Understanding the layout of key mechanical elements within a vehicle’s powertrain system is essential for ensuring proper maintenance and repairs. This guide provides a detailed look at the various interconnected elements that contribute to the smooth functioning of the propulsion mechanism. By gaining insight into the overall structure, one can better appreciate how each component works together to deliver optimal performance.

Vital assemblies within this system play crucial roles in ensuring seamless operation. Each unit has a specific function, and their interaction ensures the vehicle’s smooth movement. Identifying the relationships between these elements can simplify troubleshooting and help in pinpointing areas that require attention.

Throughout this guide, we will explore these essential mechanisms in detail, focusing on their roles within the larger framework. By following the connections and understanding how they contribute to the overall performance, you will be better equipped to manage and care for your vehicle’s technical systems.

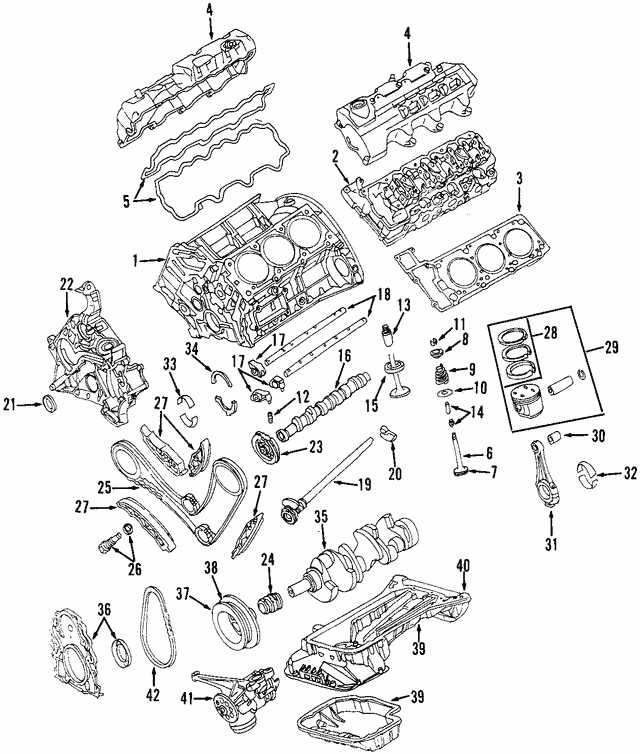

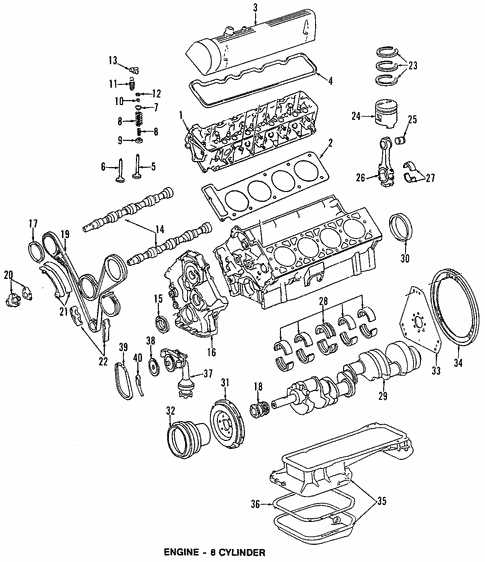

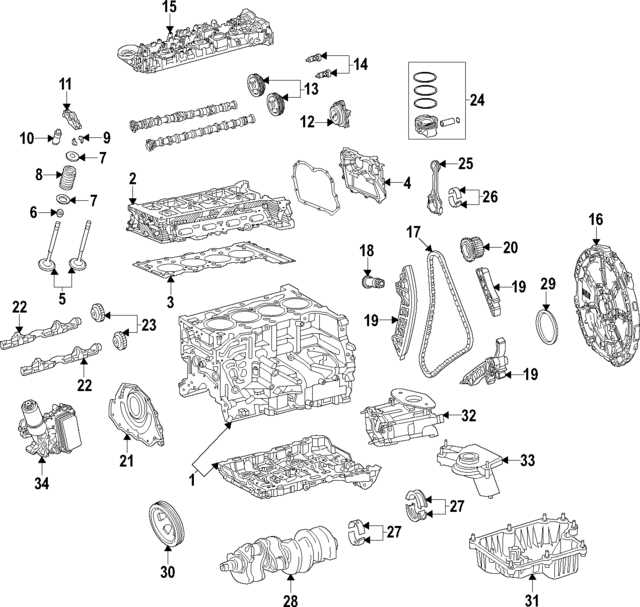

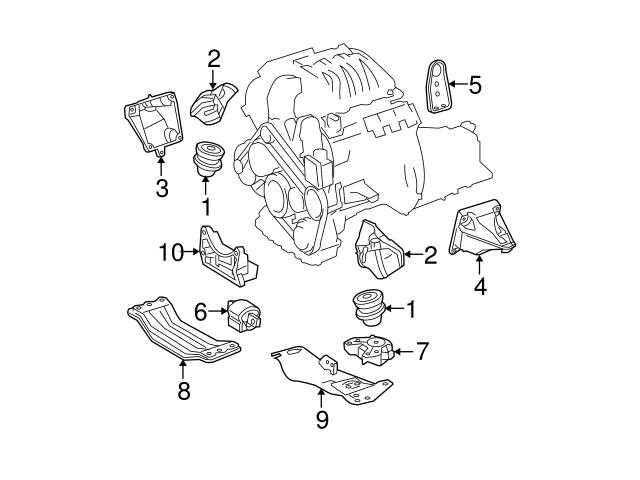

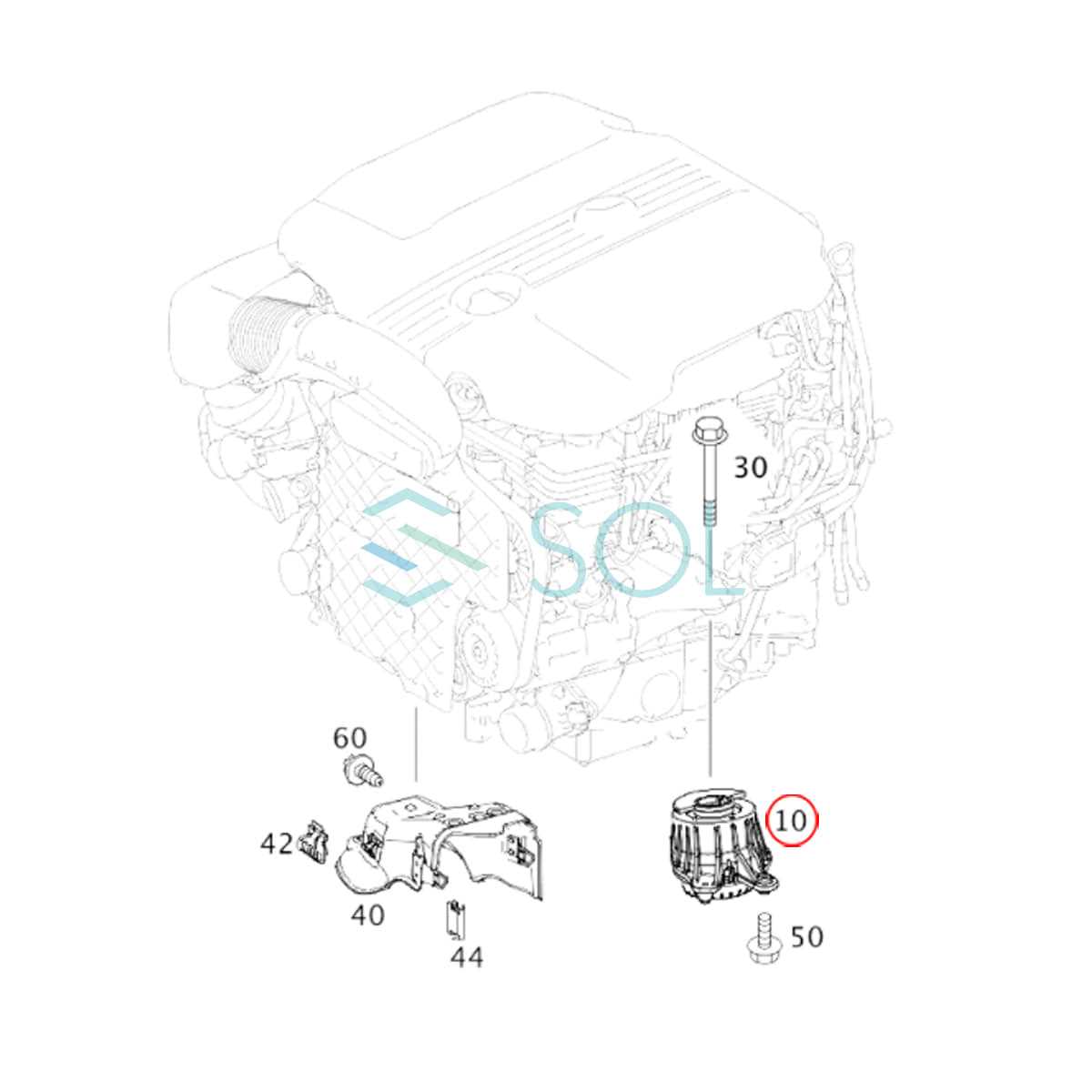

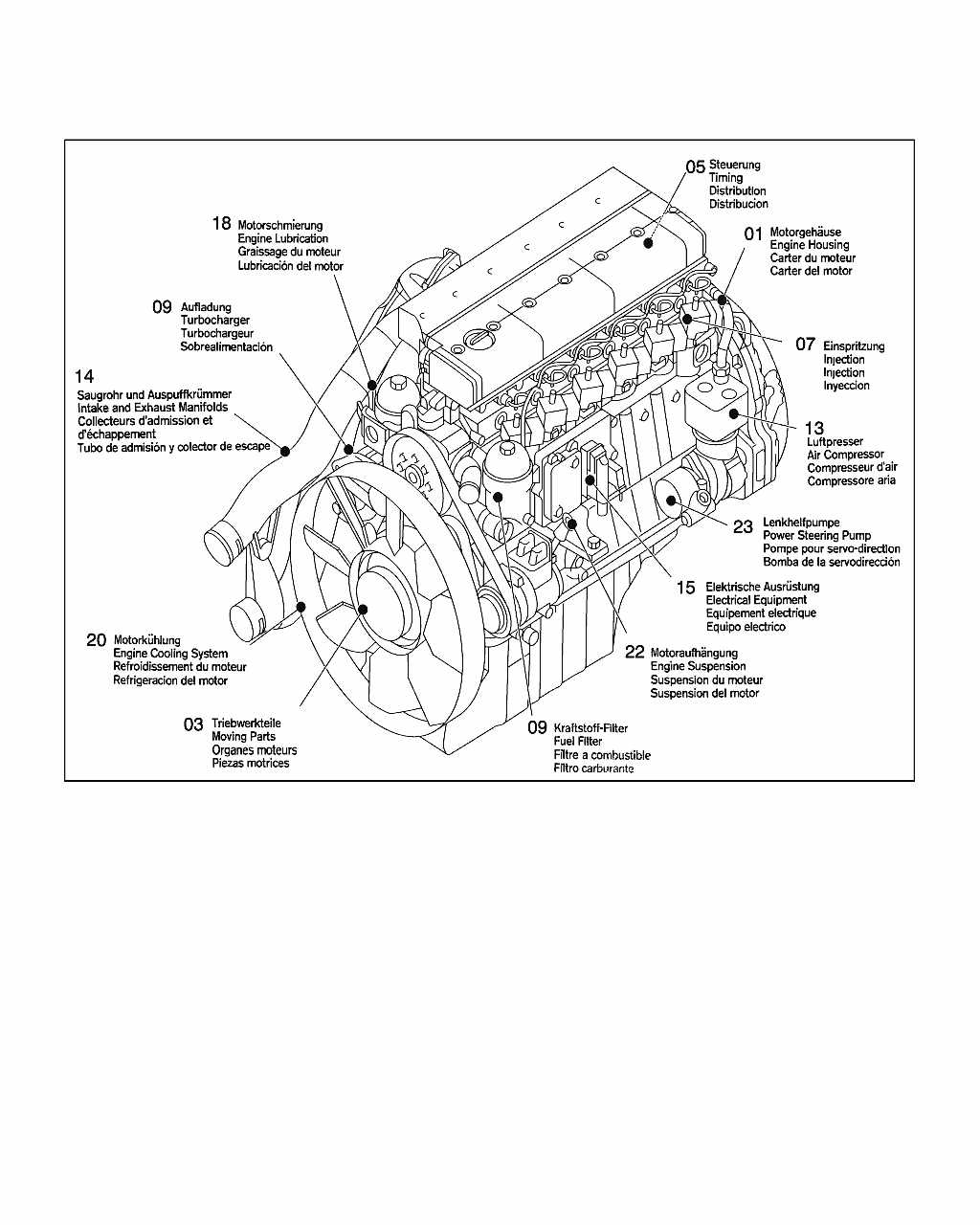

Overview of Mercedes Engine Components

The intricate assembly of a vehicle’s power unit consists of various elements that work harmoniously to ensure optimal performance. Understanding the roles of each component is essential for effective maintenance and troubleshooting.

