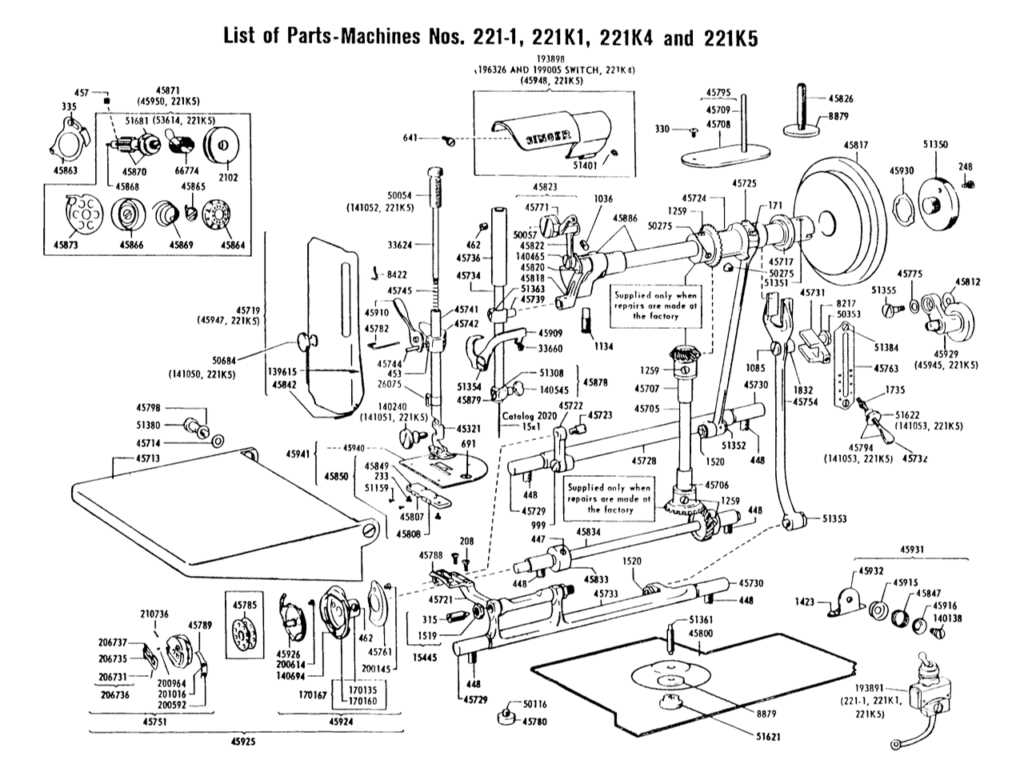

Understanding the intricacies of various mechanical assemblies is essential for anyone looking to maintain or repair equipment. Each element has a specific role, contributing to the smooth operation of the whole system. Exploring how these components interconnect offers valuable insight into the functionality of the device.

Detailed visual aids can simplify the process of identifying key elements and understanding their relationships. By studying technical layouts, you gain a better understanding of how individual pieces interact, ensuring proper function and longevity of the machinery.

Whether you’re working on upkeep or planning repairs, familiarizing yourself with the structure and placement of these parts will streamline the process, helping you achieve more accurate results and improve overall performance.

