In the world of fine art and craftsmanship, the intricacies of spray tools play a crucial role in achieving precision and creativity. A detailed exploration of these instruments unveils their complex structure, enabling artists to master their techniques effectively.

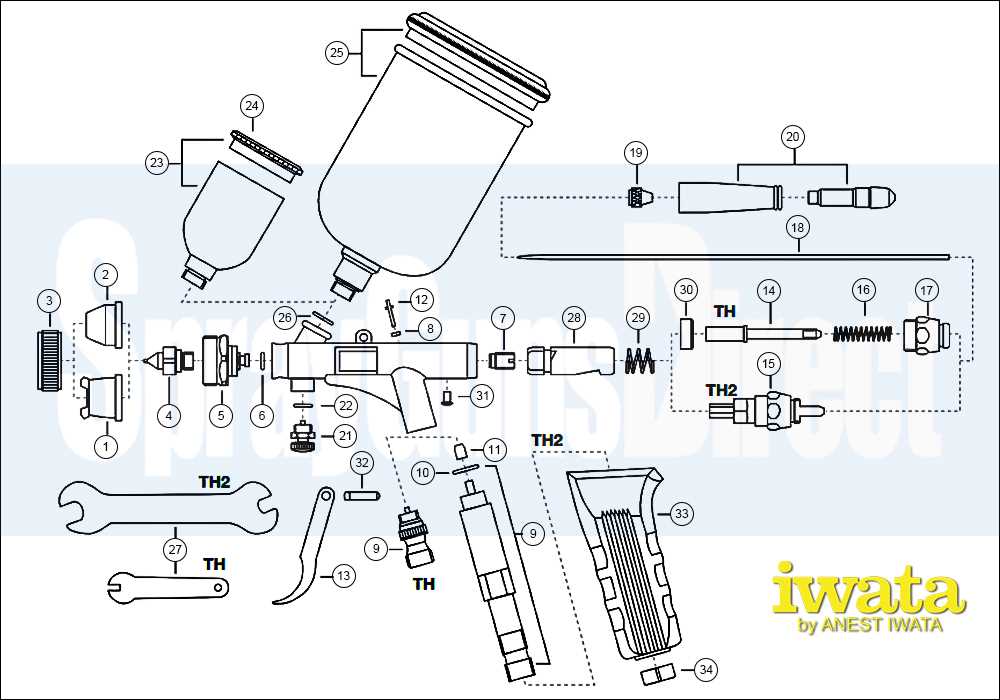

