In the realm of agricultural machinery, comprehending the various elements that contribute to the efficiency of a forage implement is crucial for optimal performance. This section delves into the intricate assembly of these machines, highlighting their essential functions and interconnections.

Knowledge of these components not only aids in effective maintenance but also enhances overall operational efficacy. By familiarizing oneself with the various pieces that work in unison, operators can ensure longevity and reliability in their equipment.

Ultimately, having a clear grasp of the assembly allows for better troubleshooting and repairs, leading to improved productivity in the field. Understanding the nuances of these elements empowers users to make informed decisions regarding their machinery.

Tonutti Hay Tedder Overview

This section provides an insightful look into a crucial implement designed for enhancing the efficiency of agricultural operations. It focuses on the functionality and components of equipment used to spread and aerate freshly cut forage, promoting quicker drying and improving overall crop quality.

Key Features

- Efficient crop management through effective spreading.

- Durable construction to withstand varying field conditions.

- User-friendly controls for seamless operation.

- Versatile design adaptable to different crop types.

Benefits of Utilizing This Equipment

- Increased productivity by reducing drying time.

- Enhanced quality of forage, resulting in better nutritional value.

- Cost-effective solution for managing larger fields.

- Minimized labor requirements due to automated functions.

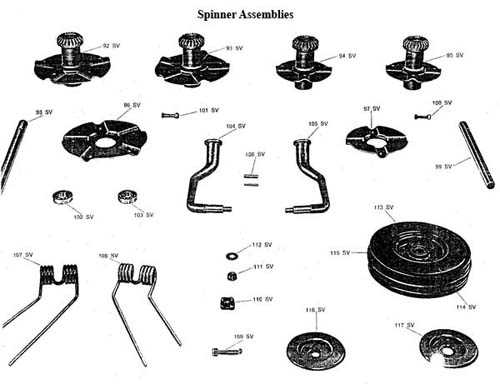

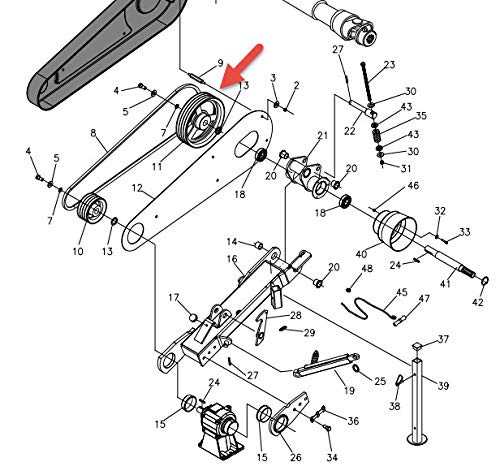

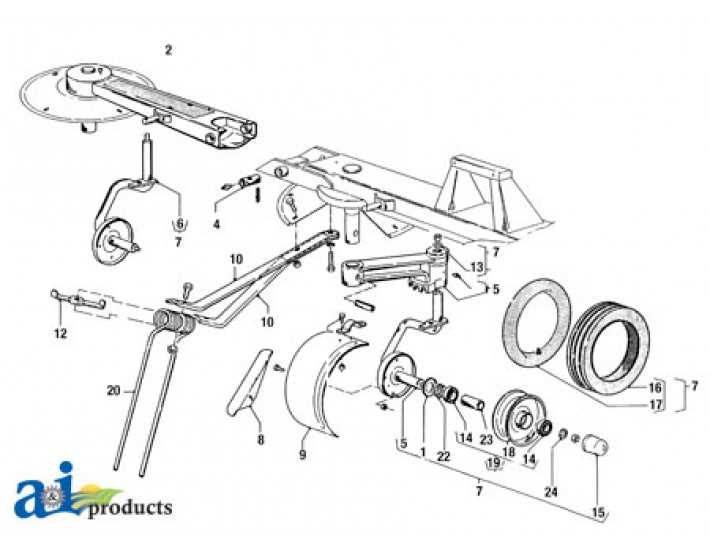

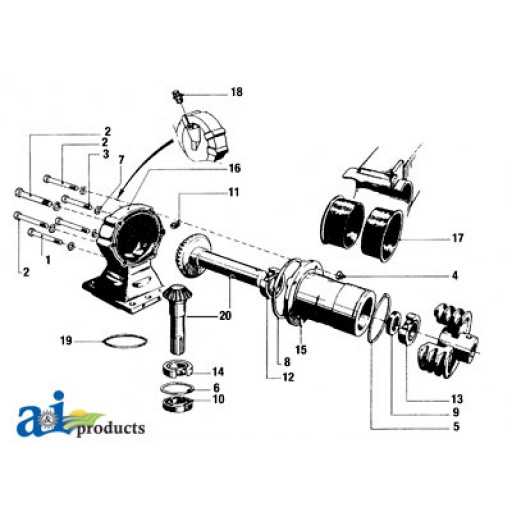

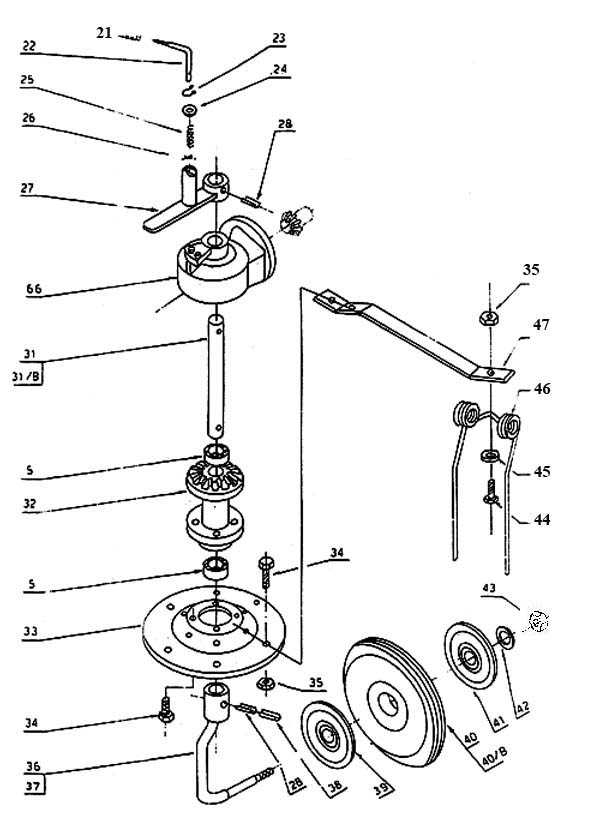

Key Components of Hay Tedders

