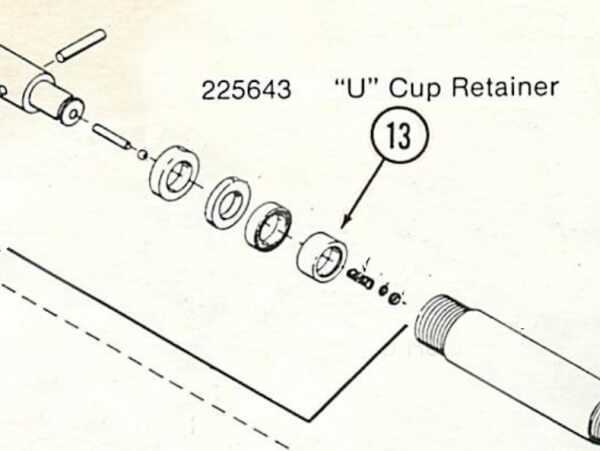

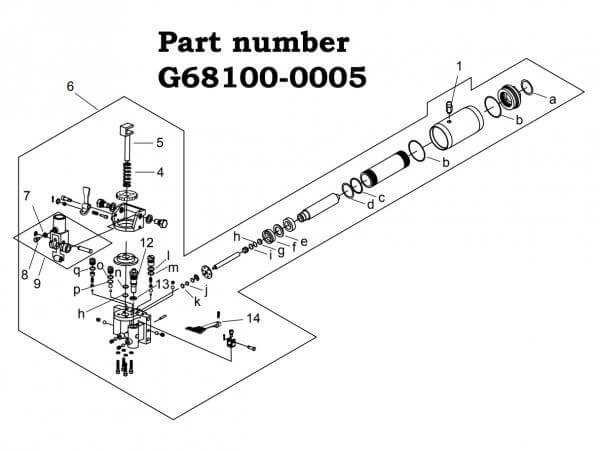

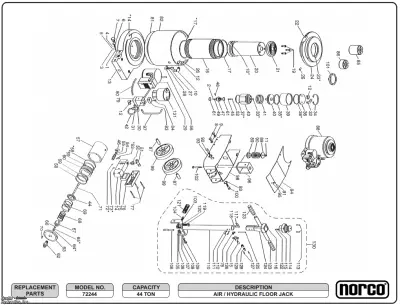

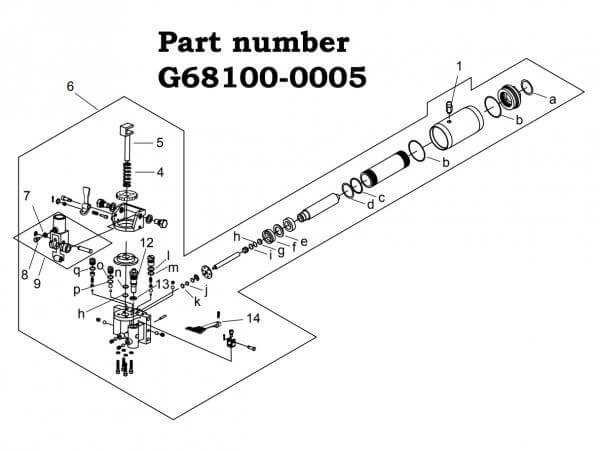

| Cylinder |

Key Features of Hein-Werner Parts

Durable and well-crafted components are essential in ensuring the reliable functioning of various mechanical systems. Each element contributes to the overall performance and longevity, emphasizing quality and precision in their design.

- Longevity: These components are engineered to last, reducing the need for frequent replacements.

- Compatibility: They are designed to fit seamlessly with various models, ensuring smooth operations.

- Strength: Built with robust materials, they handle significant wear and stress without compromising functionality.

- Ease of Maintenance: Many of these parts require minimal upkeep, streamlining the maintenance process for users.

- Reliability: They offer consistent performance, which is crucial for ensuring the safe operation of equipment.

Maintenance Tips for Hein-Werner Products

Regular upkeep is essential to ensure the longevity and optimal performance of any mechanical equipment. By following simple yet effective care routines, you can extend the life of your tools and keep them functioning smoothly.

