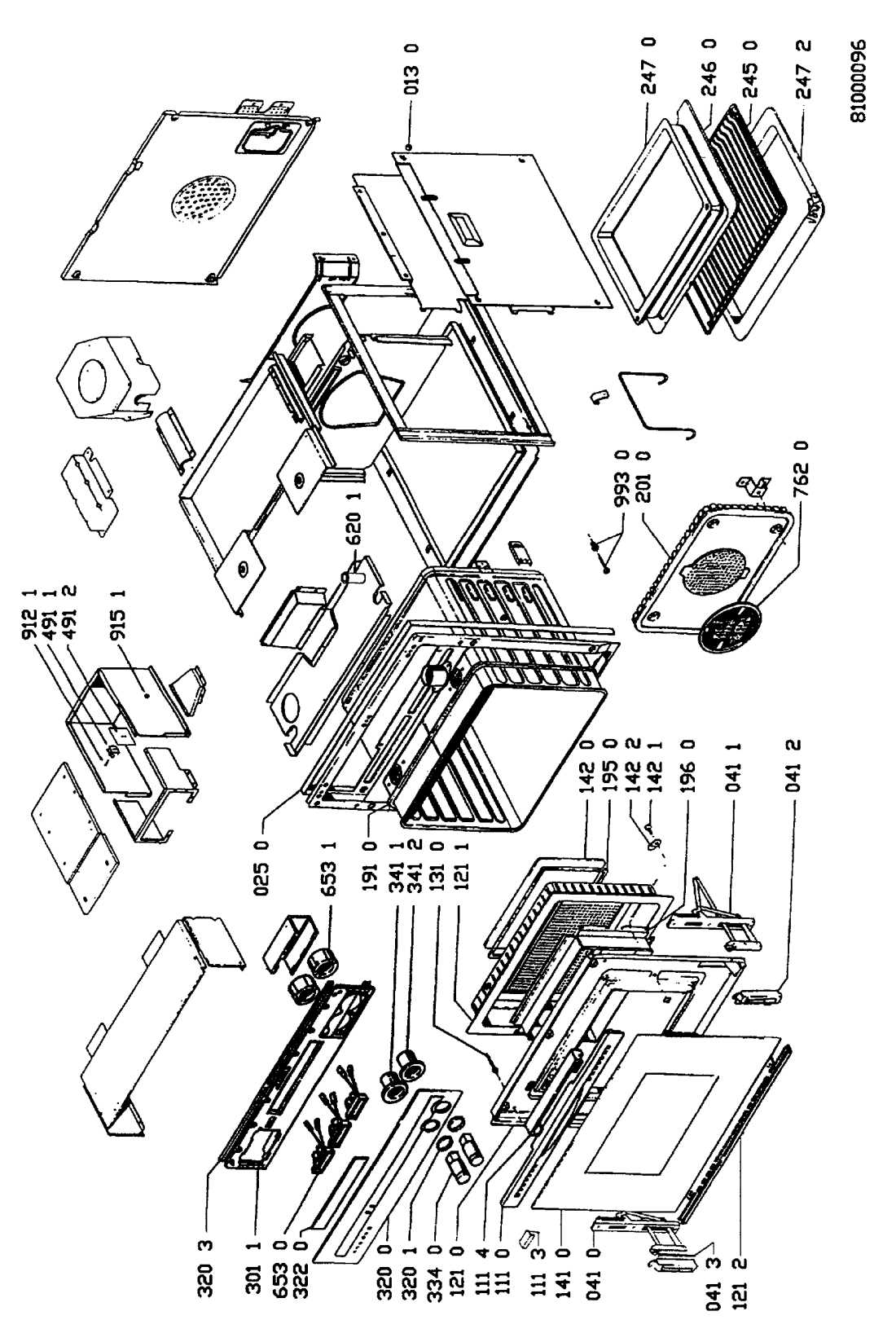

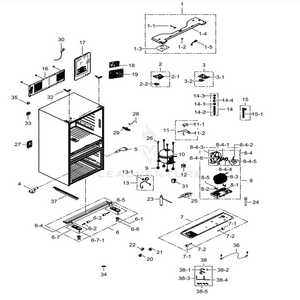

The intricate world of mechanical assemblies often requires a thorough comprehension of individual elements and their arrangements. A precise representation of these units is crucial for maintenance, troubleshooting, and efficient operation. This section aims to illuminate the various constituents that come together to form a cohesive system, showcasing their interrelations and functionalities.

