The functionality of small marine engines relies heavily on the intricate network of individual components working harmoniously. Each part plays a critical role in ensuring the engine operates efficiently and reliably. A thorough examination of these components can significantly enhance your understanding of how the entire system functions.

For enthusiasts and professionals alike, visual aids can be invaluable tools. These illustrations provide clarity and insight, allowing for easier identification and understanding of various engine elements. By studying these resources, one can gain a better grasp of the mechanics involved and how to maintain and troubleshoot effectively.

Whether you are repairing a malfunctioning unit or simply seeking to expand your knowledge, exploring the various sections of the engine can be enlightening. Each component contributes uniquely to the overall performance, and recognizing their functions can lead to more informed decisions regarding maintenance and repair.

Mercury 3.5 HP Outboard Overview

This section provides a comprehensive look at a compact and efficient marine engine designed for small boats and recreational use. It highlights the engine’s performance characteristics, unique features, and overall functionality. The model is particularly favored for its reliability and ease of use, making it an ideal choice for both novice and experienced boaters.

Key Features

The engine boasts a lightweight design, contributing to its portability and maneuverability. Its fuel efficiency is notable, ensuring longer trips without frequent refueling. Additionally, the simplicity of its controls enhances the user experience, allowing for seamless operation on the water.

Performance and Applications

Known for its solid performance, this engine is suitable for various water activities, from leisurely fishing trips to recreational cruising. Its versatility ensures that it can adapt to different boating needs, making it a popular choice among marine enthusiasts.

Common Issues with Mercury Outboards

Many users of portable marine engines encounter a variety of challenges that can affect performance and reliability. Understanding these frequent problems can help owners diagnose issues early and maintain their equipment more effectively.

One common challenge is starting difficulties, which can stem from various factors, including fuel quality, battery condition, or ignition system faults. Additionally, overheating is another prevalent issue, often caused by inadequate cooling or blocked waterways.

Fuel-related complications, such as clogging of filters and carburetors, can also hinder operation. Regular maintenance can prevent these issues, but owners should remain vigilant for signs of wear and tear.

| Issue | Possible Causes | Solutions |

|---|---|---|

| Starting Difficulties | Poor fuel quality, battery issues, ignition failure | Check fuel, inspect battery and connections, test ignition |

| Overheating | Blocked cooling system, low coolant levels | Inspect water intake, ensure proper coolant levels |

| Fuel Issues | Clogged filters, dirty carburetors | Replace filters, clean carburetors regularly |

Understanding Outboard Engine Components

Grasping the essentials of marine propulsion systems is vital for any boating enthusiast. These engines consist of various elements, each playing a crucial role in ensuring efficient operation and performance. Familiarity with these components can enhance maintenance and troubleshooting efforts, leading to a better boating experience.

At the core of any marine engine are several key elements that work harmoniously. Below is a breakdown of these fundamental components:

| Component | Description |

|---|---|

| Powerhead | The central unit housing the engine, including the cylinders and fuel system. |

| Lower Unit | This part contains the gear system and propeller, facilitating movement through water. |

| Fuel System | Responsible for delivering fuel to the engine, ensuring optimal combustion. |

| Cooling System | Maintains the engine’s temperature by circulating water to prevent overheating. |

| Ignition System | Generates the spark necessary to ignite the fuel-air mixture within the cylinders. |

Understanding these components lays the foundation for effective engine management and repairs. By being aware of how each part functions, operators can ensure their vessels remain reliable and enjoyable on the water.

Maintenance Tips for Your Mercury Engine

Proper upkeep is essential for ensuring the longevity and performance of your marine propulsion system. Regular maintenance not only enhances efficiency but also helps in preventing potential issues that could lead to costly repairs. Here are some key strategies to keep your engine running smoothly.

- Regular Inspections: Conduct frequent checks of all essential components to identify any wear or damage. Pay close attention to hoses, cables, and seals.