The efficient operation of a machine designed for the processing of grass relies on several essential elements. Each component plays a crucial role in ensuring the effective turning and spreading of the crop, facilitating optimal drying conditions for subsequent collection and storage.

Main Functional Elements

At the heart of this machinery are the rotors, which are responsible for lifting and tossing the material. These rotating arms are often equipped with fingers that gently separate the strands, allowing for even exposure to sunlight and air. The speed and movement of these rotors significantly influence the overall efficiency of the drying process.

Supporting Structures

Another critical aspect is the frame, which provides the necessary stability and support for the entire setup. It ensures that all components function harmoniously under various working conditions. Additionally, the inclusion of wheels or other mobility features allows for easy transportation and positioning in the field, making it a versatile tool for agricultural tasks.

Understanding Hay Tedder Functions

The primary objective of this agricultural implement is to enhance the efficiency of the drying process. By aerating and spreading freshly cut forage, it facilitates quicker moisture evaporation, ensuring optimal conditions for subsequent harvesting. A thorough comprehension of how this machinery operates is crucial for maximizing productivity and maintaining crop quality.

Key Mechanisms of Operation

This equipment typically employs a series of rotating arms equipped with tines or fingers. As these components spin, they engage with the crop, effectively lifting and tossing it into the air. This action allows for even exposure to sunlight and air, which are vital for efficient drying. Understanding the mechanics behind this motion is essential for ensuring proper maintenance and operation.