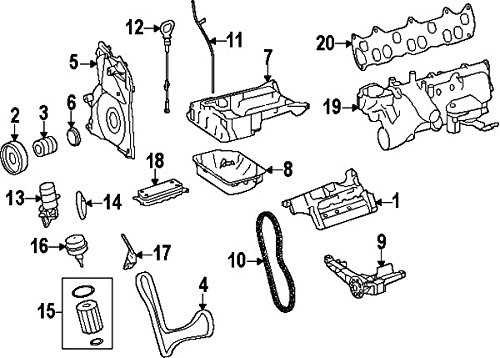

Key elements include the cylinder block, which houses the pistons, and the cylinder head, which covers the top of the cylinders and facilitates the intake and exhaust processes. Additionally, the crankshaft plays a crucial role in converting linear motion into rotational energy, while the timing belt ensures that the movements of the valves and pistons are synchronized.

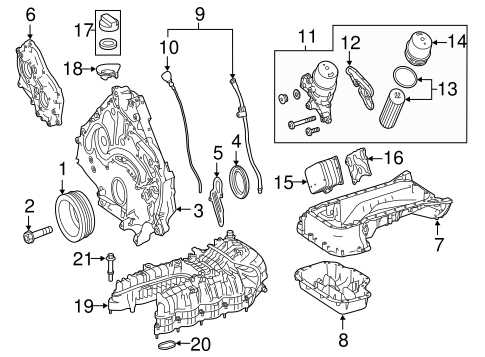

Other significant components include the oil pump, responsible for circulating lubrication throughout the system, and the cooling system, which maintains optimal temperatures to prevent overheating. Each of these elements is vital for the smooth operation of the power unit, highlighting the complexity and precision involved in automotive engineering.

Main Functions of Engine Parts

The components of a motor play a crucial role in ensuring optimal performance and efficiency. Each element contributes uniquely to the overall functionality, working in harmony to convert fuel into motion while minimizing waste and wear.

Combustion Chamber: This area is essential for the fuel-air mixture to ignite, providing the necessary power to drive the vehicle forward. The design and integrity of this chamber significantly affect overall efficiency and emissions.

Crankshaft: Acting as the heart of the mechanical system, the crankshaft transforms linear motion into rotational force. This motion is vital for driving the wheels and ensuring smooth operation.

Camshaft: This component regulates the timing of valve openings and closings, allowing air and fuel to enter and exhaust gases to exit. Its precision is crucial for maintaining optimal performance and power delivery.

Cooling System: Effective temperature management is vital for preventing overheating. This system circulates coolant, ensuring that the components operate within their ideal temperature range, enhancing longevity and reliability.

Fuel Delivery System: This system ensures that the right amount of fuel reaches the combustion chamber at the appropriate time. Its efficiency directly influences performance and fuel consumption.

Lubrication System: Proper lubrication reduces friction between moving components, minimizing wear and tear. It ensures that all parts operate smoothly, enhancing performance and extending the lifespan of the system.

Understanding these functions is vital for anyone interested in the mechanics of vehicles, as each component’s performance directly impacts the overall operation.

Understanding the Fuel Injection System

The fuel injection system plays a vital role in the performance and efficiency of a vehicle’s powertrain. It is responsible for delivering the right amount of fuel to the combustion chamber at the precise moment, ensuring optimal operation. By precisely controlling the fuel-air mixture, this system contributes significantly to the overall functionality and emissions control of the vehicle.

Components of the Fuel Delivery System

This system consists of several key components that work together seamlessly. The fuel pump draws gasoline from the tank, sending it through the fuel filter to remove impurities. The fuel injectors then spray the fuel into the combustion chamber, allowing for precise atomization and mixing with air. Sensors monitor various parameters, ensuring that the correct amount of fuel is injected based on engine demands.

Benefits of an Efficient Injection System

An efficient fuel injection system enhances vehicle performance by improving acceleration and responsiveness. It also contributes to better fuel economy, reducing overall consumption and lowering emissions. Regular maintenance and timely repairs of this system can significantly extend the life of the vehicle and enhance driving pleasure.