- Oil Changes: Change the lubricant according to the manufacturer’s recommendations. Fresh oil helps maintain optimal performance and reduces friction.

- Cooling System Maintenance: Ensure the cooling system is functioning properly. Clean the water intake screens and inspect the thermostat for any blockages.

- Fuel System Care: Use high-quality fuel and consider adding a fuel stabilizer to prevent degradation. Regularly check the fuel filter and replace it as needed.

- Battery Management: Keep the battery charged and terminals clean. Inspect for any corrosion that could affect performance.

By following these maintenance guidelines, you can ensure that your engine operates at peak performance for years to come. Consistent care not only extends the life of the engine but also enhances your overall boating experience.

Finding Replacement Parts Easily

Locating suitable components for marine engines can often be a daunting task. With a plethora of options available, knowing where to start is crucial. This section aims to provide effective strategies for sourcing essential replacements efficiently, ensuring you can get back to your water adventures without unnecessary delays.

One of the most effective methods is to utilize online platforms that specialize in marine equipment. These sites often feature comprehensive catalogs and user-friendly search functions, allowing you to narrow down your search by specifying the type of engine or component needed. Here are some tips to enhance your search:

| Tip | Description |

|---|---|

| Check Manufacturer Websites | Many manufacturers offer direct sales or links to authorized dealers, ensuring authenticity and quality. |

| Utilize Online Marketplaces | Websites like eBay or Amazon provide a vast selection of new and used items at competitive prices. |

| Join Online Forums | Participating in marine community forums can provide insights on where to find components and recommendations from experienced users. |

| Visit Local Dealers | Local marine supply stores often have knowledgeable staff who can assist in finding the right components for your needs. |

By employing these strategies, you can streamline your search process and ensure that you find the necessary components swiftly and effectively.

Identifying Engine Model Differences

Understanding the variations between different engine models is crucial for effective maintenance and troubleshooting. Each model may have distinct features, specifications, and configurations that can significantly impact performance and compatibility with accessories. Recognizing these differences ensures that owners can properly identify their specific unit and obtain the right components or service information.

Key Variations in Engine Models

One of the primary differences between engine models lies in their design characteristics. For example, some may feature variations in horsepower, cooling systems, or fuel types. Additionally, the placement of specific components, such as carburetors and exhaust outlets, can vary, affecting overall performance and maintenance requirements. It’s essential to familiarize oneself with these attributes to ensure proper functioning.

Identification Techniques

To accurately identify a particular engine model, owners can refer to the serial number and model identification plate typically found on the housing. This information provides vital details about the unit, including its manufacturing year and specific features. Moreover, consulting the manufacturer’s documentation can offer insights into any unique attributes associated with different models, aiding in accurate recognition.

Understanding Mercury’s Part Numbers

Familiarizing oneself with the numerical identifiers used in engine components is essential for ensuring proper maintenance and repairs. These codes serve as a systematic way to categorize various elements, facilitating easier identification and ordering. Each code is designed to convey specific information about the item, making it simpler for users to locate the correct replacements.

Structure of the Numerical Codes

The structure of these identifiers typically includes a combination of letters and numbers that represent different characteristics of the components. The initial letters often indicate the category of the item, while the subsequent numbers provide additional details such as size, model year, or design revisions. Understanding this framework is crucial for anyone looking to work with these components effectively.

Importance of Accurate Identification

Using the correct numerical identifiers is vital for ensuring compatibility and performance. Incorrect items can lead to inefficiencies or even damage, making it imperative for users to double-check these codes before making a purchase. Knowledge of how to read and interpret these identifiers can save both time and resources in the long run.

Tools Needed for Repairs

When undertaking maintenance or restoration of small marine engines, having the right tools at your disposal is crucial. Proper equipment ensures efficiency and accuracy during the repair process, leading to better performance and longevity of the engine. Below is a list of essential tools that every technician or enthusiast should consider when working on these types of machinery.