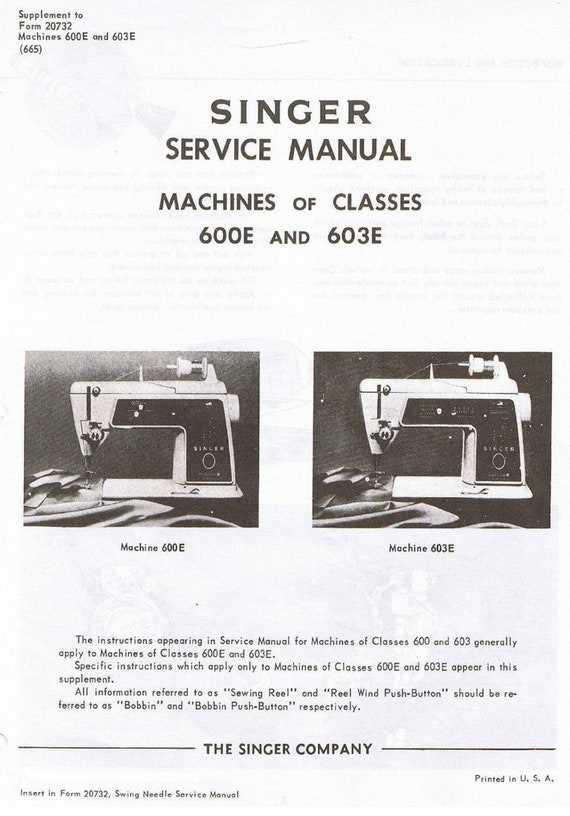

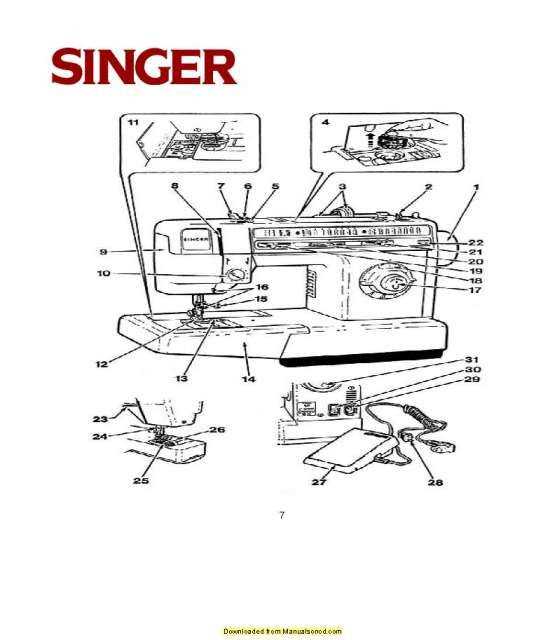

Sewing Machine Components Overview

The sewing machine is a complex device made up of numerous interconnected parts that work together to perform precise stitching operations. Understanding the key elements of this machine can help users maintain and operate it efficiently, ensuring smooth functionality during sewing tasks.

Essential Mechanical Components

- Main Frame – The sturdy foundation that holds all the components together and ensures stability during operation.

- Stitching Mechanism – This system is responsible for forming stitches by coordinating the movement of the needle, thread, and fabric.

- Needle Bar – A vertical rod that moves the needle up and down to create stitches in the fabric.

- Bobbin Case: This holds the bobbin securely in place.

- Bobbin: A small cylinder that stores the lower thread.

- Feed Dogs: These move the fabric and help guide it through the machine.

- Needle: This passes through the fabric and catches the lower thread to form stitches.

- Electric Motor: Responsible for providing the necessary power to drive the machine.

- Belt: Transfers the rotational motion from the motor to the drive shaft.

- Flywheel: Helps maintain a consistent speed and smooth operation by storing kinetic energy.

- Drive Shaft: Connects the motor to the needle mechanism, ensuring efficient transfer of motion.

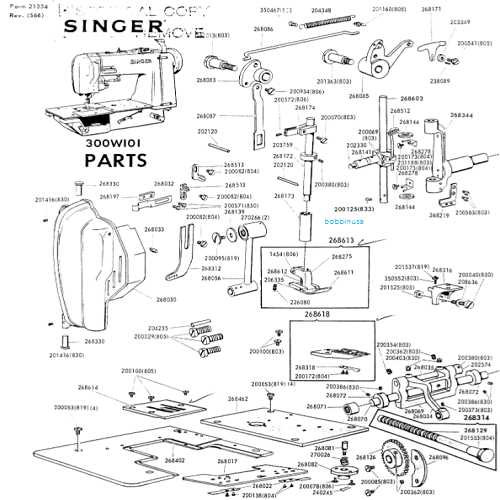

Main Mechanical Parts of Singer 301

The essential components of this classic sewing device contribute to its smooth operation and durability. These elements are intricately designed to ensure precise stitching and reliable functionality. Each section works in harmony, providing users with consistent performance and ease of maintenance.

Core Elements of the Machine

The main framework consists of multiple interconnected pieces that allow for seamless movement and control. This includes a drive mechanism, which powers the needle’s motion, and a series of gears responsible for transferring energy efficiently throughout the entire system. These mechanical components are engineered to withstand prolonged use while maintaining accuracy.

Key Moving Parts

The motion-driven elements are crucial for the fabric handling and stitching process. A well-balanced rotary system ensures the needle moves with precision, while the tension mechanism regulates thread flow, avo

How the Bobbin Mechanism Works

The bobbin mechanism is a crucial component in sewing machines, responsible for holding the lower thread that interlocks with the upper thread to form stitches. Understanding its function is essential for anyone looking to troubleshoot or maintain their sewing device effectively.