- Always clean all components after each use to prevent the buildup of dirt and debris.

- Lubricate moving parts regularly to reduce friction and wear.

- Inspect key elements frequently for signs of damage or excessive wear.

- Replace worn-out components immediately to avoid further damage.

- Store equipment in a dry, clean area to prevent rust or corrosion.

Consistent maintenance not only ensures smooth operation but also minimizes the need for extensive repairs.

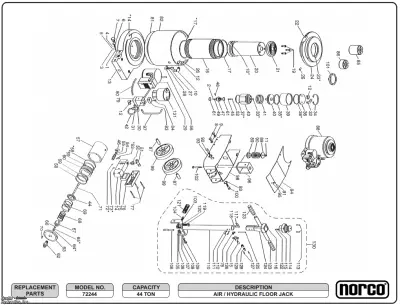

Common Issues and Replacement Solutions

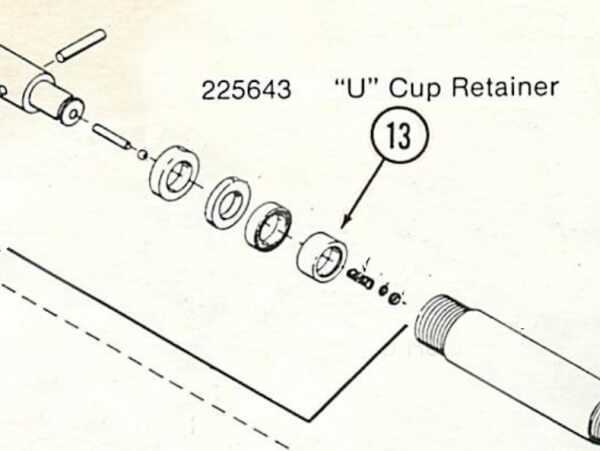

Identifying common malfunctions and finding suitable repair strategies can help maintain equipment performance over time. Understanding typical wear and tear allows for efficient troubleshooting and timely solutions.

Frequent Malfunctions

- Hydraulic system leaks

- Worn-out seals and gaskets

- Rust or corrosion on mechanical components

- Unresponsive controls or loss of pressure

Recommended Fixes

- Inspect and replace faulty hydraulic lines or fittings.

- Change seals and gaskets regularly to prevent fluid loss.

- Clean and lubricate components to prevent corrosion and ensure smooth operation.

- Test and recalibrate the control system to restore proper function.

By addressing these typical concerns, you can extend the life of the equipment and ensure reliable performance.