Importance of Adjustment and Maintenance

Regular calibration and upkeep are paramount for achieving desired results. Adjustments to the height and angle of the tines can significantly influence the quality of the process. Furthermore, routine inspections of mechanical parts can prevent breakdowns and extend the lifespan of the equipment. A proactive approach to maintenance will ensure optimal performance during critical harvesting periods.

Maintenance Tips for Optimal Performance

Ensuring peak efficiency of your equipment requires regular care and attention. By adhering to a structured maintenance routine, you can extend the lifespan of your machinery while enhancing its operational capabilities. This section provides essential strategies to maintain optimal function and reliability.

Regular Inspections

Frequent checks are crucial for identifying wear and tear early. Inspect all moving components, ensuring they are free of debris and properly lubricated. This proactive approach helps prevent unexpected breakdowns and maintains smooth operation.

Proper Storage

When not in use, store your machinery in a dry, sheltered location. Protecting it from harsh weather conditions minimizes rust and degradation. Additionally, consider covering your equipment with a breathable tarp to keep moisture at bay while allowing air circulation.

Common Issues and Solutions

In the operation of agricultural equipment, various challenges may arise that can hinder performance and efficiency. Understanding these common problems and their corresponding solutions is essential for maintaining optimal functionality.

1. Ineffective Material Distribution: One frequent issue is uneven spreading of the material. This can often be resolved by ensuring that the machine is properly calibrated and that all moving components are functioning smoothly.

2. Jamming: Blockages can occur due to debris or improper alignment. Regularly inspecting and clearing any obstructions will help maintain flow and prevent downtime.

3. Wear and Tear: Components may wear out over time, leading to reduced efficiency. Implementing a routine maintenance schedule that includes replacing worn parts will extend the lifespan of the equipment.

4. Poor Performance in Wet Conditions: Operating machinery in damp environments can result in subpar results. Utilizing equipment designed for such conditions or waiting for optimal drying times can enhance productivity.

5. Hydraulic Issues: Problems with hydraulic systems can lead to insufficient power. Checking fluid levels and inspecting hoses for leaks can mitigate these issues.

Parts Replacement Guidelines

Maintaining and ensuring the optimal performance of your equipment involves timely replacements of its components. Following systematic approaches can significantly enhance longevity and efficiency.

Here are key steps to consider during the replacement process:

- Assess the Condition:

- Regularly inspect components for wear and tear.

- Identify any signs of damage or decreased performance.

- Opt for high-quality replacements that meet or exceed original specifications.

- Consult with suppliers for trusted brands and recommendations.

- Refer to the equipment’s manual for specific guidelines on replacements.

- Adhere to suggested schedules for changing parts to prevent breakdowns.

- Ensure you have the necessary tools for safe and effective replacement.

- Familiarize yourself with the equipment’s assembly for smooth operation.

- Keep records of all replacements made, including dates and components used.

- Note any changes in performance post-replacement for future reference.

By adhering to these guidelines, you can maintain peak efficiency and prolong the lifespan of your machinery.

Safety Precautions During Use

Ensuring safety while operating agricultural equipment is crucial to prevent accidents and injuries. Proper awareness and adherence to guidelines can significantly reduce risks associated with machinery operation. Below are essential measures to consider for safe usage.

| Precaution | Description |

|---|---|

| Wear Protective Gear | Always use appropriate safety equipment, including gloves, goggles, and sturdy footwear, to shield yourself from potential hazards. |

| Inspect Equipment | Conduct thorough checks before operation. Look for any signs of wear or damage that could affect performance and safety. |

| Follow Operating Instructions | Adhere strictly to the manufacturer’s guidelines for operation and maintenance to ensure effective and safe use of the machinery. |

| Maintain Clear Work Area | Ensure the surrounding area is free of obstacles and debris to allow for safe maneuvering and operation of the equipment. |

| Stay Alert | Remain focused and attentive while using the equipment. Avoid distractions that could lead to accidents. |

By following these precautions, operators can enhance safety and efficiency during use, minimizing the likelihood of accidents in the field.

