Maintaining the crucial elements of a vehicle’s forward structure is essential for both performance and safety. A well-balanced setup ensures smooth operation and reliability during demanding conditions. Understanding how these components work together can help you ensure that everything functions optimally.

Each element within this assembly has its own role, contributing to the overall stability and handling of the vehicle. Identifying and addressing potential issues early can prevent larger problems down the road. Whether you’re conducting routine maintenance or tackling more complex repairs, knowing the essential components is key.

This section will provide a detailed look into the essential structures and mechanisms that come together to form a functional system. By gaining a deeper insight, you’ll be better equipped to maintain and repair the critical parts, ensuring long-term durability and safety.

Comprehensive Guide to 2011 F250 Front End Components

Understanding the essential mechanical elements that contribute to the smooth operation of your vehicle’s suspension and steering system is crucial for maintenance and repairs. This guide explores the various key assemblies that work together to ensure stability, safety, and control while driving. Whether you’re dealing with alignment issues or routine inspections, being familiar with the primary structural units can make a significant difference in addressing any concerns effectively.

Each section below will highlight the functionality and importance of individual components, offering a clear understanding of their roles in the overall system. From steering to suspension, these mechanisms must be maintained regularly to prevent wear and ensure optimal performance on the road.

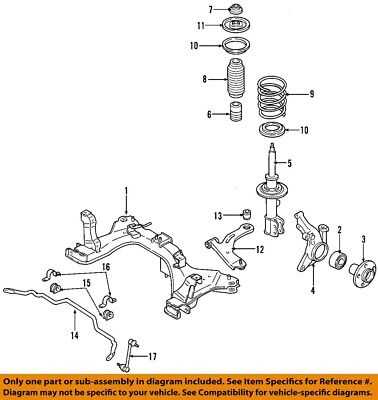

Understanding the Main Parts of the Front Assembly

The vehicle’s forward structure plays a crucial role in both stability and maneuverability. Comprising multiple interconnected components, this section is responsible for handling steering, absorbing road shocks, and ensuring overall safety. Each element works in harmony to provide a smooth and controlled driving experience.