Components of the Bobbin Mechanism

Several key elements make up the bobbin mechanism:

Working Principle

The process begins with the upper thread being threaded through the needle. When the needle moves down, it creates a loop of thread. As the needle rises, the hook catches this loop and pulls it down, intertwining it with the thread from the bobbin. This action forms a secure stitch.

To ensure smooth operation, the tension of the lower thread must be correctly adjusted. If the tension is too tight or too loose, it can lead to uneven stitching or thread breakage. Regular maintenance and inspection of the bobbin mechanism help maintain optimal performance.

Exploring the Needle Plate and Feed Dogs

The needle plate and feed dogs play a crucial role in the sewing machine’s operation, providing essential support for various fabric types during stitching. Understanding their function helps users enhance their sewing skills and achieve better results.

Function of the Needle Plate

The needle plate serves as a foundation for the needle and guides the fabric as it moves through the machine. It is typically made of durable material, ensuring longevity. Proper alignment of the needle with the plate is vital for accurate stitching. Regular maintenance of this component, including cleaning and inspection, contributes to optimal performance.

Role of Feed Dogs

Feed dogs are the small, tooth-like mechanisms that grip the fabric and move it under the needle. Their movement is synchronized with the sewing action, allowing for precise control over the fabric’s advancement. Adjusting the height and position of the feed dogs can significantly affect the sewing process, enabling the use of various fabric weights and types. Proper maintenance of these components is essential for smooth operation and consistent results.

Understanding the Motor and Drive System

The motor and drive mechanism play a crucial role in the functionality of sewing machines, enabling smooth operation and precise stitching. This system converts electrical energy into mechanical movement, powering the various components that perform the sewing tasks.

Typically, the motor consists of several key elements:

Understanding the interaction between these components is essential for troubleshooting and maintenance. Here are some key considerations:

- Motor Performance: Regularly check for any unusual noises or vibrations that may indicate wear.

- Belt Tension: Ensure the belt is properly tensioned to prevent slippage and maintain optimal performance.

- Lubrication: Keep moving parts well-lubricated to reduce friction and extend the lifespan of the motor and drive system.

Familiarity with this system enhances the ability to address common issues and ensure reliable operation of the sewing machine.

Presser Foot and Its Adjustments

The presser foot plays a vital role in sewing, ensuring that the fabric is held securely in place while the needle stitches through it. Proper adjustment of this component is essential for achieving the desired stitch quality and fabric handling. Understanding how to manipulate the presser foot can greatly enhance the sewing experience, allowing for precision and control in various projects.

Types of Presser Feet

Different sewing tasks require specific types of presser feet. Each type is designed to accommodate various materials and techniques, ensuring optimal performance. Some common varieties include:

| Type | Description |

|---|---|

| Standard Foot | Used for most basic sewing tasks, providing stability and support. |

| Zipper Foot | Facilitates the installation of zippers by allowing close stitching along the zipper edge. |

| Walking Foot | Ensures even feeding of multiple layers of fabric, ideal for quilting. |

| Buttonhole Foot | Assists in creating consistent buttonholes by guiding the fabric accurately. |

Adjusting the Presser Foot Pressure

Adjusting the pressure of the presser foot is crucial for handling different fabrics. Fabrics that are lightweight may require less pressure, while heavier materials benefit from increased pressure to maintain even stitching. Most machines offer a way to modify this setting, typically through a dial or lever. Regularly checking and adjusting the pressure can prevent puckering and ensure smooth operation.

Thread Tension Control Mechanism Explained

The thread tension control system is a crucial component in sewing machines, ensuring the perfect balance between the upper and lower threads. This mechanism plays a vital role in achieving precise stitches, preventing issues such as puckering or thread breakage. Understanding its functionality allows users to optimize their sewing experience and produce high-quality results.

Functionality of the Tension Control

The primary purpose of the tension control is to adjust the tightness of the upper thread as it passes through the machine. This adjustment is essential for various types of fabrics and sewing techniques. Key aspects include:

- Adjustment Dial: Many machines feature a dial or lever for easy tension adjustments.

- Tension Discs: These discs grip the thread and create friction, allowing for fine-tuning of the tension.

- Spring Mechanism: A spring is often employed to maintain consistent tension as the thread is pulled through.

Common Issues and Solutions

Misadjusted tension can lead to several common problems during sewing. Here are some typical issues and their solutions:

- Puckered Fabric: Decrease the tension to allow for looser stitches.

- Thread Breakage: Increase the tension gradually to find the optimal setting.

- Uneven Stitches: Reassess the tension settings and ensure proper threading through the tension mechanism.

