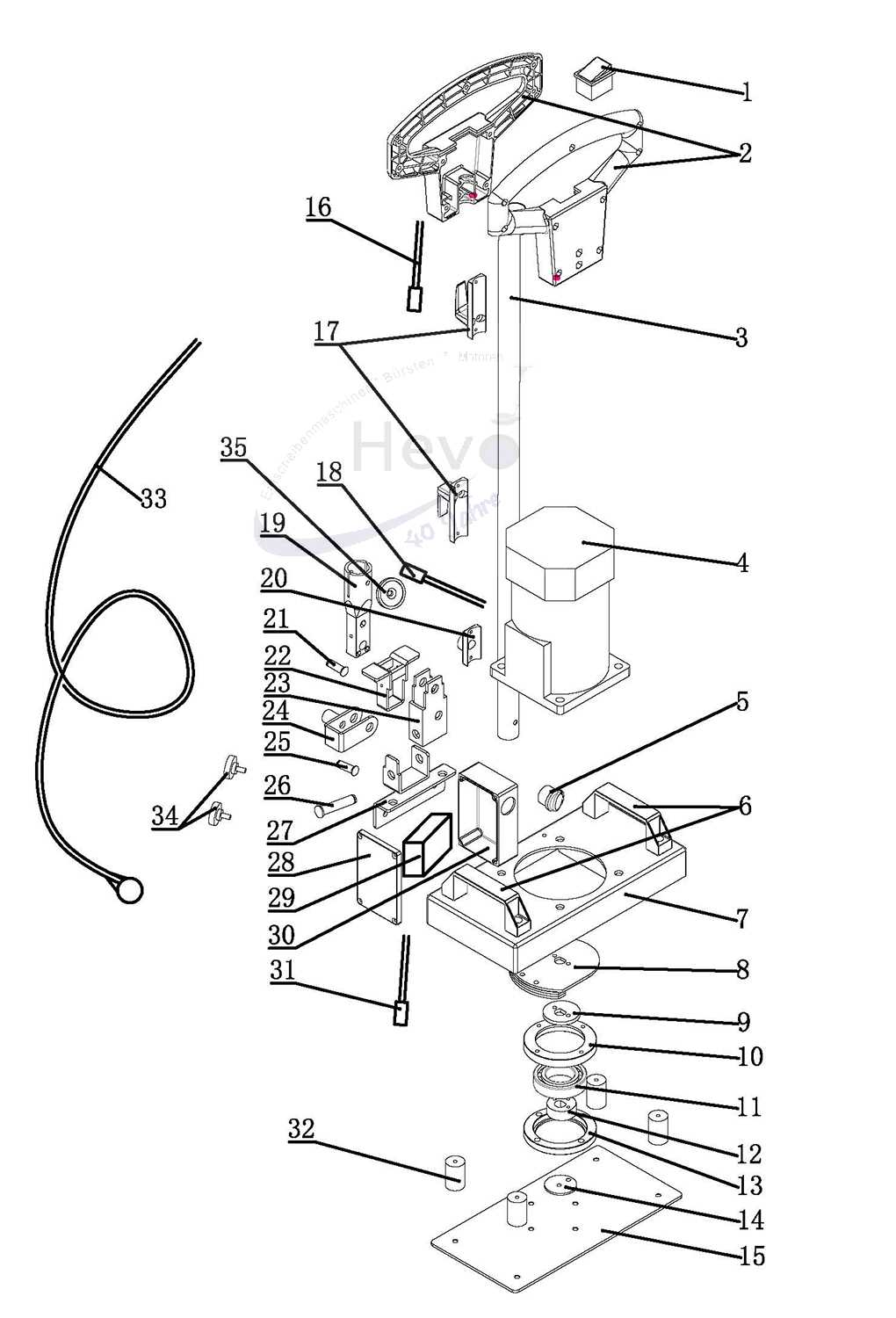

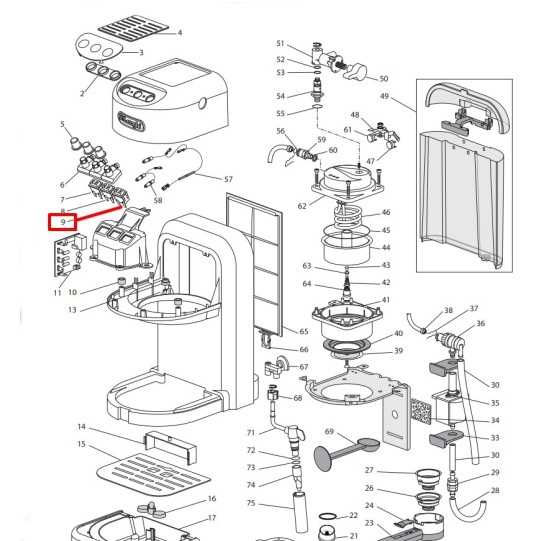

Understanding the internal composition of modern appliances allows users to effectively manage maintenance and troubleshoot potential issues. This section explores the essential elements and their configuration within a widely-used coffee machine model.

Exploring each internal unit helps identify how key functions are performed. From brewing mechanisms to control interfaces, every piece plays a specific role in ensuring smooth operation. Familiarity with these elements is beneficial not only for repair but also for extending the device’s lifespan through preventive care.

This breakdown provides clarity on individual modules, their interactions, and replacement options when necessary. Knowing what to expect when disassembling a machine aids both professionals and home users, ensuring a seamless experience in maintaining optimal functionality.

Overview of Key Components

This section provides an insight into the essential elements that make up the structure of the machine. Each component works in harmony to ensure smooth operation, contributing to the overall functionality and performance of the equipment.

Core Functional Units

- Heating Element: Responsible for warming the water to the required temperature, enabling efficient brewing.

- Water Pump: Ensures the steady flow of water through the system, crucial for consistent results.

- Control Interface: Allows the user to select settings and monitor operation during use.

Additional Supporting Elements

- Drip Tray: Collects excess liquid to prevent spills and keep the workspace clean.

- Water Reservoir: Stores water and supplies it to the system when needed.

