When it comes to home maintenance, knowing how essential appliances operate is crucial for any homeowner. The internal design of these machines often consists of intricate components that work together seamlessly, ensuring the smooth functioning of everyday tasks. Grasping how each part fits into the system can empower users to perform minor fixes and improve efficiency.

Exploring the core elements of these devices not only enhances understanding but also allows individuals to recognize potential issues early. By becoming familiar with the inner workings, one can take proactive steps in ensuring the longevity of their machine, minimizing downtime and repair costs.

In this guide, we will take a closer

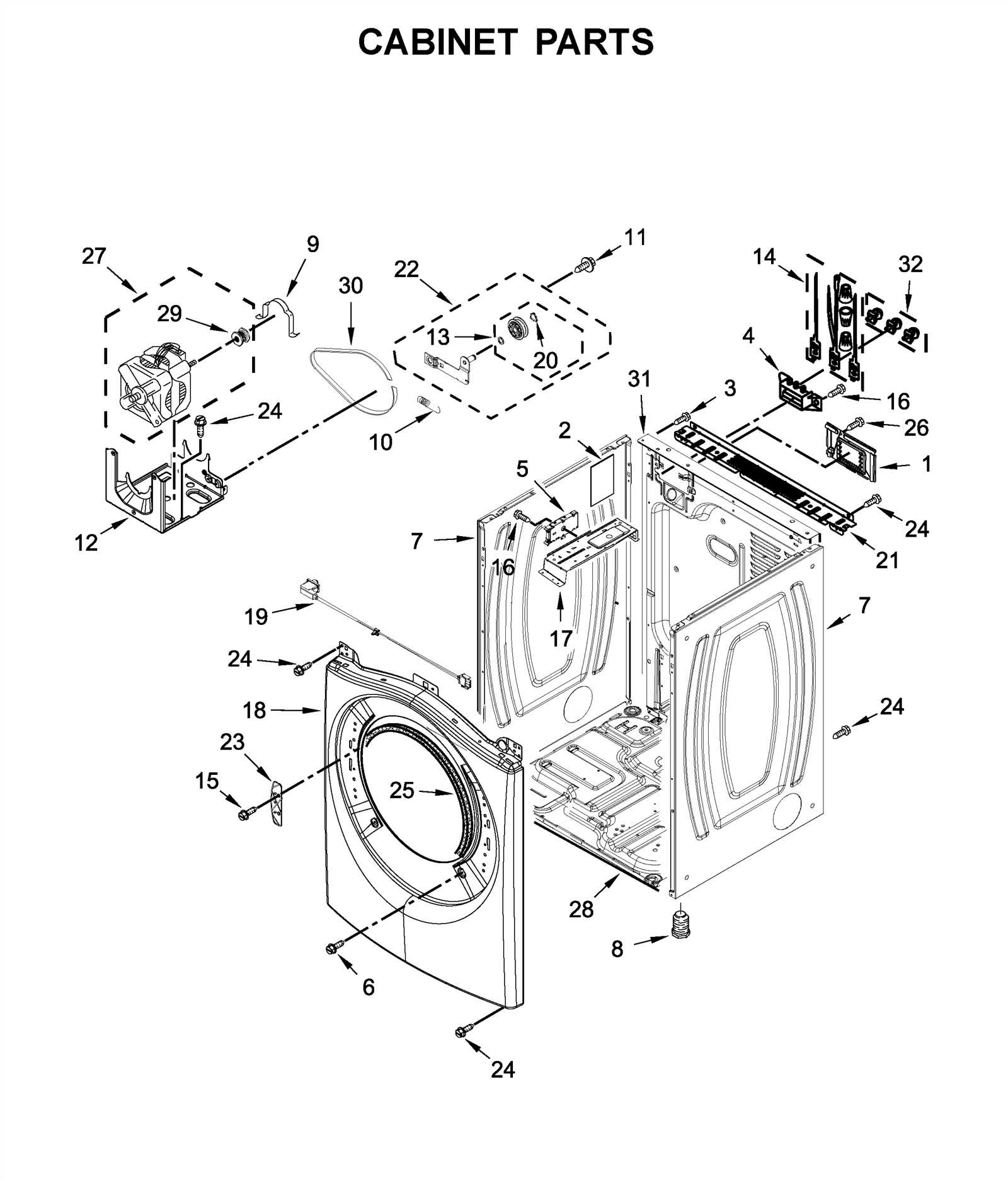

Essential Components of a Cabrio Dryer

The core mechanisms of a modern drying machine consist of various crucial elements that ensure efficient operation. Each component plays a significant role in maintaining the device’s performance, contributing to the safe and smooth drying of garments.