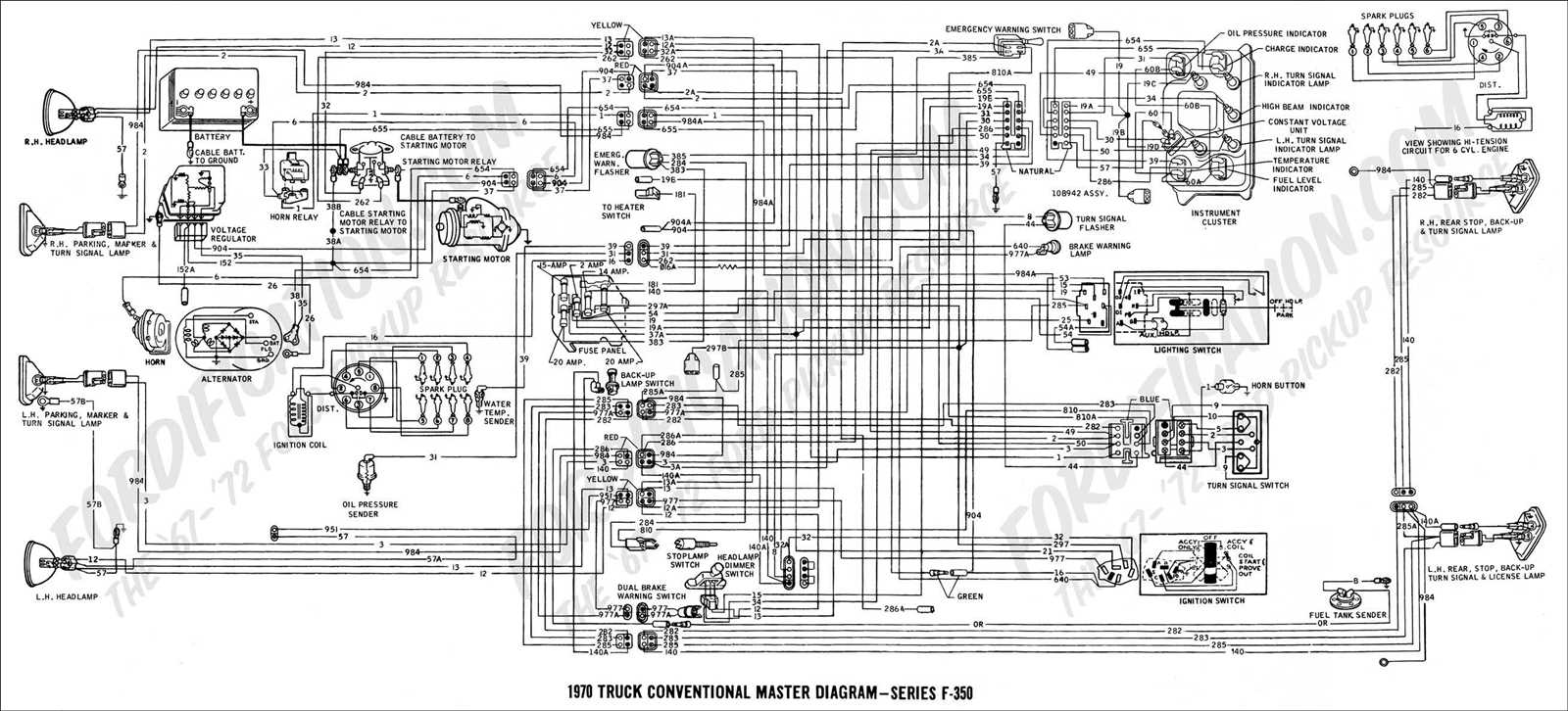

Steering system elements are vital in directing the vehicle’s movements. These components ensure that the driver maintains control, whether making sharp turns or adjusting the vehicle’s course on uneven surfaces.

The suspension system supports the vehicle’s weight and helps maintain tire contact with the road. This structure includes various springs, shock absorbers, and linkages, all designed to minimize vibrations and improve comfort.

Another critical component is the

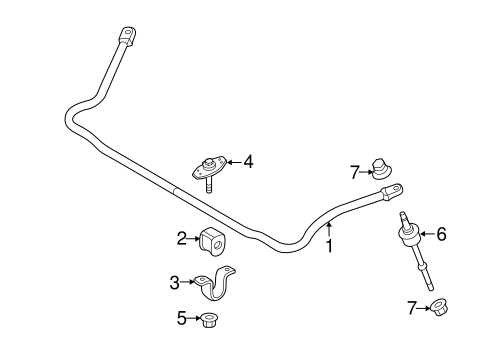

How to Identify Key Suspension Elements

Understanding the primary components of a vehicle’s suspension is crucial for ensuring optimal performance and safety. The suspension system plays a pivotal role in stabilizing the vehicle, absorbing shocks, and maintaining tire contact with the road. Identifying the core elements helps in recognizing potential issues and making necessary adjustments.

The main elements you should focus on include the system responsible for cushioning impacts, components that guide wheel alignment, and those that connect various parts to ensure a smooth and controlled ride. Each of these components works in harmony to manage forces generated during driving, providing comfort and control.

In addition to these primary elements, it’s important to inspect the linkages and joints, which allow for movement and flexibility. These are subject to wear and can cause handling issues if not maintained. By familiarizing yourself with the arrangement and function of each component, you’ll be able to identify potential problems early and take appropriate action.

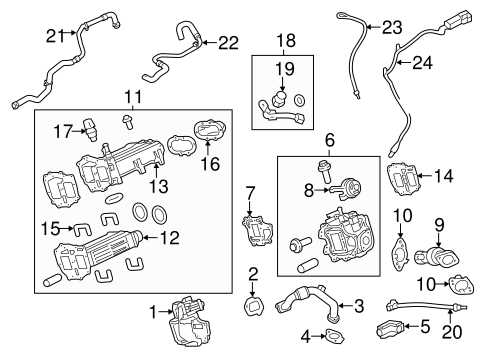

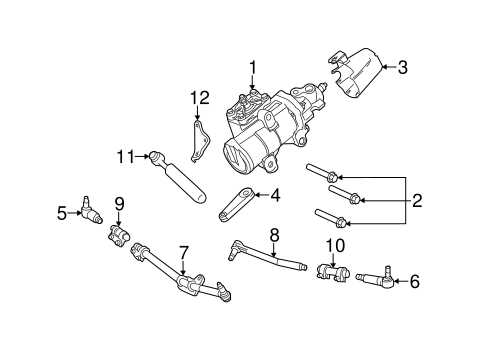

Detailed Look at Steering System Components

The steering mechanism plays a crucial role in ensuring vehicle control and maneuverability. It is responsible for translating the driver’s input into precise wheel movement, enabling smooth turns and maintaining direction. Understanding the various elements involved in this system helps to grasp how they work together to provide responsive handling and stability.

Main Components of the Steering Assembly

The steering assembly is composed of several key elements that contribute to effective control. The steering column transmits the driver’s motion from the wheel to the mechanism itself. In turn, this motion reaches the steering gear, which ensures that the movement is appropriately transferred to the wheels. Another essential part is the linkage, which connects the steering gear to the wheels, allowing synchronized movement.

Importance of Proper Maintenance

Maintaining the

Common Issues with 2011 F250 Front Parts

When maintaining the structural components at the front of a vehicle, certain problems can arise that are worth addressing promptly. These issues often impact the overall performance and safety, and neglecting them can lead to more severe damage. Below are some typical concerns drivers might encounter.

