Maintaining a pristine lawn requires a comprehensive understanding of the various elements that contribute to the functionality of your outdoor maintenance tools. Familiarizing yourself with the intricate components of these machines not only enhances their performance but also extends their longevity. Whether you’re a seasoned landscaper or a casual homeowner, knowing how to identify and replace specific pieces is essential for effective upkeep.

In this guide, we will explore the various segments that comprise a typical cutting apparatus. By delving into the structure and functionality of each element, you will gain valuable insights that can help troubleshoot issues and streamline your maintenance routine. An organized approach to understanding these components will empower you to make informed decisions, ensuring your equipment operates at its best.

Equipped with detailed visual representations and descriptive terminology, this article aims to provide a thorough overview of the essential components involved in the cutting mechanism. Whether you’re looking to enhance your knowledge or simply replace a worn-out segment, this resource will serve as a practical reference, enabling you to tackle any challenges that may arise during your lawn care endeavors.

Understanding Husqvarna Mower Deck Components

Gaining insight into the individual elements of a cutting apparatus is crucial for effective maintenance and optimal performance. Each component plays a vital role in ensuring a smooth and efficient operation, contributing to the overall functionality and longevity of the equipment.

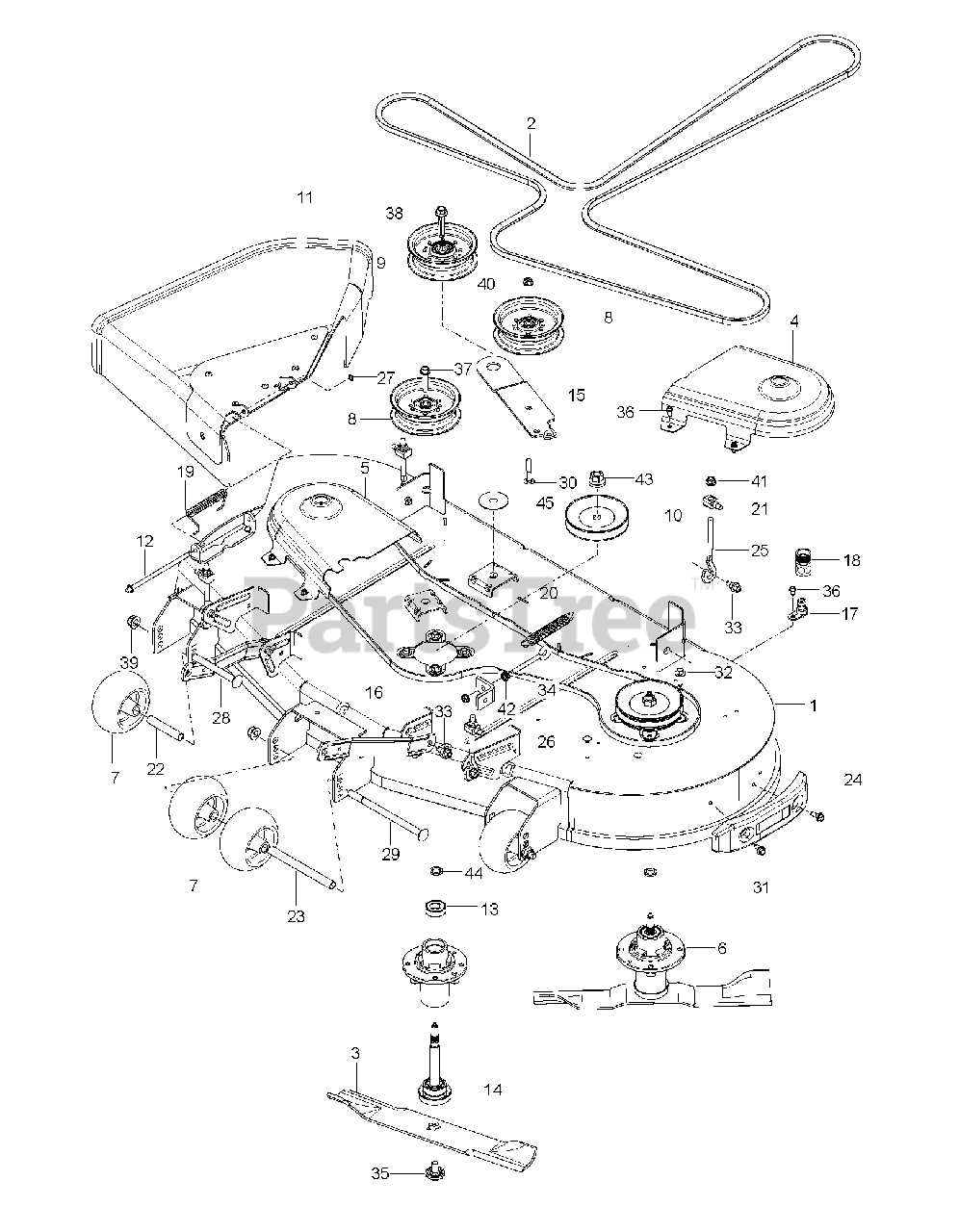

Key Elements of the Cutting System

- Blades: These are essential for achieving a clean cut. Regular inspection and sharpening are necessary for peak performance.

- Spindles: These support the blades and enable their rotation. They should be checked for wear and replaced if damaged.

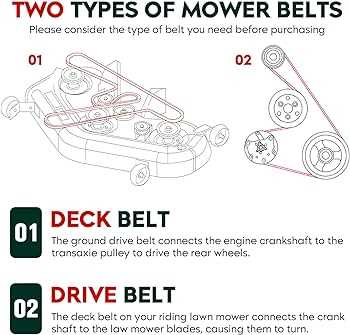

- Belt: This component transfers power from the engine to the blades. Monitoring for frays or cracks can prevent unexpected breakdowns.

- Deck Housing: This structure encases the blades and spindles. It is important to keep it clean and free from debris.

Additional Supporting Parts

- Wheels: They ensure maneuverability and stability. Regularly check for tire pressure and tread wear.

