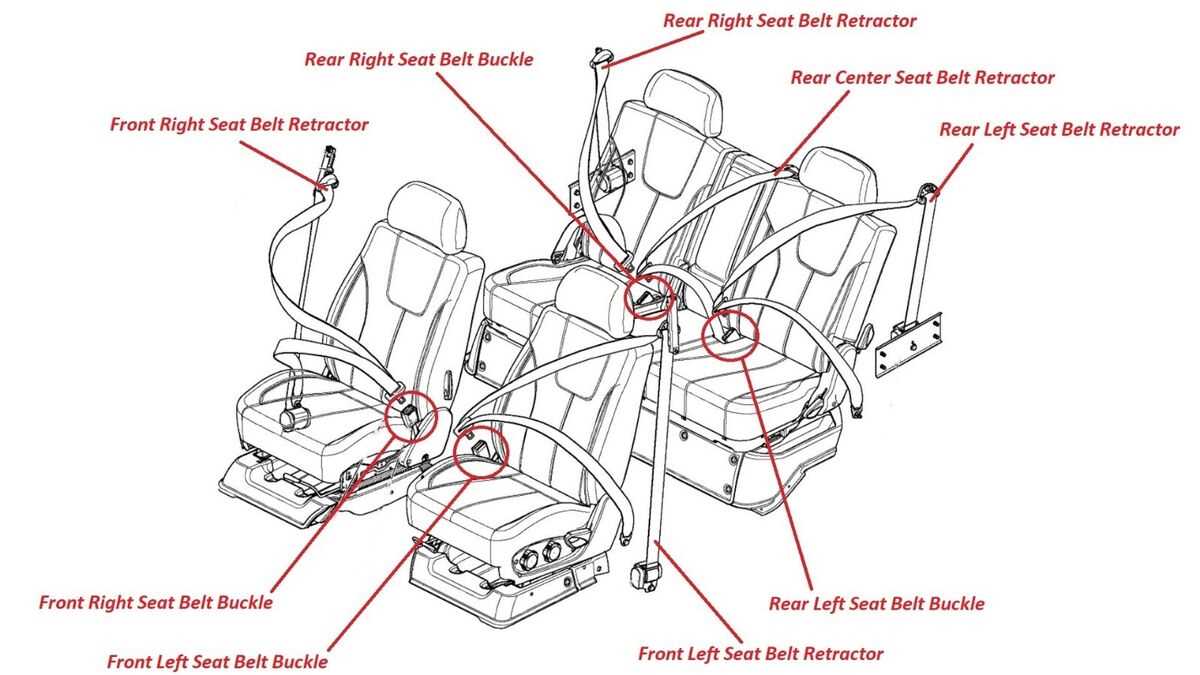

In the realm of automotive safety, the mechanisms designed to secure passengers are crucial for preventing injury during sudden stops or collisions. These intricate systems consist of various elements that work together to provide reliable protection. A thorough exploration of these components reveals the complexity behind what might seem like a simple device.

The functionality of these restraint systems hinges on a combination of mechanical and electronic features. Each segment plays a specific role, ensuring that individuals remain safely anchored within their seats while traveling. Understanding how these elements interact can significantly enhance one’s appreciation for automotive engineering and safety innovations.

By examining the individual components and their arrangement, one can gain insights into the engineering principles that prioritize occupant safety. This knowledge not only highlights the importance of proper maintenance but also emphasizes the technological advancements that have made these systems more effective over time.