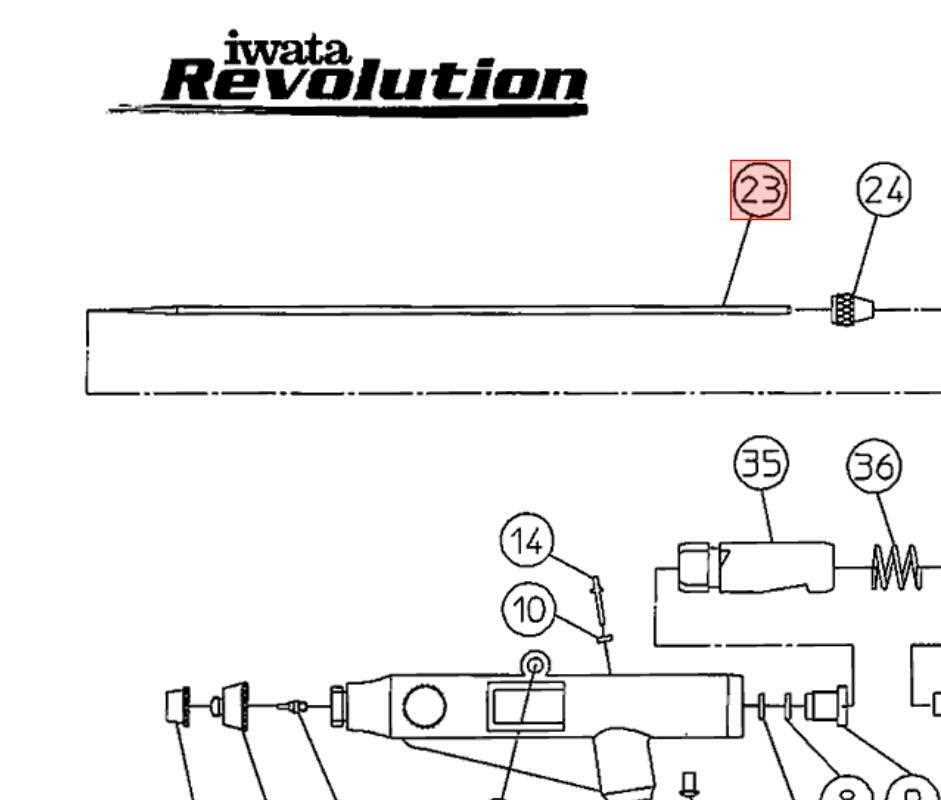

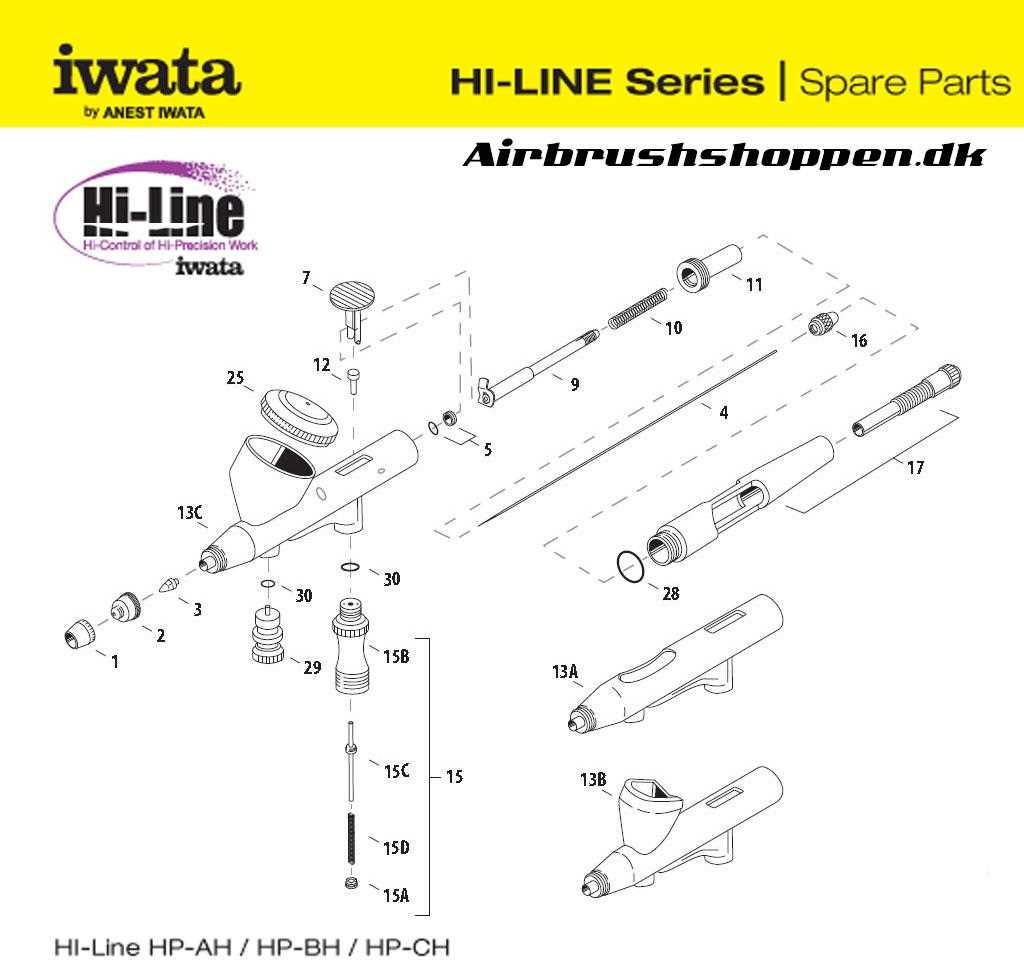

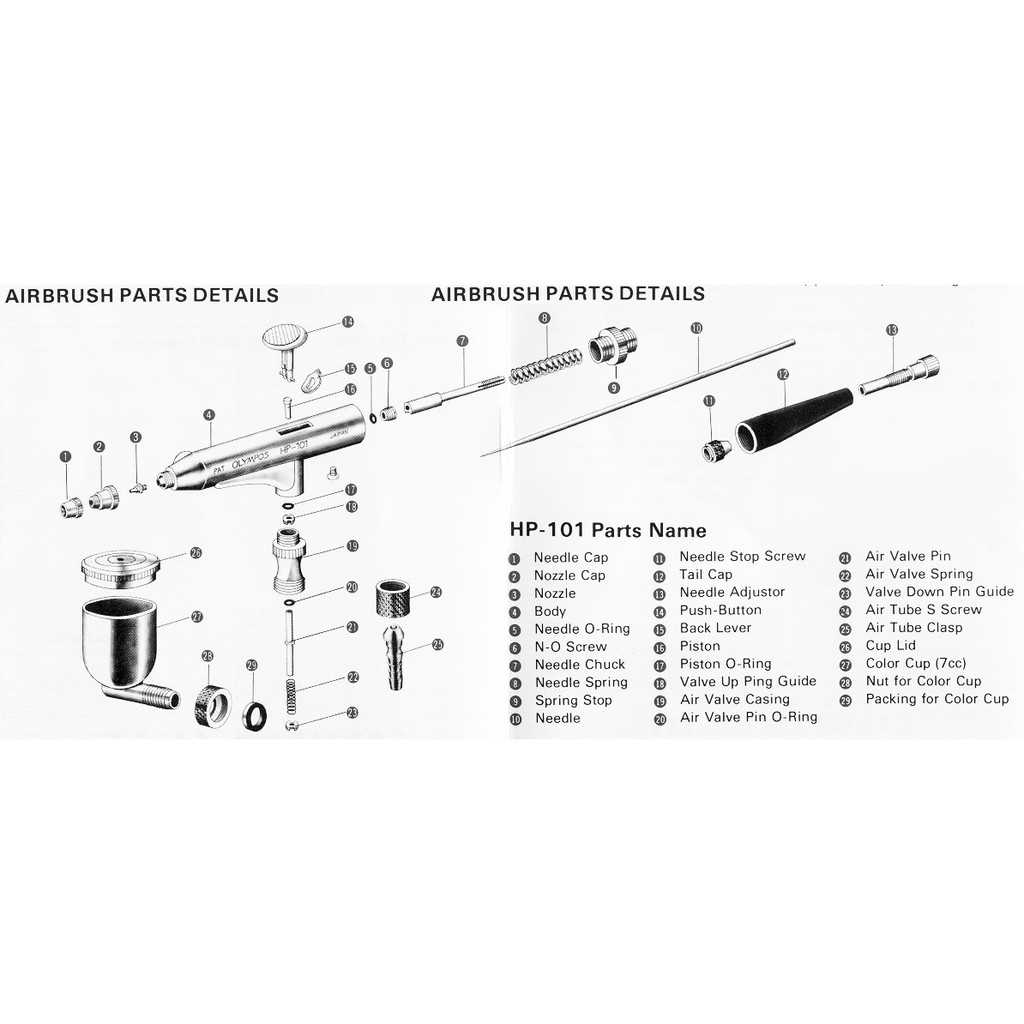

Dissecting the Elements of these essential tools can significantly enhance one’s understanding of their functionality. From the nozzle to the trigger mechanism, each component serves a specific purpose that contributes to the overall performance and versatility of the tool.

By delving into the various elements and their relationships, artists can unlock the ultimate potential of their equipment. This knowledge not only fosters improved skills but also empowers users to maintain and repair their tools with confidence.