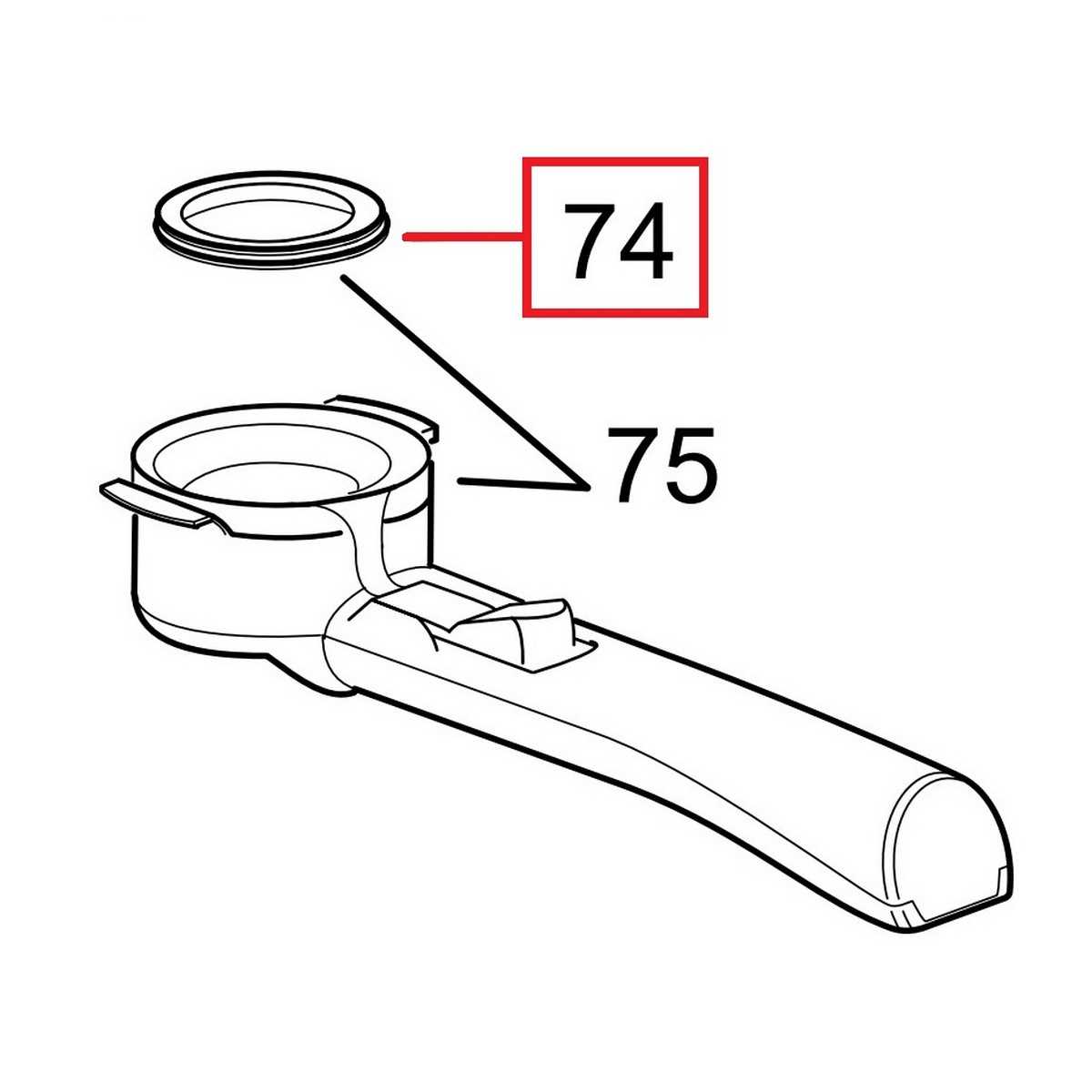

- Filter Holder:

