Understanding the essential elements of a system designed to manage vehicle stability and smoothness involves a detailed examination of its structural components. These integral parts play crucial roles in maintaining equilibrium and absorbing road-induced vibrations, ensuring optimal performance and passenger comfort.

Exploring the anatomy of these pivotal components unveils their intricate interactions within the suspension setup, highlighting their contributions to vehicle dynamics and handling. By delving into these components, we gain insights into the functional synergy that enhances driving experience and safety.

Understanding Leaf Spring Components

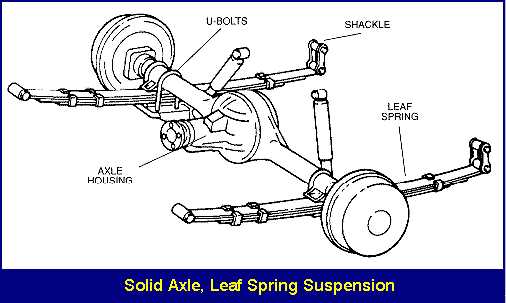

Suspension systems rely on various interconnected elements to provide stability, load-bearing capacity, and smooth movement. These systems are designed to manage weight distribution and minimize vibrations during vehicle operation. The structure we are exploring includes several key elements that ensure the proper functioning of a vehicle’s suspension. Each component plays a role in maintaining balance and providing the necessary support for different loads and road conditions.

Primary Components

- Main support structure: This is the backbone that holds the entire system together, connecting the vehicle’s frame to the axles.

- Attachment brackets: These serve as the linking points, securing the system to the vehicle’s chassis, ensuring proper alignment and stability.

- Cushioning elements: Designed to absorb impacts, they reduce the vibrations and shocks transferred to the vehicle, ensuring a smoother ride.

Additional Features

- Fastening devices: These secure the different elements together, maintaining the integrity of the system under stress.

- Load distribution points: These sections help in distributing weight evenly across the system, preventing damage and ensuring longevity.

Overview of Leaf Spring Functionality

The suspension system in vehicles plays a crucial role in ensuring stability, comfort, and handling. One key component of this system consists of a series of flexible elements that provide support and absorb shocks. This arrangement is designed to enhance the driving experience by maintaining contact between the wheels and the road surface, even under varying loads and conditions.

These flexible components work by flexing under pressure, distributing weight evenly across the system. As the vehicle encounters bumps or uneven terrain, they compress and expand, effectively mitigating impacts. This functionality not only improves ride comfort but also prolongs the lifespan of other suspension elements by minimizing stress and wear.

Additionally, the design contributes to the overall balance and stability of the vehicle. By allowing controlled movement, it helps maintain proper alignment of the wheels, which is vital for handling and safety. In essence, the system serves as a vital interface between the vehicle’s frame and the road, ensuring a smooth and stable journey.

In summary, this crucial component provides both support and flexibility, playing an indispensable role in the overall performance of a vehicle’s suspension system.

Common Leaf Spring Materials Used

The choice of materials for suspension components significantly influences their performance, durability, and overall functionality. Different substances offer varying benefits, making it essential to understand their characteristics to select the most suitable option for specific applications.

Steel is the most prevalent material, known for its excellent strength and resilience. This alloy often undergoes heat treatment to enhance its properties, ensuring longevity under stress.

Composite materials, including fiberglass and carbon fiber, are gaining popularity due to their lightweight nature and resistance to corrosion. These substances provide an alternative that can improve vehicle efficiency while maintaining effective support.

Aluminum is another option, offering a good strength-to-weight ratio. While it may not be as robust as steel, its lower weight can contribute to overall vehicle performance, especially in racing applications.

Ultimately, the choice of material plays a crucial role in achieving optimal performance, and understanding the benefits of each can lead to better decision-making in design and engineering.