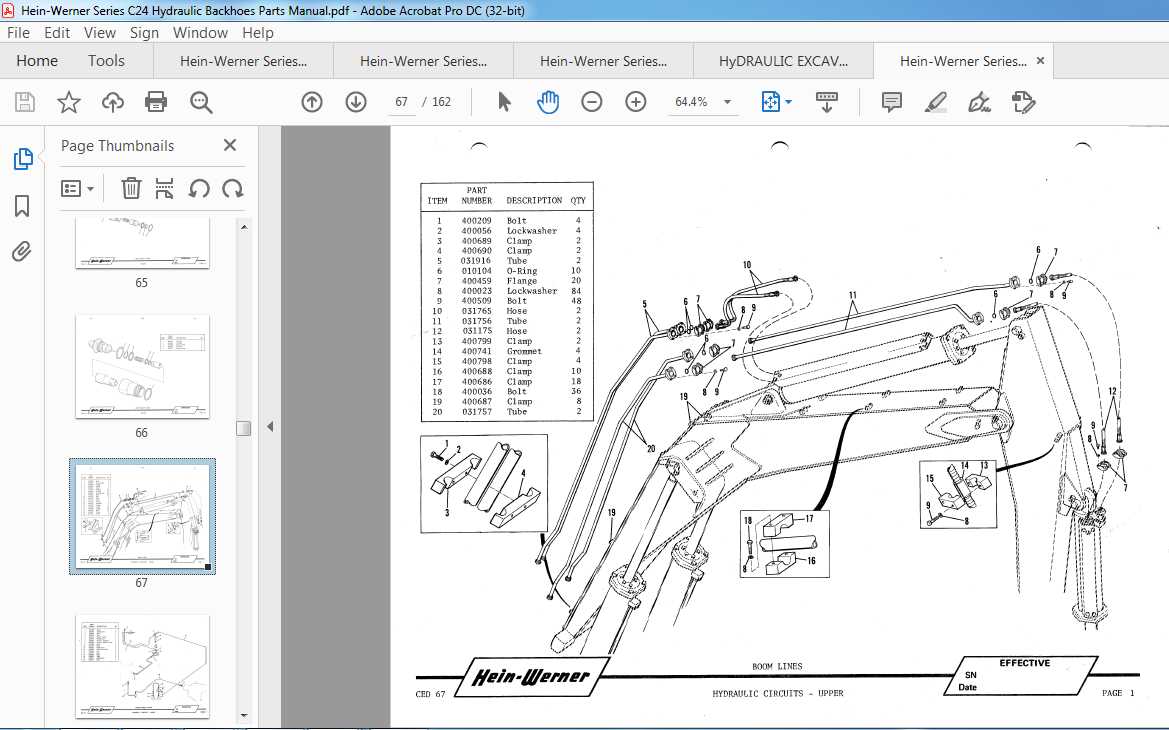

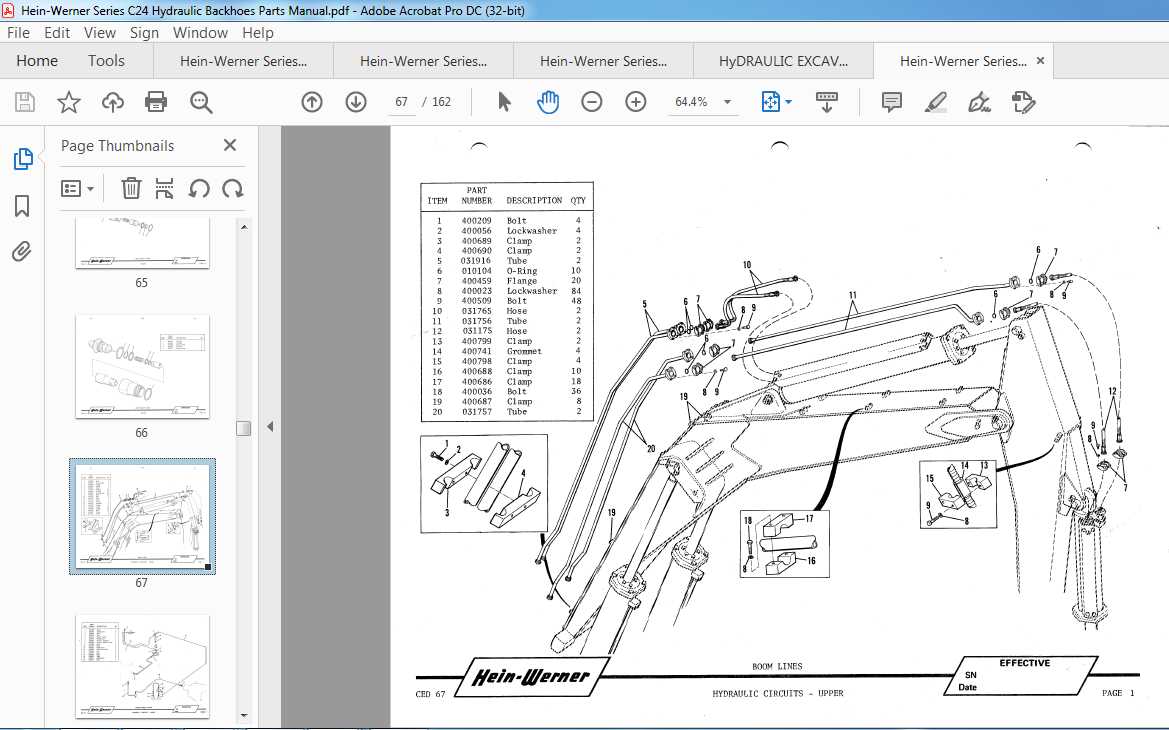

Hein-Werner Parts Compatibility Guide

This section aims to provide insights into the compatibility of various components used in specific models. Understanding these relationships ensures efficient maintenance and repair, helping users to make informed decisions about replacements and upgrades.