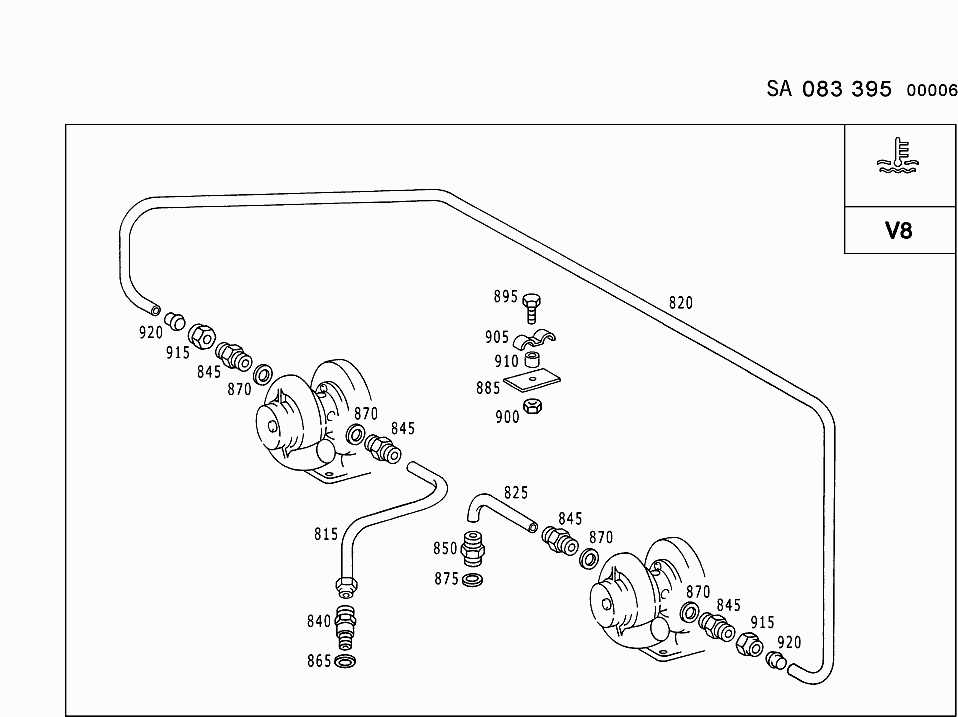

Cooling Mechanisms for Engine Efficiency

Effective thermal management is essential for maintaining optimal performance and longevity of any internal combustion system. The implementation of cooling mechanisms plays a pivotal role in regulating temperature, thereby enhancing overall functionality and preventing overheating. A well-designed cooling system not only preserves the integrity of components but also contributes to fuel efficiency and reduces emissions.

Types of Cooling Systems

There are primarily two types of cooling systems utilized in modern automotive technology: air and liquid cooling. Air cooling relies on ambient air to dissipate heat through fins or cooling ribs, making it lightweight and simple. On the other hand, liquid cooling systems circulate coolant through passages, allowing for more efficient heat transfer and better temperature control, particularly in high-performance applications.

Importance of Thermoregulation

Thermoregulation ensures that the temperature remains within an optimal range, allowing for maximum efficiency and performance. Maintaining appropriate operating temperatures minimizes wear on critical components and reduces the risk of thermal expansion-related failures. Additionally, a properly functioning cooling system aids in achieving ideal combustion conditions, thus optimizing power output and reducing fuel consumption.