In any complex mechanism, recognizing how each piece interacts with others is fundamental. By analyzing these relationships, one can gain insights into the overall performance and reliability of the apparatus. This exploration will provide a valuable reference for both seasoned technicians and those new to the field, enhancing their ability to navigate the challenges of assembly and disassembly.

Furthermore, understanding the specific functions of each segment not only aids in repair but also fosters innovation and improvement. By delving into the intricacies of these components, we can uncover best practices and potential upgrades, ultimately leading to enhanced efficiency and longevity of the entire system.

Understanding Rf267aers Components

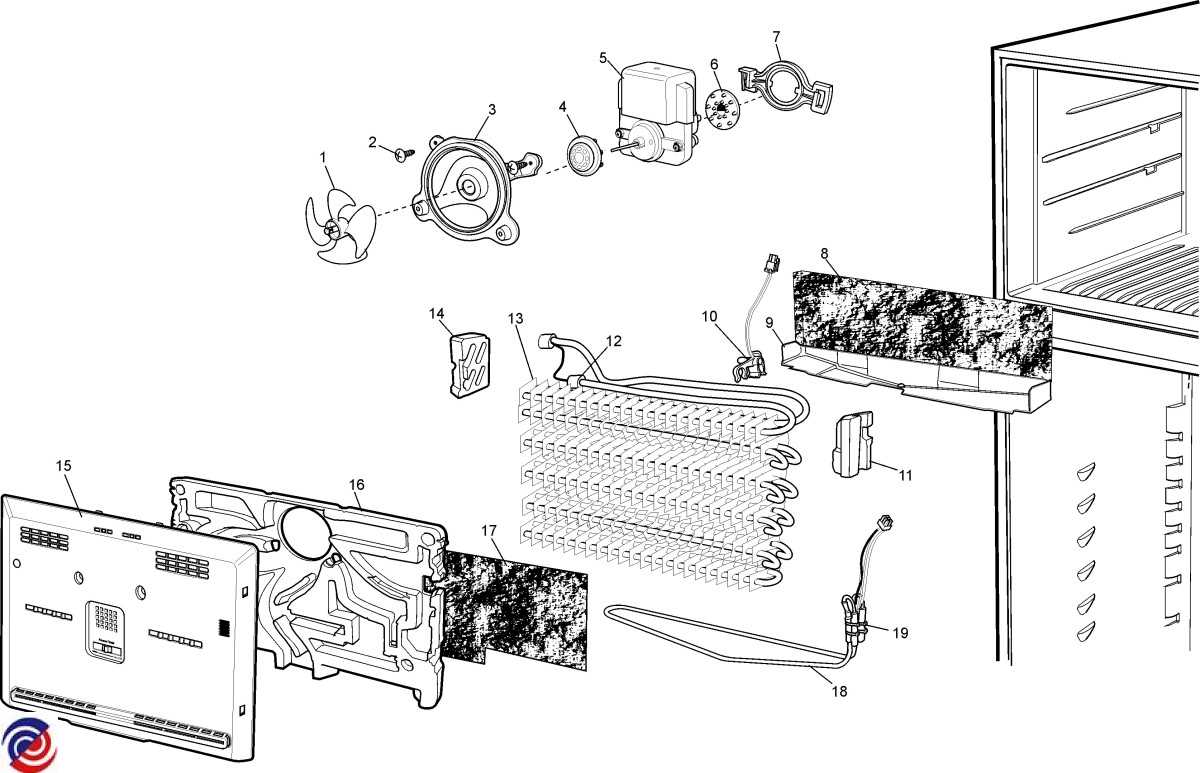

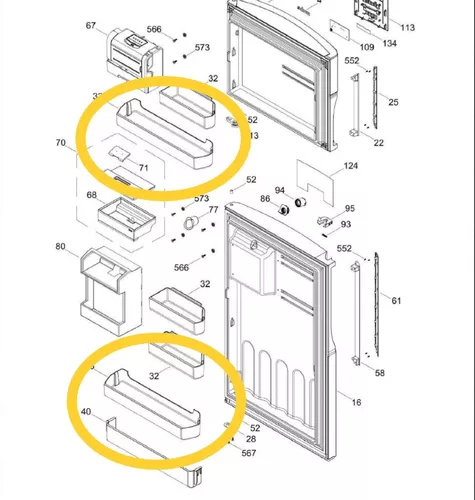

Comprehending the elements of a specific model is crucial for effective maintenance and troubleshooting. Each component plays a significant role in the overall functionality, ensuring that the system operates smoothly. By dissecting the individual parts and their interactions, users can better grasp how to optimize performance and address potential issues.

