When it comes to maintaining the efficiency and longevity of your gardening tool, a thorough understanding of its internal structure is essential. Every device comprises various elements that work in unison to deliver optimal performance. Familiarizing yourself with these components not only aids in effective upkeep but also empowers you to make informed decisions during repairs and replacements.

In this guide, we will explore the intricate assembly of your trimming equipment, detailing each essential part and its function. By visualizing the layout of these elements, you can better appreciate how they contribute to the overall operation. This knowledge is invaluable, especially when troubleshooting or looking to enhance the performance of your machine.

Whether you are a seasoned landscaper or a weekend gardening enthusiast, knowing the specifics of your tool’s configuration can greatly enhance your user experience. A well-informed operator can anticipate issues before they arise and ensure that their equipment remains in peak condition. Join us as we delve into the essential elements that make your gardening tool work efficiently.

Understanding Stihl FS110R Parts

Grasping the components of a grass trimmer is essential for efficient operation and maintenance. Familiarity with each element ensures optimal performance and longevity of the tool. Whether you are a novice user or an experienced professional, recognizing the various segments can greatly enhance your experience.

Key Components of the Trimmer

Among the primary elements are the engine, cutting head, and shaft. The engine powers the entire unit, while the cutting head is responsible for managing the grass and weeds. The shaft connects these crucial parts, allowing for maneuverability and control. Understanding how these pieces work together is vital for troubleshooting and repairs.

Maintenance and Replacement

Regular upkeep is critical to maintaining functionality. Replacing worn-out parts not only improves performance but also ensures safety. It is important to follow a systematic approach when inspecting and changing components, as this can prevent potential breakdowns and extend the life of your equipment.

Overview of FS110R Features

This section delves into the key characteristics of a popular brush cutter model, highlighting its design elements and operational advantages that cater to both professional landscapers and dedicated homeowners.

Key Characteristics

- Powerful engine delivering robust performance for demanding tasks.

- Lightweight construction for enhanced maneuverability and reduced fatigue.

- Ergonomic handle design to ensure comfort during prolonged use.

- Versatile cutting attachments allowing for various landscaping needs.

Performance Benefits

- Efficient fuel consumption contributing to lower operating costs.

- Durable components designed for longevity and reliability.

- Easy-start technology minimizing effort for ignition.

- Advanced vibration dampening system enhancing user experience.

