The efficiency of any construction tool heavily relies on the intricate design and the essential components that make it operational. Understanding the various elements involved in a tool not only enhances the user experience but also aids in effective maintenance and troubleshooting. This section aims to delve into the critical components of a specific model, offering insights into their functions and how they contribute to the overall performance of the equipment.

Every component plays a significant role in the functionality and durability of the tool. From the motor to the casing, each part has been engineered to fulfill specific tasks that enhance productivity and safety during operation. By examining these integral elements, users can better appreciate the engineering behind the device and ensure its longevity through proper care and usage.

This exploration serves as a comprehensive guide for users seeking to familiarize themselves with the workings of their equipment. By identifying and understanding the roles of different elements, operators can enhance their efficiency and make informed decisions regarding repairs and upgrades. This knowledge ultimately contributes to achieving optimal performance and reliability in various applications.

Hilti TE 3000 AVR Overview

This section provides a comprehensive look at a powerful tool designed for heavy-duty applications. Engineered for efficiency and reliability, it excels in demanding environments, making it an ideal choice for professionals in construction and renovation. Its innovative features enhance performance, ensuring optimal results in various tasks.

Key Features

Among the notable attributes of this equipment are its exceptional vibration control technology and robust construction. These characteristics contribute to improved user comfort and extended tool lifespan. Additionally, it is equipped with advanced mechanisms that facilitate easy operation, allowing users to focus on their projects without unnecessary interruptions.

Applications

Designed for a range of applications, this tool is suitable for tasks such as demolition, concrete breaking, and heavy-duty chiseling. Its versatility makes it an indispensable asset for contractors and tradespeople who require reliable performance in challenging conditions.

Key Features of Hilti TE 3000 AVR

The tool is designed to deliver exceptional performance and efficiency for heavy-duty applications. It incorporates advanced technology to enhance user experience and improve productivity in demanding environments.

Powerful Motor: Equipped with a high-performance motor, this equipment offers remarkable impact energy, making it ideal for challenging tasks such as demolition and breaking concrete surfaces.

Vibration Reduction System: The integrated system significantly minimizes vibrations, ensuring user comfort and reducing fatigue during prolonged use. This feature allows for safer operation without compromising effectiveness.

Ergonomic Design: Its user-friendly design includes an adjustable handle, providing optimal grip and control. This thoughtful design enhances maneuverability and makes it suitable for various working positions.

Durability: Constructed with high-quality materials, this machine is built to withstand the rigors of tough job sites. Its robust build ensures longevity and reliable performance over time.

