In the world of machinery, comprehending the configuration of various elements is crucial for effective maintenance and operation. A thorough examination of the arrangement and functions of individual sections can enhance performance and longevity. This knowledge empowers users to troubleshoot issues more efficiently and ensure smooth functionality.

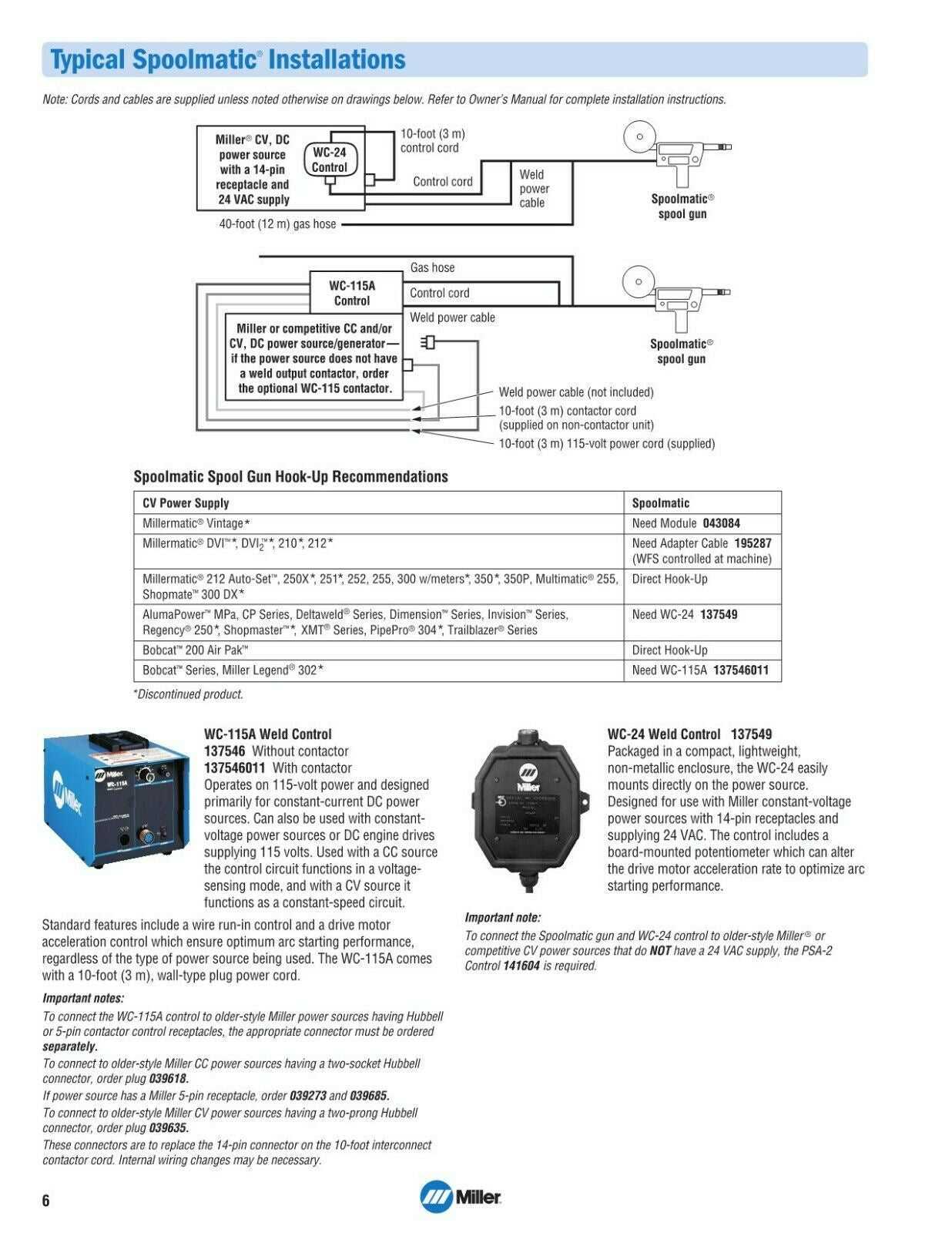

Detailed schematics serve as invaluable resources, illustrating how different components interact and fit together. These visual guides provide clarity, aiding both novices and experienced technicians in identifying necessary adjustments or replacements. By grasping the intricate relationships within the assembly, one can achieve optimal results and avoid potential pitfalls.

Whether you are a seasoned professional or a newcomer to the field, having access to well-organized visual references is essential. They not only simplify complex concepts but also promote a deeper understanding of the mechanics at play. Emphasizing the importance of these layouts can transform routine tasks into opportunities for learning and improvement.

Understanding the Spoolmatic 30A

This section explores the essential components and functionality of a specialized welding tool designed for efficiency and precision. Understanding its mechanisms can enhance user experience and improve welding outcomes significantly.