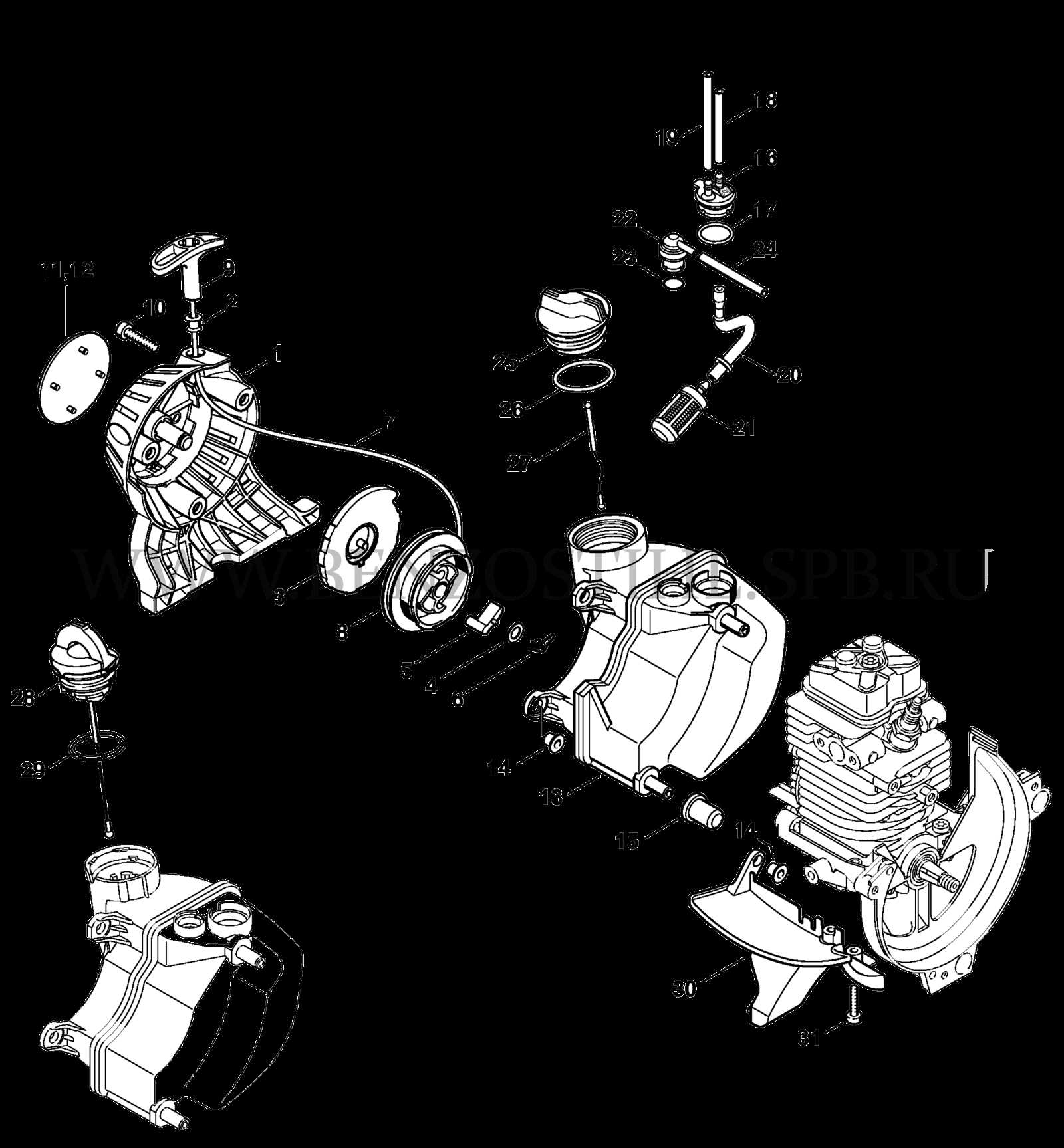

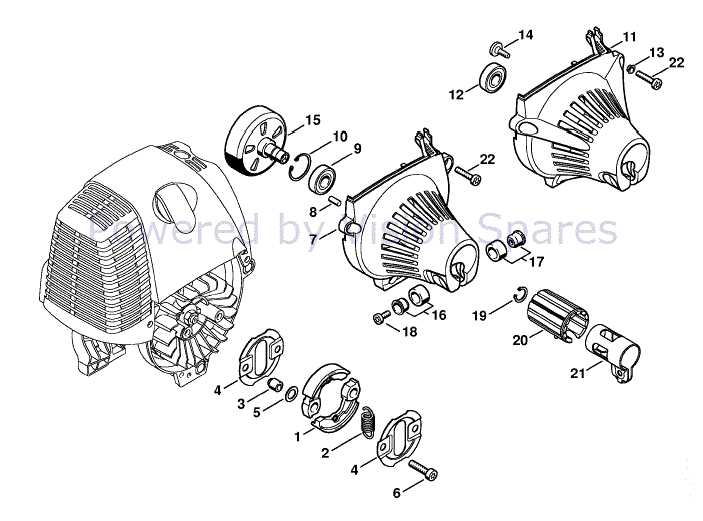

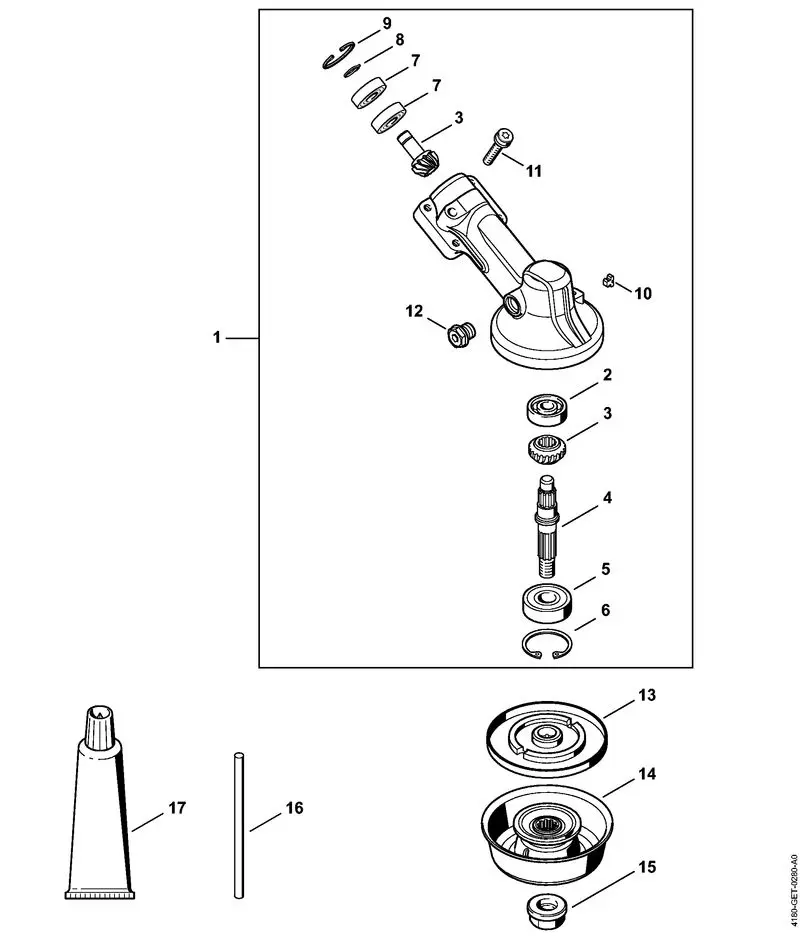

Importance of Parts Diagrams

Understanding the components of machinery is crucial for effective maintenance and repair. Visual representations of these elements play a vital role in simplifying complex structures, allowing users to easily identify and locate specific sections. This clarity not only aids in troubleshooting but also enhances the overall efficiency of the repair process.

Utilizing these visual aids fosters better comprehension of how individual elements interact within the system. When users can see the layout and connection of various components, they are more equipped to perform necessary tasks without confusion. This knowledge ultimately leads to more informed decisions regarding repairs and replacements.

Furthermore, having access to such illustrations encourages a proactive approach to maintenance. By identifying wear and tear early, users can prevent larger issues from arising. This preventative mindset not only saves time but also extends the lifespan of the equipment.

In summary, visual representations of machinery components serve as essential tools in the realms of maintenance and repair, enhancing understanding, efficiency, and longevity.

Key Components of the FS110R

This section explores the essential elements that contribute to the functionality and performance of the tool. Understanding these components is crucial for maintenance and effective operation, ensuring longevity and efficiency in various tasks.

Essential Features

The main features of this model include a powerful engine, ergonomic design, and a variety of attachments that enhance its versatility. Each part plays a significant role in the overall effectiveness, making it suitable for different applications.

