symbols and their meanings, you can effectively delve into the schematic and identify key aspects crucial for understanding functionality and performance.

Common Issues in Motor Parts

In the realm of machinery, various components can experience dysfunction, leading to inefficiencies and potential failures. Understanding these common challenges is essential for ensuring optimal performance and longevity of equipment.

- Wear and Tear: Over time, constant usage can result in degradation of materials, affecting the overall functionality.

- Lubrication Failures: Inadequate lubrication can lead to friction, increasing the risk of overheating and damage.

- Electrical Problems: Faulty wiring or connections can cause erratic behavior, impacting the efficiency of the system.

- Contamination: Dust, dirt, and other particles can enter critical areas, leading to blockages and reduced performance.

- Misalignment: Components that are not properly aligned can create excessive strain, resulting in premature failure.

Addressing these issues promptly through regular maintenance and inspections can significantly enhance the reliability and effectiveness of any mechanical system.

Maintenance Tips for Marathon Motors

Proper upkeep is essential for ensuring the longevity and efficiency of your equipment. Regular maintenance not only prevents unexpected breakdowns but also enhances performance, allowing for smoother operation and reduced energy consumption. By following a few straightforward guidelines, you can extend the lifespan of your machinery and ensure it runs optimally.

Regular Inspections

Conducting frequent checks is crucial. Examine all components for signs of wear or damage, paying close attention to seals and connections. Identifying issues early can save time and resources, preventing minor problems from escalating into major repairs. Schedule inspections at regular intervals based on usage patterns.

Lubrication and Cleaning

Keeping your equipment clean and properly lubricated is vital for optimal function. Use appropriate lubricants and ensure that all moving parts are well-maintained. Regularly remove dust and debris from surfaces to prevent overheating and mechanical failure. Implement a cleaning schedule to maintain a pristine working environment.

Replacing Worn Motor Components

Over time, various elements within a machine can experience deterioration due to constant use and environmental factors. Addressing these issues promptly is crucial for maintaining efficiency and prolonging the lifespan of the equipment. This section discusses the importance of timely replacement and the overall benefits of keeping all components in optimal condition.

Identifying Signs of Wear is the first step in the replacement process. Regular inspections can reveal symptoms such as unusual noises, vibrations, or decreased performance. Recognizing these indicators early can prevent further damage and costly repairs.

Choosing the Right Replacement is essential for ensuring compatibility and performance. It’s advisable to refer to the specifications of the original components when sourcing new ones. Utilizing high-quality materials can also contribute to better durability and reliability.

Installation Considerations should not be overlooked. Proper techniques and adherence to guidelines are necessary to avoid potential issues. If unsure, consulting a professional can provide peace of mind and ensure the job is done correctly.

In conclusion, maintaining the functionality of your equipment involves regular assessments and timely replacements of any worn elements. This proactive approach not only enhances performance but also safeguards against unexpected failures.

Tools for Motor Parts Replacement

When it comes to the process of substituting essential components within a vehicle, having the right instruments is crucial. These tools not only ensure efficiency but also enhance safety during the replacement process. Below is a comprehensive list of the necessary equipment that can make the task easier and more effective.

- Wrenches: A variety of sizes, including adjustable and socket wrenches, are essential for loosening and tightening fasteners.

- Screwdrivers: Both flathead and Phillips screwdrivers are vital for working with different types of screws.

- Pliers: Needle-nose and standard pliers help in gripping, bending, and cutting wires or components.

- Jack and Jack Stands: These are necessary for lifting the vehicle safely, providing access to the lower sections.

- Torque Wrench: This tool ensures that fasteners are tightened to the manufacturer’s specifications, preventing over or under-tightening.

In addition to the basic tools, several specialized instruments can enhance the replacement experience:

- Oil Filter Wrench: Specifically designed to remove and install oil filters with ease.

- Breaker Bar: This tool provides additional leverage for stubborn bolts, making them easier to loosen.

- Multimeter: Useful for diagnosing electrical issues and testing circuits.

- Compression Tester: Assists in checking the health of the engine by measuring cylinder pressure.

Equipping oneself with these essential tools not only simplifies the replacement of components but also contributes to a more effective and safe repair process. Understanding the proper use of each tool is equally important to achieve the best results.