Key Features

The tool is equipped with various elements that work in harmony to ensure smooth operation. From its adjustable feed system to the protective housing, each part plays a vital role in delivering optimal performance.

Maintenance Tips

Overview of Spoolmatic 30A Features

This section delves into the essential characteristics of a high-performance welding device designed for optimal user experience and efficiency. Its innovative design and advanced functionalities make it a valuable tool in various welding applications.

Key Characteristics

- Exceptional feedability: Ensures smooth wire delivery, reducing the risk of jams.

- Versatile settings: Offers adjustable parameters to accommodate different materials and thicknesses.

- Lightweight construction: Facilitates easy handling and transport, ideal for both workshop and field use.

- Durable components: Engineered to withstand rigorous conditions while maintaining reliability.

- Enhanced cooling system: Prevents overheating, ensuring prolonged operation without performance degradation.

User-Friendly Design

- Intuitive controls: Simplifies operation, making it accessible for both beginners and experienced welders.

- Clear display: Provides real-time feedback on settings and performance metrics.

- Compact size: Saves space and allows for easy integration into existing setups.

- Ergonomic features: Reduces fatigue during extended use, improving overall productivity.

Importance of Parts Diagrams

Understanding the intricate details of machinery is crucial for effective maintenance and repair. Visual representations play a vital role in simplifying complex assemblies and aiding technicians in identifying components. Such illustrations serve not only as guides but also as valuable resources for both novices and experienced professionals.

Here are some key reasons why these visual tools are essential:

- Clarity: They provide a clear view of the arrangement and function of each component, making troubleshooting more efficient.

- Efficiency: Technicians can quickly locate parts and understand how they interact with one another, reducing repair time.

- Organization: They help in categorizing components, ensuring that everything is in its designated place during reassembly.

- Training: Visual aids are invaluable in training new staff, allowing them to grasp complex systems more rapidly.

- Documentation: They serve as a reference for future maintenance, helping to keep track of replacements and repairs.

In conclusion, these illustrations are not just helpful; they are integral to maintaining the efficiency and longevity of machinery. A solid understanding of how components fit together enhances both repair quality and operational reliability.

Main Components of Spoolmatic 30A

This section delves into the essential elements that contribute to the efficient operation of this advanced welding apparatus. Understanding these components is crucial for optimal performance and maintenance, ensuring that users can achieve precise results in various applications.

Welding Torch

The welding torch is a vital part, responsible for directing the filler material into the joint. Its design allows for easy maneuverability and control, enabling the operator to maintain a steady hand while working. The nozzle plays a significant role here, as it influences the heat distribution and the flow of the welding wire, impacting the quality of the weld.

Drive Mechanism

The drive mechanism is another key feature, facilitating the feeding of the wire into the welding area. This system includes components such as the feed rollers and the motor, which work together to ensure a consistent and reliable supply of material. Proper adjustment and maintenance of this mechanism are essential to prevent feeding issues and ensure smooth operation during welding tasks.

How to Read the Parts Diagram

Understanding the visual representation of components is essential for efficient maintenance and repair. This graphical tool provides valuable insights into the various elements that make up the system, helping users identify parts and their functions effectively.

Identifying Components

Each item in the illustration is typically numbered or labeled, allowing for easy reference. Pay attention to the annotations, as they often include crucial information such as specifications and part numbers. Familiarizing yourself with these identifiers can significantly streamline the repair process.

Understanding Relationships

It’s important to grasp how different elements interact with one another. Lines and arrows may indicate connections or dependencies, showing how components work together to achieve optimal functionality. Recognizing these relationships is key to troubleshooting and ensuring proper assembly.

Identifying Common Replacement Parts

Understanding the key components of a welding machine is essential for maintenance and effective operation. Recognizing the most frequently replaced elements can enhance performance and prolong the lifespan of the equipment. In this section, we will explore typical components that may require replacement due to wear or damage.

One crucial element often needing attention is the contact tip. This small but vital piece ensures a stable electrical connection during operation. Regular inspection for signs of erosion can prevent issues during welding tasks.

Another important component is the nozzle, which directs the shielding gas to protect the weld pool. A worn or obstructed nozzle can lead to poor weld quality. Keeping it clean and replacing it when necessary will improve results significantly.

The liner within the torch also plays a pivotal role, guiding the welding wire smoothly. If the liner becomes kinked or worn, it can cause feeding problems, leading to interruptions during work. Regular checks can help identify the need for a replacement.

Lastly, the power cable is essential for maintaining a strong connection to the power source. Inspecting for frays or damage ensures consistent performance and safety during use. Timely replacements can prevent potential hazards and maintain optimal function.