Key Mechanical Parts

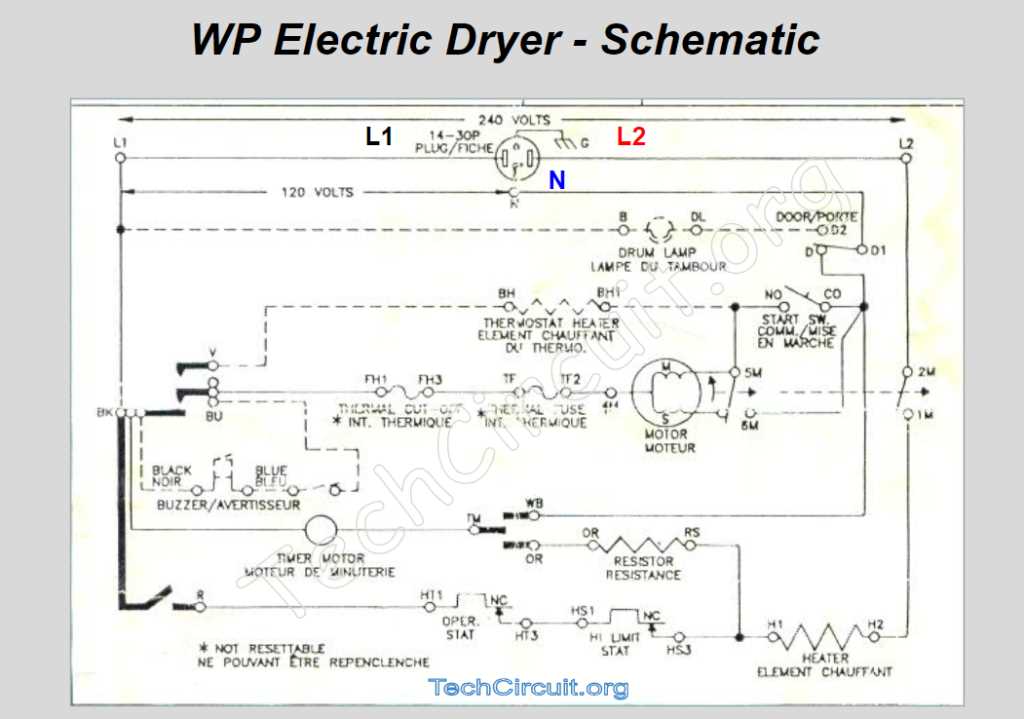

- Heating element: This unit provides the necessary warmth for the drying process, regulating temperature for different fabric types.

- Blower fan: It circulates hot air inside the drum, ensuring even drying by maintaining constant airflow.

- Drum: The rotating section where clothes are placed, responsible for tumbling garments to promote thorough drying.