Component Overview

| Component | Description |

|---|---|

| Engine | A robust motor that provides the necessary power for demanding tasks. |

| Handle | Designed for comfort and control, reducing fatigue during extended use. |

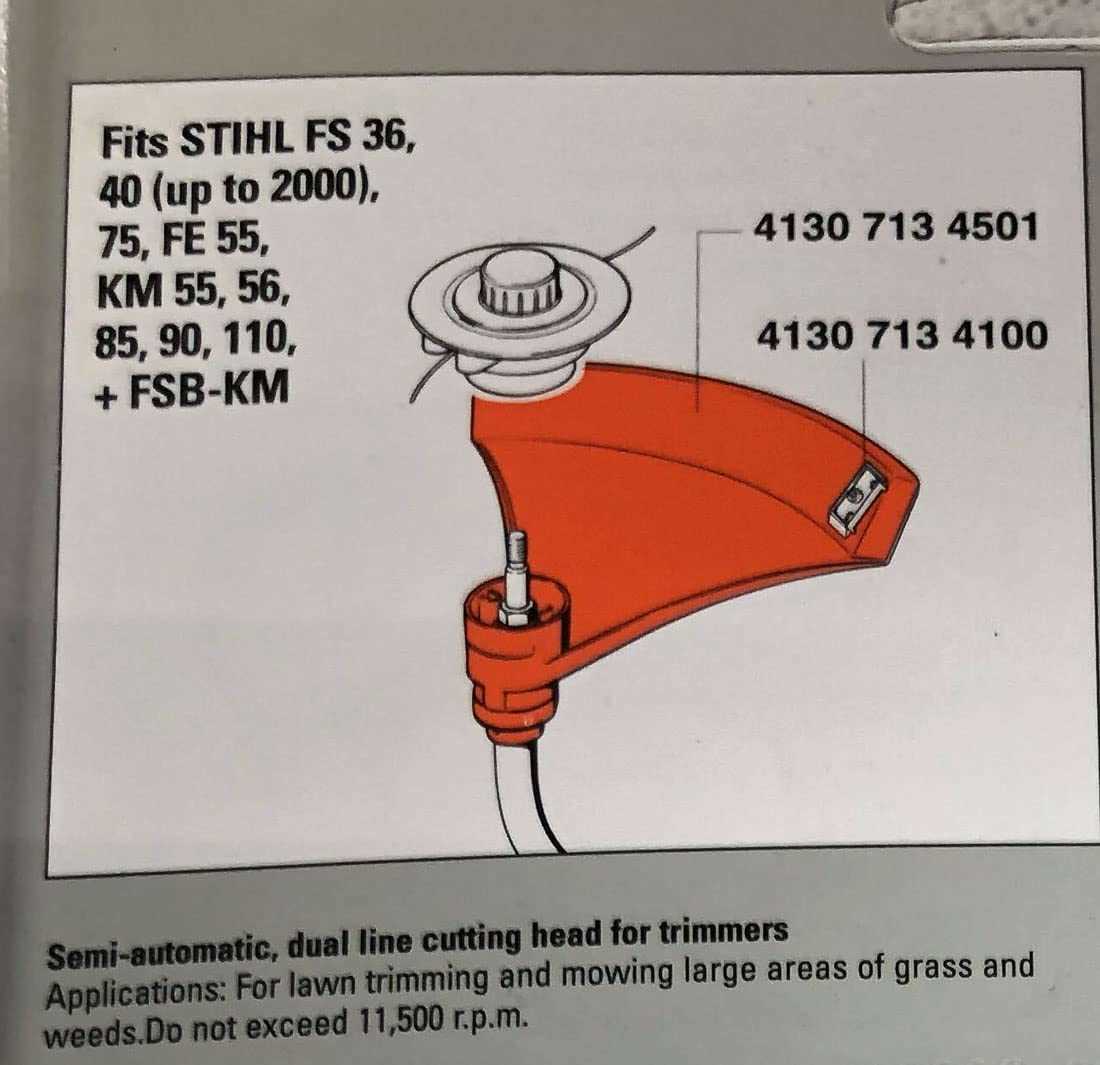

| Cutting Head | Interchangeable heads allow for different cutting techniques and applications. |

| Fuel System | Optimized for efficient fuel consumption and easy starting. |

| Drive Shaft | Transfers power from the engine to the cutting attachments, ensuring performance. |

How to Read the Diagram

Understanding the visual representation of components is essential for effective maintenance and repair tasks. This guide will help you navigate through the intricate details, making it easier to identify each part and its function within the larger system. By familiarizing yourself with the layout, you can streamline your work and ensure that all elements are in proper working order.

