In the realm of heavy machinery, having a clear understanding of the internal structures and their functions is crucial for effective maintenance and troubleshooting. This section aims to provide a comprehensive overview of the intricate arrangements found within specific engine models, offering insights into how each element contributes to the overall performance.

By delving into the layout of various components, users can better grasp the interconnections and functionalities that drive these powerful machines. This knowledge not only enhances operational efficiency but also aids in identifying potential issues before they escalate, ensuring longevity and reliability.

Whether you are a seasoned technician or a newcomer to the field, familiarizing yourself with the configurations of essential components can significantly impact your work. Gaining clarity on these layouts empowers individuals to make informed decisions and implement effective solutions during maintenance and repairs.

Key Specifications and Features

This section provides an overview of essential characteristics and functionalities related to the specific engine model. Understanding these aspects is crucial for evaluating performance and suitability for various applications.

Performance Metrics

- Power Output: Typically ranges around 100 to 250 horsepower, depending on configuration.

- Displacement: Engine displacement is approximately 10.5 liters, contributing to its robust power delivery.

- Torque: Provides a high torque output, enhancing its capability for heavy-duty tasks.

Design Features

- Configuration: Inline-six design, known for its balance and efficiency.

- Cooling System: Equipped with an efficient cooling system to maintain optimal operating temperatures.

- Fuel System: Advanced fuel injection technology ensures better fuel economy and performance.

Essential Components of the Cat 3306

The functionality of a robust machinery system relies heavily on its fundamental elements. Understanding the core components that contribute to the efficient operation of a specific engine model enhances maintenance and troubleshooting efforts. These components work harmoniously to deliver the necessary performance and reliability, ensuring the machinery meets operational demands.

Key Functional Elements

The principal components include various assemblies that facilitate power generation, fuel efficiency, and overall engine operation. Each element plays a significant role in the engine’s performance and longevity.

Component Overview

| Component Name | Function |

|---|---|

| Fuel Injector | Delivers fuel into the combustion chamber for optimal combustion. |

| Piston | Converts fuel energy into mechanical energy through movement within the cylinder. |

| Crankshaft | Transforms the reciprocating motion of the piston into rotational motion. |

| Turbocharger | Increases engine efficiency and power output by forcing more air into the combustion chamber. |

| Cooling System | Maintains optimal operating temperatures to prevent overheating and ensure performance stability. |

Understanding the Parts Layout

In any complex machinery, grasping the arrangement of components is crucial for effective maintenance and operation. A clear layout facilitates easier identification of each element, allowing for quicker troubleshooting and repairs. By comprehending how these elements interact, users can ensure optimal functionality.

Each component serves a specific role, contributing to the overall efficiency of the system. Recognizing these roles enables operators to pinpoint potential issues and address them proactively. Furthermore, a well-organized configuration aids in inventory management, ensuring that necessary replacements are readily available when needed.

Moreover, understanding the layout not only enhances repair processes but also improves safety protocols. Familiarity with the placement of components can prevent accidents and promote a safer working environment. Overall, a thorough understanding of the arrangement of elements is vital for anyone involved in the operation or upkeep of such machinery.

Common Maintenance Requirements

Regular upkeep of heavy machinery is essential for optimal performance and longevity. Routine checks and servicing help prevent unexpected breakdowns and ensure that the equipment operates efficiently. Below are key maintenance activities to consider for effective management.

- Inspect fluid levels regularly, including oil, coolant, and fuel.

- Change oil and replace filters according to the manufacturer’s recommendations.

- Examine belts and hoses for signs of wear or damage, replacing them as necessary.

- Clean air filters to ensure proper airflow and engine performance.

- Check electrical connections and wiring for any signs of corrosion or loose connections.

In addition to the above tasks, it is important to:

- Monitor operating temperatures to avoid overheating.

- Conduct regular visual inspections for leaks or abnormal noises.

- Calibrate and adjust components to maintain optimal settings.

- Document all maintenance activities for future reference.

Adhering to these maintenance requirements can significantly enhance the reliability and efficiency of your machinery.

Identifying Replacement Parts

Understanding how to pinpoint the necessary components for your machinery is essential for effective maintenance and repairs. Whether addressing a malfunction or conducting routine upkeep, recognizing the specific elements involved can significantly enhance the efficiency of your equipment. By familiarizing yourself with the various parts and their functions, you can ensure that your machinery operates smoothly and reliably.

Utilizing Manufacturer Resources

One of the most effective methods for locating suitable components is to consult the resources provided by the manufacturer. These resources typically include detailed documentation that outlines the various components and their respective roles within the system. Technical manuals and service guides are invaluable tools that provide insights into the specifications and compatibility of each element.

