The functionality of specialized machinery is reliant on the harmonious interaction of various mechanical elements. Whether it’s for industrial tasks or home use, having a clear understanding of how these components work together ensures effective operation and timely maintenance. By recognizing each element’s role, users can troubleshoot issues efficiently and keep the equipment in top shape.

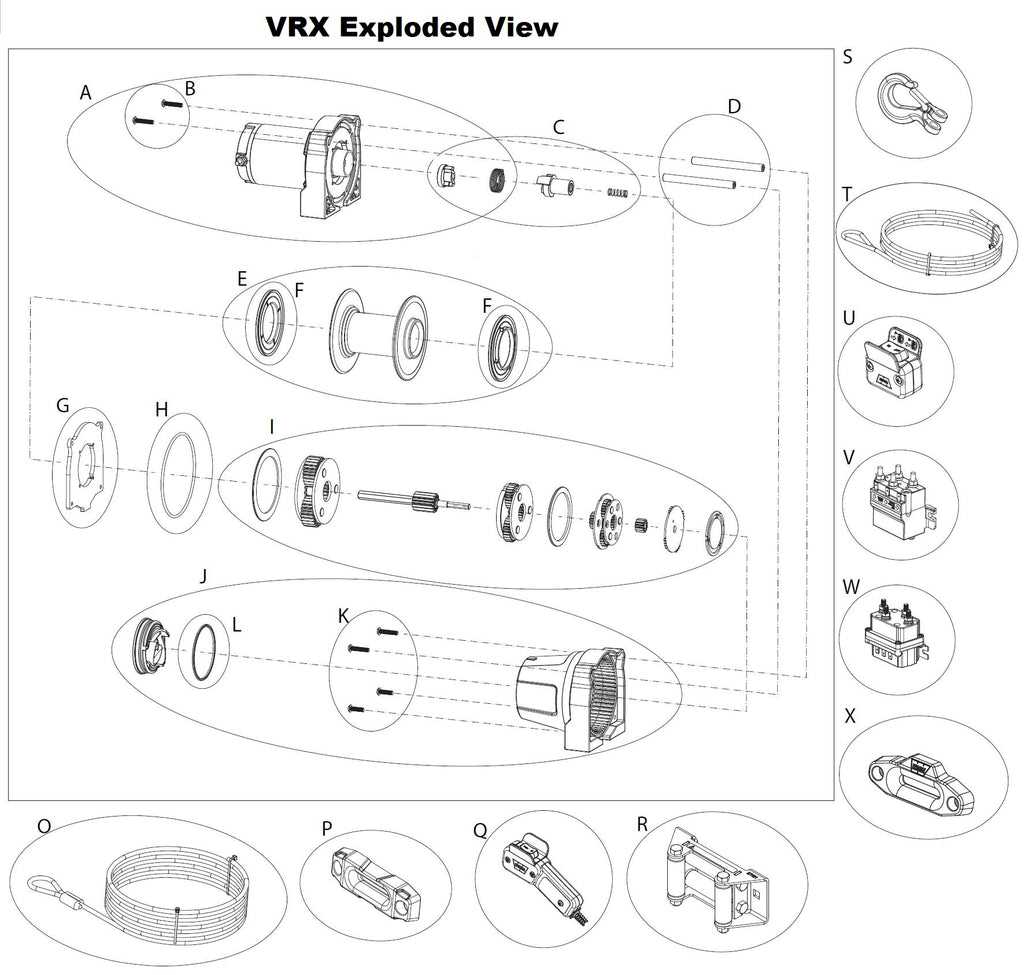

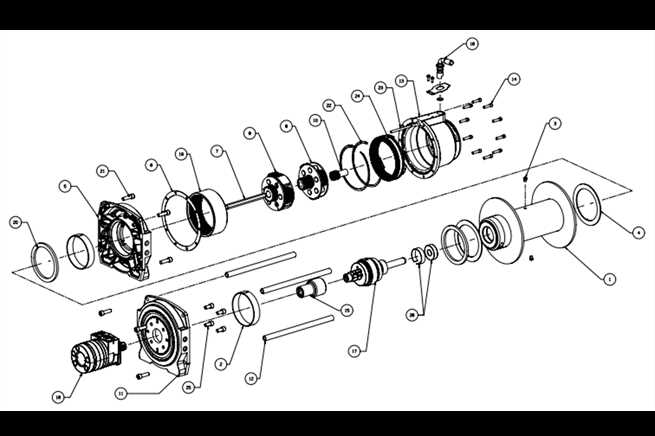

In this section, we will delve into the configuration of key mechanical systems used in heavy-duty equipment. We’ll outline the different elements involved, providing clarity on how these units connect and function as a whole. Understanding these details can enhance your ability to perform repairs or upgrades, ultimately ensuring smoother performance.

