When it comes to maintaining trees and shrubs, a telescopic pruner can be an invaluable tool for both professionals and enthusiasts alike. These devices are designed to extend your reach, making it easier to trim branches without the need for ladders or scaffolding. A comprehensive knowledge of the various components involved can enhance the user experience and ensure optimal performance.

Within this section, we will delve into the intricate assembly of this specific model. Each element plays a crucial role in the overall functionality, from the cutting mechanisms to the power source. Understanding how these components interact will not only aid in efficient operation but also facilitate maintenance and repairs when necessary.

For those seeking to enhance their expertise, exploring the structure of the device will provide insights into its engineering and design. Familiarity with the assembly will empower users to troubleshoot issues and optimize their gardening tasks effectively.

This section highlights the essential characteristics and technical details of the equipment, providing users with insights into its performance and capabilities. Understanding these features is crucial for effective operation and maintenance, ensuring the tool meets the demands of various tasks.

Performance and Efficiency

- Engine Type: Powerful two-stroke engine designed for optimal torque and efficiency.

- Cutting Reach: Extended reach allows for accessing high branches without a ladder.

- Weight: Lightweight construction enhances maneuverability and reduces user fatigue.

Safety and Comfort

- Anti-Vibration System: Reduces vibrations during operation, improving user comfort.

- Ergonomic Handle: Designed for a secure grip, enhancing control and stability.

- Safety Features: Equipped with safety mechanisms to prevent accidental starts.

Understanding the Parts Breakdown

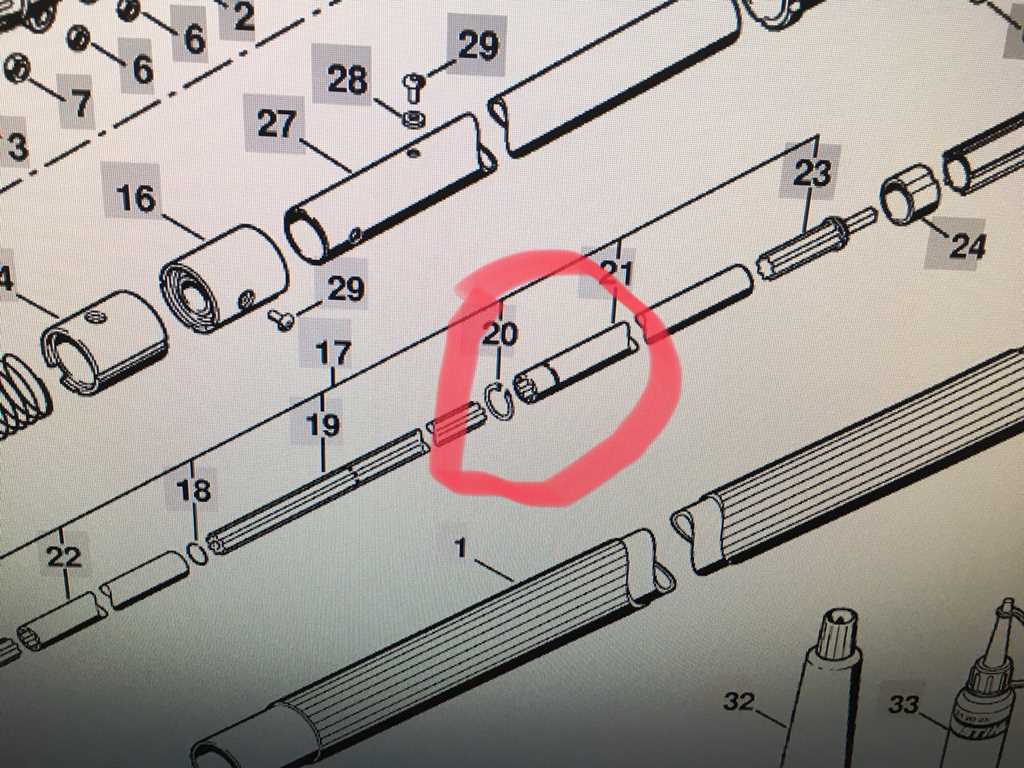

Comprehending the assembly of a cutting tool is essential for effective maintenance and repair. Each component plays a vital role in the overall functionality, ensuring optimal performance during operation. By analyzing the structure, users can identify areas that may require attention or replacement, facilitating a smoother user experience.