Types of Leaf Spring Designs

There are various configurations used in suspension systems to provide support and enhance vehicle performance. Each design serves specific purposes and is tailored for different applications, reflecting the diversity in engineering solutions.

| Design Type | Description | Applications |

|---|---|---|

| Multileaf | Consists of multiple layers stacked together, offering increased strength and load capacity. | Heavy-duty trucks, commercial vehicles |

| Monoleaf | Made from a single piece, providing a lightweight and compact option with good flexibility. | Light trucks, passenger cars |

| Variable Rate | Features a changing thickness along its length, allowing for better load management. | Performance vehicles, off-road applications |

| Composite | Constructed from advanced materials, offering corrosion resistance and reduced weight. | Modern vehicles, sports cars |

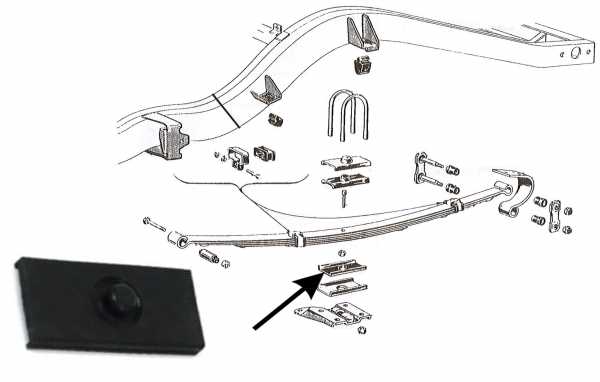

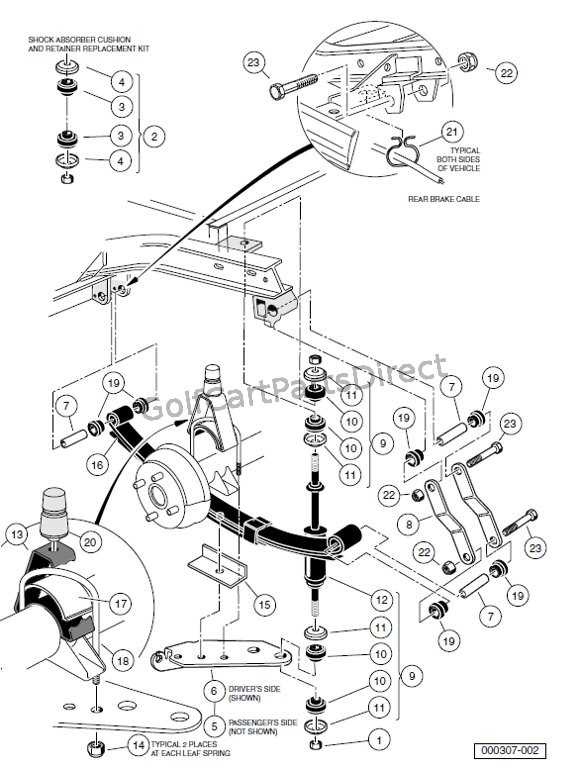

Leaf Spring Installation Process

Properly installing suspension components is crucial for vehicle performance and safety. This guide outlines the steps to ensure a secure and efficient installation, promoting optimal handling and comfort on the road.

Preparation is key before beginning the installation. Gather all necessary tools, including wrenches, jacks, and safety equipment. Ensure the vehicle is parked on a flat surface and the wheels are securely chocked.

Next, remove the old suspension elements. Begin by raising the vehicle and supporting it on jack stands. Carefully detach the existing components, taking note of their arrangement for reference during reinstallation.

After removal, install the new components in the reverse order. Align each piece correctly, making sure to follow manufacturer specifications for torque settings. It’s vital to ensure that everything fits snugly to avoid future issues.

Finally, conduct a thorough inspection once installation is complete. Check all connections and components for tightness and alignment. Test drive the vehicle at low speeds to verify proper operation and make adjustments if necessary.

Maintaining Leaf Spring Durability

Ensuring the longevity of these critical components is essential for optimal vehicle performance. Regular care and attention can significantly enhance their lifespan and functionality. Here are some key practices to consider.

Regular Inspections

- Check for signs of wear and tear.

- Look for cracks or deformation in the structure.

- Ensure all connections are secure.

Proper Lubrication

- Apply lubricant to reduce friction between elements.

- Use high-quality grease suitable for heavy loads.

- Reapply lubricant at regular intervals.

By following these steps, you can greatly enhance the resilience of these crucial components and ensure a smooth driving experience.

Symptoms of Leaf Spring Wear

Identifying deterioration in suspension components is crucial for maintaining vehicle performance and safety. As these elements endure constant stress, their wear can manifest in various noticeable signs, affecting ride quality and handling.

| Symptom | Description |

|---|---|

| Unusual Noises | Clunking or squeaking sounds when driving over bumps may indicate degradation. |

| Poor Handling | Increased swaying or difficulty in steering can signify compromised stability. |

| Uneven Tire Wear | Irregular tread patterns on tires often suggest alignment issues due to worn components. |

| Lowered Vehicle Height | Excessive sagging may indicate a loss of support, impacting ground clearance. |

| Increased Bouncing | Excessive up-and-down motion after hitting bumps points to a lack of control. |

Benefits of Upgrading Leaf Springs

Enhancing your vehicle’s suspension system can lead to significant improvements in performance and comfort. By investing in higher-quality components, you can experience better handling, increased stability, and improved load-carrying capacity, all of which contribute to a smoother ride.