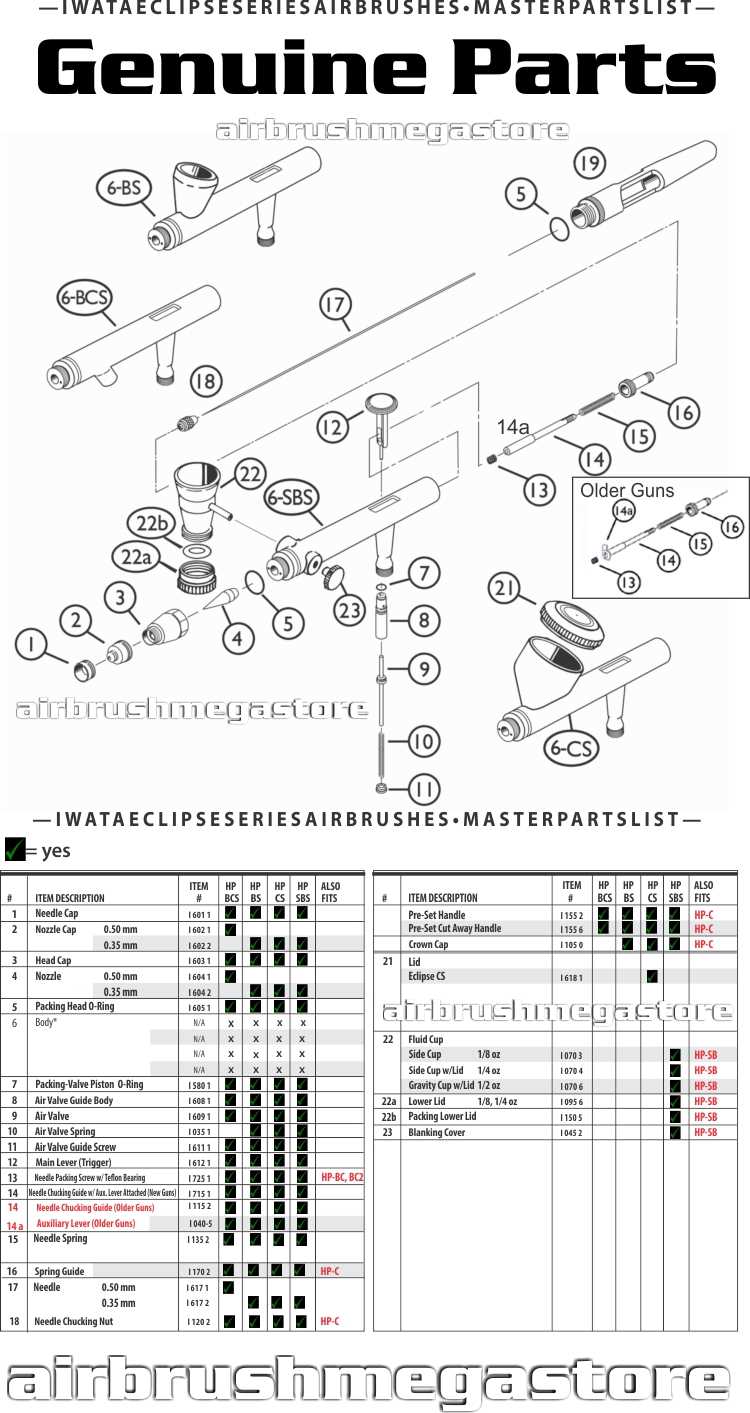

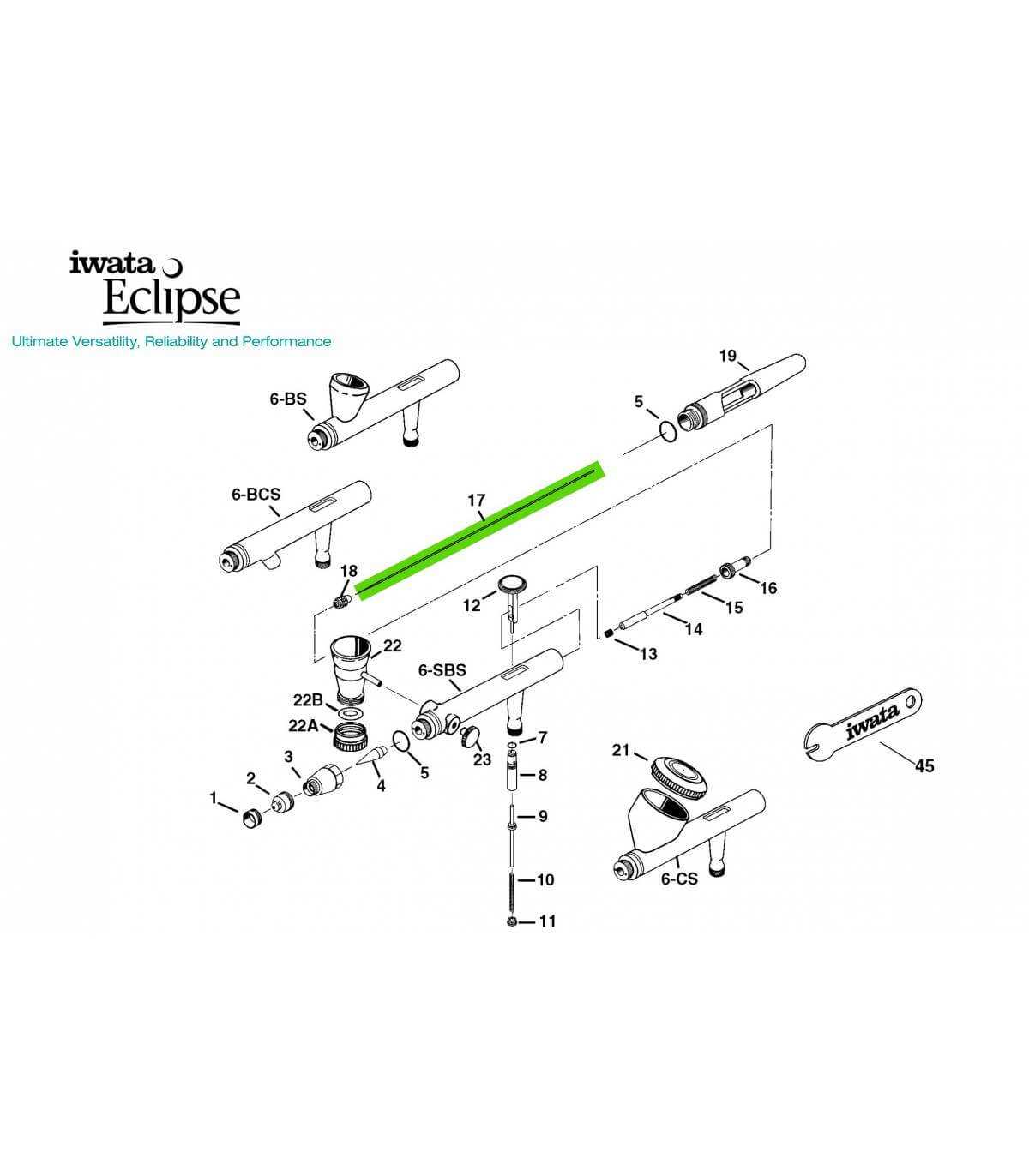

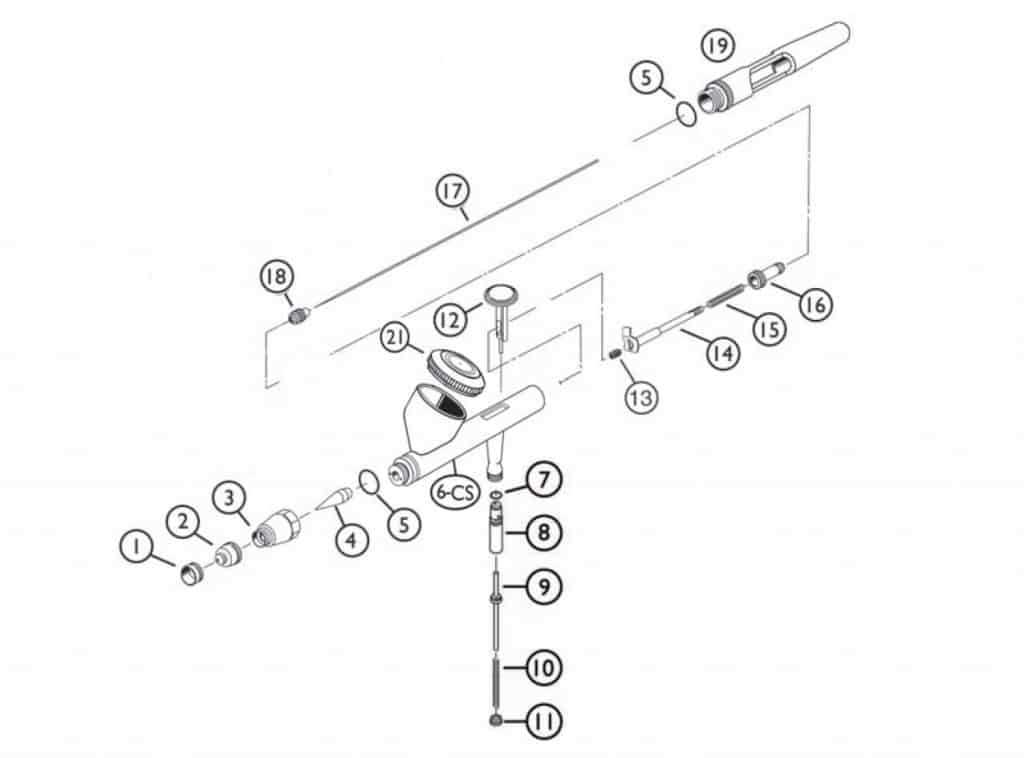

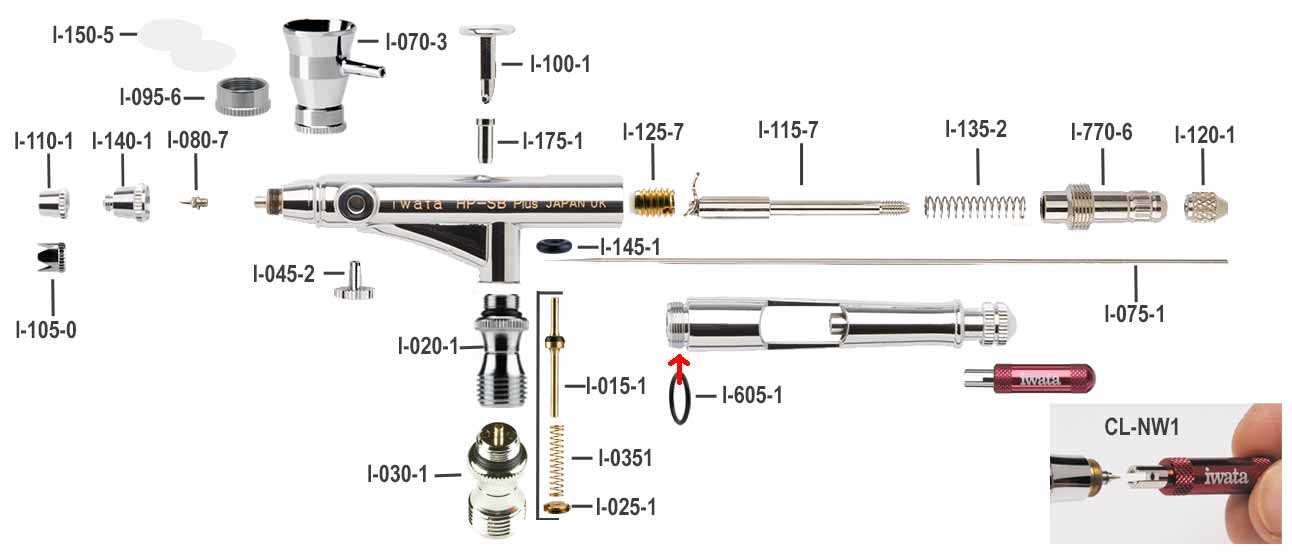

Understanding Iwata HP-C Plus Parts

Exploring the intricacies of a spray tool involves delving into its various components, each playing a crucial role in achieving precision and quality in application. A comprehensive understanding of these elements enhances the overall user experience and contributes to more effective performance.

Key Components

Each element of the device serves a distinct function, from the nozzle that controls the spray pattern to the trigger mechanism that regulates flow. Familiarity with these parts allows users to maintain and troubleshoot their equipment efficiently, ensuring longevity and optimal results.

Maintenance and Care

Regular inspection and upkeep of the components are vital for maintaining functionality. Knowing how to disassemble, clean, and replace specific sections can prevent common issues and enhance the tool’s lifespan. A proactive approach to care not only improves performance but also saves time and resources in the long run.