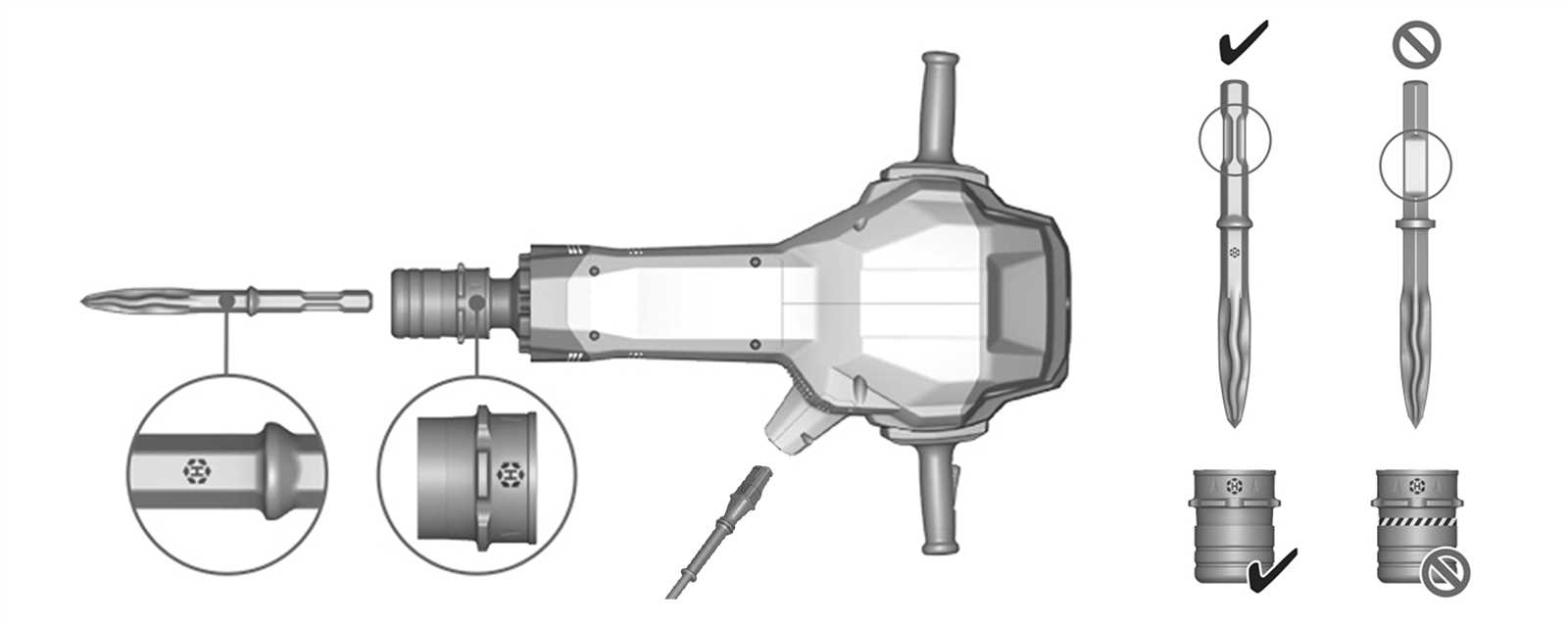

Versatility: This tool is compatible with a range of accessories, enabling users to tackle different applications with ease. Whether it’s breaking through hard surfaces or performing lighter tasks, it adapts seamlessly to various needs.