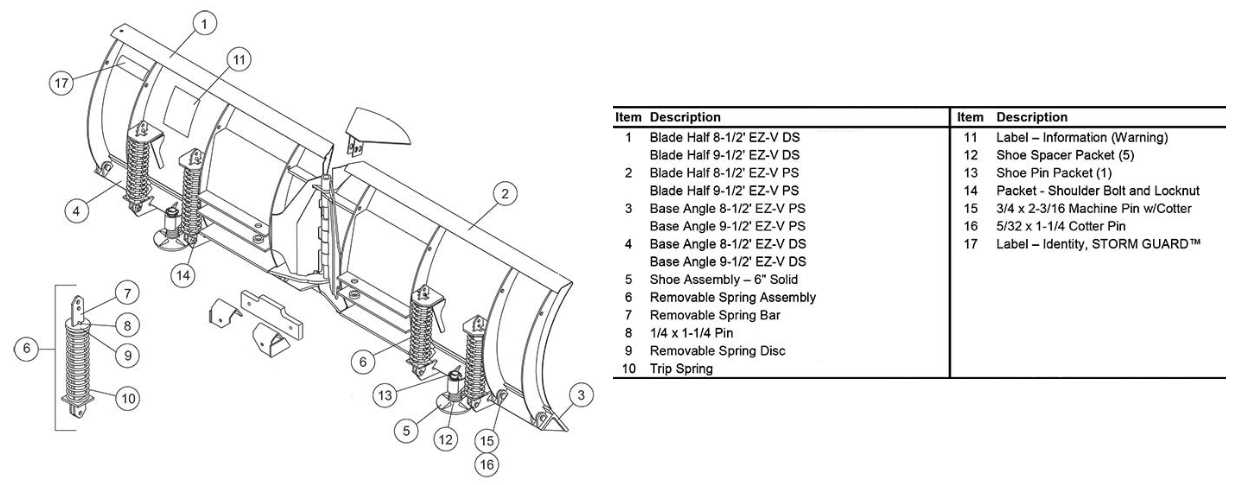

Understanding Key Components of Snow Plow Systems

To ensure effective operation, a thorough understanding of the individual elements that comprise this equipment is essential. Each component works in unison to provide reliable and efficient performance, allowing for smooth movement and control. Knowing the main mechanical and electrical features helps in diagnosing issues and maintaining optimal functionality.

Hydraulic System

The hydraulic mechanism is at the heart of the equipment, controlling the vertical and horizontal movement. This system is responsible for lifting and angling the blade, offering precise control for the operator. Regular maintenance of the hydraulic pump, hoses, and fluid levels ensures that it performs as expected.

Control Module

The control unit allows the operator to manage the movement and positioning with ease. Whether it’s a joystick or a handheld controller, this interface provides the link between the user and the machine. Understanding how this module interfaces with other components is crucial for troubleshooting operational issues.

Identifying Essential Parts for Effective Plowing

For any system designed to clear pathways efficiently, understanding the critical components that enable smooth operation is key. Ensuring optimal performance involves recognizing the primary elements responsible for moving debris, adjusting angles, and maintaining stability throughout the process. This section will explore the core elements that contribute to effective clearing operations.

Key Components for Optimal Performance

Several vital elements work in unison to achieve an efficient result. From mechanisms that control elevation to those that manage lateral movement, each piece plays an integral role in maintaining control and precision. Understanding how these parts function together helps enhance overall efficiency and reduce downtime.

Essential Features and Their Functions

| Component | Function | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Hydraulic System | Regulates the raising and lowering mechanism, providing smooth transitions between positions. | |||||||||||||

| Maintenance Task | Frequency | |

|---|---|---|

| Lubrication of moving components | Every 10 uses |

| Problem | Description | Potential Solution |

|---|---|---|

| Hydraulic Leaks | Hydraulic fluid can escape due to worn seals or damaged hoses, leading to reduced pressure and functionality. | Inspect hoses and seals regularly; replace any damaged parts to prevent further leaks. |

| Electrical Failures | Connection issues or faulty wiring may result in the malfunction of critical components like motors and controls. | Ensure proper wiring connections and test electrical systems for faults. |

| Blade Misalignment | The blade may become misaligned due to

Enhancing Snow Plow Performance with Proper UpgradesImproving the efficiency and effectiveness of your winter equipment can significantly impact performance and user satisfaction. By focusing on the right enhancements, operators can ensure that their machinery not only meets the demands of challenging conditions but also operates smoothly and reliably. Key Modifications for Optimal Functionality