Essential Components of the Airbrush

An airbrush is a sophisticated tool designed for precision in art and application. Understanding its key elements is crucial for achieving optimal performance and results. Each component plays a vital role in how the device functions, contributing to the overall efficacy of the spraying technique.

Main Elements

- Nozzle: The part where paint exits, determining the width and precision of the spray.

- Needle: Controls the flow of paint and air, affecting the spray pattern.

- Body: The main structure housing all components, offering balance and grip.

- Trigger: Allows for control over paint flow and air pressure, enabling intricate details.

- Fluid Cup: Holds the paint, available in various sizes for different applications.

Additions for Enhanced Functionality

- Air Source: Compressors or tanks provide the necessary pressure for operation.

- Hoses: Connect the air source to the airbrush, facilitating paint delivery.

- Cleaning Tools: Essential for maintaining the airbrush and ensuring longevity.

Benefits of Knowing the Parts Diagram

Understanding the components of a device enhances both maintenance and functionality. Familiarity with the assembly allows users to identify issues quickly, ensuring efficient operation and prolonging the lifespan of the equipment.

First and foremost, being aware of each element’s role aids in troubleshooting, as users can pinpoint malfunctions more effectively. This knowledge not only saves time but also reduces the likelihood of costly repairs.

Additionally, grasping the layout encourages better cleaning and care practices, which are essential for optimal performance. Regular maintenance becomes simpler when one knows the specifics of each section.

Lastly, having access to this information can foster a greater appreciation for the technology, leading to more informed decisions regarding upgrades or replacements. This ultimate understanding empowers users to utilize their equipment to its fullest potential.