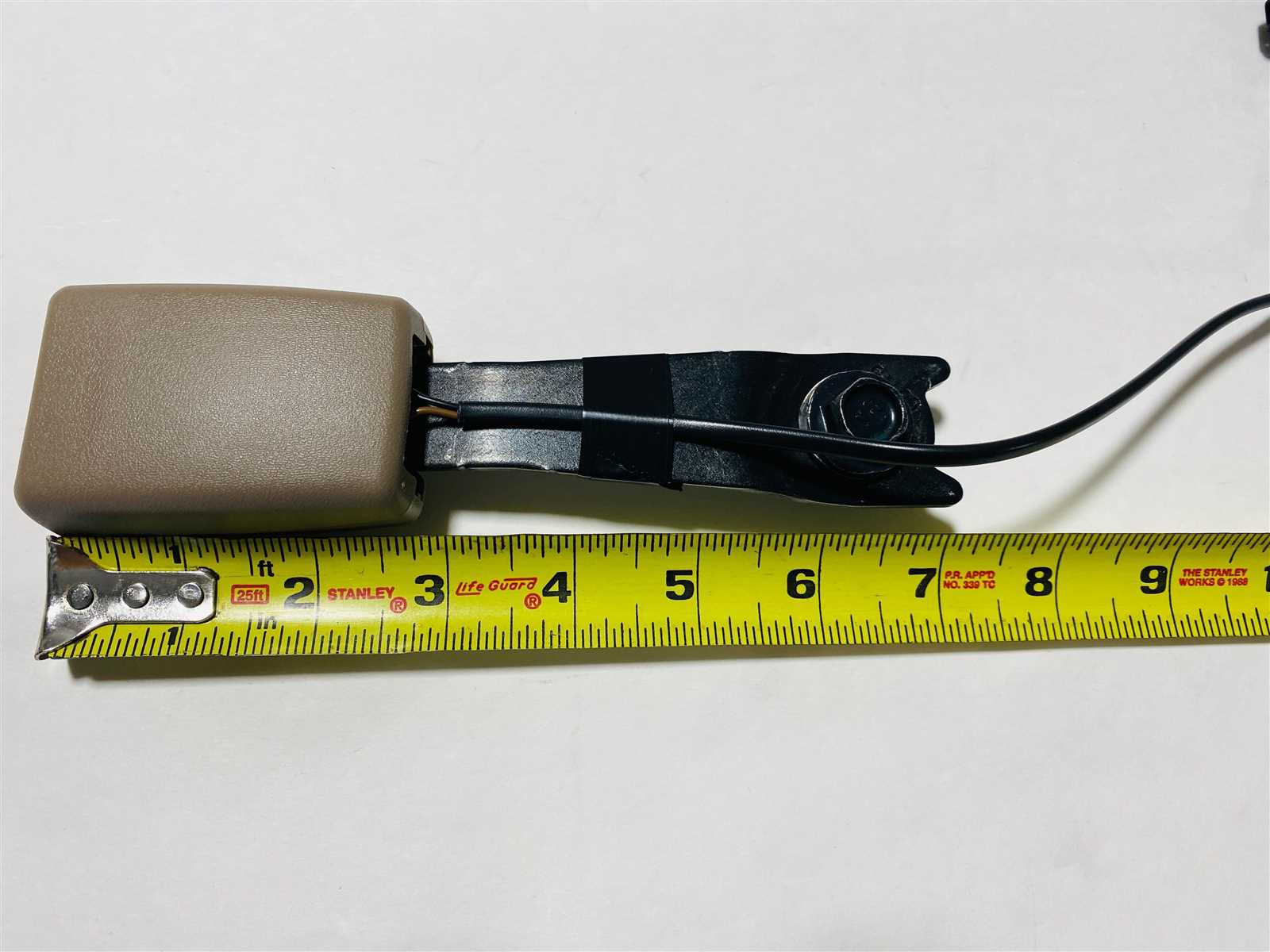

Understanding Seat Belt Buckle Components

This section delves into the various elements that make up the fastening mechanism designed for occupant safety in vehicles. By examining each component, we can gain a clearer understanding of how they function together to provide security and reliability during travel.

Key Elements of the Fastening Mechanism

The fastening system consists of several crucial components, each playing a distinct role in ensuring effective operation. From the release mechanism to the latch, understanding these elements is essential for comprehending how safety is maintained.

| Component | Description |

|---|---|

| Release Button | Facilitates the quick disengagement of the fastening system when needed. |

| Latch | Engages to secure the mechanism, holding it in place during movement. |

| Housing | Encloses the internal components, providing structural integrity and protection. |

| Spring | Maintains tension within the mechanism, aiding in the engagement and disengagement process. |

Importance of Each Component

Each element plays a vital role in the overall functionality and safety of the mechanism. Proper understanding of their interactions can help in maintenance and troubleshooting, ensuring optimal performance for occupant protection.

Types of Seat Belt Buckles

This section explores the various classifications of fastening mechanisms designed to secure occupants within vehicles. Each type serves a specific function and is constructed to ensure safety and reliability during travel.

- Classic Latch: The most common design, featuring a simple release mechanism, typically found in standard vehicles.

- Push-Button Release: A user-friendly option that allows for quick disengagement, often preferred in family-oriented models.

- Twist Lock: A mechanism requiring a twisting action to release, providing an extra layer of security against accidental unfastening.