Every assembly is comprised of various elements, each serving a distinct purpose. Familiarity with these parts allows for informed decisions regarding repairs and replacements. Understanding how each element contributes to the whole enables users to identify weak points and improve the efficiency of the system.

Furthermore, recognizing the relationships between different components can lead to a deeper insight into the operational dynamics. This knowledge is essential not only for maintenance but also for enhancing the performance of the entire unit. A thorough exploration of the essential features equips users with the tools needed for effective problem-solving and system enhancement.

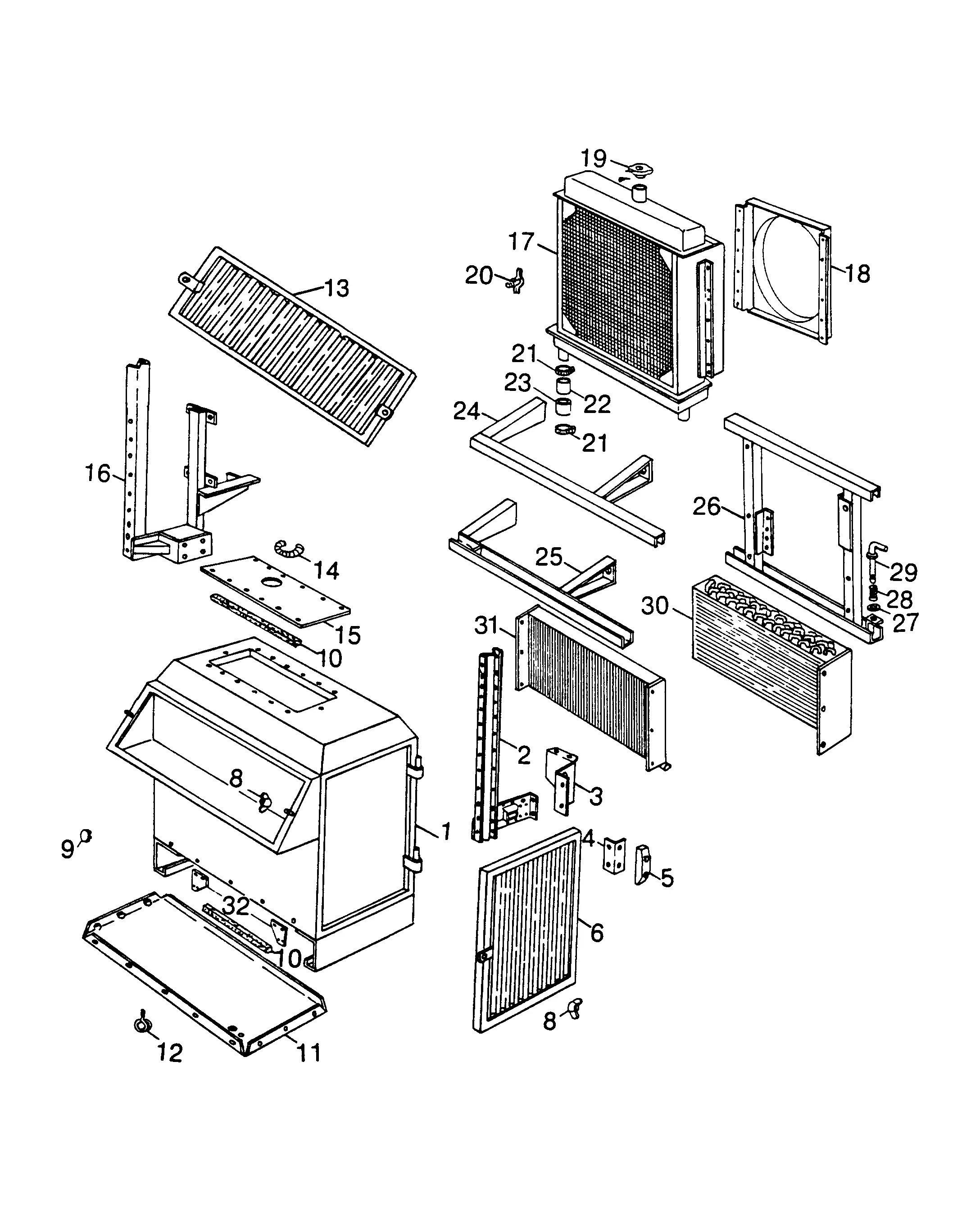

Importance of Parts Diagrams

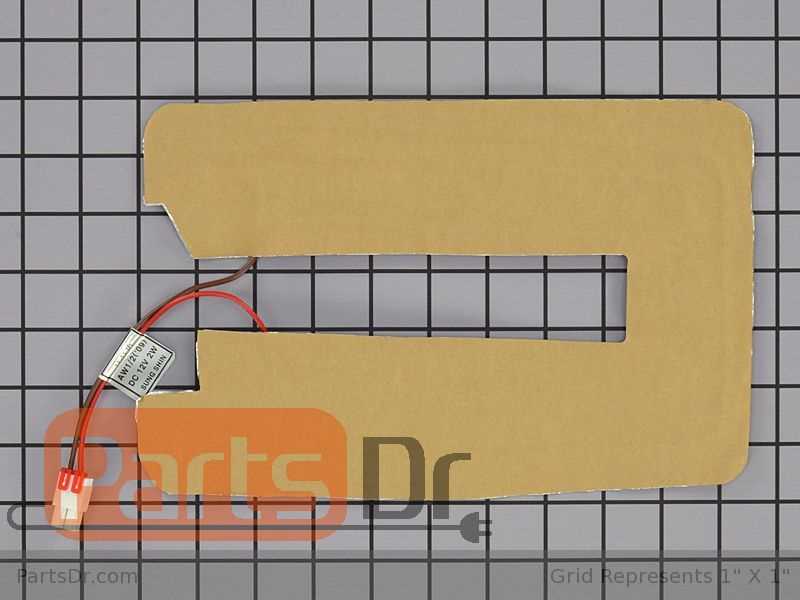

Understanding the intricate components of a system is crucial for effective maintenance and repair. Visual representations serve as essential tools for identifying individual elements and their functions, allowing users to navigate complex assemblies with ease. Such illustrations facilitate a clearer comprehension of how various pieces interconnect and operate within a whole.

Effective Communication: Visual aids enhance communication among technicians, engineers, and manufacturers. They provide a common reference point, reducing misunderstandings and errors during discussions about specific components. This clarity is vital in ensuring everyone involved has a unified understanding of the system.