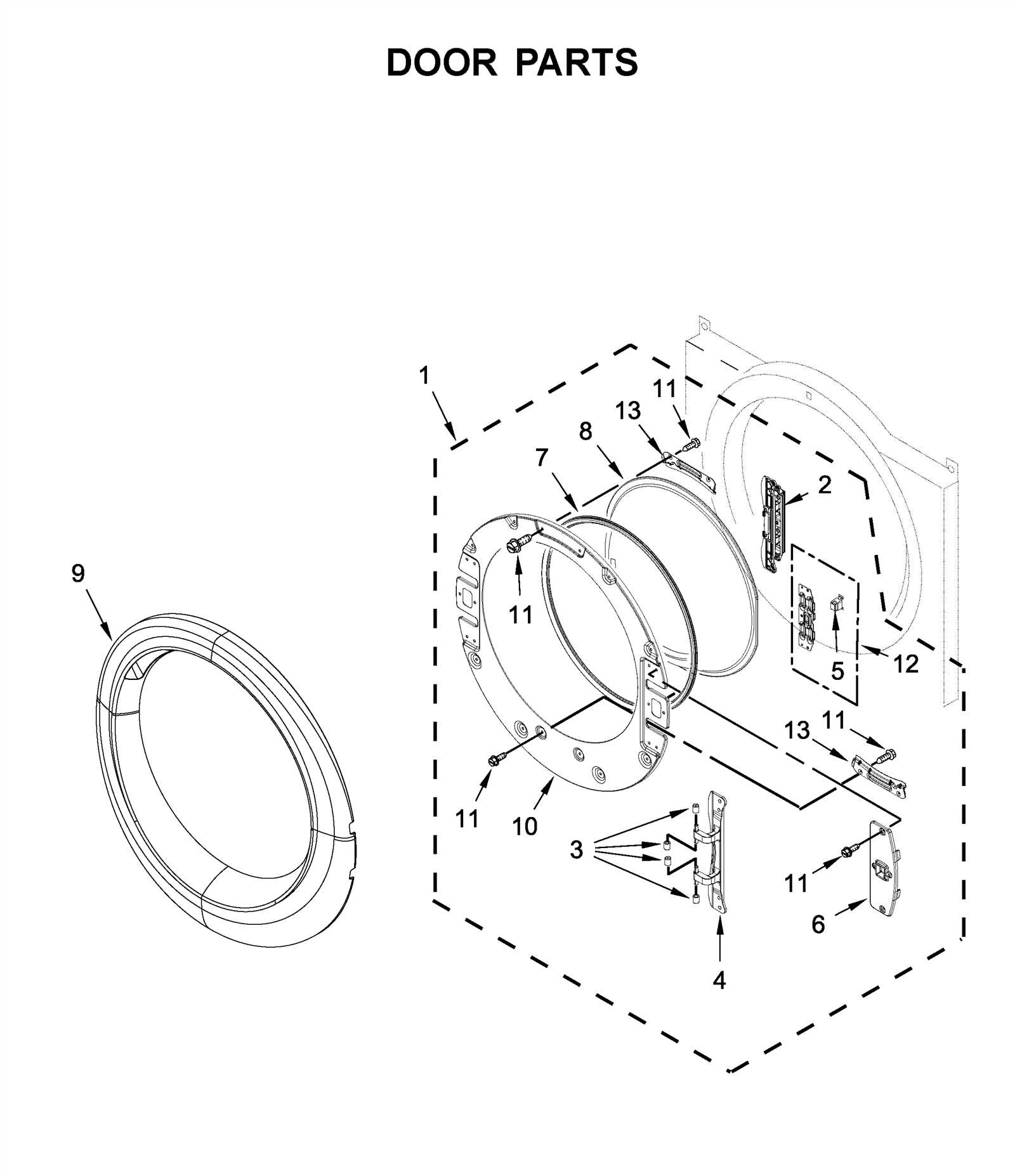

Understanding the Control Panel Layout

The control panel on modern drying machines offers users a range of options to customize the drying process. It is designed with clear and accessible buttons that help manage settings effectively. By understanding the layout, you can navigate various functions with ease and optimize your laundry experience.

Main Buttons and Their Functions

The central section of the panel usually includes key options for selecting cycles, adjusting temperature, and setting the timer. These controls allow for precise customization, depending on the fabric type and drying preferences.

Additional Features and Indicators

In addition to the main controls, the panel may include additional indicators for monitoring cycle status, temperature, or system alerts. These features ensure that you stay informed about the machine’s performance throughout the process.