- Frame: The backbone of the equipment, providing structure and support. Inspect for rust or damage that could compromise integrity.

- Height Adjustment Mechanism: This allows users to customize cutting heights for various grass types. Ensure it operates smoothly and accurately.

Understanding these components enables users to carry out effective maintenance, ensuring that the equipment operates efficiently and lasts for years to come.

Importance of Mower Deck Maintenance

Proper upkeep of cutting equipment is crucial for ensuring optimal performance and longevity. Regular attention to this component not only enhances the quality of the cut but also prevents potential breakdowns that can lead to costly repairs. By dedicating time to maintenance, users can enjoy a more efficient and reliable experience during their gardening tasks.

One of the primary reasons to maintain this equipment is to achieve a clean and even cut. Over time, debris can accumulate, affecting the sharpness of blades and the overall efficiency of the machine. Keeping everything clean and well-lubricated reduces friction and wear, thereby extending the life of essential parts.

Additionally, routine inspections help identify any signs of wear or damage before they escalate into major issues. This proactive approach allows for timely replacements and repairs, ultimately saving money in the long run. Ignoring maintenance can lead to reduced performance, increased fuel consumption, and even safety hazards.

Furthermore, regular care contributes to better overall aesthetics of the lawn. Well-maintained equipment promotes healthier grass growth by providing an even cut, which in turn enhances the visual appeal of the outdoor space. A beautifully manicured lawn can also increase property value and create a welcoming environment.

In summary, maintaining cutting equipment is essential for performance, safety, and aesthetic appeal. By investing time and effort into regular upkeep, users can ensure their tools remain efficient, reliable, and effective for years to come.

Common Issues with Mower Decks

Many users encounter a range of challenges when maintaining their cutting apparatus. Understanding these frequent problems can help enhance performance and longevity. Issues may arise from wear and tear, improper use, or environmental factors, necessitating timely attention to avoid further complications.