Streamlined Maintenance: For service professionals, having access to detailed illustrations significantly simplifies maintenance tasks. Technicians can quickly locate and address issues, minimizing downtime and improving efficiency. With clear visual references, identifying worn or damaged elements becomes a straightforward process.

Training and Education: For those new to the field, visual representations play an educational role. They serve as valuable learning resources, helping newcomers grasp the layout and functionality of various components. This foundational knowledge is essential for building expertise and confidence in handling complex systems.

Cost-Effectiveness: By using accurate representations, organizations can save time and resources. Effective troubleshooting leads to faster repairs and fewer mistakes, which ultimately results in lower operational costs. Investing in detailed visual guides pays off by enhancing overall productivity.

In summary, well-crafted visual representations are indispensable in the realm of maintenance and repair. They foster clear communication, streamline tasks, support training efforts, and contribute to cost-effective operations, underscoring their importance in any technical field.

Common Issues with Rf267aers

Appliances of this type often encounter a variety of problems that can affect their efficiency and functionality. Understanding these issues is crucial for maintaining optimal performance and prolonging the lifespan of the equipment.

One frequent challenge is temperature inconsistency. Users may notice fluctuations in cooling or heating levels, leading to spoiled food or inadequate climate control. This issue can arise from faulty thermostats or compressor malfunctions, necessitating careful inspection and potential replacement.