Upgrading specific components can lead to improved maneuverability and durability. Consider investing in high-quality blades and attachments that provide superior cutting edges and resistance to wear. Additionally, enhancing the hydraulic system with advanced controls can lead to better responsiveness and precision in operation. Maintenance and Regular AssessmentsConsistent upkeep is essential for maintaining performance standards. Regularly check and replace worn-out elements to prevent larger issues from arising. Furthermore, conducting seasonal assessments can help identify areas for improvement, ensuring that your equipment remains in peak condition throughout its operational lifespan. Choosing the Right Accessories for Snow PlowsWhen preparing for winter conditions, selecting suitable enhancements can significantly impact efficiency and performance. Various components are available to complement the primary equipment, ensuring optimal operation and versatility. Understanding the unique requirements of your setup is crucial for making informed decisions. Essential Additions: Certain items can enhance the functionality of your equipment. Consider options such as blade extensions, which provide increased width for broader coverage, or adjustable skids that allow for better control over the depth of material being moved. Additionally, auxiliary lights can improve visibility during low-light conditions, ensuring safety and precision. Durability and Compatibility: Opt for accessories made from high-quality materials that can withstand harsh environments. Compatibility with your existing setup is vital; verify that any additional components are designed to work seamlessly with your equipment to avoid performance issues. Seasonal Adaptability: Think about versatile solutions that can be used in various conditions. Features like removable attachments or those that allow for quick changes can be beneficial, allowing for adjustments based on specific needs throughout the winter. Investing in the right enhancements not only improves the performance of your equipment but also ensures that you are well-prepared to tackle challenging winter tasks with confidence. Safety Features Built Into Snow Plow SystemsWhen it comes to winter equipment, ensuring user protection and operational reliability is paramount. Various built-in mechanisms enhance safety during use, reducing risks associated with harsh weather conditions and heavy machinery. These elements are designed to provide peace of mind for operators, ensuring efficient and secure functionality. Key Safety Mechanisms

Operator Protection Features

Wiring and Electrical Components in Snow PlowsUnderstanding the wiring and electrical components in vehicle-mounted clearing equipment is essential for optimal operation and maintenance. These systems are crucial for ensuring efficient functionality and reliability during harsh winter conditions. Proper knowledge of these elements can enhance performance and extend the lifespan of the equipment. The electrical system typically comprises various components that work together to power the unit. Here are some key elements commonly found in these systems:

For efficient maintenance, it’s vital to regularly inspect and test these electrical components. Here are some essential maintenance tips:

By focusing on these wiring and electrical components, operators can ensure their equipment functions reliably and effectively, even in the most challenging conditions. Troubleshooting Problems in Snow Plow OperationsAddressing challenges during winter maintenance tasks is crucial for ensuring efficiency and safety. Identifying and resolving issues promptly can prevent delays and enhance performance. This section focuses on common concerns that may arise during the operation of equipment used for snow management, offering insights into effective troubleshooting strategies. Electrical Failures: One of the primary issues encountered is malfunctioning electrical components. Inspect connections, fuses, and relays to confirm they are functioning correctly. A thorough check can often reveal loose wires or damaged connectors that require attention. Hydraulic Problems: Hydraulic systems play a vital role in the functioning of these machines. If the lifting mechanism is sluggish or unresponsive, examine the hydraulic fluid levels and inspect for leaks. Regular maintenance of hoses and fittings can prevent significant failures. Mechanical Wear: Over time, wear and tear can lead to diminished performance. Regularly inspect blades, pivots, and other moving parts for signs of wear. Replacing worn components promptly can maintain optimal efficiency and reduce the risk of breakdowns. Performance Issues: If the machine does not operate as expected, evaluate the operational settings and ensure they align with manufacturer specifications. Adjustments may be necessary to optimize performance under varying conditions. Preventive Measures: Regular maintenance checks can significantly reduce the likelihood of operational problems. Creating a routine schedule for inspections and servicing will enhance reliability and prolong the lifespan of the equipment. How to Ensure Smooth Blade Movements

Maintaining optimal functionality of your equipment involves ensuring that the cutting edge operates efficiently and effectively. Smooth transitions are essential for achieving the desired performance, preventing unnecessary wear and tear. By focusing on key factors, users can enhance the operation and longevity of their systems. Regular Maintenance ChecksConsistent inspections play a vital role in identifying potential issues before they escalate. Inspect hydraulic systems, ensuring that all connections are secure and free from leaks. Lubrication of moving components is essential to minimize friction and promote seamless operation. Regularly cleaning any debris or buildup around the mechanism will also contribute to smoother functionality. Adjusting Hydraulic PressureProper hydraulic pressure is crucial for achieving the desired responsiveness. Calibrating the pressure settings ensures that the blade reacts appropriately to user inputs, enhancing overall control. Monitor the pressure levels consistently to maintain optimal performance, as fluctuations can lead to erratic movements. |