One of the ultimate advantages of this upgrade is the enhanced durability. Modern alternatives are designed to withstand greater stress and wear, reducing the frequency of maintenance and replacements. This not only saves you money over time but also boosts your vehicle’s reliability.

Furthermore, improved suspension components can elevate your vehicle’s overall appearance. A more balanced stance not only enhances aesthetics but also optimizes weight distribution, leading to improved fuel efficiency. Ultimately, these enhancements result in a more enjoyable driving experience.

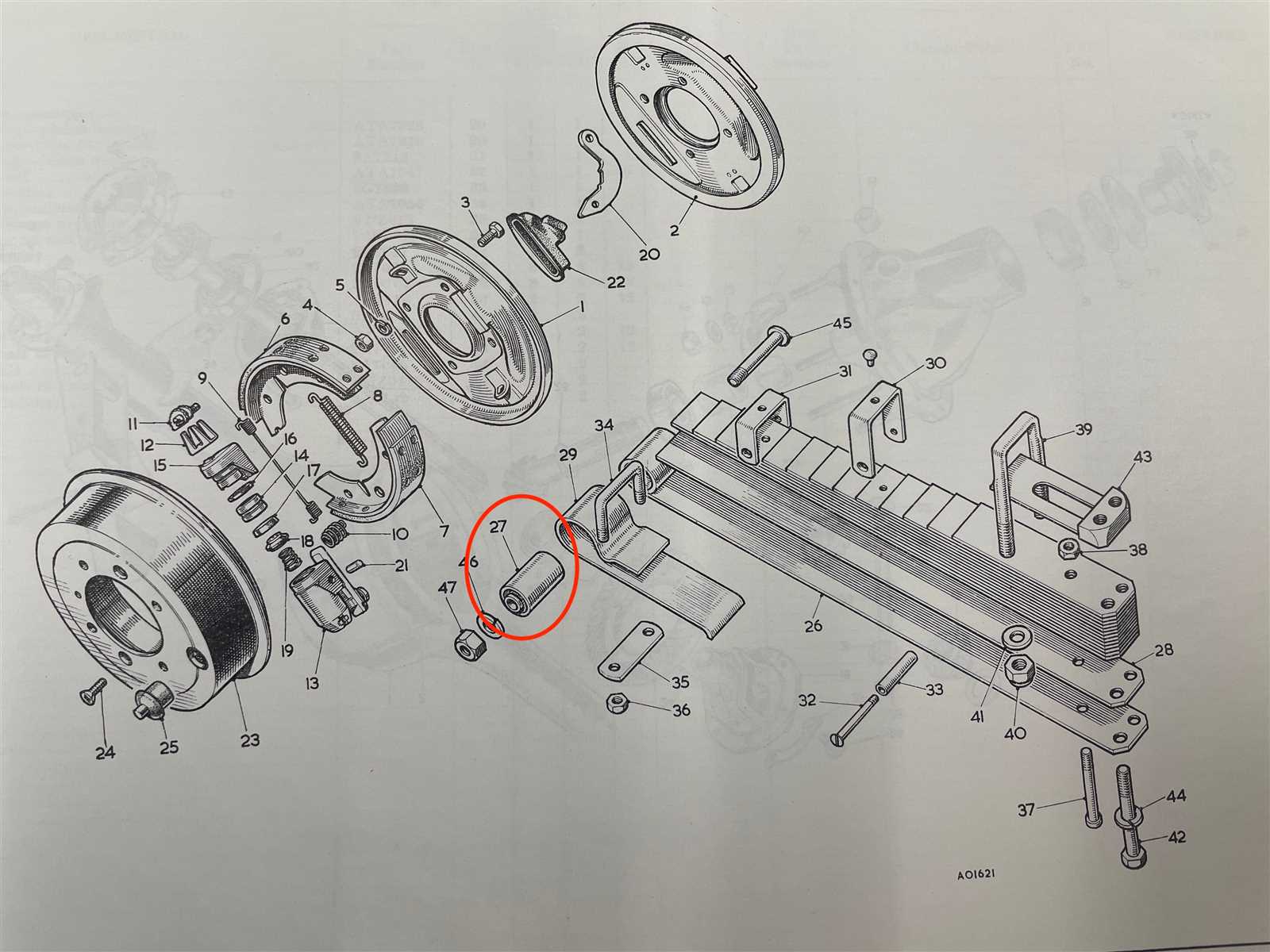

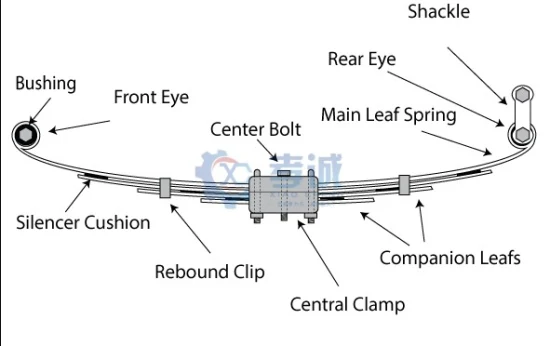

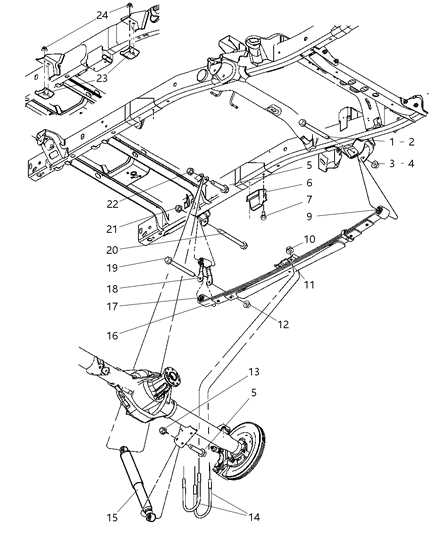

Identifying Leaf Spring Parts

Understanding the various components of a suspension system is crucial for maintenance and repair. Each element plays a specific role, contributing to the overall functionality and performance of the vehicle. Recognizing these elements can help in diagnosing issues and ensuring optimal operation.

Main Components

The primary components include the main arch and the additional elements that support the load. These elements work in tandem to absorb shocks and maintain stability during movement. Knowing their arrangement enhances comprehension of the system’s dynamics.

Support and Attachments

Critical attachments like bushings and shackles ensure the connections are secure and allow for necessary flexibility. Identifying these features can facilitate efficient repairs and replacements, ultimately leading to improved safety on the road. Understanding the interaction between these elements is key to maintaining the integrity of the entire assembly.

Comparing Leaf Springs to Other Systems

This section explores the various suspension systems used in vehicles, highlighting their unique characteristics and advantages. By examining these alternatives, we can understand how different technologies meet the demands of performance, comfort, and durability.