Safety Precautions When Working

Ensuring a secure environment while engaging in any technical task is crucial for preventing accidents and promoting efficiency. Adhering to specific guidelines not only protects individuals but also enhances the overall quality of the work performed. Awareness and preparation are key components in fostering a safe workspace.

General Safety Guidelines

Before beginning any project, it is essential to familiarize oneself with the necessary safety protocols. Here are some fundamental practices to consider:

| Practice | Description |

|---|---|

| Wear Protective Gear | Always use gloves, goggles, and appropriate clothing to safeguard against injuries. |

| Maintain Cleanliness | Keep the workspace organized and free of clutter to prevent trips and falls. |

| Use Tools Correctly | Familiarize yourself with tools and equipment, ensuring proper usage to avoid accidents. |

| Follow Instructions | Adhere to all guidelines and manuals to mitigate risks associated with equipment use. |

Emergency Preparedness

In addition to preventive measures, having a plan for emergencies is vital. Knowing how to react in unforeseen situations can significantly reduce the severity of incidents:

| Emergency Action | Steps to Follow |

|---|---|

| Fire | Evacuate immediately, use fire extinguishers if trained, and call emergency services. |

| Injury | Administer first aid if qualified, and seek medical assistance as necessary. |

| Electrical Shock | Do not touch the affected person; turn off the power source and call for help. |

| Spill | Contain the spill if safe, use appropriate materials for cleanup, and report the incident. |

Comparing Marathon Motors to Others

When evaluating different brands within the industry, it’s essential to understand how one name stands apart from the competition. Each manufacturer offers unique features, technologies, and performance metrics that cater to specific needs. A detailed examination reveals key distinctions in efficiency, durability, and application versatility.

One significant factor is the level of innovation present in each design. Some brands emphasize cutting-edge technology, resulting in enhanced energy efficiency and reduced operational costs. In contrast, others may focus on traditional designs that prioritize reliability over modern features. This divergence often influences the choice of consumers based on their specific requirements.

Additionally, the quality of materials used plays a critical role in performance longevity. Higher-grade components often lead to extended service life and lower maintenance demands. Consumers must weigh the initial investment against potential savings in upkeep and energy consumption, making informed decisions based on their long-term operational goals.

Support and service offerings also vary widely among competitors. Companies that provide comprehensive customer assistance, including easy access to resources and responsive maintenance options, tend to foster greater customer satisfaction. This aspect can significantly impact overall user experience, reinforcing brand loyalty and repeat purchases.

Resources for Motor Parts Diagrams

Finding reliable information is essential for anyone involved in the maintenance or repair of engines and related components. Access to accurate visuals and documentation can significantly enhance understanding and facilitate efficient troubleshooting. This section provides an overview of various sources where one can obtain comprehensive illustrations and schematics relevant to engine assembly.

Online Libraries: Numerous digital archives and repositories offer extensive collections of technical manuals and guides. These resources often feature high-quality images and detailed explanations that cater to both novices and experienced technicians.

Manufacturer Websites: Many producers provide downloadable resources directly on their platforms. These include interactive tools that allow users to view and print detailed schematics, ensuring that all necessary information is at one’s fingertips.

Community Forums: Engaging with online communities can yield valuable insights. Members often share diagrams, tips, and personal experiences, creating a rich knowledge base for anyone looking to deepen their understanding of engine systems.

Technical Support Services: Some specialized organizations offer professional guidance and access to proprietary schematics. Consulting with experts can help clarify complex issues and provide tailored solutions for specific challenges.

Educational Institutions: Many colleges and universities with automotive programs may provide resources to the public. These can include instructional materials, workshops, and access to libraries filled with pertinent information.

Utilizing these diverse resources can enhance one’s ability to effectively work with engine components and ensure optimal performance.

FAQs About Marathon Motors

This section aims to address common inquiries related to a specific brand known for its robust engines and components. Here, we will explore essential information that users often seek, ensuring clarity and understanding.

What types of applications are these engines suitable for?

The engines are designed for a wide range of uses, including industrial machinery, agricultural equipment, and various commercial applications. Their versatility makes them an excellent choice for many sectors.

How can I maintain my engine for optimal performance?

Regular maintenance is crucial for longevity. Key practices include routine oil changes, checking coolant levels, and inspecting filters. Following the manufacturer’s guidelines will help ensure peak performance and reliability.