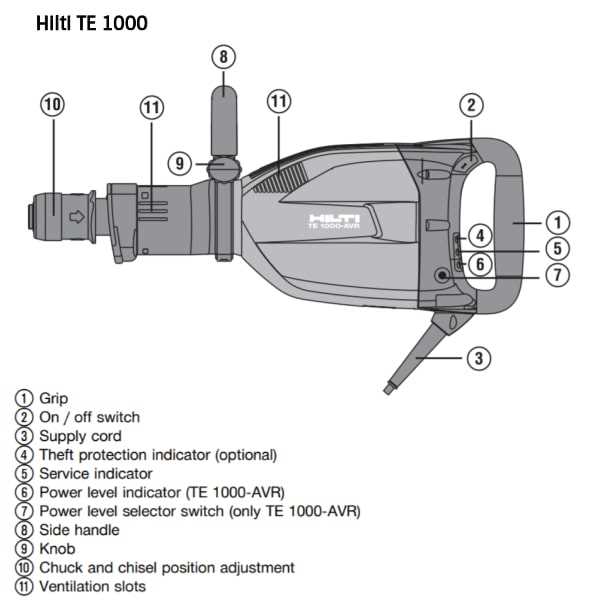

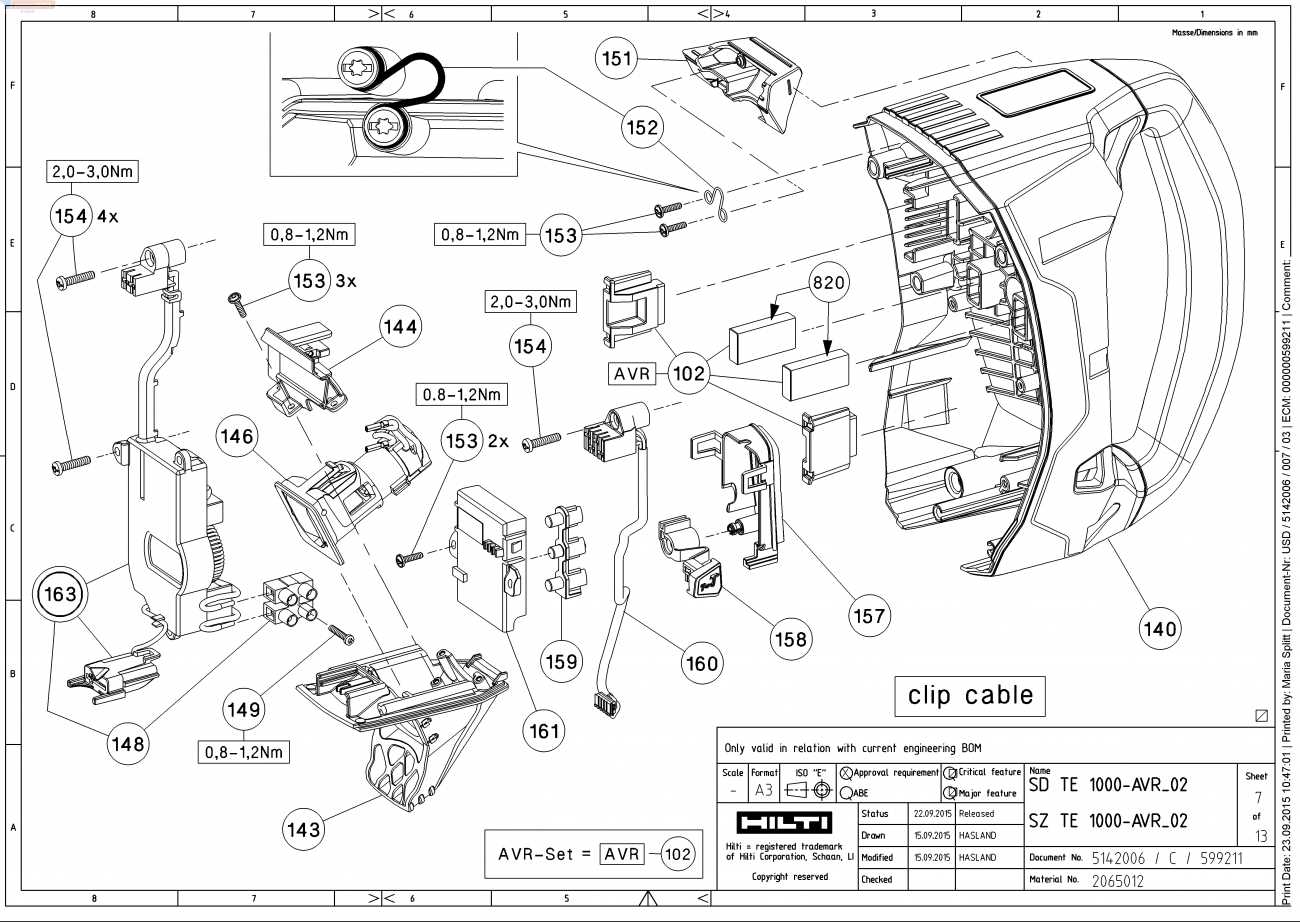

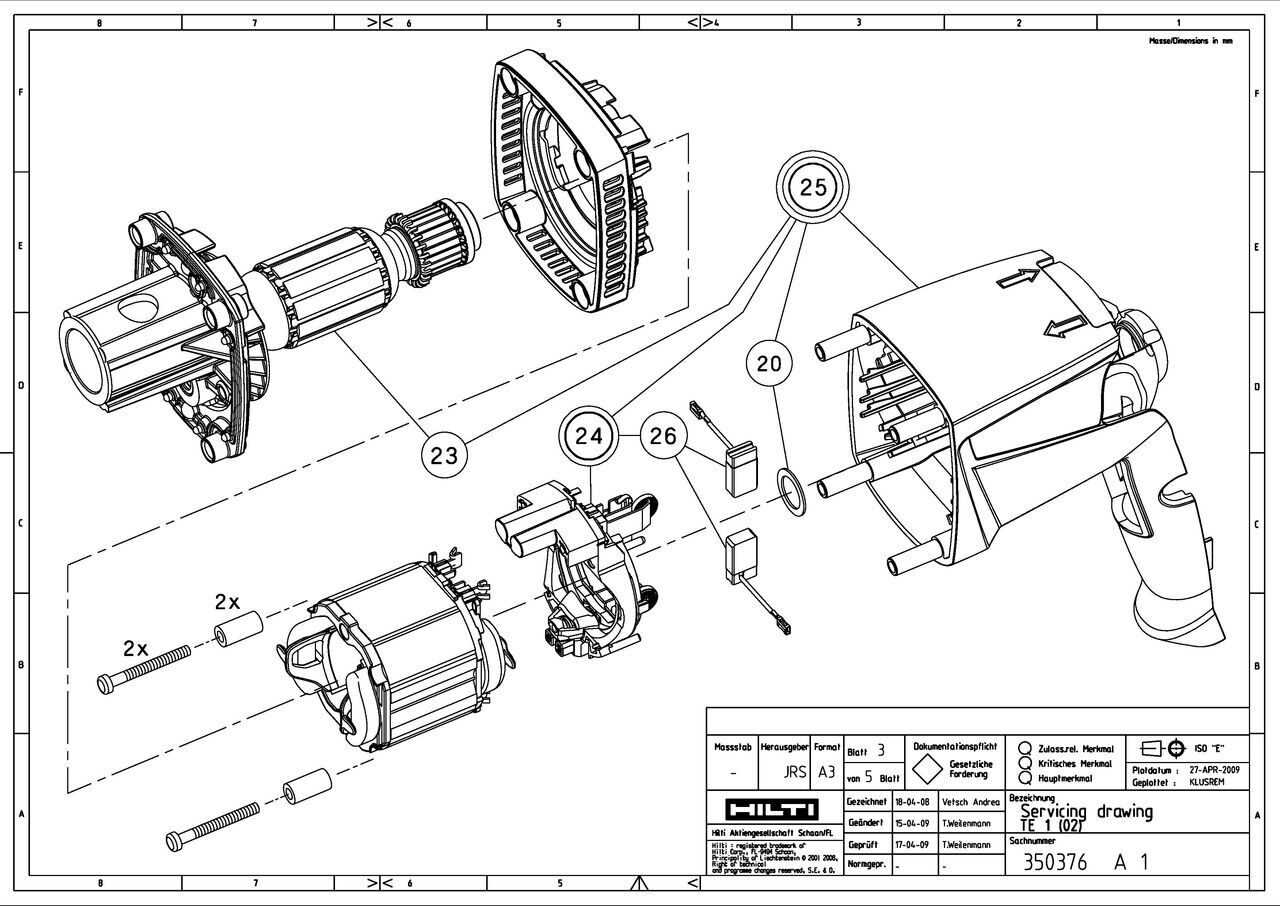

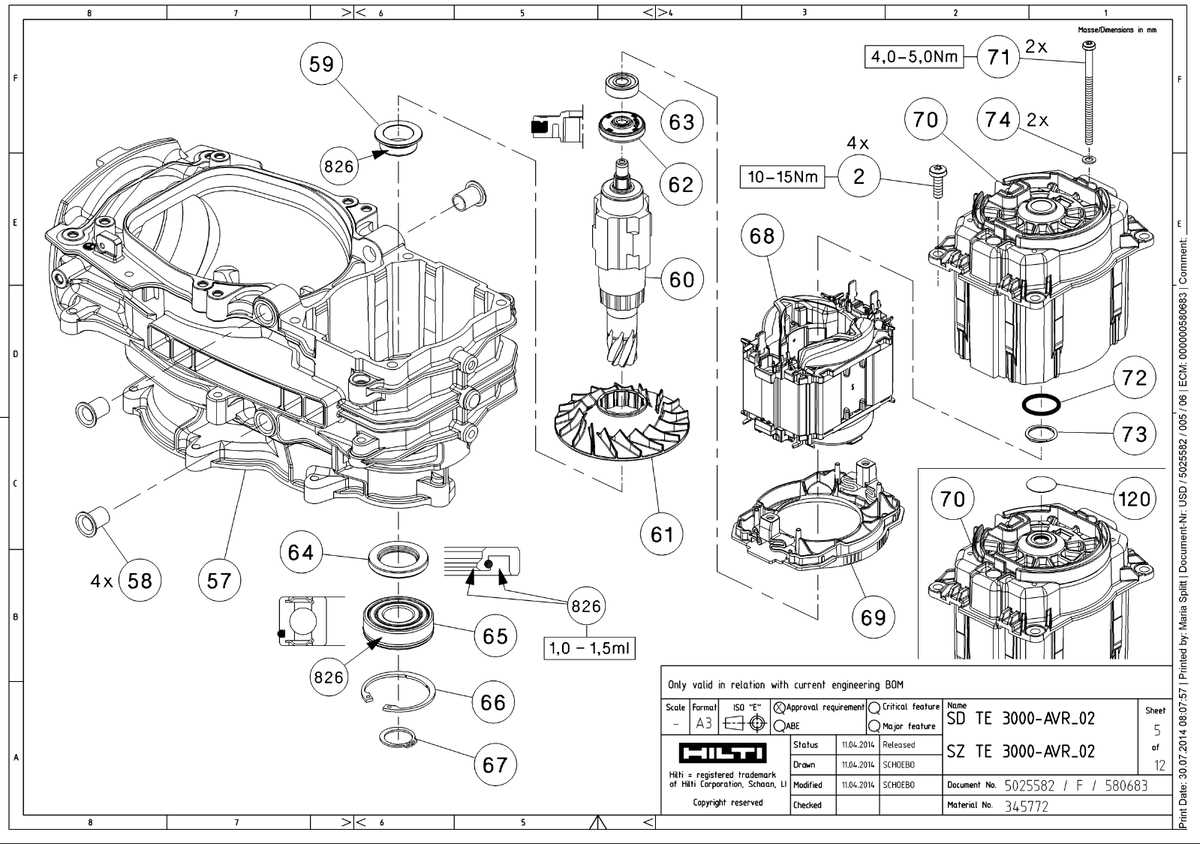

Understanding the Parts Diagram

This section delves into the illustration of components that make up a specific tool, providing valuable insights into its structure and function. Familiarizing oneself with this visual representation is essential for effective maintenance and troubleshooting.

Importance of Component Identification

Identifying individual elements within the illustration allows users to comprehend how each piece contributes to the overall operation. This knowledge not only facilitates repairs but also enhances the understanding of the device’s performance and capabilities.

Utilizing the Illustration for Maintenance

Referencing the schematic during servicing or part replacement ensures that all necessary components are accounted for, minimizing the risk of errors. Recognizing the relationship between the various elements can lead to more efficient repairs and prolong the lifespan of the equipment.