Adjustments for Different Field Conditions

Adapting equipment to varying terrain and environmental factors is crucial for optimal performance. Each setting presents unique challenges that require specific modifications to ensure efficiency and quality in operation. By understanding the characteristics of the ground and the conditions under which work is performed, operators can enhance productivity and maintain equipment longevity.

Soil Type Considerations

The nature of the soil significantly impacts the required adjustments. Looser soils may necessitate different settings compared to compacted or clay-rich grounds. Operators should assess the soil composition to determine appropriate configurations that minimize damage to both the machinery and the field.

Weather Impact

Weather conditions can also dictate adjustments. Wet or humid environments might require changes to prevent clogging or excessive moisture retention, while dry conditions may need settings that enhance airflow and promote faster drying. Monitoring weather forecasts and adapting accordingly is essential for effective operation.

| Condition | Recommended Adjustment |

|---|---|

| Loamy Soil | Moderate speed with standard height |

| Clay Soil | Lower speed, higher height to avoid mud |

| Wet Conditions | Increase height, reduce speed |

| Dry Conditions | Lower height, increase speed for airflow |

Comparing Models and Features

This section explores the differences and similarities among various equipment models designed for forage processing. Understanding these distinctions can help users make informed decisions based on their operational needs.

| Model | Weight (lbs) | Working Width (ft) | Drive Type | Number of Rotors |

|---|---|---|---|---|

| Model A | 800 | 10 | Hydraulic | 4 |

| Model B | 900 | 12 | Mechanical | 5 |

| Model C | 950 | 14 | Hydraulic | 6 |

Each model offers unique specifications that cater to different operational scales, providing users with the flexibility to select the most suitable option for their requirements.

Parts Sourcing and Availability

In the realm of agricultural machinery, acquiring essential components is crucial for maintaining optimal functionality and performance. Understanding the avenues for sourcing these elements can significantly impact operational efficiency and minimize downtime.

Identifying Reliable Suppliers

To ensure the procurement of quality components, it is vital to identify trustworthy suppliers. Look for vendors who specialize in agricultural machinery and offer a broad selection of items. Online marketplaces and local distributors can provide valuable resources, allowing for comparative analysis of pricing and availability.

Assessing Inventory Levels

Before making purchases, assess the inventory levels of potential suppliers. This step helps to confirm that the necessary items are readily accessible and can be delivered promptly. Additionally, maintaining a list of preferred suppliers can streamline the process, facilitating quicker access to the required elements when needed.

Operational Efficiency Improvements

Enhancing operational efficiency in agricultural machinery can lead to significant gains in productivity and cost-effectiveness. By focusing on various aspects of performance and maintenance, operators can ensure that their equipment functions at optimal levels, reducing downtime and improving overall output.

Regular Maintenance Practices

Implementing a routine maintenance schedule is crucial for ensuring that machinery remains in peak condition. Regular inspections and timely replacements of wear components can prevent breakdowns, extend equipment lifespan, and enhance performance efficiency.

Upgrading Components

Investing in advanced components and technology can drastically improve operational capabilities. Utilizing modern materials and innovative designs can lead to better efficiency, allowing for more effective use of resources and improved functionality in various conditions.

Innovations in Hay Tedder Design

Recent advancements in agricultural machinery have significantly transformed the efficiency and effectiveness of grass and forage processing. New technologies and design principles aim to enhance performance, reduce operational costs, and improve user experience. These innovations cater to the evolving needs of modern farming, focusing on greater adaptability and precision in fieldwork.

One notable development is the incorporation of advanced materials that reduce weight while increasing durability. Lightweight components facilitate easier maneuverability and fuel efficiency, allowing operators to cover larger areas in less time. Additionally, smart technology integration enables real-time monitoring of machine performance, optimizing productivity and minimizing downtime.

Another trend is the emphasis on ergonomic design, which ensures that equipment is user-friendly and reduces physical strain on operators. Features like adjustable controls and improved visibility contribute to a safer working environment. Furthermore, enhanced maintenance accessibility allows for quicker servicing, ensuring that machines remain in peak condition.