A typical construction consists of several key components, each serving distinct functions:

- Power Unit: This is the heart of the device, responsible for generating the necessary energy.

- Drive Mechanism: A crucial element that transfers power from the engine to the cutting attachment.

- Cutting Attachment: Designed to perform the actual cutting, this element varies in design depending on the intended use.

- Control Handle: Provides a means for the operator to manage the tool effectively, ensuring comfort and control during use.

- Safety Features: Essential components that prevent accidents and enhance user protection.

Familiarity with these elements allows for better troubleshooting and efficient maintenance practices. Understanding how each component interacts promotes more effective repairs and enhances overall longevity.

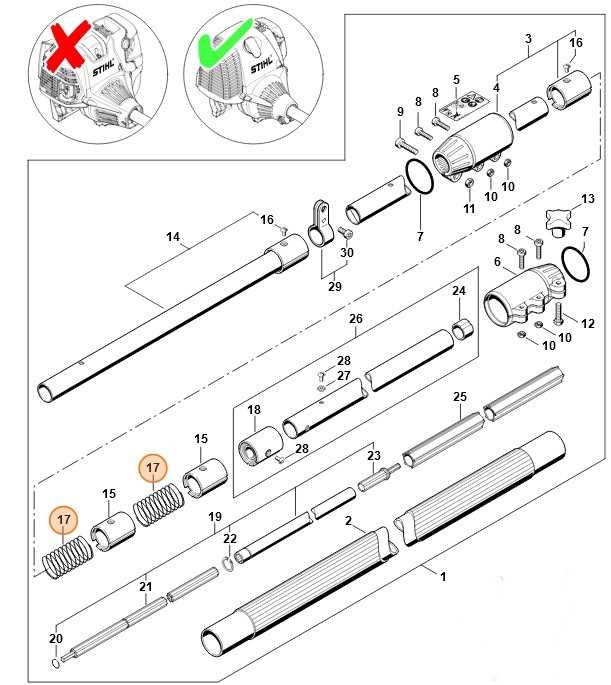

Main Components of the Pole Saw

The effective operation of a cutting tool relies on various essential elements that work together seamlessly. Understanding these key components enhances the user’s ability to maintain and troubleshoot the equipment efficiently.

Engine: The heart of the tool, this unit provides the necessary power for cutting. Its performance directly influences the overall efficiency of the mechanism.

Bar: This elongated piece serves as the foundation for the cutting mechanism. It supports the chain and guides it during operation, ensuring smooth and precise movements.

Chain: An integral part of the cutting assembly, this loop of sharp links slices through material. The design and sharpness of the links determine the effectiveness of the cutting action.

Handle: Providing grip and control, this component enables the user to maneuver the tool comfortably. Its ergonomic design is crucial for reducing fatigue during prolonged use.

Safety Features: Built-in mechanisms such as chain brakes and protective guards are vital for user safety. They help prevent accidents and injuries while operating the tool.