Online Databases and Communities

In addition to official documentation, numerous online platforms offer extensive databases where users can search for specific components. These resources often include diagrams, user forums, and community discussions that can assist in identifying the right items for replacement. Engaging with these communities can also yield practical advice and recommendations from experienced users.

Diagnostic Tools for Cat 3306

Efficient troubleshooting and maintenance of heavy machinery require specialized instruments designed to assess functionality and performance. These tools play a vital role in identifying issues, ensuring optimal operation, and extending the lifespan of equipment.

Types of Diagnostic Instruments

- Electronic Diagnostic Scanners: These devices interface with the machinery’s electronic systems to retrieve error codes and performance data.

- Multimeters: Essential for measuring electrical properties, multimeters help diagnose electrical faults and verify system integrity.

- Pressure Gauges: Used to monitor fluid pressures, these tools are crucial for assessing hydraulic and fuel systems.

Benefits of Using Diagnostic Tools

- Improved Accuracy: Precision instruments provide reliable data for informed decision-making.

- Time Efficiency: Quick assessments lead to faster troubleshooting and reduced downtime.

- Preventive Maintenance: Regular diagnostics help identify potential issues before they escalate, ensuring smooth operation.

Assembly and Disassembly Guidelines

When handling complex machinery components, adhering to proper assembly and disassembly practices is essential for maintaining functionality and longevity. These processes involve a systematic approach to ensure that all elements fit together correctly and operate as intended.

Preparation is crucial before beginning any procedure. Ensure that you have the necessary tools and equipment on hand. Review the specific component layout and consult any relevant documentation to familiarize yourself with the assembly sequence and critical points to monitor.

During disassembly, proceed cautiously. Start by removing any external attachments or coverings that may obstruct access to the internal parts. Keep track of all fasteners and components, as losing these can complicate reassembly. Utilize appropriate tools to avoid damaging any sensitive components.

Once disassembly is complete, take the opportunity to inspect each part for wear or damage. Clean any dirt or debris to facilitate a smooth reassembly process. When reassembling, follow the reverse order of disassembly while ensuring each part is properly aligned and secured. Pay attention to torque specifications to avoid overtightening, which could lead to component failure.

In summary, thorough preparation, careful disassembly, and meticulous reassembly are vital for ensuring optimal performance and extending the lifespan of machinery components.