1. Uneven Cutting

One prevalent concern is uneven trimming, often resulting from blade misalignment or wear. This can lead to an inconsistent lawn appearance and requires careful inspection and adjustment.

2. Clogging

Another issue is clogging, which can occur due to grass buildup or debris accumulation. Regular cleaning and maintenance can mitigate this problem significantly.

| Issue | Potential Cause | Solution |

|---|---|---|

| Uneven Cutting | Blade misalignment | Adjust or replace blades |

| Clogging | Debris accumulation | Regular cleaning |

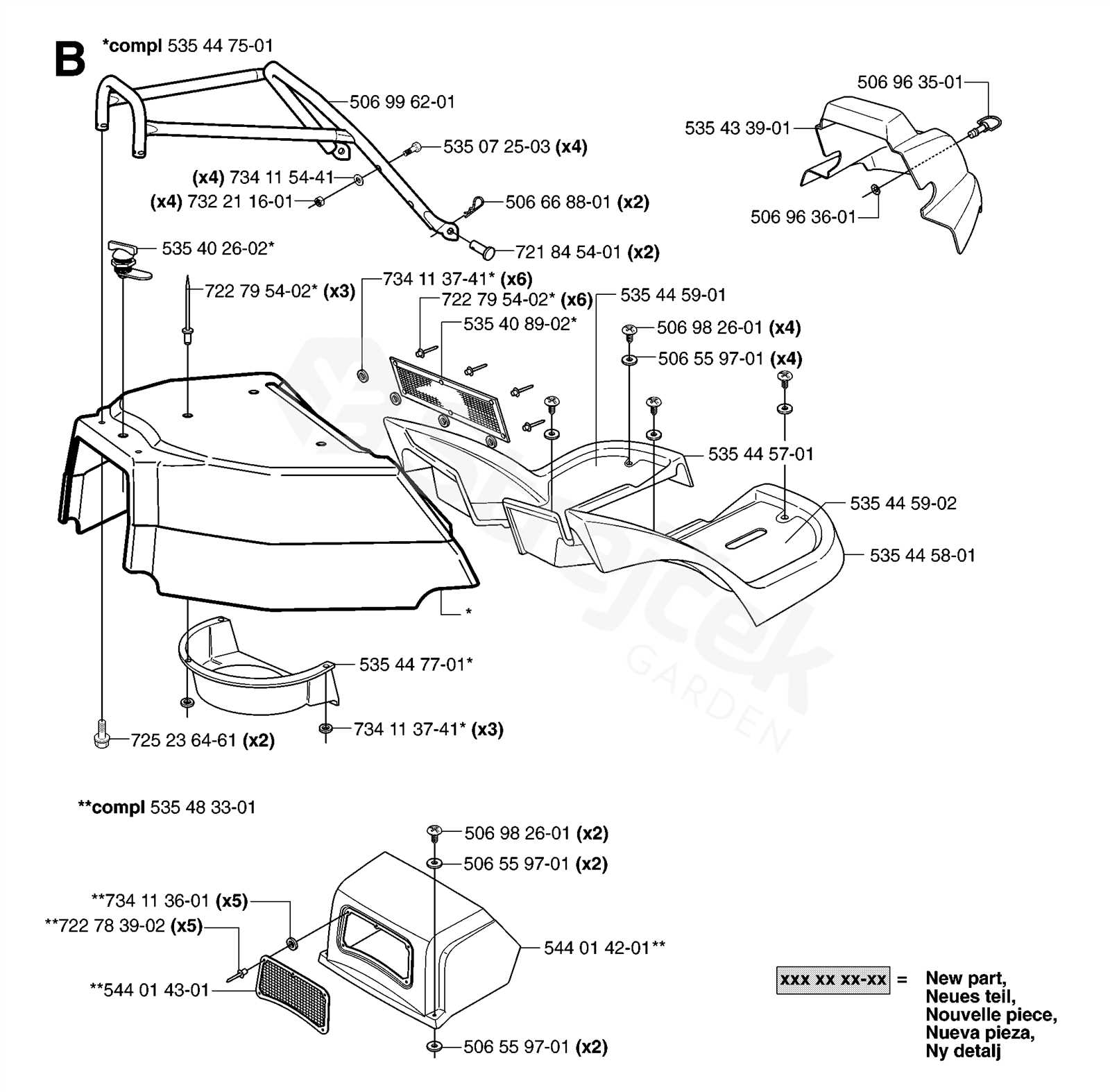

How to Read Parts Diagrams

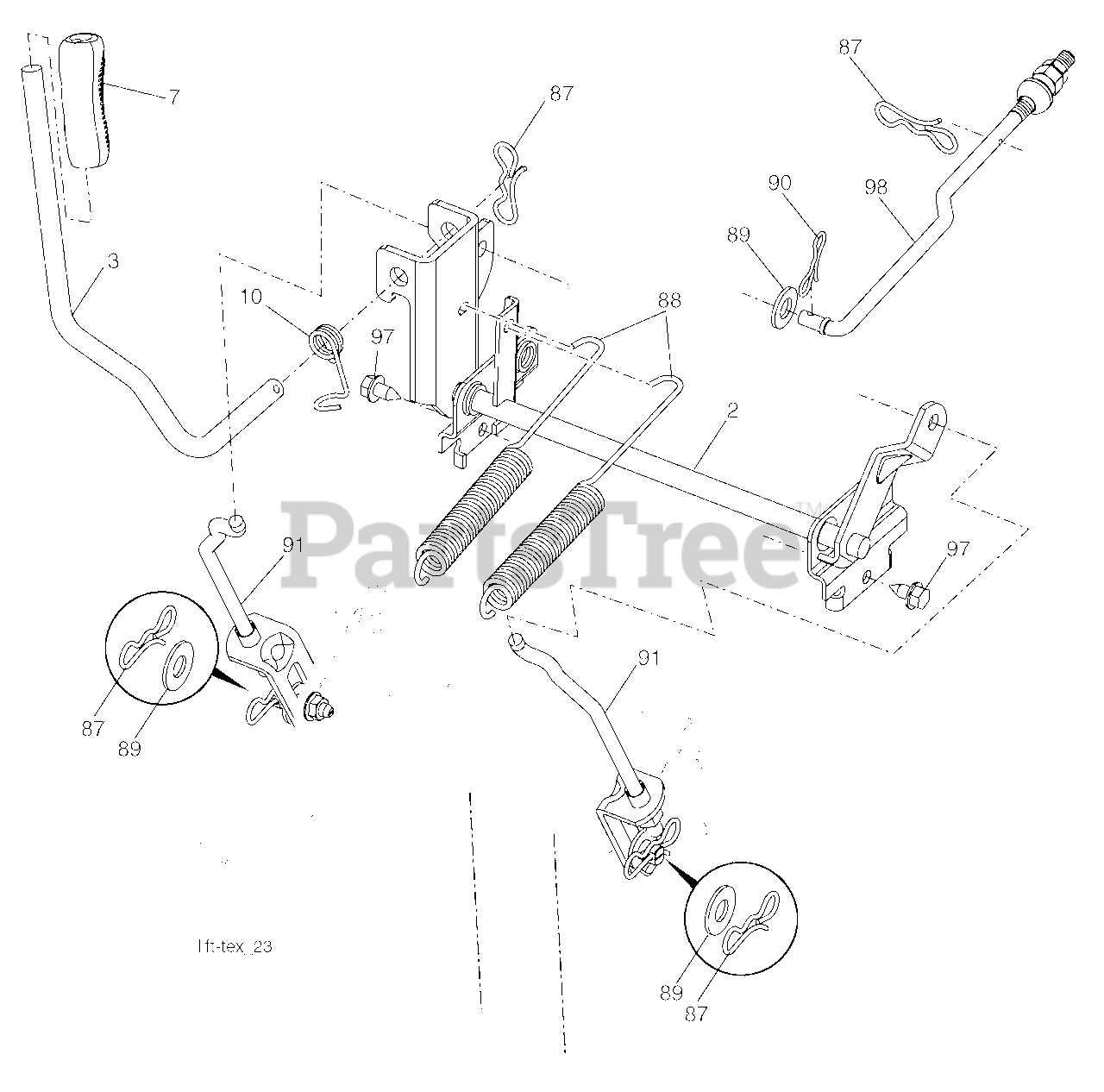

Understanding illustrations that represent components is essential for effective maintenance and repair. These visuals provide a clear overview of the various elements, their arrangement, and how they interact within the system. Knowing how to interpret these images can save time and enhance the efficiency of any repair process.

Key Elements to Consider

- Labels: Each component is usually accompanied by a label that identifies its name or function. Pay close attention to these descriptions.

- Numbers: Often, parts are numbered for reference. Ensure you cross-check these numbers with accompanying lists or manuals for accurate identification.

- Lines and Arrows: These indicate connections and the flow of operations. Understanding these can clarify how parts work together.

- Color Coding: Some illustrations use different colors to represent various categories of components. Familiarize yourself with the color scheme for quicker identification.