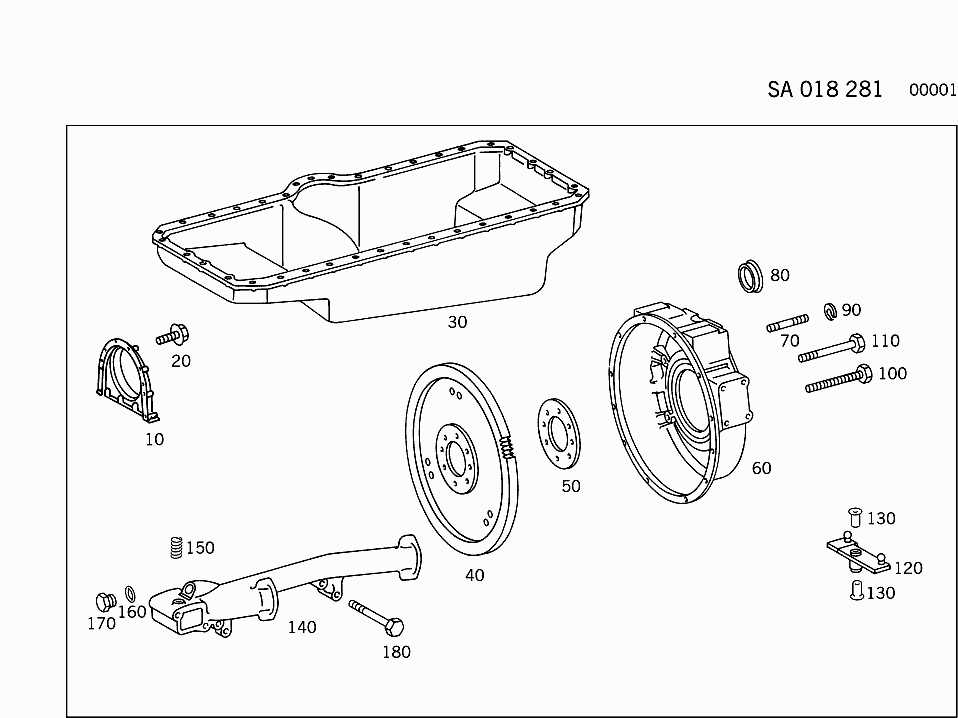

Lubrication Pathways in Mercedes Engines

The lubrication system in modern automotive machinery is essential for ensuring smooth operation and longevity. It plays a crucial role in minimizing friction and wear between moving components, allowing for efficient performance. Understanding the various routes through which lubricant flows can provide valuable insights into maintaining the reliability and efficiency of these complex systems.

Typically, the lubricant is drawn from a reservoir and circulated throughout the machinery via a network of channels. These pathways are designed to deliver the fluid precisely where it is needed, ensuring that critical areas receive adequate protection. Various components, such as pumps and filters, are integral to this system, working together to maintain optimal lubrication levels and keep contaminants at bay.

Moreover, the design of these routes is optimized for effective heat dissipation and pressure management, contributing to the overall functionality of the machinery. Regular maintenance and checks of the lubrication pathways are vital to prevent potential issues and ensure that the system operates smoothly, extending the lifespan of the components involved.

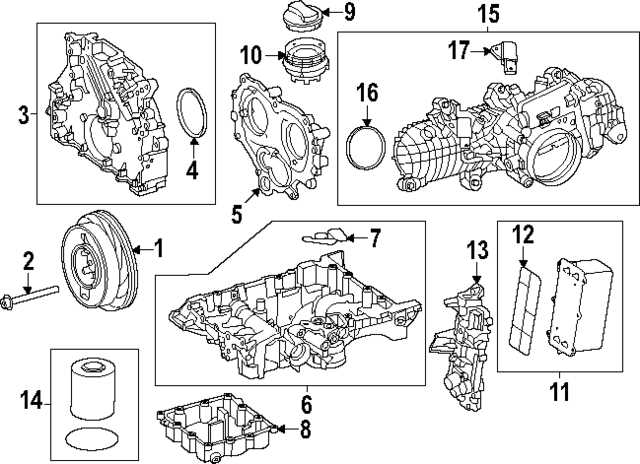

The Role of the Crankshaft and Pistons

The crankshaft and pistons play a vital role in the conversion of energy within a mechanical system. These components work together to transform linear motion into rotational motion, ensuring the effective operation of various mechanisms.

The crankshaft acts as the core element that receives the force generated by the pistons. As the pistons move up and down within their cylinders, they exert pressure on the crankshaft, causing it to rotate. This rotational movement is essential for driving the overall system, facilitating the transfer of power to other components.

Pistons, on the other hand, are responsible for compressing the mixture within their chambers, creating a powerful force when ignited. This process generates the necessary thrust that propels the crankshaft’s motion, establishing a continuous cycle of energy transfer. Together, these two components form a critical partnership that ensures smooth and efficient performance.

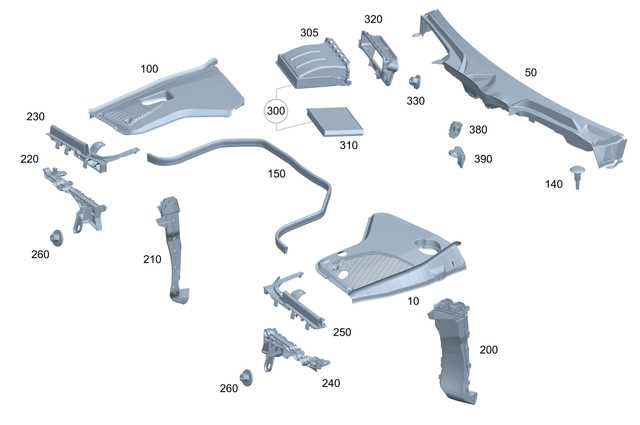

Exhaust and Emission Control Systems

The exhaust and emission control systems play a crucial role in modern vehicles, ensuring that harmful substances are minimized and managed effectively. These systems are designed to treat exhaust gases and reduce pollutants before they are released into the atmosphere, contributing to environmental protection and compliance with regulations.