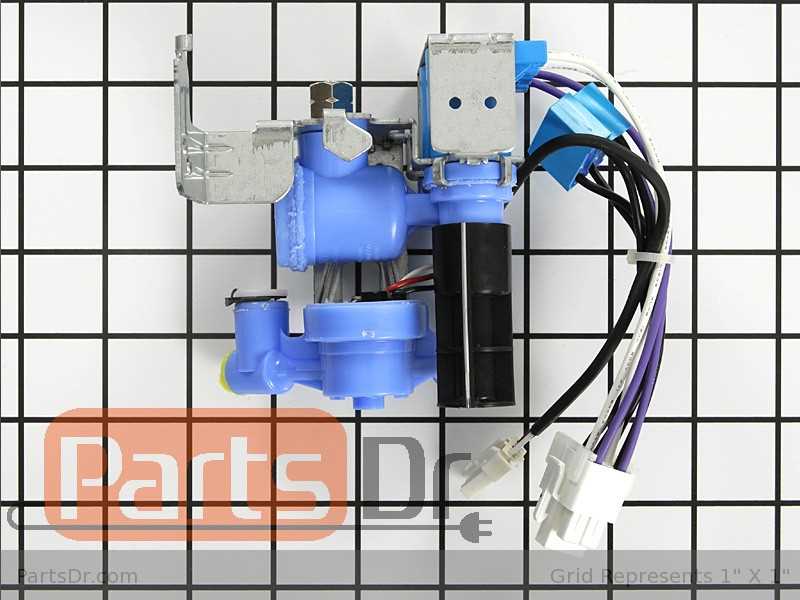

Another common concern involves unusual noises during operation. Clanging, buzzing, or hissing sounds might indicate loose components, worn-out motors, or issues with the fan. Identifying the source of these sounds early on can prevent more significant damage and costly repairs.

Water leaks represent yet another issue, often stemming from clogged defrost drains or damaged seals. Such leaks can not only damage the appliance itself but also lead to water damage in the surrounding area. Regular maintenance and prompt attention to leaks are essential for preventing further complications.

Power failures can also occur, where the unit may fail to turn on or experience interruptions during operation. This can be linked to electrical issues, including blown fuses or faulty power cords. Troubleshooting these electrical components is vital to restore functionality.

By recognizing and addressing these common challenges, users can ensure better performance and longevity of their equipment. Regular maintenance and timely repairs are key to mitigating these issues effectively.

How to Read a Parts Diagram

Understanding an assembly layout is crucial for effective maintenance and repairs. It provides a visual representation of the various components involved, helping users to identify, locate, and understand the relationships between different elements. Familiarity with the layout can significantly enhance your ability to troubleshoot issues and facilitate efficient disassembly and reassembly processes.

Familiarize Yourself with the Symbols

Each representation in the assembly layout typically employs specific symbols or notations to indicate different parts and their functions. Take the time to familiarize yourself with these icons, as they convey essential information about the components, such as size, orientation, and material. Often, a legend is included, offering a detailed explanation of each symbol, making it easier to interpret the overall design.

Follow the Flow of the Assembly

Another important aspect of understanding an assembly layout is to follow the flow from one component to another. This can provide insight into how various pieces interact and work together. By tracing the connections and assembly order, you can better grasp the assembly process, ensuring that each part is installed correctly and functions as intended. Pay attention to any directional arrows or lines that indicate assembly sequences or operational flows.

Essential Tools for Maintenance

When performing regular upkeep, having the right instruments can significantly simplify the process and ensure effective results. Proper equipment not only helps you identify issues quickly but also makes repairs smoother, reducing potential wear over time. It’s crucial to be prepared with versatile and reliable gear to handle any task that may arise during the maintenance routine.

Basic Hand Tools: A sturdy set of screwdrivers, wrenches, and pliers will cover most of your needs. These tools allow you to disassemble, adjust, or tighten various components with precision.

Testing Equipment: Using diagnostic devices such as voltage testers or multimeters can help you pinpoint issues in electrical systems or confirm that components are functioning correctly.

Cleaning and Lubrication

Step-by-Step Repair Guide

In this guide, you will learn how to troubleshoot and fix common issues that can arise during the operation of your appliance. Whether you’re dealing with minor malfunctions or more complex technical problems, following the steps outlined here will help restore normal functionality without requiring expert assistance. The instructions provided are designed for ease of understanding, ensuring that even those with little technical experience can confidently carry out the necessary tasks.

Begin by identifying the issue through observation, such as unusual noises, lack of cooling, or inconsistent performance. Once the problem has been pinpointed, proceed with the corresponding solution outlined in the following steps. Make sure to turn off the power supply before starting any repairs to ensure safety.