Common Applications of the Tool

This versatile equipment is widely used in various industries for heavy-duty tasks. Its powerful design allows it to tackle demanding jobs effectively, making it an essential choice for professionals looking for reliability and efficiency in their work.

1. Construction and Demolition

- Breaking through concrete and masonry for structural alterations

- Removing old flooring and tiles to prepare for renovations

- Creating openings for windows and doors in existing walls

2. Heavy Machinery Installation

- Mounting heavy equipment securely to foundations

- Assisting in the installation of HVAC systems and large appliances

- Anchoring supports for scaffolding and other temporary structures

Overall, the tool’s robust performance makes it a preferred choice for those involved in construction, renovation, and heavy industrial applications.

Maintenance Tips for Longevity

Ensuring the extended lifespan of your equipment requires consistent care and attention. Regular maintenance not only enhances performance but also prevents unexpected breakdowns. Implementing a few simple practices can significantly improve durability and efficiency.

Regular Cleaning

Keeping your device clean is essential for optimal operation. Dust and debris can accumulate and affect performance. Follow these steps for effective cleaning:

- Use a soft brush or cloth to remove dust from external surfaces.

- Check air vents and filters regularly, ensuring they are free from blockages.

- Avoid using excessive moisture when cleaning; instead, use a slightly damp cloth.

Routine Inspections

Conducting frequent inspections allows you to identify potential issues before they escalate. Focus on the following aspects:

- Examine electrical connections for signs of wear or damage.

- Check moving parts for proper lubrication and functionality.

- Look for any unusual noises or vibrations that may indicate a problem.