Essential Hand Tools

Basic hand tools form the foundation of any repair toolkit. They are indispensable for disassembling components, tightening bolts, and performing various tasks that require precision and care.

| Tool | Purpose |

|---|---|

| Screwdrivers | For fastening or loosening screws of various sizes. |

| Wrenches | To grip and turn nuts and bolts securely. |

| Pliers | Used for gripping, twisting, and cutting wires or small parts. |

| Socket Set | For quick removal and installation of fasteners in tight spaces. |

Specialized Tools

In addition to general hand tools, some specialized instruments can greatly enhance repair efficiency and accuracy. These tools are designed for specific tasks related to engine upkeep.

| Tool | Purpose |

|---|---|

| Torque Wrench | Ensures fasteners are tightened to the manufacturer’s specifications. |

| Compression Tester | Measures the compression pressure in the engine cylinders. |

| Fuel Pressure Gauge | Monitors the fuel system’s pressure for proper operation. |

| Multimeter | Used for diagnosing electrical issues by measuring voltage and resistance. |

Exploring Aftermarket Parts Options

When it comes to enhancing the performance and longevity of marine engines, considering alternative components can be a game-changer. Many boat owners explore various avenues to find compatible substitutes that not only meet but often exceed the original specifications. This section delves into the benefits and considerations of utilizing aftermarket solutions.

One significant advantage of opting for alternative components is the potential cost savings. Typically, these replacements can be more budget-friendly than their original counterparts. Additionally, the aftermarket market is often more extensive, offering a wider selection that may not be available from the manufacturer. Here are some key points to consider:

- Quality and Compatibility: It’s crucial to ensure that the aftermarket products are of high quality and compatible with the existing engine setup.

- Warranty Considerations: Some replacements might come with warranties, providing peace of mind regarding their performance.

- Performance Enhancements: Many alternative options are designed to enhance engine efficiency and power output.

- Availability: Aftermarket components can often be found at local marine supply stores or online, making them readily accessible.

In conclusion, exploring alternatives to original engine components can yield significant benefits. By understanding the various options and making informed choices, boat enthusiasts can optimize their marine experience while potentially saving costs.

Importance of Regular Inspections

Conducting routine evaluations of your marine engine is crucial for ensuring its longevity and optimal performance. Regular checks help identify potential issues before they escalate, allowing for timely maintenance and repairs. By being proactive, boat owners can enhance the reliability and efficiency of their vessels.

Here are several reasons why frequent inspections are essential:

- Prevention of Major Failures: Regular assessments can detect early signs of wear and tear, reducing the risk of catastrophic breakdowns.

- Cost Savings: Identifying and addressing minor problems can save significant expenses associated with extensive repairs.

- Improved Performance: Keeping the engine well-maintained ensures it operates smoothly, providing better speed and fuel efficiency.

- Safety Assurance: Routine checks ensure that all components are functioning correctly, enhancing the safety of your boating experience.

- Extended Lifespan: Regular care and maintenance contribute to the overall longevity of the engine, allowing for years of enjoyable use.

In conclusion, integrating regular inspections into your maintenance routine is a wise investment. It not only enhances performance and safety but also fosters a positive boating experience.

Safety Precautions for Outboard Work

When engaging in maintenance or repairs of small marine engines, it is essential to prioritize safety to prevent accidents and injuries. Proper precautions not only protect the individual performing the task but also ensure the longevity of the equipment involved. Following established guidelines can significantly reduce the risk of mishaps.

Personal Protective Equipment

Wearing appropriate personal protective equipment (PPE) is crucial during any mechanical work. This includes items such as gloves, safety goggles, and sturdy footwear to shield against potential hazards. Proper clothing can also help prevent entanglement with moving parts, making it a vital aspect of workplace safety.