- Electromechanical: An advanced type that incorporates electronic components, often found in luxury vehicles, which may include automatic locking features.

- Quick-Release: Designed for emergency situations, this type can be rapidly unfastened with minimal effort.

Each fastening type offers unique benefits tailored to different user needs, contributing to the overall safety and comfort of passengers on the road.

Functionality of Each Part

This section explores the various components involved in ensuring safety and security within a vehicle. Each element plays a vital role in enhancing user protection and ease of use, contributing to overall effectiveness in preventing injury during travel.

Components Overview

Every individual component serves a specific purpose. The first element is designed to facilitate secure engagement, while the second acts as a release mechanism. Together, these features provide both reliability and accessibility, ensuring that users can swiftly engage or disengage as needed.

Safety Mechanisms

Crucial features are integrated to prevent accidental releases. The locking mechanism ensures that the system remains secure during motion, while the adjustment features allow for customization based on user preference, further enhancing comfort and safety.

Common Materials Used in Buckles

When it comes to fasteners used in various applications, the choice of materials plays a crucial role in functionality, durability, and safety. Understanding the different substances that comprise these mechanisms can help in selecting the right option for specific needs.

Metals

Steel and aluminum are among the most prevalent choices due to their strength and resistance to wear. Stainless steel is particularly favored for its corrosion resistance, making it ideal for environments exposed to moisture.

Plastics

Polypropylene and polycarbonate are commonly utilized for their lightweight properties and versatility. These synthetic materials offer a balance between durability and flexibility, catering to a wide range of applications.

How to Identify Buckle Issues

Recognizing problems with fastening mechanisms is essential for ensuring safety and functionality. When these components fail, it can lead to serious consequences. Here are some key indicators and steps to assess their condition.

Common signs of malfunction include:

- Difficulty in fastening or unfastening.

- Unusual noises during operation.

- Visible wear or damage on the mechanism.

- Improper alignment or fit with the receiving end.

To properly evaluate the fastening device, follow these steps:

- Inspect the exterior for any signs of cracks or breaks.

- Test the functionality by engaging and disengaging multiple times.

- Check for any obstructions that may prevent smooth operation.

- Ensure all components are securely attached and not loose.

By staying vigilant and conducting regular checks, you can ensure that these mechanisms remain reliable and safe for use.

Safety Standards for Buckle Design

Ensuring the utmost protection for individuals relies heavily on the meticulous design of fastening mechanisms. These components must adhere to rigorous guidelines that prioritize user safety and functionality. Compliance with established regulations not only enhances the reliability of these devices but also fosters consumer trust.

Key criteria in the design process include durability, ease of use, and resistance to unintended release. Testing procedures often evaluate performance under various conditions to ensure that these mechanisms can withstand everyday stresses. Additionally, manufacturers are required to implement materials that meet safety specifications, minimizing risks associated with failure.

Furthermore, ongoing advancements in technology prompt regular updates to safety standards. Staying informed about these developments is crucial for designers aiming to create innovative solutions that safeguard users effectively. By prioritizing these regulations, manufacturers contribute to a culture of safety and reliability in everyday life.

Comparing Traditional and Modern Buckles

The evolution of fastening mechanisms showcases the balance between functionality and innovation. Historically, these devices were designed for simplicity and durability, while contemporary models emphasize advanced technology and user convenience.

Traditional mechanisms often relied on straightforward designs, ensuring reliable engagement and disengagement. These systems were crafted from robust materials, focusing on longevity and ease of use, making them dependable choices for their time.

In contrast, modern designs integrate cutting-edge materials and ergonomic features. Enhanced safety measures, such as automatic locking systems and lightweight composites, offer improved performance. Additionally, the aesthetic appeal of current models reflects contemporary style trends, appealing to a broader audience.

Ultimately, the shift from conventional to advanced systems highlights a commitment to safety and user experience, bridging the gap between tradition and innovation in fastening technology.

Maintenance Tips for Seat Belt Systems

Ensuring the proper functionality of your vehicle’s restraint systems is crucial for safety on the road. Regular checks and maintenance can significantly enhance their reliability and longevity. Here are some essential practices to keep in mind.

1. Regular Inspection: Periodically examine the mechanism and webbing for any signs of wear, fraying, or damage. Look for cracks or signs of corrosion in the metal components.

2. Clean Thoroughly: Use mild soap and water to clean the fabric. Avoid harsh chemicals that could weaken the fibers. Ensure that the retracting mechanism is free of dirt and debris.