Conventional Coil Systems are often favored for their superior ride quality and flexibility. They allow for greater suspension travel, making them suitable for applications where comfort is paramount. However, their design can lead to increased complexity and maintenance needs.

Air Suspension offers an innovative approach by utilizing air-filled components. This system excels in adjustability, allowing users to modify ride height and firmness based on load conditions. While providing excellent comfort, it may be more prone to failures due to leaks or punctures.

Hydraulic Systems, found in heavy-duty applications, provide robust support and stability. They are ideal for high loads, but their weight and complexity can limit their use in lighter vehicles.

Ultimately, each system presents its own set of benefits and drawbacks, making it essential to delve into specific requirements when selecting the appropriate solution for any vehicle. Understanding these differences aids in making informed decisions for optimal performance and reliability.

Leaf Spring Repair Techniques and Tips

Maintaining the integrity of suspension components is crucial for vehicle performance and safety. Understanding various repair methods and practical tips can help extend the lifespan of these elements and ensure a smoother ride. This section delves into effective techniques for addressing common issues that may arise with these vital components.

Common Issues and Solutions

Over time, these components may experience wear and tear, leading to various problems such as sagging or cracking. Identifying the issue early is key. For sagging, consider replacing worn-out bushings or using a shim kit to restore height. Cracks may require welding or complete replacement, depending on severity.

Maintenance Tips

Regular inspections are essential to catch potential issues before they escalate. Lubricate moving parts to minimize friction and wear. Keeping these components clean from debris and rust will also contribute to their longevity. If repairs are necessary, always use high-quality materials to ensure durability and performance.