Wear and Tear of Suspension Elements

One of the primary areas where wear is frequently observed is in the suspension system. Components such as bushings and joints can degrade over time due to constant stress, leading to poor handling and reduced comfort during driving. Regular inspections and timely replacements are essential to maintain optimal functionality.

Alignment and Steering Problems

Another common issue involves alignment and steering mechanisms. If the alignment is off, the vehicle may pull to one side, and

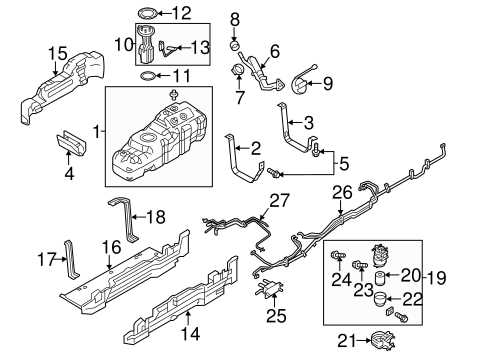

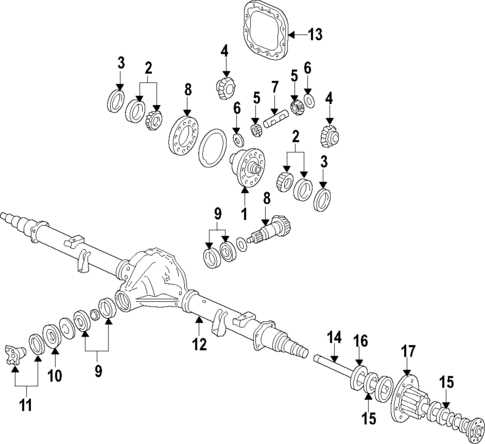

Exploring the Role of the Front Axle

The front axle plays a crucial role in the overall performance and stability of a vehicle. It serves as a vital component that connects the wheels to the chassis, allowing for effective steering and weight distribution. Understanding its functions helps in appreciating how vehicles maneuver and maintain control during various driving conditions.

One of the primary responsibilities of the front axle is to facilitate the steering mechanism. By allowing the wheels to pivot in response to the driver’s input, it enables the vehicle to change direction smoothly. Additionally, the axle supports the weight of the vehicle, which is essential for proper handling and safety. The strength and integrity of this component are paramount, as they ensure that the vehicle can withstand the stresses of daily driving.

Moreover, the front axle contributes to the overall suspension system. It absorbs shocks from uneven road surfaces, enhancing ride comfort and stability. A well-maintained axle is critical for minimizing wear on tires and other related systems, ensuring longevity and optimal performance. Regular inspection and maintenance of this component can prevent issues that may arise from neglect, such as misalignment or excessive wear.

In summary, the front axle is integral to a vehicle’s functionality, influencing both handling and comfort. Its role in steering, weight distribution, and suspension makes it essential for safe and effective operation on the road.

Replacement Tips for Front-End Bearings

When it comes to maintaining the stability and performance of your vehicle, proper attention to wheel support elements is crucial. These components play a vital role in ensuring smooth steering and overall drivability. Replacing worn or damaged bearings can significantly improve handling and extend the lifespan of associated parts.

Here are some essential tips for replacing wheel support components:

- Gather Necessary Tools: Ensure you have the right tools before starting. Common tools include a socket set, torque wrench, and bearing puller.

- Consult the Manual: Refer to your vehicle’s service manual for specific instructions and torque specifications related to the installation process.

- Inspect Related Components: Check adjacent elements, such as seals and hubs, for wear. It’s wise to replace any damaged parts simultaneously.

- Use Quality Bearings: Invest in high-quality replacements to ensure longevity and reliability. Avoid low-cost options that may lead to premature failure.

- Proper Lubrication: Apply appropriate grease or lubricant during installation. This reduces friction and prevents premature wear.

- Follow Safety Protocols: Always prioritize safety. Use jack stands to secure the vehicle and wear safety goggles when working.

By following these guidelines, you can ensure a successful replacement process, leading to enhanced performance and safety on the road.

Maintaining the Integrity of the Ball Joints

Ensuring the reliability and performance of the suspension system is crucial for the overall functionality of a vehicle. Ball joints play a vital role in this system, connecting various components and allowing for smooth movement. Regular maintenance of these elements is essential to prevent premature wear and ensure optimal handling.

Importance of Regular Inspections

Frequent inspections of ball joints help identify potential issues before they escalate. Here are some key points to consider:

- Look for signs of wear such as cracks or excessive play.

- Check for grease leaks, which may indicate a loss of lubrication.

- Assess the alignment of the wheels, as improper alignment can lead to increased stress on the joints.