These systems consist of several key components, each serving a specific function:

- Exhaust Manifold: Collects exhaust gases from multiple cylinders and directs them into the exhaust system.

- Catalytic Converter: Facilitates chemical reactions to convert harmful gases into less harmful emissions.

- Oxygen Sensors: Monitor the level of oxygen in the exhaust gases to optimize combustion efficiency.

- Diesel Particulate Filter (DPF): Captures and stores soot particles produced by diesel engines to reduce emissions.

- Exhaust Gas Recirculation (EGR) System: Reintroduces a portion of the exhaust back into the intake manifold to lower nitrogen oxide emissions.

Proper functioning of these systems is essential for maintaining performance and efficiency while minimizing the environmental impact. Regular maintenance and timely inspections are necessary to ensure that these components are in optimal condition and to prevent any potential issues.

Advancements in technology continue to improve the effectiveness of exhaust and emission control systems, ensuring compliance with stringent regulations while enhancing vehicle performance.

Timing Belt and Chain Operation

The timing belt and chain play crucial roles in coordinating the movements of various components within a vehicle’s propulsion system. Their primary function is to ensure that the rotation of the crankshaft synchronizes perfectly with the rotation of the camshaft, allowing for efficient performance of the internal combustion cycle.

Types of Timing Mechanisms

- Timing Belt: A flexible belt made of reinforced rubber, often used in lighter vehicles due to its lower weight and noise levels.

- Timing Chain: A robust chain made of metal, typically more durable than belts and suited for higher-performance applications.

Importance of Maintenance

Regular maintenance of the timing mechanism is essential for ensuring optimal functionality. Neglecting this crucial component can lead to significant performance issues and costly repairs.

- Inspect for wear and tear periodically.

- Replace according to manufacturer guidelines.

- Ensure proper tension is maintained for optimal operation.

Understanding the operation and maintenance of timing belts and chains is vital for preserving the overall efficiency of a vehicle’s mechanical system.