Tools Needed for Repairs

Having the right equipment is essential for any repair job. Utilizing appropriate instruments not only enhances efficiency but also ensures that tasks are completed safely and accurately. Below is a list of commonly required tools for successful maintenance and repair work.

| Tool | Purpose |

|---|---|

| Wrench Set | For loosening or tightening bolts and nuts. |

| Screwdriver Set | To fasten or remove screws in various sizes. |

| Pliers | Used for gripping, bending, or cutting wires. |

| Socket Set | For reaching fasteners in tight spaces. |

| Measuring Tape | To accurately measure distances and dimensions. |

| Safety Goggles | To protect eyes from debris and hazards. |

| Gloves | To safeguard hands from cuts and abrasions. |

Equipping yourself with these essential tools will greatly facilitate the repair process and contribute to a successful outcome. Whether you’re a professional or a DIY enthusiast, preparation is key.

Maintenance Tips for Spoolmatic 30A

Regular upkeep is essential for ensuring optimal performance and longevity of your welding equipment. By following a few key practices, you can prevent common issues and enhance efficiency.

- Inspect cables regularly for wear and tear.

- Clean the feed rollers to ensure proper wire movement.

- Lubricate moving parts to reduce friction and prevent damage.

- Check electrical connections for tightness and signs of corrosion.

By implementing these maintenance strategies, you can help ensure your equipment operates at its best for years to come.

Where to Purchase Replacement Parts

Finding quality components for your equipment can enhance its performance and longevity. It is essential to source these items from reliable vendors to ensure you receive the best value and quality. Whether you are seeking original equipment or aftermarket alternatives, there are numerous options available.

Online Retailers offer a vast selection, allowing you to compare prices and read customer reviews. Websites specializing in industrial supplies often provide detailed descriptions and specifications, making it easier to identify the right fit for your needs.

Local Distributors can be an excellent choice for immediate availability. Visiting a physical store allows you to speak with knowledgeable staff who can assist you in finding the exact components you require.

Manufacturer Websites frequently list authorized dealers and provide direct purchasing options. This route ensures you obtain genuine items tailored for optimal performance with your equipment.

Networking with other users can also yield recommendations for trustworthy sources. Online forums and social media groups often share experiences and tips that can guide you to reputable suppliers.

Comparing Spoolmatic 30A with Other Models

When evaluating various welding machines, it’s crucial to understand the differences in features, performance, and usability. This comparison highlights key aspects that set one model apart from others in the market, providing insights for potential users.

Performance Features

- Power output variations across models

- Welding speed and efficiency

- Capability to handle different materials

User Experience

- Ease of setup and operation

- Maintenance requirements

- Weight and portability factors

By examining these elements, users can better assess which machine meets their ultimate needs, ensuring a more informed purchasing decision.

Common Issues and Solutions

In any complex machinery, various challenges may arise that can hinder performance and efficiency. Identifying these problems and implementing effective solutions is crucial for maintaining optimal functionality.

Frequent Problems

- Inconsistent performance due to faulty components

- Overheating caused by inadequate cooling

- Worn-out parts leading to excessive noise

- Electrical failures disrupting operations

Effective Solutions

- Regularly inspect and replace defective elements.

- Ensure proper ventilation and cooling mechanisms are in place.

- Lubricate moving parts to minimize friction and noise.

- Check electrical connections and components for any signs of wear.

Assembly Instructions for Spoolmatic 30A

Proper assembly of your unit ensures optimal performance and longevity. Following a structured approach will facilitate a smooth setup process, enabling you to achieve the best results in your projects. Each component plays a vital role, and understanding their arrangement is essential.

Step-by-Step Assembly

Begin by laying out all components in an organized manner. Start with the base, ensuring it is stable. Attach the main assembly parts according to the manufacturer’s guidelines, aligning them securely. Double-check connections to avoid any misalignment that could hinder functionality.

Final Adjustments

Once assembled, perform a thorough inspection of all connections. Make necessary adjustments to ensure everything operates seamlessly. Test the unit to confirm proper function before use, which will ultimately enhance your experience and efficiency in handling tasks.

Expert Recommendations for Users

For those looking to enhance their experience with specialized equipment, understanding key components and maintenance tips is crucial. This guide offers insights to help users make informed decisions, ensuring optimal performance and longevity of their devices.

Maintenance Tips

- Regularly inspect and clean all components to prevent buildup of debris.

- Follow the manufacturer’s guidelines for lubrication and servicing.

- Keep an eye on wear and tear, replacing any worn parts promptly.

- Store equipment in a dry, cool place to avoid corrosion.

Usage Best Practices

- Always refer to the user manual for specific operating instructions.

- Utilize appropriate settings for different tasks to achieve the best results.

- Experiment with various techniques to enhance your skill level.

- Engage with community forums for tips and troubleshooting advice.