Common Issues with Iwata HP-C Plus

Airbrush enthusiasts often encounter a range of challenges that can hinder performance and affect the quality of work. Understanding these common problems can help users maintain their tools effectively and achieve better results.

- Clogging: A frequent issue that arises when paint dries within the nozzle or other components, leading to inconsistent flow.

- Inconsistent Spray Pattern: This can occur due to improper needle alignment or wear, affecting the application of materials.

- Air Leaks: Small leaks can develop at connection points, causing a loss of pressure and inconsistent performance.

- Difficulty in Cleaning: Residual paint can accumulate in hard-to-reach areas, making thorough cleaning essential for optimal function.

Addressing these issues promptly can prolong the lifespan of the airbrush and enhance the overall user experience. Regular maintenance and understanding the mechanics involved can significantly mitigate these common problems.

How to Identify Each Part

Understanding the components of your airbrush is essential for effective use and maintenance. Each element plays a crucial role in achieving optimal performance and precision in your work. Here’s a guide to help you recognize and differentiate these vital pieces.

- Nozzle: This is the component where the paint exits, creating the spray pattern. It comes in various sizes for different effects.

- Needle: Positioned within the nozzle, this part controls the paint flow. It must be handled with care to avoid damage.

- Trigger: The mechanism that allows you to control the airflow and paint volume simultaneously.

- Body: The main structure of the airbrush, housing all the internal components. It typically features ergonomic designs for ease of handling.

- Cap: Protects the nozzle and helps prevent paint from drying on the tip, ensuring consistent performance.

By familiarizing yourself with these components, you’ll be better equipped to troubleshoot issues and maintain your tool for the ultimate creative results.

Maintenance Tips for Longevity

Ensuring the durability of your equipment requires a systematic approach to upkeep and care. Regular maintenance not only enhances performance but also prolongs the lifespan of the tools. Following best practices can prevent wear and tear, ensuring reliable operation for years to come.

Regular Cleaning

One of the most critical aspects of maintenance is consistent cleaning. After each use, make sure to remove paint residue and other debris. Using a suitable cleaning solution will help maintain the functionality of the internal components. Additionally, periodic deep cleaning can eliminate any buildup that might impair performance over time.

Proper Storage

How you store your equipment significantly impacts its longevity. Keep it in a dry, temperature-controlled environment to prevent corrosion and damage. Utilizing protective cases or covers can shield it from dust and accidental impacts. Always ensure that the components are disassembled, if necessary, to avoid unnecessary pressure on delicate parts.

Replacing Worn or Damaged Parts

Maintaining the optimal performance of your airbrush requires regular attention to its components. Over time, various elements may wear out or become damaged, affecting the overall functionality and efficiency of the tool. Recognizing when to replace these components is essential for preserving the quality of your work and ensuring a smooth painting experience.

Identifying Issues

Before proceeding with any replacements, it’s important to diagnose the problem accurately. Common signs of wear or damage include:

- Inconsistent paint flow

- Frequent clogging

- Unusual noises during operation

- Visible cracks or deterioration on parts

Replacement Process

Once you’ve identified the affected components, follow these steps for effective replacement:

- Gather necessary tools, such as a wrench, pliers, and replacement components.

- Disassemble the airbrush carefully, taking note of the order of parts.

- Remove the damaged or worn elements.

- Install the new components, ensuring a secure fit.

- Reassemble the airbrush, checking for proper alignment.

- Test the tool to confirm improved functionality.

Regular maintenance and timely replacement of worn elements will help extend the life of your airbrush, ensuring it continues to perform at its best.

Tools Needed for Disassembly

When undertaking the task of dismantling an airbrush, having the right instruments is essential for a smooth and efficient process. Proper tools not only facilitate the removal of components but also help prevent damage to delicate parts. Below is a guide to the necessary equipment that will ensure a successful disassembly.

Essential Tools

To begin, a screwdriver set is crucial for loosening screws that hold various sections together. A precision screwdriver, especially in smaller sizes, will allow you to access tighter areas without risk of stripping the screws. Additionally, a pair of needle-nose pliers can be invaluable for gripping small parts and pulling them free.

Optional Tools

In some cases, you may find that a magnifying glass is helpful for examining tiny components, ensuring you do not miss any critical details. A cleaning brush can also aid in clearing away debris that may interfere with the reassembly process. Lastly, a small container or organizer is beneficial for keeping track of removed parts, preventing loss or mix-up.