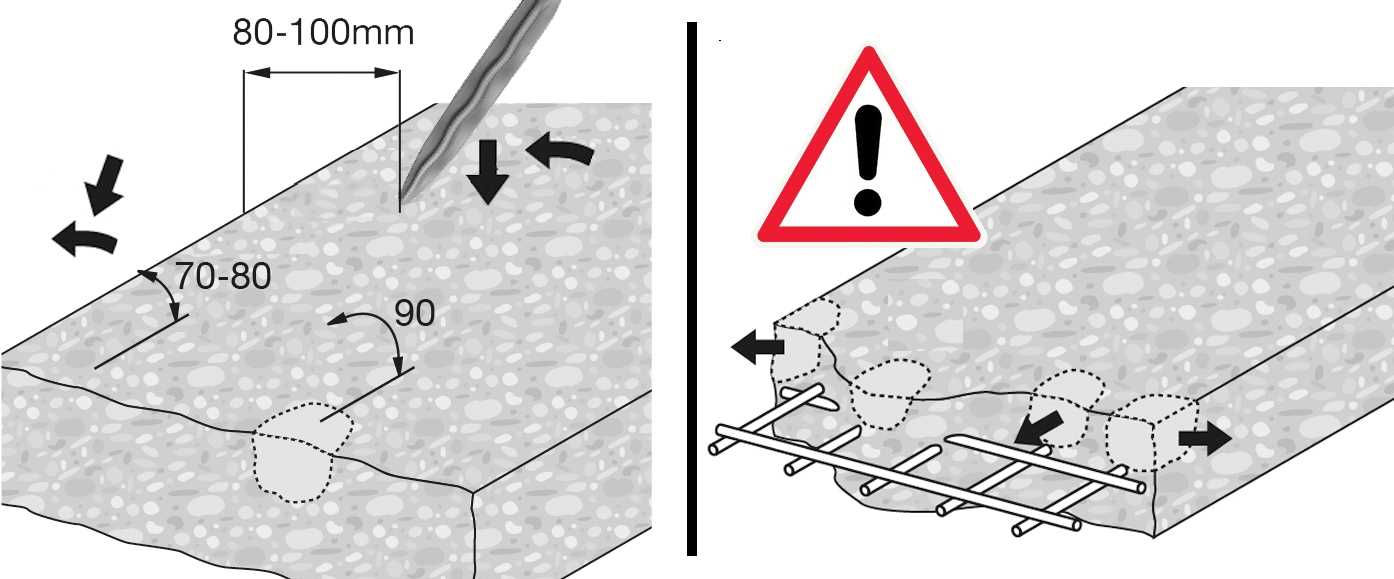

Safety Precautions When Using

Ensuring safety during the operation of heavy-duty equipment is essential to prevent accidents and injuries. Users must adhere to specific guidelines and recommendations to maintain a secure working environment. Understanding and following these safety measures can significantly reduce risks associated with power tools.

Always wear appropriate personal protective equipment, such as safety glasses, gloves, and ear protection, to safeguard against potential hazards. Inspect the equipment thoroughly before each use to identify any signs of wear or damage that may compromise its functionality. It is crucial to maintain a clean and organized workspace to minimize distractions and obstacles that could lead to accidents.

Follow the manufacturer’s instructions closely regarding operation and maintenance procedures. Never bypass safety features or attempt to modify the equipment for personal convenience. Be aware of your surroundings and ensure that no one is in close proximity while the tool is in use. Additionally, proper training and knowledge of the tool’s capabilities will enhance user safety and efficiency.

Replacement Parts Availability

Access to essential components for repair and maintenance is crucial for ensuring the longevity and performance of any equipment. Knowing where to source these items can significantly reduce downtime and enhance operational efficiency.

Numerous suppliers offer a wide range of alternatives, catering to the needs of professionals and DIY enthusiasts alike. These distributors often provide genuine components as well as high-quality aftermarket options, ensuring that users have access to the best solutions for their specific requirements. Additionally, online platforms have made it easier to compare prices and availability, allowing for informed purchasing decisions.

To facilitate smooth operations, it is advisable to maintain a list of trusted vendors and to stay informed about any updates in inventory or new product releases. This proactive approach can prevent delays and support continuous productivity.

How to Interpret the Diagram

Understanding a schematic representation is crucial for effectively utilizing and maintaining complex tools. These illustrations serve as visual guides, detailing the components and their relationships within a specific mechanism. By familiarizing yourself with the layout, you can enhance your troubleshooting and repair skills.