When considering component interchangeability, keep in mind the following factors:

- Model specifications: Different models may require distinct items, even if they appear similar.

- Manufacturer recommendations: Always refer to guidelines provided by the maker for optimal performance.

- Quality standards: Utilizing high-quality substitutes can enhance durability and reliability.

To assist in selecting the correct items, here’s a simplified overview:

- Check compatibility: Verify that the component aligns with the specific model you are using.

- Consult user manuals: Documentation often includes detailed information about compatible items.

- Seek expert advice: If uncertain, reach out to professionals or authorized dealers for assistance.

By adhering to these guidelines, users can ensure their equipment functions smoothly and efficiently, minimizing downtime and enhancing overall performance.

Benefits of Using Genuine Hein-Werner Parts

Utilizing authentic components in machinery offers numerous advantages that significantly enhance performance and longevity. These original elements are designed specifically for compatibility with equipment, ensuring optimal functioning and reliability.

Durability is a key benefit, as genuine components are manufactured to meet rigorous quality standards, resulting in a longer lifespan and reduced need for frequent replacements. This not only saves time but also minimizes operational costs.

Additionally, performance is greatly improved when using original parts. These components are engineered to work seamlessly with existing systems, leading to increased efficiency and productivity. Users can expect better handling and enhanced safety during operation.

Warranty support is another important aspect. Authentic components often come with a warranty, providing peace of mind and assurance of quality. This can be crucial in maintaining the integrity of machinery over time.

Finally, using genuine parts contributes to resale value. Equipment that has been maintained with original components typically retains its value better, making it a smarter investment in the long run.

How to Identify Original Hein-Werner Parts

When it comes to selecting authentic components for your equipment, recognizing the genuine article is essential. Many individuals may find themselves in situations where they need to determine the authenticity of certain items to ensure quality and compatibility. Understanding the key characteristics that distinguish real products from imitations can greatly enhance your purchasing experience.

First and foremost, always check for proper labeling. Authentic items typically carry specific branding or markings that reflect their origin. Look for consistent logos and serial numbers that are unique to the manufacturer. These details often serve as the first line of defense against counterfeits.

Next, examine the materials used. Genuine components are often made from high-quality materials that contribute to their durability and performance. If the texture or weight seems off, it might be a sign of a less reliable version. Trusted items usually have a robust feel and construction, designed to withstand regular use.

Additionally, consider the source of your purchase. Acquiring from authorized dealers or reputable retailers can significantly reduce the risk of obtaining non-genuine items. Always research the seller and read reviews from previous customers to gauge their reliability.

Finally, consult documentation or online resources that provide detailed information about the products. Many manufacturers offer guides or charts that illustrate key features and specifications of their authentic components. This information can be invaluable in making informed decisions and ensuring you choose the right items for your needs.

Upgrading Hein-Werner Equipment with New Parts

Enhancing machinery with fresh components can significantly improve performance and longevity. Upgrading older models not only increases efficiency but also ensures safety and reliability in operations.

When considering enhancements, it’s important to follow a structured approach:

- Assessment of Current Condition: Evaluate the existing equipment to identify areas needing improvement.

- Research Compatible Components: Look for suitable replacements that align with your equipment specifications.

- Consult with Experts: Seek advice from professionals or manufacturers to ensure the selected components meet quality standards.

- Installation Process: Follow proper guidelines for the installation of new components to maintain operational integrity.

Regular upgrades not only keep machinery functioning optimally but also extend its useful life. By investing in quality replacements, users can enhance overall productivity and safety.

Overall, staying informed about the latest options available for enhancing your equipment can lead to smarter maintenance decisions and better operational outcomes.

Best Practices for Ordering Hein-Werner Parts

Efficiently acquiring components is crucial for maintaining the functionality of various equipment. Understanding effective strategies can enhance the ordering experience and ensure timely delivery of necessary items.