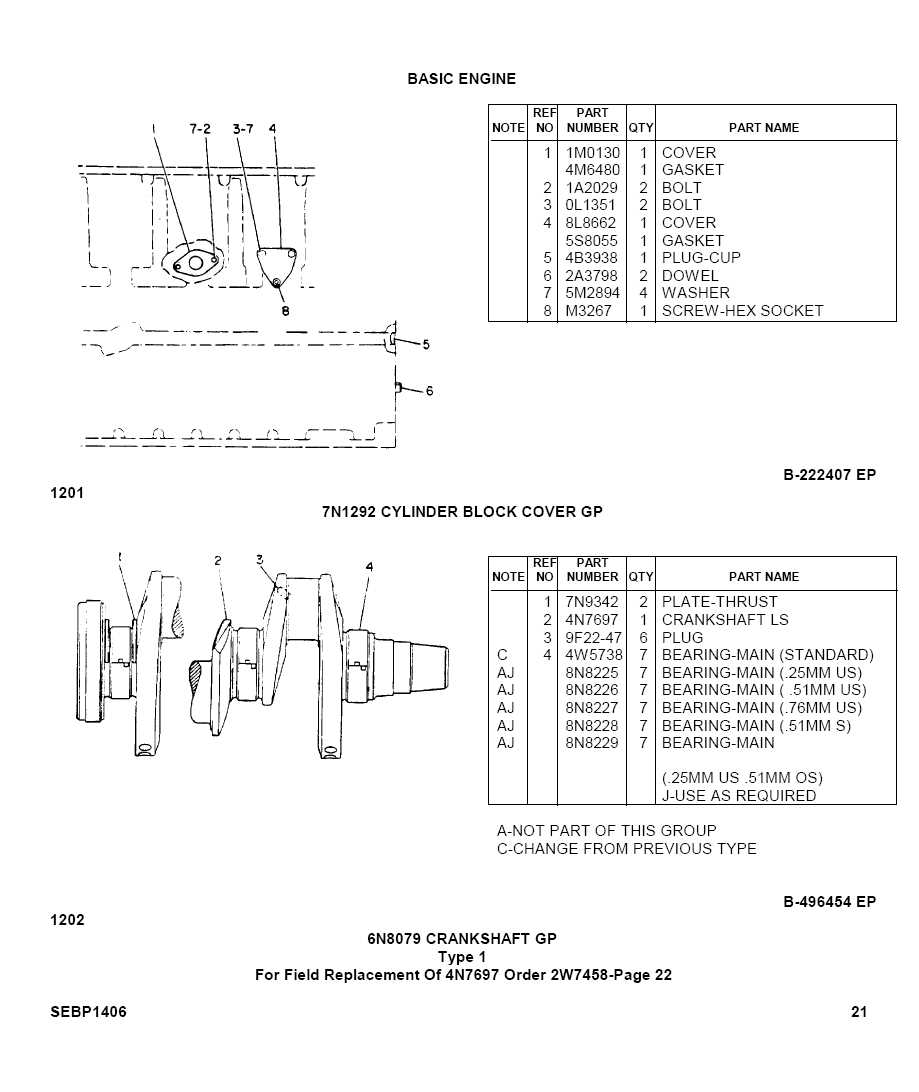

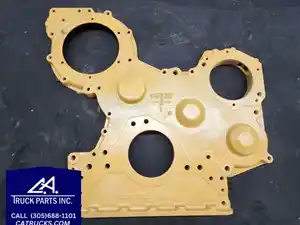

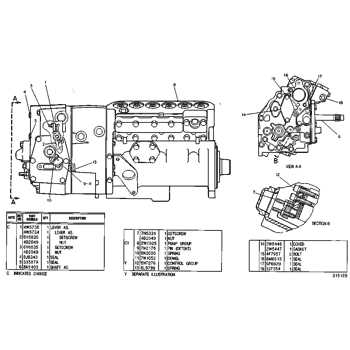

Visual Representation of Components

This section aims to illustrate the various elements that make up a complex mechanical system. By providing a clear visual outline, users can gain a deeper understanding of how each piece interacts and contributes to overall functionality. This visual guide serves as an essential reference for those seeking to familiarize themselves with the intricate details of machinery.

Component Overview

The representation highlights key elements, showcasing their positions and interconnections. Each component is identified clearly, allowing for easier navigation through the assembly. Understanding the layout facilitates better maintenance and troubleshooting, enhancing operational efficiency.

Interconnectivity and Functionality

Moreover, the visual layout emphasizes how various parts function together within the system. Recognizing these relationships is crucial for anyone involved in repair or optimization tasks. A well-organized representation not only simplifies identification but also improves the overall comprehension of mechanical operations.

Maintenance Tips for Longevity

Ensuring the prolonged functionality of heavy machinery requires diligent upkeep and attention to detail. By following a structured maintenance routine, operators can significantly enhance the operational lifespan of their equipment.

Regular Inspections: Conduct frequent assessments to identify wear and tear before it leads to severe issues. Checking fluid levels, filters, and belts regularly can prevent unexpected breakdowns.

Routine Cleaning: Keeping the machinery clean from dirt and debris helps maintain optimal performance. Regularly removing accumulated grime from vital components will promote efficiency and reduce overheating.

Quality Lubrication: Using high-quality lubricants in appropriate amounts can reduce friction and wear on moving parts. Regularly replacing and replenishing oils and greases is crucial for smooth operation.

Scheduled Servicing: Adhering to a manufacturer-recommended service schedule ensures that critical components receive professional attention. This proactive approach helps to address potential issues before they escalate.

Operator Training: Educating operators on best practices for handling and operating machinery can prevent misuse and reduce wear. Skilled operators are better equipped to spot problems early and respond effectively.

Component Upgrades: Investing in updated components can enhance performance and efficiency. Replacing outdated parts with newer, more efficient alternatives can lead to improved functionality and longevity.

Resources for Parts Acquisition

When seeking components for heavy machinery, it’s essential to utilize a variety of sources to ensure access to quality items. Understanding where to locate reliable suppliers can significantly enhance the maintenance and repair process of your equipment. This section outlines the most effective resources for acquiring necessary elements, catering to various preferences and needs.

Authorized Dealers

Official dealers are a prime source for high-quality components, providing products that meet stringent standards. They often have extensive inventories and can assist with locating specific items tailored to your machine’s specifications. Additionally, these vendors typically offer warranties and support services, ensuring that you receive proper guidance throughout the purchasing process.

Online Marketplaces

For those looking for convenience, online marketplaces present a vast selection of components, often at competitive prices. Platforms such as eBay or Amazon host numerous sellers, allowing buyers to compare options quickly. However, it’s vital to review seller ratings and product reviews to ensure the reliability of the items you are purchasing.