Understanding the Coffee Maker’s Mechanism

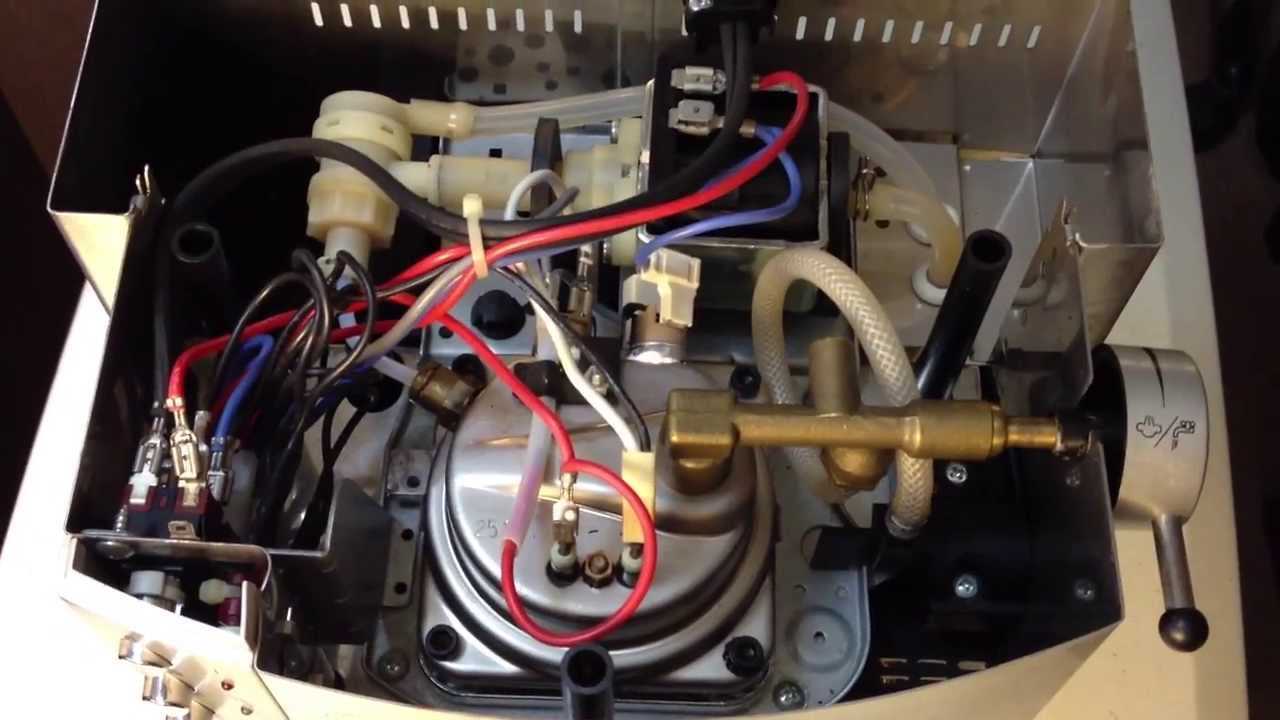

Modern coffee machines operate through a complex interaction of components, each contributing to the brewing process. The internal system ensures that water is heated to the optimal temperature, pressurized, and directed through the coffee grounds to extract flavors effectively. Knowing how these parts work together provides insight into maintaining the machine and troubleshooting common issues.

Water Flow and Heating Process

Water from the reservoir moves through tubing, where it is heated by a thermoblock or boiler. This hot water is then pressurized by a pump, which ensures a steady flow through the ground coffee. The balance between temperature and pressure plays a critical role in achieving the desired aroma and consistency.

Brewing and Filtration System

The hot water is pushed through a portafilter containing the coffee grounds, where the brewing process takes place. Filters ensure that only the liquid extract passes through, leaving residues behind. At the final stage, the prepared beverage flows into the cup, ready to serve.

How to Identify Spare Parts

Recognizing the correct replacement components ensures smooth operation and extends the life of your equipment. Understanding how to match compatible items requires attention to detail and familiarity with the design and function of each element within the system.

Checking Model Numbers and Labels

Every device typically has a model number or serial label, often located on the back or bottom. These identifiers help match the original equipment with suitable replacements. Use manuals or online databases to cross-reference codes and find the corresponding components.

Examining Wear and Tear

Look for signs of damage or aging on individual elements, such as discoloration, cracks, or wear marks. Identifying these issues helps you focus on which items need immediate attention. Regular inspections can prevent more severe malfunctions by allowing timely replacements.

Tip: When in doubt, bring the old piece to a professional or supplier to ensure an exact match. Visual comp

Tips for Recognizing Compatible Elements

Identifying suitable components for devices ensures smooth operation and prevents potential malfunctions. Focusing on specific attributes helps users confirm that a replacement item will fit seamlessly with existing systems.

Verify model specifications: Always match the key parameters, such as voltage, dimensions, or connectors, with the original part. This reduces the risk of incompatibility.

Inspect material and build quality: Components with similar construction materials and manufacturing standards tend to perform reliably and last longer, ensuring better integration.

Use reference numbers and labels: Identifiers such as serial numbers, barcodes, or product codes can be invaluable in matching elements correctly, as they often contain detailed compatibility information.

Seek expert opinions or manuals: Consulting experienced technicians or documentation can help confirm whether a component aligns with the intended usage, minimizing trial-and-error replacements.

Common Issues with Internal Components

Coffee machines rely on precise coordination between internal elements to function properly. However, with prolonged use, some of these components can experience wear, leading to common malfunctions. Understanding these potential issues helps ensure smoother operation and timely maintenance.