Identifying Key Sections

Diagrams are typically divided into distinct areas, each representing a specific group of elements. Recognizing these sections allows for a more focused approach when analyzing the overall setup. Look for headers or labels that indicate different functionalities or categories, which will guide your understanding of how each component interacts.

Understanding Symbols and Labels

Each component is usually accompanied by a symbol or label that denotes its name or function. Familiarizing yourself with these identifiers can significantly enhance your ability to troubleshoot or replace parts. Pay attention to any accompanying notes that may provide additional context or instructions.

| Symbol | Description |

|---|---|

| A | Fuel Tank |

| B | Engine |

| C | Cutting Head |

| D | Handle |

By mastering these elements, you will be better equipped to carry out repairs and maintenance, ensuring your equipment remains in optimal condition.

Common Replacement Parts Explained

When maintaining outdoor power equipment, understanding the various components that may require periodic replacement is crucial for optimal performance. This section highlights some frequently needed items that ensure smooth operation and longevity of your tools.

Trimmer Line: The cutting mechanism often relies on durable trimmer line, which can wear down over time. Choosing the right diameter and material can enhance cutting efficiency and reduce downtime.

Fuel Filter: A clean fuel filter is essential for proper fuel flow to the engine. Over time, these filters can become clogged, leading to reduced performance. Regular inspection and replacement can prevent engine strain and improve reliability.

Air Filter: An effective air filter keeps contaminants from entering the engine, ensuring clean airflow. Replacing this component regularly can significantly affect engine efficiency and longevity.

Spark Plug: This small yet vital part ignites the fuel-air mixture in the combustion chamber. A worn spark plug can cause misfiring and difficulty starting the equipment. Regular checks and replacements can maintain smooth operation.

Throttle Cable: The throttle cable controls the engine speed. If it becomes frayed or damaged, it may affect responsiveness. Monitoring and replacing this cable as needed ensures that the equipment responds appropriately to user input.

Clutch Assembly: For machines that feature a clutch system, wear and tear can lead to slipping or poor engagement. Regular maintenance and timely replacement can preserve the functionality and efficiency of the equipment.

Understanding these common components and their role in the overall functionality of your tools can empower you to keep them in peak condition, ensuring a longer lifespan and enhanced performance.

Tools Needed for Repairs

When undertaking maintenance or repair tasks on outdoor equipment, having the right tools is essential for ensuring efficiency and effectiveness. This section outlines the necessary instruments that can help facilitate a smooth repair process, making it easier to address any issues that may arise.

Essential Tools

- Wrenches: A variety of sizes is needed to fit different nuts and bolts.

- Screwdrivers: Both flathead and Phillips types are essential for removing screws.

- Socket Set: A good socket set will allow for easier access to hard-to-reach fasteners.

- Pliers: Useful for gripping, twisting, and cutting wire or small parts.

- Utility Knife: Ideal for cutting through tough materials, such as cords or plastic casing.

Additional Equipment

- Safety Gear: Always wear gloves and safety goggles to protect yourself during repairs.

- Workbench: A sturdy surface helps keep tools organized and provides ample space for work.

- Flashlight: Proper lighting can be crucial when working in dimly lit areas.

- Oil or Lubricant: Helps maintain moving parts and prevent rust.

Equipping yourself with these tools will streamline the repair process, ensuring that you are well-prepared to tackle any task that comes your way.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the durability and optimal performance of your outdoor power equipment. By following a few key practices, you can significantly extend the lifespan of your tools and maintain their efficiency throughout their usage. Regular attention to maintenance tasks not only enhances performance but also reduces the likelihood of costly repairs.