Identify Your Requirements

Before placing an order, it is essential to clearly define your needs. This step can save time and prevent errors. Consider the following:

- Assess the condition of the current equipment.

- Make a list of all required components.

- Check for any specifications or model numbers.

Utilize Reliable Suppliers

Selecting a trustworthy source is vital for quality and prompt service. Consider the following points:

- Research suppliers for reviews and reliability.

- Verify that they stock genuine items.

- Compare prices and shipping options.

By following these guidelines, you can ensure a smooth ordering process and maintain the efficiency of your machinery.

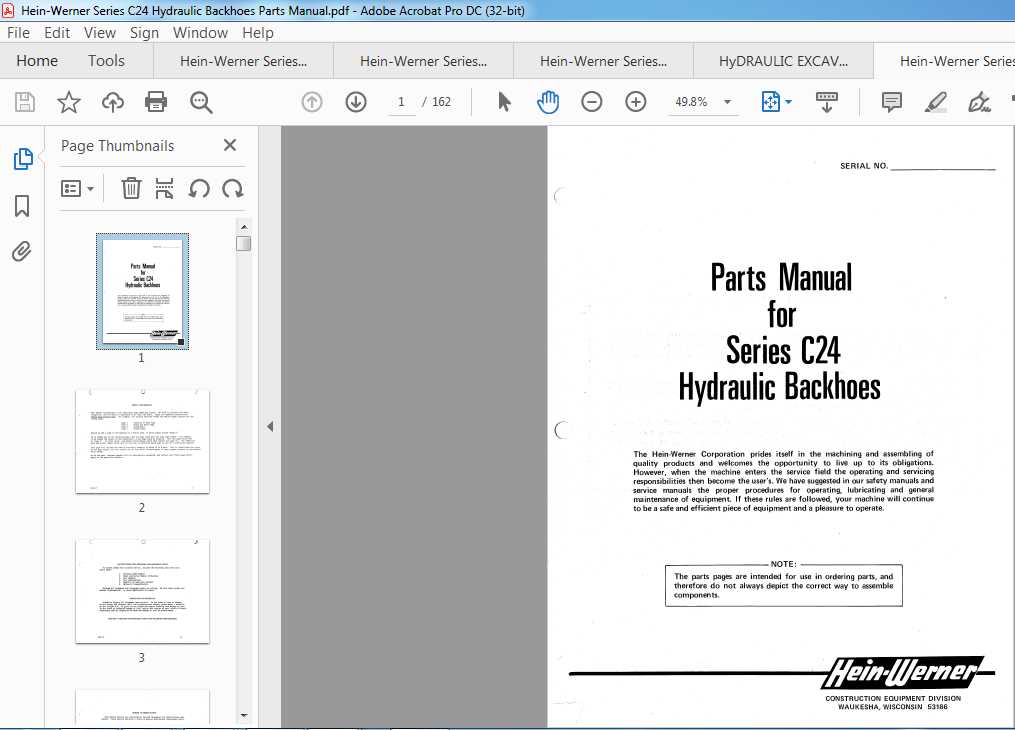

Where to Find Hein-Werner Diagrams and Manuals

Locating essential documents and illustrations for a specific brand can be crucial for effective maintenance and repairs. Many resources are available to assist individuals in finding detailed manuals and visual guides for various equipment. Utilizing these resources can ensure proper understanding and usage of the machinery in question.

Online Resources

The internet is a valuable tool for accessing various resources. Numerous websites offer downloadable manuals and visual aids for different equipment. Some key websites to consider include:

| Website |

Description |

| Manufacturer’s Website |

Official site often provides the latest manuals and diagrams directly related to their products. |

| Online Retailers |

Many retailers list manuals in the product description section, which can be a quick source for needed information. |

| Forums and Community Pages |

Online forums may have shared resources from other users, including tips and diagrams. |

Local Resources

Local dealers and service centers are also excellent sources for manuals and guides. They often possess physical copies of the necessary documents and can provide personalized assistance based on specific needs. Additionally, local libraries may have resources that include manuals for various types of equipment.