For simple fixes like resetting or adjusting components, basic tools may be required, while more advanced solutions could involve replacing specific elements. Always refer to the manual or trusted sources for additional guidance if needed. With patience and careful attention, most issues can be resolved effectively.

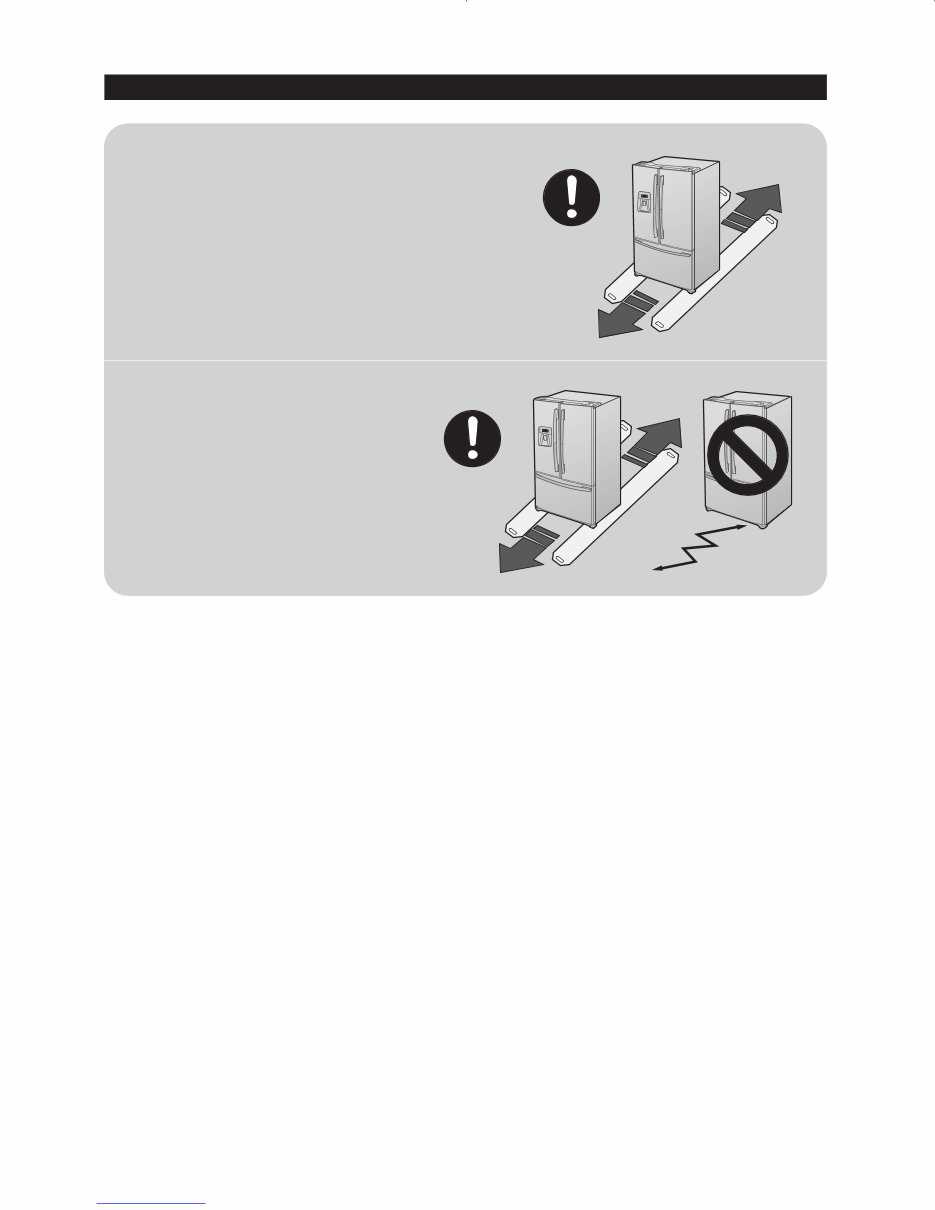

Safety Precautions When Repairing

When handling any maintenance or restoration tasks, it is crucial to follow essential safety measures to avoid accidents and ensure the process runs smoothly. Whether you are addressing a small issue or conducting a more complex fix, adhering to proper safety guidelines can prevent serious harm and costly mistakes.

- Always disconnect the appliance from any power sources before beginning any repair work.

- Ensure the work area is clean, dry, and free from any obstructions that could cause tripping or slipping.