Proper Lubrication Techniques

Maintaining adequate lubrication is crucial for the longevity of ball joints. Follow these practices:

- Use high-quality grease suitable for your vehicle’s specifications.

- Apply grease regularly, especially after off-road use or exposure to harsh conditions.

- Inspect the protective boots for any damage and replace them if necessary to keep contaminants out.

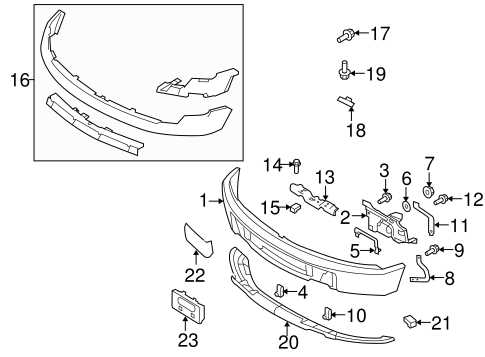

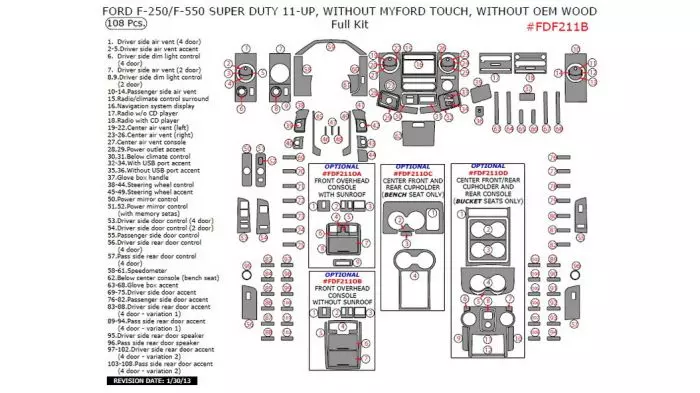

Upgrading the Front Bumper and Grille

Enhancing the vehicle’s aesthetics and functionality can significantly transform its overall appeal. One effective way to achieve this is by upgrading the front fascia components, such as the bumper and grille. These modifications not only improve visual appeal but can also provide better protection and airflow to the engine.

When selecting new components, consider materials that offer durability and lightweight characteristics. Options like high-strength plastic or aluminum can withstand harsh conditions while minimizing extra weight. Additionally, styles vary widely, ranging from rugged off-road designs to sleek, modern finishes, allowing owners to tailor their vehicle’s look to their personal taste.

Installation typically requires basic tools and a few hours of time, depending on the complexity of the chosen components. Always refer to the manufacturer’s instructions for a precise fit. After the upgrade, regular maintenance and inspections will ensure that these features continue to perform effectively and retain their appearance over time.

The Importance of Proper Alignment Components

Ensuring accurate positioning of a vehicle’s wheels is crucial for optimal performance and safety. Misalignment can lead to uneven tire wear, reduced handling, and compromised stability, ultimately affecting the driving experience. By focusing on the correct components for wheel alignment, vehicle owners can maintain their automobiles more effectively, enhancing longevity and overall functionality.

Benefits of Accurate Wheel Positioning

Properly aligned wheels contribute significantly to fuel efficiency and extend the lifespan of tires. When the wheels are in the right position, they create less rolling resistance, allowing the vehicle to travel more efficiently. Additionally, this alignment reduces the strain on other mechanical components, resulting in fewer repairs and lower maintenance costs over time.

Signs of Misalignment

Common indicators of misalignment include uneven tire wear, a vehicle pulling to one side, and a steering wheel that is off-center. Paying attention to these signs can help drivers address alignment issues promptly. Regular inspections and adjustments of alignment components are essential for ensuring that vehicles operate smoothly and safely on the road.

Best Practices for Front End Maintenance

Regular upkeep of the vehicle’s forward assembly is essential for ensuring optimal performance and safety. Proper maintenance not only prolongs the lifespan of various components but also enhances overall driving experience. Adopting systematic approaches can lead to significant improvements in handling and stability.

One of the key practices is to conduct routine inspections to identify wear and tear on crucial elements such as suspension systems, steering mechanisms, and associated linkages. Addressing any signs of damage promptly can prevent more extensive issues down the road.

Additionally, maintaining proper alignment is critical. Misalignment can lead to uneven tire wear and compromised handling. Regularly scheduled alignment checks can help ensure that the wheels are properly positioned, which enhances both safety and fuel efficiency.

Lubrication of moving parts is another important aspect. Ensuring that joints and bushings are adequately lubricated helps reduce friction, thereby minimizing wear. Regularly scheduled lubrication not only keeps components functioning smoothly but also protects against premature failure.

Lastly, keeping a close eye on fluid levels and quality is essential. Regularly checking and replacing fluids in systems related to the vehicle’s forward assembly ensures that all components operate efficiently and reduces the risk of damage caused by contamination or degradation.