When examining the illustration, begin by identifying the key sections, each representing different functionalities. Labels are typically provided to denote various elements, which help in recognizing their roles within the system. Pay attention to any color coding or symbols that indicate specific features or operational characteristics.

Furthermore, take note of the connection points between parts, as they are essential for understanding how the entire assembly works. By grasping these relationships, you can make informed decisions when assembling, disassembling, or replacing components.

Lastly, it’s beneficial to consult any accompanying documentation or manuals for additional context. These resources can provide further insights into the functionality of individual elements, helping you to interpret the schematic more effectively and confidently.

Comparative Analysis with Other Models

This section provides a thorough examination of a specific tool in relation to its counterparts in the market. By assessing various features, functionalities, and overall performance, we aim to highlight the strengths and weaknesses of each model, enabling users to make informed decisions based on their needs.

When comparing this tool with other similar devices, several key aspects should be considered:

- Power Output: Evaluating the wattage and impact energy can reveal how effectively each model performs under demanding conditions.

- Weight and Ergonomics: The weight distribution and handle design influence user comfort during extended use.

- Durability and Build Quality: Assessing the materials used in construction helps predict the lifespan and reliability of the equipment.

- Versatility: Analyzing the range of applications for which each device is suited can indicate its practicality for various tasks.

Furthermore, user feedback and expert reviews play a crucial role in understanding real-world performance. Common aspects highlighted in reviews include:

- Ease of maintenance and repair.

- Availability of accessories and attachments.

- Service support and warranty offerings.

By synthesizing this information, potential buyers can gain a clearer perspective on how this tool stands against its competition, facilitating a more strategic purchase decision.

User Reviews and Feedback

This section delves into the experiences and opinions of users regarding a specific tool known for its powerful performance and reliability. Insights gathered from various reviews provide valuable information about the functionality, durability, and overall satisfaction levels associated with this equipment. Feedback from users plays a crucial role in understanding its strengths and areas for improvement.

Overall Satisfaction

Many users have expressed their contentment with the tool’s performance, highlighting its efficiency in handling demanding tasks. Robust design and user-friendly features are frequently mentioned, contributing to a positive overall impression. Customers appreciate how well it meets their expectations in both professional and personal applications.

Areas for Improvement

Despite the favorable reviews, some users have pointed out specific aspects that could be enhanced. Suggestions often include the need for better ergonomics and more accessible maintenance options. Addressing these concerns could further elevate user satisfaction and overall usability.

Frequently Asked Questions

This section addresses common inquiries related to the maintenance and functionality of a specific tool model. Understanding the most frequently posed questions can help users navigate issues more effectively and optimize the use of their equipment.

General Inquiries

Many users often seek clarity on operational aspects and best practices to ensure longevity and performance. Below are some common concerns:

| Question | Answer |

|---|---|

| What maintenance steps should be performed regularly? | Regular cleaning and inspection of components are essential. Ensure all moving parts are lubricated, and check for any wear and tear. |

| How can I troubleshoot power issues? | First, check the power source and ensure connections are secure. If problems persist, inspect the internal wiring and components for faults. |

Replacement and Repairs

Users often need guidance on when and how to replace various elements. Here are key points to consider:

| Question | Answer |

|---|---|

| When should I consider replacing internal components? | Replacement is advisable if you notice a significant decline in performance or if any part is damaged beyond repair. |

| Where can I find suitable replacement parts? | Replacement components can typically be found at authorized dealers or through reputable online suppliers. |

Resources for Further Learning

Expanding your knowledge in the field of power tools and construction equipment can significantly enhance your expertise and efficiency. This section provides various resources that can help you delve deeper into the technical aspects, maintenance, and operational techniques of specialized machinery.

Online platforms such as instructional videos and tutorials can offer hands-on demonstrations and practical insights. Additionally, industry-specific forums and discussion groups serve as excellent venues for exchanging ideas, troubleshooting issues, and learning from experienced professionals. Books and manuals focusing on tool maintenance and repair can also provide valuable guidance and detailed information.

Attending workshops and training sessions led by experts is another effective way to gain practical experience and stay updated on the latest advancements in technology. Engaging with manufacturer resources and community events can further enhance your understanding and skills in this domain.