Safe Working Environment

Ensure that the workspace is well-ventilated and free from clutter. A clean and organized area minimizes distractions and potential hazards. Additionally, keeping all tools and equipment in their designated places helps to maintain an efficient workflow. Always have a first aid kit accessible in case of emergencies, and familiarize yourself with its contents.

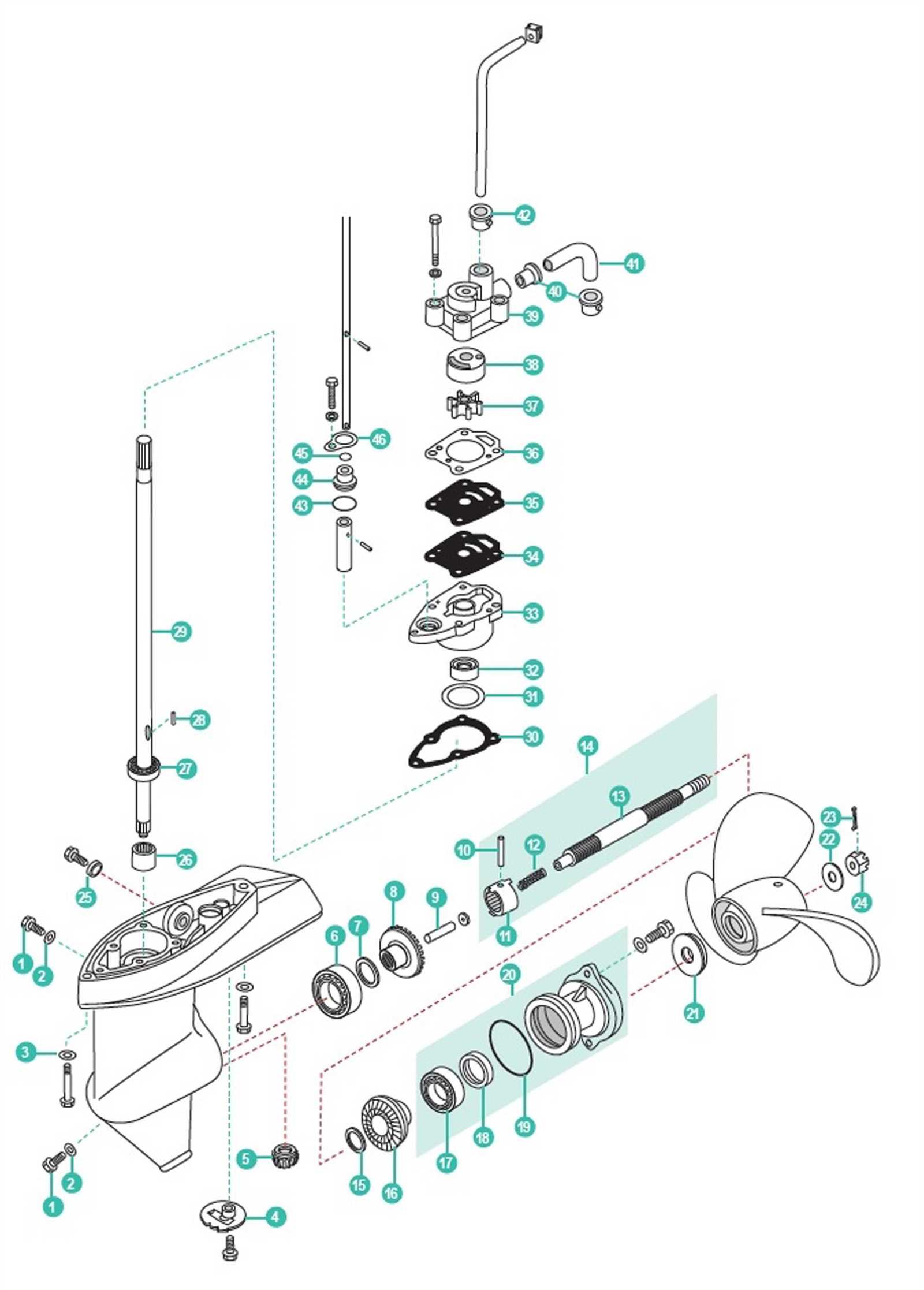

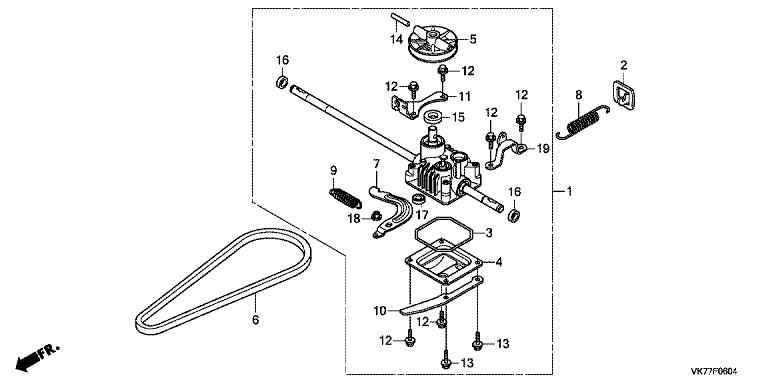

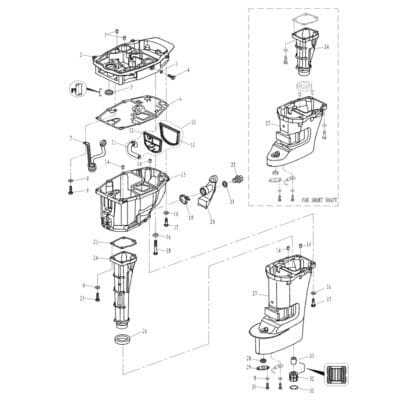