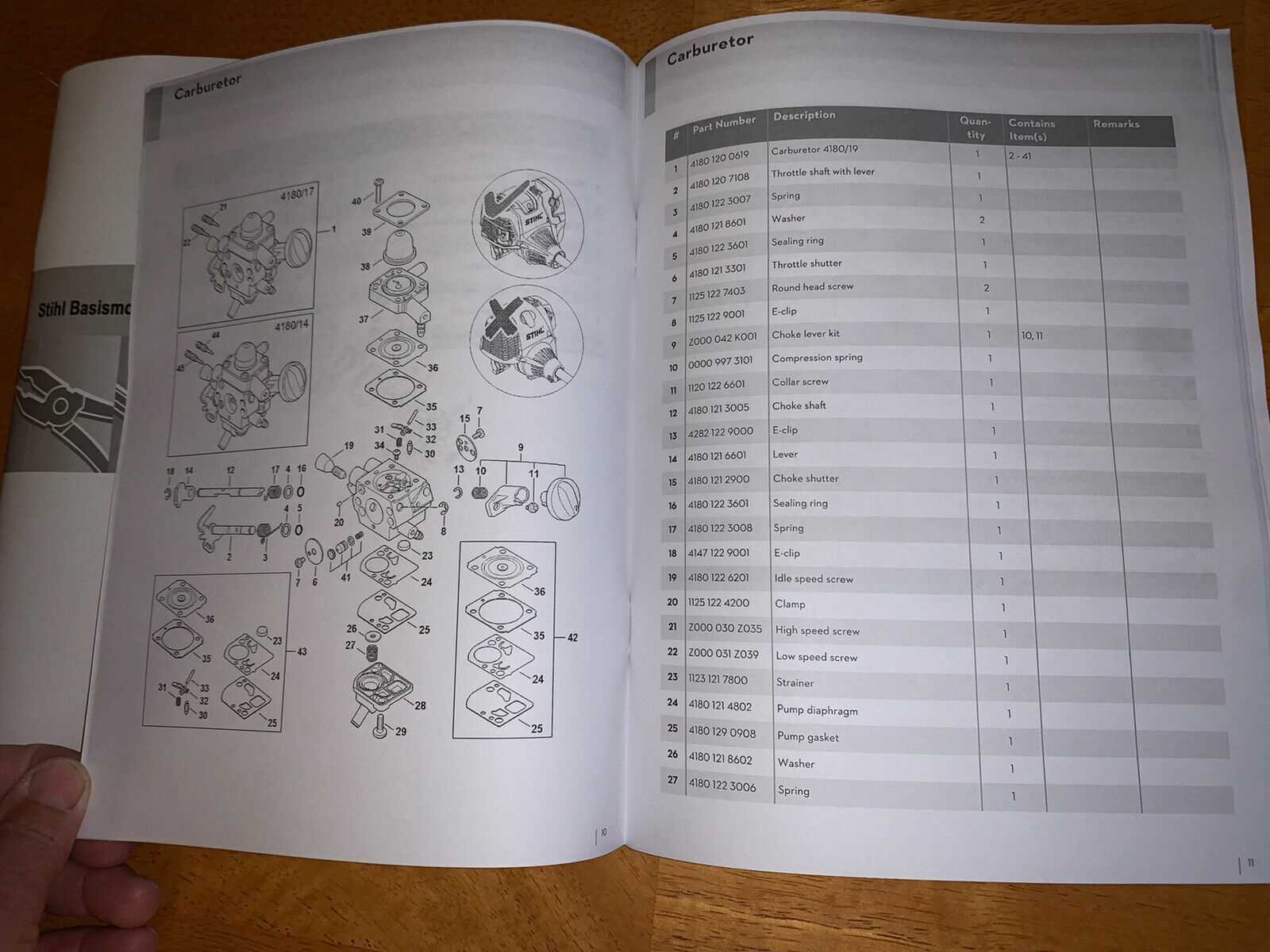

Fuel System: This system manages the intake and delivery of fuel to the engine. Proper maintenance of this component ensures reliable performance and efficiency.

By familiarizing oneself with these critical components, users can optimize the functionality of their cutting tools and enhance their overall experience.

Assembly and Disassembly Guide

This section provides a comprehensive overview of the steps required to assemble and disassemble a cutting tool effectively. Understanding these processes is essential for maintenance, repairs, and ensuring optimal performance of the equipment.

Before beginning, gather all necessary tools and components to streamline the procedure. Follow the instructions carefully to avoid damaging any parts or compromising safety.

Disassembly Steps

- Ensure the tool is powered off and disconnected from any power source.

- Use appropriate tools to remove any protective covers or casings.

- Carefully detach the main components, starting from the top and moving downward.

- Keep all screws and fasteners organized to facilitate reassembly.

- Inspect each part for wear or damage as you disassemble.

Assembly Steps

- Begin by ensuring all parts are clean and free from debris.

- Reattach components in the reverse order of disassembly, making sure to align all connections correctly.

- Secure each part with screws or fasteners as necessary.

- Reinstall any protective covers, ensuring they fit snugly.

- Conduct a final inspection to confirm everything is in place and properly secured.

Following these guidelines will help maintain the longevity and functionality of the equipment, allowing for efficient use during operation.

Maintenance Tips for Longevity

Proper care and upkeep of your equipment can significantly extend its lifespan and ensure optimal performance. Regular attention to detail will not only enhance functionality but also reduce the likelihood of unexpected failures.