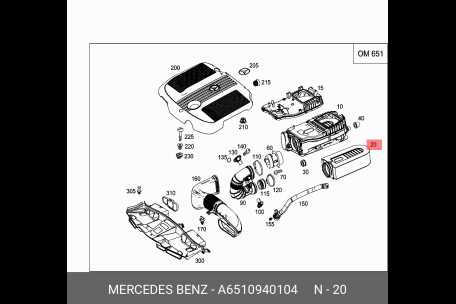

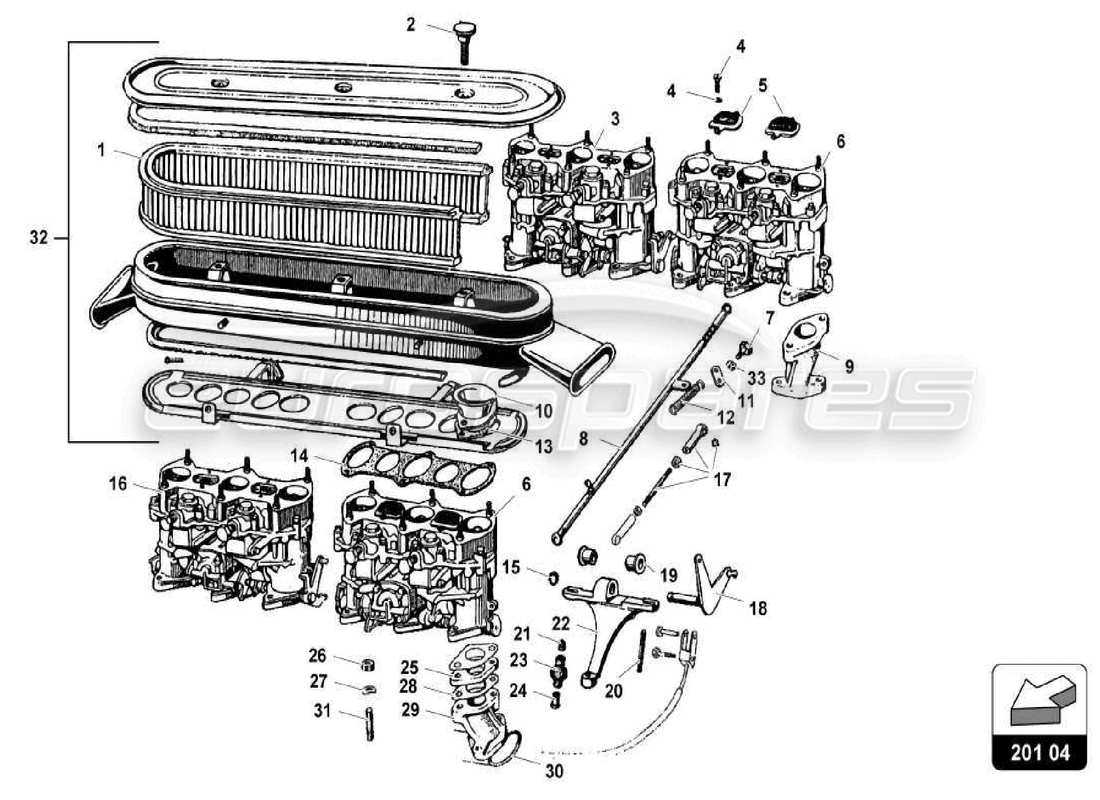

Air Intake System and Turbochargers

The air intake system plays a vital role in enhancing the performance of a vehicle’s propulsion unit by efficiently delivering the necessary air for combustion. This system works in tandem with turbochargers, which are devices designed to boost airflow, thereby increasing power output. Understanding the components and functions of these systems can significantly improve overall efficiency and performance.

Components of the Air Intake System

- Air Filter: Cleans incoming air to prevent contaminants from entering.

- Intake Manifold: Distributes the air evenly to each cylinder.

- Throttle Body: Controls the flow of air into the combustion chamber.

- Intercooler: Reduces the temperature of the compressed air from the turbocharger for better performance.

Functionality of Turbochargers

Turbochargers utilize exhaust gases to spin a turbine, which in turn compresses the incoming air. This process enhances air density, allowing for a greater volume of air to enter the combustion chamber. The increased air supply leads to more fuel being burned, resulting in higher power output and improved efficiency.

In summary, a well-designed air intake system combined with effective turbocharging can lead to significant performance improvements, making these systems crucial for modern automotive engineering.

Electrical Systems Supporting Engine Function

The functionality of a vehicle’s power unit heavily relies on its electrical components, which play a crucial role in ensuring optimal performance and efficiency. These systems facilitate various operations, from starting mechanisms to fuel management, contributing to the overall reliability of the automotive unit.

Power Distribution: One of the key aspects of these systems is the effective distribution of electrical energy throughout the vehicle. This process involves various wiring harnesses and connectors, which ensure that all components receive the necessary power for their operation.

Control Modules: Advanced control units are essential for monitoring and managing the various functions of the power unit. These modules interpret data from numerous sensors, making real-time adjustments to maintain performance and efficiency. They act as the brain of the system, processing information and issuing commands to other components.

Ignition Systems: A reliable ignition mechanism is fundamental for starting the power unit. This includes spark plugs, coils, and other elements that work together to create the necessary spark for combustion. Efficient operation of these components is vital for smooth vehicle performance and fuel efficiency.

Sensors and Feedback: Various sensors are integrated within the electrical network, providing vital feedback to the control modules. These sensors monitor parameters such as temperature, pressure, and airflow, allowing for precise adjustments to enhance performance and ensure safe operation.

Common Issues in Engine Components

Understanding frequent complications in mechanical assemblies is crucial for maintaining optimal performance. Various elements within the power unit can exhibit malfunctions due to wear and tear, environmental conditions, or manufacturing defects. Recognizing these issues can help prevent significant failures and extend the lifespan of the vehicle.

Here are some of the typical challenges associated with various components:

| Component | Common Issues | Symptoms |

|---|---|---|

| Valvetrain | Worn lifters, valve seat erosion | Engine noise, poor performance |

| Fuel System | Clogged injectors, fuel pump failure | Stalling, hard starting |

| Cooling System | Radiator leaks, thermostat failure | Overheating, coolant loss |

| Lubrication System | Oil leaks, pump failure | Low oil pressure, engine noise |

Maintenance Tips for Engine Longevity

Ensuring the durability and efficiency of your vehicle’s power unit requires regular care and attention. By following a few key practices, you can significantly extend the lifespan of this critical component and enhance its performance.

Regular Fluid Checks

Monitoring fluid levels is essential for optimal functioning. Make it a habit to inspect the various fluids, including oil, coolant, and transmission fluid, regularly. Keeping these at the appropriate levels prevents overheating and reduces wear on the internal mechanisms.

Routine Inspections and Tune-Ups

Scheduling periodic inspections can identify potential issues before they escalate. Routine tune-ups, including replacing filters and spark plugs, ensure that all systems are working harmoniously. Such preventative measures can save you from costly repairs in the future.