- Pump Malfunctions: A weak or inconsistent water flow may indicate problems with the pump, such as blockages or reduced pressure output.

- Heating Element Failures: If the machine takes too long to heat or the water isn’t reaching the desired temperature, the heating element might be malfunctioning or scaled.

- Valve Blockages: Residue buildup inside the valves can prevent the proper flow of water or steam, impacting beverage quality and machine performance.

- Gasket Wear: Over time, seals and gaskets may degrade, leading to leaks around key connections or pressure loss during brewing.

- Sensor Calibration Issues: Sensors controlling water levels and temperature can lose accuracy, causing incorrect brewing cycles or inconsistent output

Troubleshooting Problems with the Device

When encountering issues with an appliance, it’s essential to systematically identify the source of the problem. This process involves examining various components and functions to determine what might be causing malfunctions. By following a structured approach, users can effectively resolve common operational difficulties.

Common Issues and Solutions

- Device Fails to Start:

- Check if the unit is plugged in securely.

- Inspect the power source for any interruptions.

- Ensure that any safety mechanisms are disengaged.

- Unusual Noises:

- Examine for loose parts or components.

- Verify that the appliance is placed on a stable surface.

- Check for foreign objects that may have entered the machine.

Maintenance Tips

- Regularly clean and descale the appliance to prevent buildup.

- Inspect seals and gaskets for wear or damage.

- Store the device in a dry place to avoid moisture-related issues.

By adhering to these guidelines and conducting periodic checks, users can maintain optimal performance and longevity of their appliance.

Maintenance Tips for Longevity

Ensuring the durability and performance of your appliance requires regular upkeep and attention. By following a few essential maintenance practices, you can extend its lifespan and enhance its functionality. These tips aim to help users achieve optimal performance while preventing common issues that may arise over time.

Regular Cleaning

Keeping your device clean is crucial for maintaining its efficiency. Regularly wipe down the exterior and interior surfaces to prevent the buildup of grime and residue. Pay special attention to any removable components, ensuring they are free from any debris that could impact performance.

Proper Storage and Handling

Storing the appliance in a safe and dry environment can significantly contribute to its longevity. Avoid placing it in areas with extreme temperatures or humidity levels. Additionally, handle the device with care to prevent any unnecessary damage during use or transport.

How Regular Cleaning Extends Lifespan

Maintaining equipment through consistent cleaning practices is essential for enhancing durability and functionality. By regularly attending to various components, users can prevent the accumulation of residues that may hinder performance over time. This proactive approach not only ensures optimal operation but also prolongs the overall lifespan of the machine.

Frequent maintenance helps in several ways:

- Prevents Build-Up: Regular cleaning eliminates dirt and debris, reducing wear and tear on parts.

- Improves Efficiency: A clean machine operates more smoothly, leading to better performance and energy efficiency.

- Reduces Repairs: By catching potential issues early through regular cleaning, the likelihood of costly repairs diminishes.

- Enhances Safety: Clean equipment minimizes risks associated with malfunctions or hazardous materials.

In conclusion, implementing a routine cleaning schedule is an investment in the longevity and reliability of the equipment. By prioritizing cleanliness, users can enjoy a seamless experience while maximizing the functional lifespan of their machinery.

Differences Between Models and Variants

When exploring various types of coffee-making machines, it’s essential to recognize that different models and versions can exhibit distinct features and functionalities. Understanding these variations can help users choose the appliance that best suits their preferences and brewing needs.

Here are some key aspects that differentiate these devices:

- Design and Aesthetics: Variants may come in different colors, materials, and finishes, impacting the overall look of the machine in any kitchen setting.

- Brewing Capacity: Some models may offer larger water tanks or coffee grounds compartments, allowing for more significant quantities to be prepared at once.

- Control Features: Certain versions may include advanced control panels, offering programmable settings for brewing strength, temperature, and even timing.