3. Check Functionality: Test the locking mechanism regularly to ensure it engages properly. Pull the strap to verify that it retracts smoothly without sticking.

4. Ensure Proper Storage: Keep the webbing untangled and properly positioned when not in use. Avoid letting it rest against sharp edges or hot surfaces that could cause damage.

5. Seek Professional Help: If you notice any issues or if the system has been involved in a collision, consult a professional for a thorough inspection and necessary repairs.

By following these tips, you can contribute to the overall safety and effectiveness of your vehicle’s restraint systems.

Impact of Buckle Design on Safety

The design of fastening mechanisms plays a crucial role in ensuring occupant protection during vehicular incidents. Variations in construction and functionality can significantly influence the effectiveness of these devices in minimizing injury. Understanding these differences is vital for improving overall safety standards in automotive engineering.

Key Design Features

Several features in the design of these mechanisms contribute to their performance in critical situations. Factors such as ease of use, material strength, and release mechanism reliability are essential for ensuring that the device functions correctly when needed.

| Design Feature | Impact on Safety |

|---|---|

| Material Strength | Durable materials prevent failure under stress, maintaining restraint integrity. |

| Ease of Use | Intuitive designs encourage proper engagement, reducing the risk of improper use. |

| Release Mechanism | Reliable release systems ensure quick egress post-collision, aiding in evacuation. |

Conclusion

In summary, the design of fastening mechanisms is integral to vehicle safety. Ongoing innovation and testing are essential to enhance these systems, ensuring they provide maximum protection during unexpected events.

Assembly Process of Seat Belt Buckles

The construction of fastening mechanisms involves a series of meticulous steps aimed at ensuring safety and reliability. Each component must be precisely crafted and assembled to function effectively under various conditions.

The initial stage includes the fabrication of individual elements, which are typically made from durable materials to withstand significant stress. These components undergo rigorous quality checks to ensure they meet the necessary standards before proceeding to assembly.

Once the parts are verified, the assembly begins with the alignment of the primary elements. Specialized tools are utilized to secure these components together, guaranteeing a snug fit. The use of automated machinery enhances precision and consistency throughout this phase.

After the initial assembly, the mechanism undergoes functional testing. This step is crucial, as it assesses the performance and ensures that the fastening system operates smoothly and efficiently. Any discrepancies are addressed immediately to maintain quality control.

The final stage involves applying protective coatings or finishes to enhance durability and resistance to wear. Once all procedures are completed, the finished products are packaged and prepared for distribution, ready to provide safety and peace of mind to users.

Innovations in Seat Belt Technology

Advancements in restraint systems have significantly transformed passenger safety in vehicles. Recent developments focus on enhancing both comfort and protection, integrating smart technologies to adapt to various scenarios and user needs.

One notable innovation is the incorporation of sensors that monitor passenger status and adjust tension dynamically during a collision. This ensures optimal protection by adapting to the specific characteristics of the individual, thereby minimizing injury risk.

Moreover, the integration of materials that absorb energy has improved impact resistance, leading to a reduction in forces experienced by occupants during an accident. These cutting-edge materials enhance overall safety without compromising on comfort.

Additionally, some manufacturers are exploring automated systems that remind users to fasten their restraints or provide feedback on their proper usage. These initiatives aim to increase awareness and compliance, ultimately contributing to safer travel experiences.

As technology continues to evolve, the future of occupant protection systems promises even more innovative features, making travel not only safer but also more intuitive for users.

Resources for Further Research

This section aims to provide valuable materials and references for those interested in exploring the intricate components and mechanisms involved in securing safety devices within vehicles. By delving into various resources, readers can enhance their understanding of design, functionality, and safety standards.

Books: Comprehensive texts on automotive safety often include detailed analyses of fastening systems and their evolution. Look for titles focusing on engineering principles and safety innovations.

Online Courses: Many educational platforms offer courses related to automotive design and safety technology, providing insights into the mechanics and standards that govern these essential features.

Industry Journals: Peer-reviewed publications frequently present cutting-edge research on safety mechanisms, materials science, and regulatory changes, which are crucial for anyone looking to deepen their knowledge.

Government Websites: Regulatory bodies provide guidelines and safety information that are vital for understanding the standards that ensure the effectiveness of securing systems in vehicles.

Forums and Community Groups: Engaging with online communities can facilitate discussions with experts and enthusiasts alike, fostering a collaborative environment for sharing knowledge and experiences.