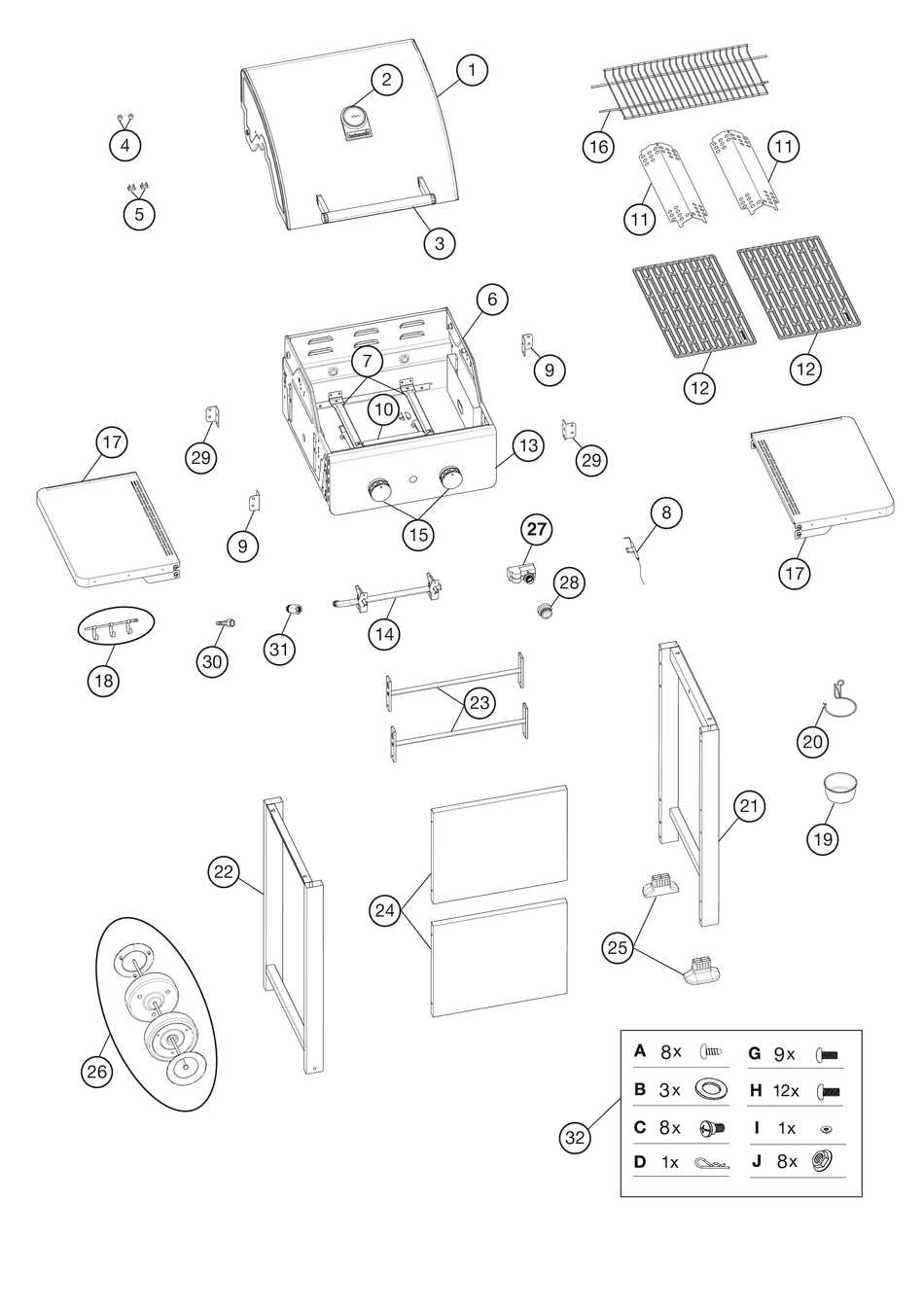

| Component | Description |

|---|---|

| Belt | A flexible loop that transfers motion from the motor to the drum, enabling rotation. |

| Pulley | A wheel on which the belt rides, directing and guiding its movement for efficient operation. |

| Idler Pulley | A tensioning component that helps maintain appropriate tension on the belt, preventing slippage. |

| Motor Pulley | The part connected to the motor that drives the belt, initiating the movement. |

Understanding the roles and interactions of these components is vital for effective troubleshooting and maintenance. Regular checks can help ensure that the assembly operates smoothly, extending the lifespan of the appliance.

Maintenance Tips for Sensors and Moisture Detection

Ensuring optimal performance of moisture detection mechanisms is essential for efficient operation. Proper care and regular checks can prevent issues and extend the lifespan of these critical components.

Regular Cleaning

Dust and lint accumulation can hinder the effectiveness of moisture sensors. It is advisable to clean these sensors periodically to maintain their sensitivity. Use a soft cloth or a vacuum attachment to remove debris gently. Avoid using harsh chemicals that could damage the components.

Check Connections

Loose or corroded connections can lead to inaccurate readings. Regularly inspect the wiring and connectors associated with the moisture detection system. Ensure they are securely attached and free from corrosion to guarantee reliable performance.

| Tip | Frequency | Action |

|---|---|---|

| Cleaning Sensors | Every 3 months | Use a soft cloth or vacuum attachment |

| Inspect Connections | Every 6 months | Check for looseness or corrosion |

| Function Test | Annually | Run a moisture detection test to ensure accuracy |

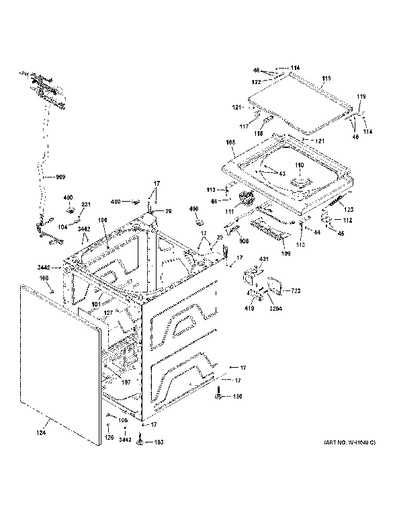

Examining the Blower Wheel and Airflow System

The blower wheel and airflow mechanism play a crucial role in ensuring efficient operation of the appliance. Understanding these components helps in identifying potential issues and maintaining optimal performance. A well-functioning blower wheel is essential for proper circulation of air, which directly impacts drying efficiency.

Blower Wheel Functionality

The blower wheel is responsible for generating airflow within the unit. Its design and operation significantly influence how effectively moisture is removed from clothing. Key aspects include:

- Material composition for durability

- Shape and size affecting airflow rate

- Rotation speed that determines air movement

Airflow Path and Considerations

A clear airflow path is essential for the appliance’s performance. Blockages or restrictions can lead to inefficiencies. Important considerations include:

- Inspecting ducts for debris or lint buildup

- Ensuring seals are intact to prevent leaks

- Regular maintenance to avoid airflow restrictions