Steps for Effective Interpretation

- Start by reviewing the entire illustration to get a general understanding of the layout.

- Identify and note the labeled components that you are interested in.

- Look for any numerical references and match them with the corresponding parts list.

- Follow the lines and arrows to understand how the components interact.

- Consult any accompanying documentation for additional context and details.

By mastering these techniques, you can streamline your repair efforts and enhance your understanding of the system’s architecture.

Essential Tools for Repairs

Having the right tools at your disposal is crucial for effective maintenance and troubleshooting. A well-equipped toolkit can significantly simplify the repair process, ensuring that tasks are completed efficiently and accurately.

Basic Hand Tools

- Wrenches

- Screwdrivers

- Pliers

- Socket set

Specialized Equipment

- Torque wrench

- Feeler gauges

- Multimeter

- Safety gear

With these essential instruments, you can delve deeper into repairs and ensure optimal performance of your equipment.

Replacement Parts for Husqvarna Models

Maintaining the efficiency and performance of your outdoor equipment is essential for achieving the best results. Having access to quality components ensures that your machinery runs smoothly and lasts longer. This section focuses on the vital elements that can be replaced to keep your equipment in top shape.

| Component | Description | Purpose |

|---|---|---|

| Blades | Sharp, durable cutting tools. | To ensure a clean and precise cut. |

| Belt | Drive mechanism for power transfer. | To connect the engine to the cutting system. |

| Spindle | Rotational component housing. | To support the blades and allow rotation. |

| Wheel Assembly | Includes tires and hubs. | To enable smooth mobility across various terrains. |

| Filter | Air or fuel filtration unit. | To maintain optimal engine performance by keeping contaminants out. |

Finding Genuine Husqvarna Parts

Ensuring the longevity and efficiency of your equipment hinges on sourcing authentic components. When maintenance or replacements are necessary, utilizing original items guarantees compatibility and performance. This section explores how to identify and obtain quality essentials for your machinery.

Identifying Authentic Components

To determine if you are acquiring legitimate items, check for specific identifiers such as serial numbers and manufacturer logos. Authentic components often come with detailed documentation, which can aid in confirming their origin. Researching suppliers is crucial; opt for authorized dealers or trusted online platforms to minimize the risk of counterfeit products.

Benefits of Using Genuine Items

Investing in original components provides several advantages, including enhanced durability, optimal performance, and warranty protection. Using authentic items ensures that your machinery operates smoothly, reducing the likelihood of unexpected breakdowns and costly repairs. Prioritize quality to achieve the ultimate efficiency in your tasks.