1. Regular Cleaning: After each use, take the time to clean the exterior and components of your equipment. Removing dirt, debris, and grass clippings helps prevent buildup that can cause damage over time.

2. Lubrication: Ensure that all moving parts are properly lubricated according to the manufacturer’s guidelines. This reduces friction and wear, allowing for smoother operation and reducing the risk of mechanical failure.

3. Fuel Quality: Always use fresh and high-quality fuel. Stale or contaminated fuel can lead to engine issues, so it’s best to avoid using leftover fuel from previous seasons.

4. Air Filter Maintenance: Check and clean or replace the air filter regularly. A clogged air filter can hinder performance and lead to engine overheating.

5. Blade Sharpening: Keeping the cutting blades sharp is crucial for efficiency. Dull blades require more power and can cause unnecessary strain on the engine.

6. Storage Conditions: Store your equipment in a dry, sheltered area to protect it from the elements. If possible, use a cover to further shield it from dust and moisture.

By implementing these practices, you can ensure that your outdoor tools remain reliable and efficient, helping you tackle tasks with ease and confidence.

Where to Purchase Genuine Parts

Finding authentic components for your equipment is crucial for maintaining optimal performance and longevity. Whether you are in need of replacement items or upgrades, selecting reliable sources ensures quality and compatibility.

Authorized Dealers are often the best starting point. They provide a selection of original items and can offer expert advice tailored to your specific model.

Online Retailers have made it easier to access genuine components from the comfort of your home. Reputable websites often feature extensive catalogs, making it simple to compare options and prices.

Another option is Manufacturer Websites. These platforms frequently list available items and provide insights into compatible models, ensuring you receive exactly what you need.

Finally, consider Local Repair Shops. They may have a stock of authentic items and can assist in identifying the correct replacements for your equipment.

Common Issues and Solutions

In any outdoor power equipment, users may encounter various challenges that affect performance and efficiency. Understanding these common problems and their solutions can help in maintaining optimal functionality and prolonging the lifespan of the device.

Frequent Challenges

- Engine Won’t Start

- Overheating

- Loss of Power

- Excessive Vibration

Possible Solutions

- Engine Won’t Start:

- Check fuel levels and ensure fresh fuel is being used.

- Inspect the spark plug for wear and replace if necessary.

- Verify that the choke is in the correct position.

- Overheating:

- Ensure the air filter is clean and unobstructed.

- Inspect cooling fins for dirt or debris that may cause blockage.

- Use the machine at the recommended operating speeds.

- Loss of Power:

- Examine the fuel lines for leaks or blockages.

- Check the condition of the spark arrestor screen.

- Adjust the carburetor settings as needed.

- Excessive Vibration:

- Inspect the cutting attachment for damage or imbalance.

- Tighten any loose screws or fasteners.

- Replace worn-out dampers or anti-vibration components.

Expert Recommendations for Users

When it comes to maintaining outdoor power equipment, having the right knowledge and tools is essential for ensuring optimal performance and longevity. Users can greatly benefit from understanding key components and best practices that enhance both safety and efficiency during operation. Below are some expert suggestions that can help you make the most of your equipment.

Maintenance Tips

Regular maintenance is crucial for the durability of your machinery. Following a structured routine can prevent costly repairs and improve functionality.

| Task | Frequency | Notes |

|---|---|---|

| Check air filter | Every 10 hours | Replace if dirty to ensure proper airflow. |

| Inspect spark plug | Every 20 hours | Clean or replace for efficient ignition. |

| Sharpen cutting blade | Every 25 hours | A sharp blade reduces strain on the engine. |

| Change fuel | Every 30 days | Use fresh fuel to avoid engine issues. |

Safety Precautions

Implementing safety measures is vital when operating any machinery. Adhering to these guidelines can help prevent accidents and ensure a safer working environment.

Always wear appropriate protective gear, such as gloves and eye protection, to shield yourself from debris. Additionally, familiarize yourself with the user manual and operational controls to enhance safety and efficiency during use.