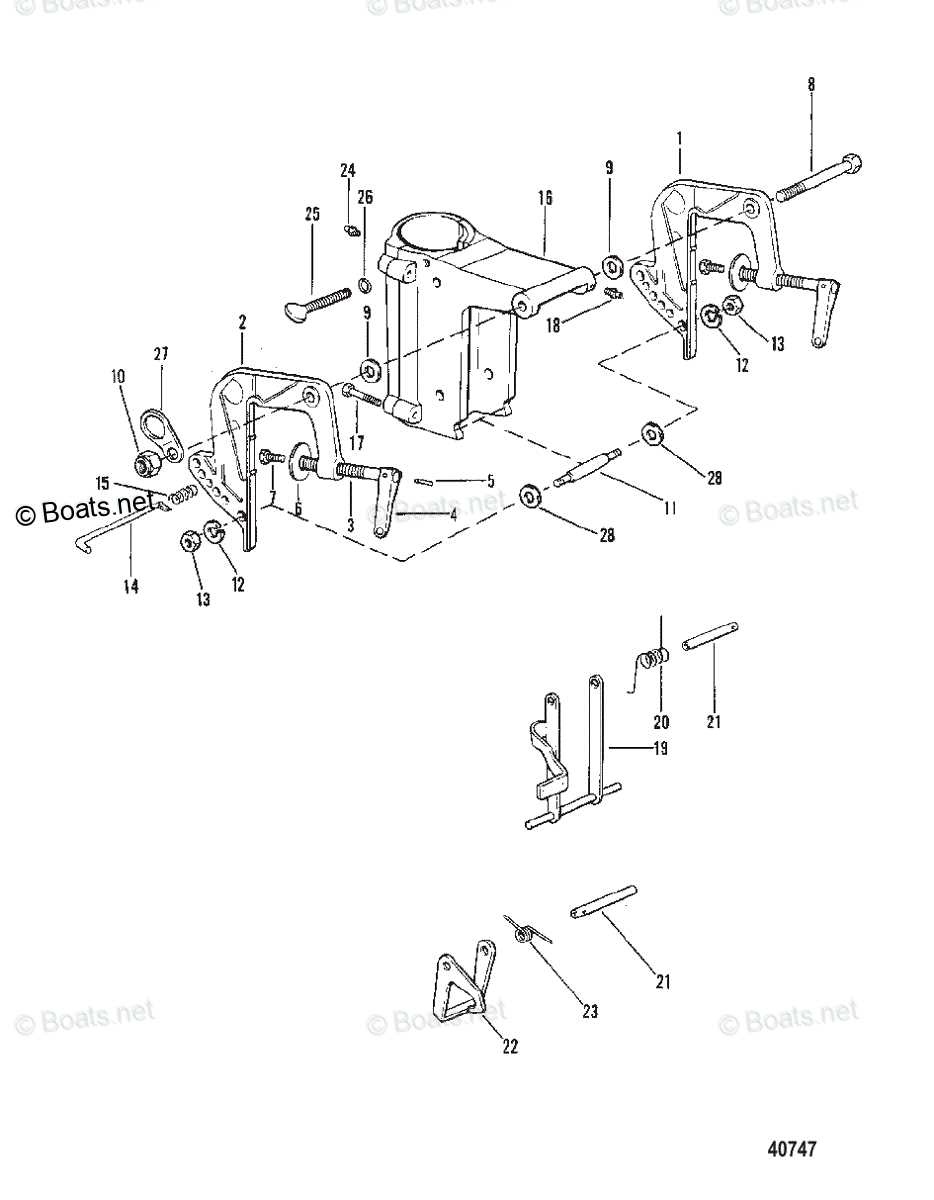

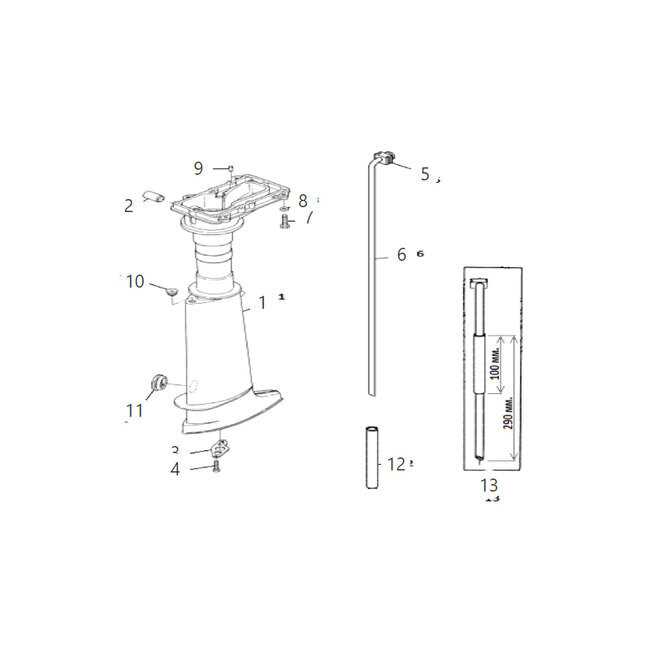

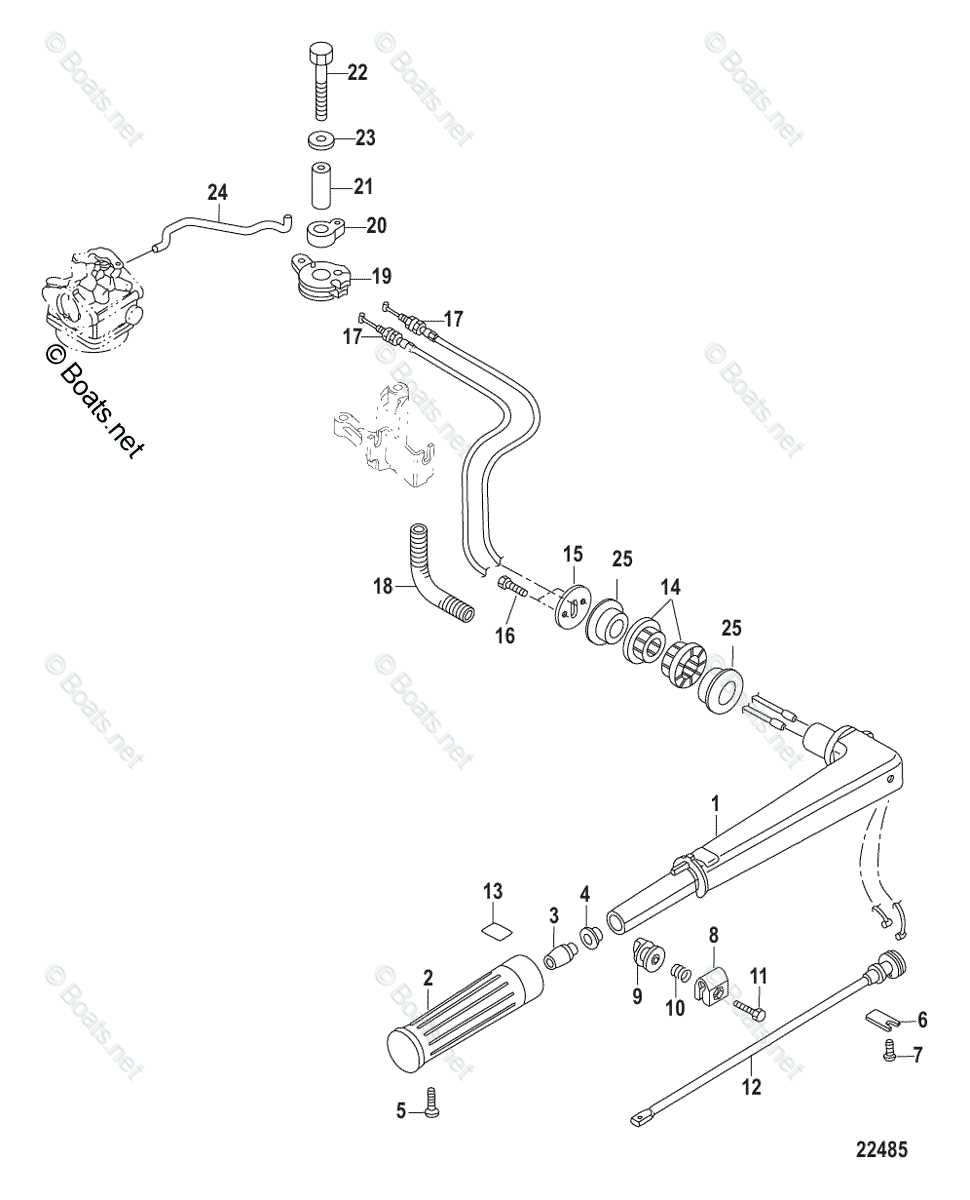

How to Read Parts Diagrams

Understanding assembly illustrations is essential for anyone looking to maintain or repair their equipment. These visuals provide a clear representation of the components involved and how they fit together, allowing users to identify specific elements needed for service or replacement. By familiarizing oneself with the layout and symbols used in these images, the process of troubleshooting becomes more efficient and straightforward.

Key Elements of Assembly Illustrations

Typically, assembly visuals include numbered items, which correspond to a list of components, often with descriptions. The organization of these illustrations usually follows a logical sequence, guiding the user from one section to another. It’s important to pay attention to the details, such as size and orientation, which can influence how components interact within the overall structure.

Tips for Effective Interpretation

To effectively interpret these visuals, start by reviewing the legend or key provided, as it explains the symbols and numbering system used. Next, cross-reference the illustration with the parts list to ensure you are looking at the correct components. Taking notes or marking items of interest can further simplify the process, making it easier to track down specific elements when performing maintenance or repairs.