Visual Guide to Assembly Process

This section aims to provide a comprehensive overview of the assembly workflow, offering a clear representation of each stage. By breaking down the process into easily digestible steps, users can better understand the intricacies involved in putting together the equipment efficiently.

| Step | Description | Tools Needed |

|---|---|---|

| 1 | Gather all necessary components and tools. | Screwdriver, wrench |

| 2 | Start with the base unit, ensuring all parts are clean. | Cloth, cleaning solution |

| 3 | Attach the primary assembly components using screws. | Screwdriver |

| 4 | Install any necessary seals or gaskets for a tight fit. | Sealant, gasket tool |

| 5 | Connect the final components, ensuring proper alignment. | Torque wrench |

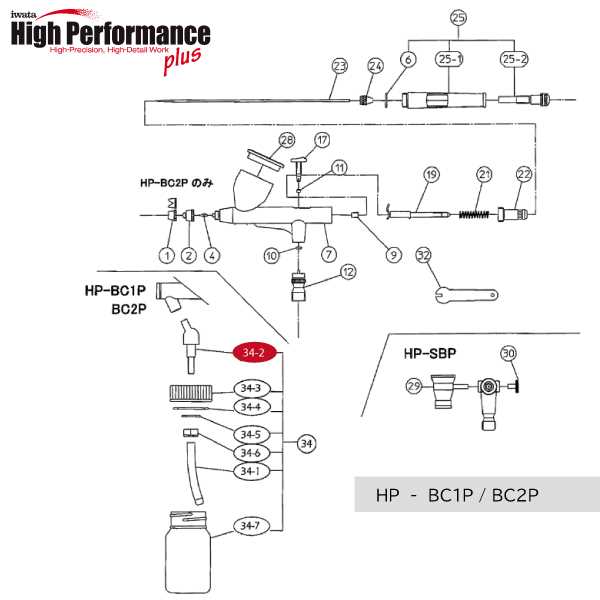

Compatibility with Other Models

Understanding how various airbrush systems can interchange parts and components is crucial for maximizing usability and performance. Many enthusiasts seek to know which models share similarities, enabling them to utilize accessories across different brands.

- Similar nozzle sizes and shapes can allow for cross-compatibility.

- Common components like needles often fit multiple airbrush models.

- Some brands design their products to accommodate standard fittings.

When exploring compatibility, consider the following:

- Check the manufacturer’s specifications for part dimensions.

- Research user experiences to identify successful pairings.

- Evaluate the performance impact of using parts from other models.

Upgrading Your Airbrush Setup

Enhancing your spray equipment can significantly improve your artistic results and efficiency. By selecting the right components and accessories, you can elevate your work to a new level, allowing for more precision and creativity in your projects.

Key Components to Consider

- Needle and nozzle size: Experimenting with different diameters can lead to varied effects.

- Air compressor: A reliable, adjustable compressor ensures consistent airflow.

- Hoses and connectors: Quality hoses minimize pressure loss and enhance mobility.

Accessories That Make a Difference

- Cleaning kit: Regular maintenance prolongs the lifespan of your equipment.

- Color cups: Different sizes accommodate various paint quantities and types.

- Filter: Incorporating a moisture trap prevents unwanted water in your paint.

Resources for Further Learning

Expanding your knowledge in the realm of precision tools can greatly enhance your skills and creativity. Accessing quality resources will provide insights into maintenance, operation techniques, and innovative practices that can elevate your artistry. This section highlights valuable materials to deepen your understanding and proficiency.

Online platforms such as forums and instructional websites offer a wealth of information shared by experienced users. Engaging with communities allows for the exchange of tips, troubleshooting advice, and personal experiences that can be invaluable for both beginners and seasoned practitioners.

Books focused on tool usage and artistic techniques can serve as comprehensive guides, providing in-depth explanations and illustrated examples. These resources often cover a wide range of topics, from basic handling to advanced applications, ensuring that you find information relevant to your skill level.

Video tutorials present a dynamic way to learn, allowing you to see techniques in action. Many creators share their expertise through step-by-step demonstrations, making complex processes more accessible and easier to replicate.

Workshops and local classes offer hands-on experience, allowing you to practice under the guidance of professionals. Such interactive settings foster a supportive learning environment where you can ask questions and receive immediate feedback on your progress.

Lastly, consider subscribing to specialized publications or online courses that focus on tool mastery and artistic development. These resources often provide up-to-date trends and techniques, ensuring you remain informed and inspired in your craft.