Regular Cleaning: After each use, it is crucial to clean the tool thoroughly. Remove any debris, dirt, or sap that may have accumulated. This simple step helps prevent corrosion and maintains the overall integrity of the machinery.

Inspecting Components: Periodically check all elements for wear and tear. Look for signs of damage or loosening, especially in critical areas. Timely replacements or adjustments can prevent more significant issues down the line.

Lubrication: Ensure that moving parts are well-lubricated according to the manufacturer’s recommendations. Adequate lubrication minimizes friction, which can lead to premature wear and overheating.

Storage Conditions: Store the equipment in a dry, sheltered area to protect it from harsh weather conditions. Extreme temperatures and moisture can adversely affect its components and functionality.

Follow Usage Guidelines: Adhere to the operational guidelines provided by the manufacturer. Understanding the limits of your tool will help in preventing misuse and prolonging its life.

Common Issues and Solutions

When using a specialized trimming tool, users may encounter various challenges that can affect performance and efficiency. Understanding these issues and their solutions can help maintain optimal functionality and prolong the lifespan of the equipment.

Typical Problems

- Power Loss: Inadequate power can hinder cutting efficiency.

- Difficulty Starting: The device may struggle to initiate operation.

- Excessive Vibration: Increased vibrations can lead to user discomfort and affect control.

- Chain Tension Issues: Improper tension can cause chain slippage or damage.

Effective Solutions

- For power loss, check fuel levels and ensure the fuel mixture is correct.

- To address starting difficulties, inspect the ignition system and clean the air filter.

- If excessive vibration occurs, ensure all screws and bolts are tight and consider replacing worn components.

- For chain tension problems, adjust the tension according to the manufacturer’s guidelines and regularly check for wear.