- Wear appropriate protective gear, such as gloves and safety goggles, to shield yourself from potential hazards.

- Use tools that are in good condition and designed for the specific task you are performing.

-

Where to Find Replacement Parts

When dealing with appliance maintenance, finding appropriate substitutes for worn-out or malfunctioning components is crucial to ensuring smooth operation. Whether it’s a minor detail or a more significant element, knowing where to source these items can make all the difference in getting the device back to optimal condition.

Authorized Retailers

The best approach for securing authentic and reliable substitutes is to reach out to certified sellers. Many manufacturers work closely with trusted distributors, ensuring that the replacements you acquire will perfectly fit the model you are servicing. This guarantees both compatibility and long-term durability.

Online Marketplaces

Numerous online platforms specialize in providing high-quality components. These platforms allow users to browse through extensive catalogs and compare different options. To avoid counterfeit or poorly made items, always check customer reviews and look for verified sellers.

Comparing Rf267aers to Similar Models

When selecting an appliance for cooling and storage, it’s important to evaluate how various models perform in terms of efficiency, space optimization, and technology integration. Understanding the differences between various models allows users to make informed decisions based on their specific needs and preferences.

Performance and Features

Models in this category generally offer advanced cooling technologies and a variety of settings for optimal food preservation. Some models might have superior energy efficiency ratings, while others may offer more flexible shelving configurations or specialized compartments for different types of produce. Comparing these aspects can help highlight which design offers better performance in specific conditions.

Space and Design

The overall structure and layout are essential factors when choosing between similar options. While some designs prioritize internal capacity with wider storage areas, others may focus on fitting into compact kitchen spaces. Evaluating

Expert Tips for Efficient Repairs

When dealing with appliance maintenance, maximizing efficiency during the repair process is crucial. By following strategic methods and making informed decisions, you can ensure that the work is completed quickly and effectively, minimizing downtime and preventing potential future issues.

- Always begin by gathering the right tools and materials. This will save time and prevent interruptions during the process.

- Thoroughly inspect the equipment before starting any work. Identifying the root cause of the malfunction will help you address the problem more accurately.

- Make sure to follow step-by-step instructions tailored to your appliance, ensuring that each component is handled with care.

- Regularly maintain and clean your machine to avoid more significant repairs in the future, extending its lifespan.

- Consult professional resources or guides when faced with complex issues that require specialized knowledge.

By taking these precautions, you can enhance

Understanding Electrical Schematics

Electrical schematics are essential for anyone looking to grasp the inner workings of various devices. These illustrations serve as a universal language for technicians and engineers, showcasing how electrical components are interconnected to ensure smooth functionality. While at first glance they may seem intricate, understanding the basics can provide invaluable insight into troubleshooting and maintaining complex systems.

Key Symbols and Their Meanings

In any schematic, symbols represent the different elements of a system, such as wires, switches, and power sources. Recognizing these visual markers is crucial for interpreting how each component interacts with the others. By familiarizing yourself with these symbols, you can navigate through even the most complex diagrams with confidence.

How to Read Circuit Pathways

Circuit pathways illustrate the flow of electricity throughout a system

Maintenance Schedule for Longevity

To ensure the optimal performance and extended lifespan of your appliance, regular upkeep is essential. A consistent maintenance routine helps to prevent potential issues, ensuring that the equipment operates efficiently for many years. This section provides a recommended schedule for routine tasks that should be performed at specified intervals.

Maintenance Task Frequency Clean condenser coils Every 6 months Inspect seals and gaskets Every 3 months Check temperature settings Monthly Replace water filter Every 6 Resources for Further Learning

To gain a deeper understanding and explore more advanced information on the subject, there are numerous resources available online and in print. These materials provide a more comprehensive overview and can guide you in expanding your knowledge.

- Online Guides: Websites offer extensive tutorials and articles covering various technical details. These are ideal for step-by-step instructions and troubleshooting tips.

- Video Tutorials: Many platforms host educational videos that demonstrate processes visually, making complex topics easier to grasp.

- Manufacturer Support: Most producers provide official documents and FAQs to assist users. Access to official support ensures that you’re getting accurate and up-to-date information.

- Community Forums: Engaging in discussions with other users in online forums can offer practical advice and real-world solutions from experienced individuals.

- Books and Manuals: Printed resources still hold value for those seeking detailed explanations and structured