Maintaining proper thread tension is vital for achieving professional results in any sewing project. Regularly checking and adjusting the tension mechanism will lead to better performance and more satisfying outcomes.

The Role of the Spool Pin in Threading

The spool pin serves a crucial function in the process of threading a sewing machine. It acts as a support system for the thread spool, ensuring that the thread unwinds smoothly and efficiently during operation. Understanding its significance can enhance the sewing experience and improve the overall performance of the machine.

Here are some key aspects of the spool pin’s role:

- Stability: The spool pin provides a stable base for the thread spool, preventing it from tipping over or moving during sewing.

- Smooth Unwinding: It allows the thread to unwind in a controlled manner, reducing the risk of tangling and fraying.

- Thread Tension: Proper placement of the thread spool on the pin helps maintain consistent tension, which is essential for even stitching.

- Compatibility: Different spool pins may be designed to accommodate various thread types and sizes, making it important to select the right one for your project.

In conclusion, the spool pin is a vital component in the threading process, contributing to the efficiency and effectiveness of sewing tasks. Proper attention to its function can lead to better results and a more enjoyable sewing experience.

Needle Bar Functionality and Maintenance

The needle bar plays a crucial role in the sewing process, facilitating the movement of the needle during stitching. Understanding its operation and upkeep is essential for ensuring optimal performance and longevity of the sewing machine. Proper maintenance can prevent issues that may arise from wear and tear, contributing to smoother fabric handling and enhanced stitching quality.

Functionality of the Needle Bar

The needle bar is designed to perform specific functions that are vital for effective sewing. Its primary responsibilities include:

- Positioning the needle accurately for various stitching techniques.

- Enabling the up-and-down movement of the needle, which is essential for creating stitches.

- Allowing the attachment of different types of needles depending on the fabric and project requirements.

Maintenance Tips for the Needle Bar

To keep the needle bar functioning efficiently, follow these maintenance guidelines:

- Regularly clean the needle bar to remove dust and lint buildup.

- Check for any signs of wear or damage and replace the needle if necessary.

- Ensure proper lubrication according to the manufacturer’s instructions to prevent rust and friction.

- Adjust the needle bar height if stitching problems occur, ensuring it is set correctly for optimal performance.

Stitch Length Selector and Its Purpose

The stitch length selector is a vital component in sewing machines that allows users to adjust the length of the stitches produced. This feature plays a crucial role in determining the overall appearance and functionality of the sewn item, enabling creativity and precision in various projects.

By manipulating this selector, users can customize stitch lengths to suit different fabrics and techniques. For example, shorter stitches are typically employed for delicate fabrics or intricate designs, ensuring a tighter seam, while longer stitches are ideal for basting or sewing heavier materials. Understanding how to effectively utilize this feature enhances the versatility of the sewing machine and allows for more refined outcomes.

In summary, the stitch length selector is essential for achieving the desired results in sewing projects. Its proper use not only affects the aesthetics but also the durability and strength of seams, making it an indispensable tool for both novice and experienced sewers.

Examining the Handwheel and Its Uses

The handwheel is a crucial component in many sewing machines, playing an essential role in the operation and control of the device. It provides the user with a means to manually advance the needle, allowing for precise adjustments during sewing tasks. This feature is particularly useful when handling delicate fabrics or executing intricate designs that require careful attention to detail.

In addition to its primary function, the handwheel often enables various adjustments and settings, enhancing the overall functionality of the sewing machine. For instance, it can assist in lifting the presser foot or altering the stitch length, facilitating smoother transitions between different sewing techniques. Understanding the significance of this component can greatly improve the user experience and efficiency in crafting projects.

Identifying and Replacing Worn Out Parts

Regular maintenance is essential to ensure the longevity and optimal performance of any machine. Over time, components may wear out, leading to diminished functionality. Recognizing the signs of wear and knowing how to replace these elements can enhance the efficiency of your device and extend its lifespan.

Signs of Wear

Several indicators can help you identify if a component is reaching the end of its service life. These may include unusual noises, reduced performance, or visible damage. Monitoring these symptoms can help prevent further complications and costly repairs.

Replacement Process

Once you’ve identified a worn component, replacing it is straightforward. Gather the necessary tools and refer to the manufacturer’s guide for specific instructions. Ensure that the replacement part is compatible with your device to avoid operational issues.

| Indicator | Action |

|---|---|

| Unusual Noises | Inspect for loose or damaged components. |

| Reduced Performance | Evaluate the condition of essential elements. |

| Visible Damage | Replace damaged components promptly. |