Step-by-Step Repair Instructions

This section provides a comprehensive guide to effectively addressing common issues related to your cutting equipment. By following these instructions, you can ensure optimal performance and longevity of your device.

Preparation

- Gather necessary tools: wrenches, screwdrivers, and safety gear.

- Ensure the machine is turned off and disconnected from the power source.

- Review the manual for specific safety instructions.

Repair Process

- Inspect all components for wear or damage.

- Replace any broken or worn parts with new ones.

- Clean all surfaces to remove debris and grass buildup.

- Tighten all fasteners to the manufacturer’s specifications.

- Reconnect the power source and perform a functionality test.

Tips for Preventing Damage

Maintaining the longevity of your outdoor equipment is crucial for optimal performance. By following a few simple guidelines, you can significantly reduce the risk of wear and tear, ensuring your machine operates smoothly for years to come.

- Regular Cleaning: After each use, clean the surfaces to remove grass clippings and debris, which can lead to rust and corrosion.

- Inspect Components: Periodically check for loose or worn parts. Early detection can prevent more severe issues later on.

- Proper Storage: Store your equipment in a dry, sheltered area to protect it from the elements.

- Check Fluid Levels: Ensure that oil and fuel levels are appropriate and replace them as needed to maintain efficiency.

- Follow Manufacturer Guidelines: Adhere to the recommended maintenance schedule for servicing and replacing parts.

Implementing these practices will help you safeguard your machinery against unnecessary damage, promoting a longer service life and reliable functionality.

Understanding Mower Deck Adjustments

Proper calibration of cutting equipment is essential for achieving an even and precise finish on your lawn. Adjustments can significantly influence performance, helping to optimize cutting height and enhance overall efficiency. Familiarizing yourself with the adjustment mechanisms can lead to a more satisfactory mowing experience.

Importance of Proper Calibration

Ensuring accurate settings is crucial not just for aesthetics, but also for the health of your grass. Inconsistent heights can lead to uneven growth and increased susceptibility to pests. Regular maintenance and correct adjustments can promote a lush, vibrant lawn.

Adjustment Techniques

There are several methods to fine-tune your cutting apparatus, typically involving height settings and alignment. Following the manufacturer’s guidelines is vital for achieving the best results.

| Adjustment Type | Description |

|---|---|

| Height Setting | Modifies the cutting elevation to suit grass type and season. |

| Leveling | Ensures uniform contact with the ground for consistent results. |

| Alignment | Corrects blade positioning for optimal cutting performance. |

Seasonal Maintenance Checklist

Proper upkeep of your equipment is essential for optimal performance and longevity. A seasonal maintenance checklist can help ensure that every aspect is addressed, keeping everything in peak condition throughout the year.

Spring Maintenance

- Inspect and clean air filters.

- Sharpen or replace blades.

- Check oil levels and replace if necessary.

- Inspect tires for wear and proper inflation.

- Examine belts for fraying or damage.

Fall Maintenance

- Drain and replace fuel to prevent stale fuel issues.

- Clean the equipment thoroughly to remove debris.

- Inspect cables and connections for wear.

- Store in a dry, protected area.

- Check battery condition and charge if necessary.

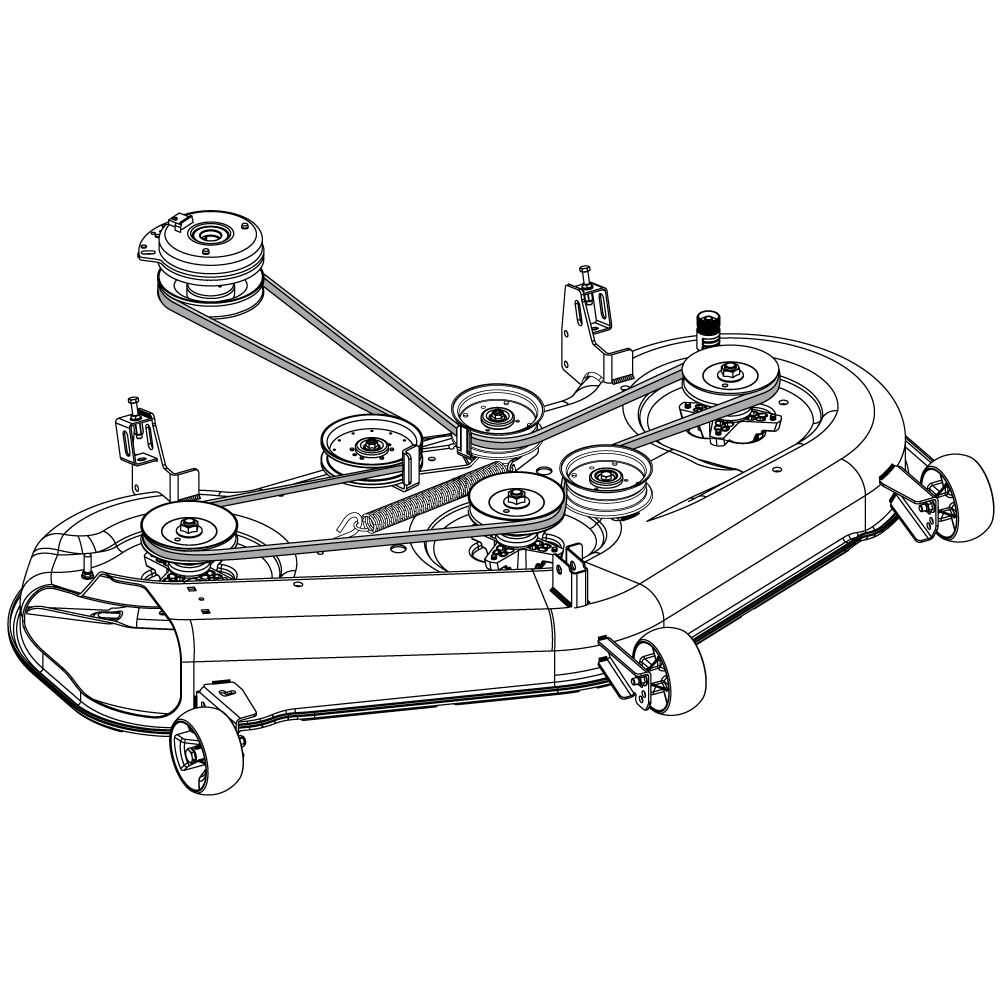

Comparing Mower Deck Designs

When evaluating various cutting apparatus configurations, it’s essential to understand the nuances that differentiate them. Each design offers unique benefits, influencing both performance and user experience. Factors such as cutting efficiency, ease of maintenance, and overall durability play crucial roles in determining the most suitable option for specific needs.

Design Variations

Different configurations come with their distinct shapes and features. Some may prioritize a wider cutting path, while others focus on maneuverability in tighter spaces. The choice of materials also affects weight distribution and longevity, which can impact how well the equipment performs over time.

Performance Metrics

Evaluating performance involves looking at how effectively each design can handle various terrains and grass types. Cutting height adjustments and blade arrangement are critical elements that can enhance or hinder effectiveness. Users must consider their specific landscape needs to determine which configuration will provide the best results.

Expert Recommendations for Efficiency

Maximizing performance and minimizing downtime are essential for achieving the best results in outdoor maintenance tasks. Below are some expert suggestions that can help enhance efficiency and extend the lifespan of your equipment.

- Regular Maintenance: Schedule routine checks to ensure all components are functioning optimally.

- Proper Cleaning: Remove debris and buildup after each use to prevent clogs and damage.

- Sharp Blades: Keep cutting implements sharp for cleaner cuts and reduced strain on the machine.

Implementing these strategies can lead to significant improvements in both performance and productivity.