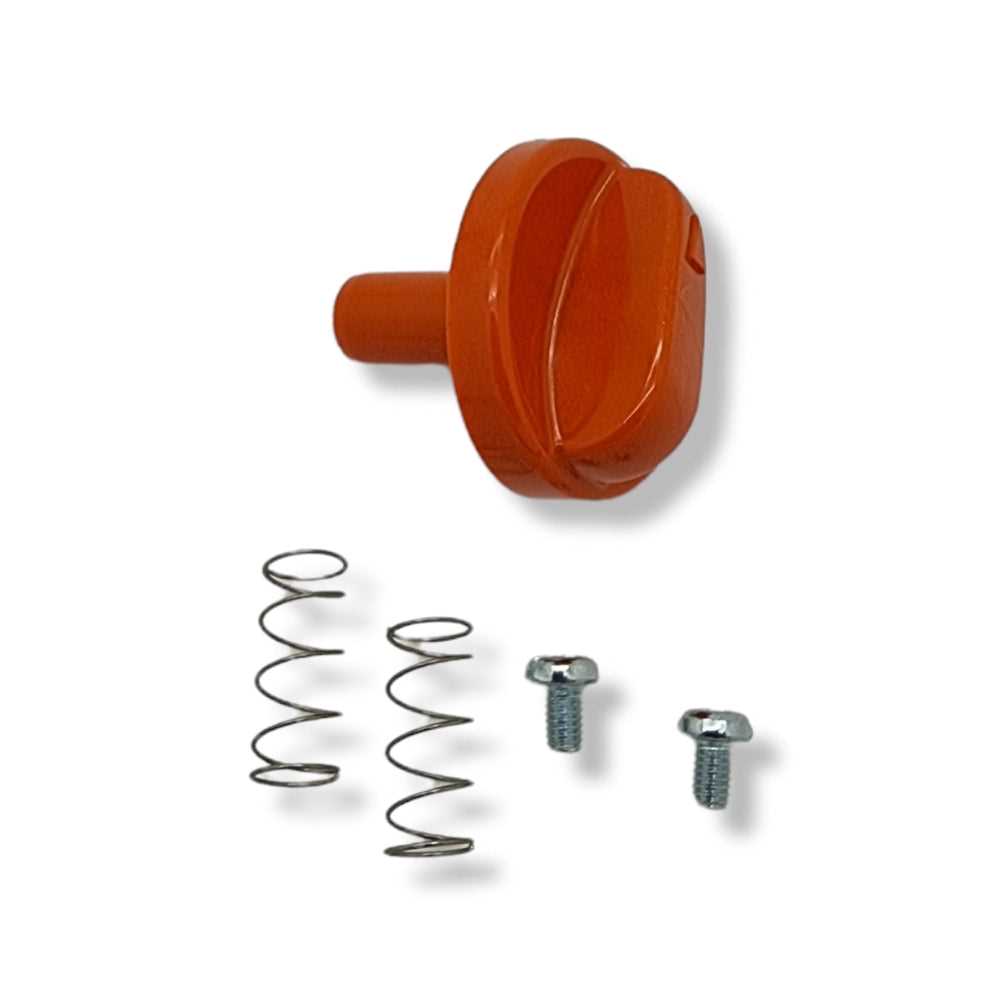

Replacement Parts Availability

Access to essential components is crucial for maintaining the functionality of your equipment. Ensuring that replacement elements are readily obtainable not only extends the life of your tool but also enhances its performance. Understanding where to source these components can save time and effort, providing peace of mind for users.

Authorized Dealers and Retailers

Finding certified sellers is the most reliable way to acquire authentic components. These vendors typically stock a comprehensive selection of replacements, ensuring compatibility with your specific model. Engaging with authorized retailers often guarantees access to the latest components, along with valuable customer support and expert advice.

Online Marketplaces

Numerous online platforms offer a vast range of replacement options. Websites specializing in tool accessories frequently feature customer reviews and ratings, assisting in selecting quality items. While shopping online, it’s advisable to verify the credibility of the seller and check return policies to avoid complications.

Upgrades and Accessories for Efficiency

Enhancing the performance and versatility of your cutting tool can significantly improve productivity and ease of use. A variety of modifications and supplementary components are available to ensure that you get the most out of your equipment.

Consider the following upgrades and accessories to optimize efficiency:

- Extended Reach Attachments: These allow users to access higher branches without the need for ladders, making tasks safer and more efficient.

- Lightweight Harnesses: A well-designed harness can reduce fatigue, enabling longer periods of operation without discomfort.

- Enhanced Cutting Blades: Upgrading to high-performance blades can lead to cleaner cuts and reduced maintenance time.

- Lubrication Systems: Automatic or improved manual lubrication systems ensure that moving parts remain in optimal condition, reducing wear and tear.

- Storage Solutions: Custom storage options keep tools organized and accessible, minimizing downtime when switching between tasks.

By investing in these enhancements, operators can achieve greater efficiency, ensuring that every job is completed with precision and ease.

Comparing Models in the Series

When evaluating various options within a specific product line, it’s essential to consider the unique features and capabilities each model offers. This approach helps users make informed decisions based on their specific needs and preferences.

The following table highlights key characteristics of different models in the series, allowing for a straightforward comparison:

| Model | Engine Power (cc) | Weight (lbs) | Bar Length (inches) | Fuel Capacity (oz) |

|---|---|---|---|---|

| Model A | 30 | 10.5 | 10 | 12 |

| Model B | 25 | 9.5 | 8 | 10 |

| Model C | 40 | 12 | 12 | 14 |

By analyzing the information in the table, users can better understand how each model stacks up against the others, facilitating a choice that aligns with their operational requirements.

User Reviews and Experiences

This section aims to highlight the feedback and insights shared by users regarding their experiences with a specific outdoor tool designed for cutting high branches. User reviews can provide valuable information about the performance, durability, and ease of use of this equipment, helping potential buyers make informed decisions.

Overall Satisfaction

Many users express a high level of satisfaction with the tool’s efficiency and functionality. One user noted that the equipment significantly reduced the time and effort required to maintain their garden. Others appreciated its lightweight design, making it easier to handle during extended use. The combination of power and convenience has led to positive remarks about its ability to tackle various cutting tasks with ease.

Common Challenges

While the overall feedback is favorable, some users have reported challenges related to maintenance and accessibility of certain components. For instance, a few individuals mentioned that the assembly process could be complex and time-consuming. Additionally, users emphasized the importance of regular upkeep to ensure optimal performance. Despite these challenges, the general consensus remains that the benefits of using this tool far outweigh any minor drawbacks.