- Attachments and Accessories: Different models might come with various tools, such as milk frothers or additional brewing baskets, enhancing the versatility of the machine.

- Energy Efficiency: Newer variants often focus on energy-saving features, making them more environmentally friendly and cost-effective in the long run.

Recognizing these differences enables consumers to make informed decisions, ensuring that they select a model that aligns perfectly with their coffee-making habits and lifestyle.

Unique Features Across the Product Range

Various models within the product lineup showcase distinctive characteristics that enhance user experience and functionality. These features not only improve performance but also cater to diverse preferences, ensuring that every consumer can find a model that meets their specific needs.

Innovative Design Elements

Many devices incorporate cutting-edge design elements that promote efficiency and ease of use. From ergonomic handles to intuitive controls, these innovations simplify operation, making them accessible for users of all skill levels.

Versatile Functionality

The range offers versatile functionality that allows users to enjoy a wide array of beverages with just a single machine. Features such as customizable settings and multi-functional capabilities empower users to experiment with different drink styles, creating a unique experience every time.

Replacing Worn-Out Accessories

Over time, certain components of your appliance may become less effective due to wear and tear. Regular maintenance and timely replacement of these elements are essential for ensuring optimal performance and prolonging the lifespan of your device. Identifying which accessories need replacement can greatly enhance the efficiency and functionality of your equipment.

Begin by assessing the condition of each accessory. Look for signs of damage, such as cracks, discoloration, or reduced performance. Common components that may require attention include filters, seals, and brewing elements. When a part shows signs of deterioration, it is crucial to replace it with a compatible substitute to maintain the overall effectiveness of the appliance.

Consult the manufacturer’s guidelines or a reliable resource for assistance in identifying suitable replacement parts. This will ensure that the new accessories fit properly and function as intended. Taking the time to replace worn components not only improves performance but also contributes to a better user experience.

How to Swap Out Damaged Parts

Replacing worn or faulty components is essential to maintaining the functionality and longevity of your device. This process involves identifying the defective parts and carefully removing them to install new replacements. Here, we will outline the necessary steps to ensure a smooth transition during the replacement process.

Identifying the Issue

Before proceeding with any replacement, it is crucial to diagnose the problem correctly. Common signs of malfunction may include:

- Unusual noises during operation

- Inconsistent performance

- Visible wear and tear on exterior components

- Leaking fluids

Once you have recognized the symptoms, you can determine which components need to be swapped out.

Steps for Replacement

- Turn off the device and unplug it from the power source to ensure safety.

- Consult the user manual or schematic for guidance on accessing the internal structure.

- Carefully remove the outer casing using appropriate tools, ensuring not to damage any clips or screws.

- Identify the damaged component and disconnect it from any electrical connections or fasteners.

- Install the new part by reversing the disassembly steps, making sure all connections are secure.

- Reattach the casing and verify that all screws and clips are properly in place.

- Plug in the device and conduct a test run to confirm that the replacement was successful.

Following these steps will help ensure that your device functions optimally and that any issues are effectively resolved.

Tools Required for Assembly

When assembling any appliance, having the right tools at hand is crucial for a smooth and efficient process. This section outlines the essential equipment you will need to ensure that the assembly is completed correctly and safely.

Gathering the appropriate instruments not only facilitates the assembly but also helps in preventing damage to the components. Below is a list of recommended tools:

- Screwdriver Set: Various sizes are necessary for different screw types.

- Wrench: An adjustable wrench is useful for tightening and loosening nuts and bolts.

- Pliers: Needle-nose pliers are ideal for reaching into tight spaces.

- Hex Key Set: Required for screws with hexagonal sockets.

- Measuring Tape: Useful for ensuring correct dimensions during assembly.

- Utility Knife: Handy for cutting packaging or securing materials.

Having these tools prepared will enhance your efficiency and ensure a successful assembly process.

- Device Fails to Start: