The maintenance and functionality of a well-known cutting tool hinge on the precise arrangement and interaction of its various components. Knowing how these elements work together not only enhances the performance of the device but also extends its lifespan. Each section of the tool serves a specific purpose, and understanding this can simplify repairs and replacements.

In this guide, we delve into the intricate structure of a highly regarded chainsaw model. By exploring the arrangement and identification of its components, users can better grasp how to optimize performance. This knowledge is invaluable for both novice and experienced operators, as it empowers them to make informed decisions regarding upkeep and enhancement.

For those looking to troubleshoot or upgrade their equipment, familiarity with the individual elements is crucial. This exploration will highlight the essential features and interactions, providing a comprehensive overview that aids in efficient maintenance and repair tasks. With the right information, users can ensure their cutting tool remains a reliable ally in their endeavors.

Overview of Stihl MS 261 C

The MS 261 C is a powerful and efficient tool designed for both professional and hobbyist users. This model is known for its durability and ease of use, making it a preferred choice among those who require reliability in their cutting tasks. With advanced technology and thoughtful engineering, it offers features that enhance performance and user comfort, ensuring a productive experience in various applications.

Key Features

This model incorporates a range of innovative features that set it apart from other tools in its category. The lightweight design contributes to reduced fatigue during extended use, while the ergonomic handle ensures a comfortable grip. Additionally, the engine delivers impressive power output, making it suitable for demanding jobs. The incorporation of anti-vibration technology allows for smoother operation, minimizing discomfort for the user.

Applications

Ideal for a variety of tasks, this machine excels in both commercial and residential settings. Whether you’re trimming trees, cutting firewood, or performing maintenance work, it provides the versatility needed to tackle different challenges. Its efficiency not only saves time but also enhances productivity, allowing users to accomplish more in less time.

Key Features of the Chainsaw

This powerful tool is designed to deliver exceptional performance and efficiency for various cutting tasks. With a combination of innovative technology and ergonomic design, it provides users with a reliable solution for both professional and recreational woodwork. Understanding the key attributes can help users maximize their experience and productivity.

Engine and Performance

The heart of any chainsaw lies in its engine. A high-performance engine ensures quick starts and efficient fuel consumption. Features such as low vibration and reduced emissions not only enhance the user experience but also promote environmental sustainability.

Safety and Ergonomics

Safety is paramount when operating a cutting device. Integrated safety features such as chain brakes and anti-kickback mechanisms are essential for preventing accidents. Additionally, the ergonomic design allows for comfortable handling, reducing fatigue during extended use.

| Feature | Description |

|---|---|

| Engine Type | Powerful two-stroke engine for optimal performance. |

| Vibration Control | Reduces operator fatigue and improves comfort. |

| Safety Features | Chain brake, anti-kickback, and throttle lock for enhanced safety. |

| Fuel Efficiency | Designed for low fuel consumption, ensuring longer operation times. |

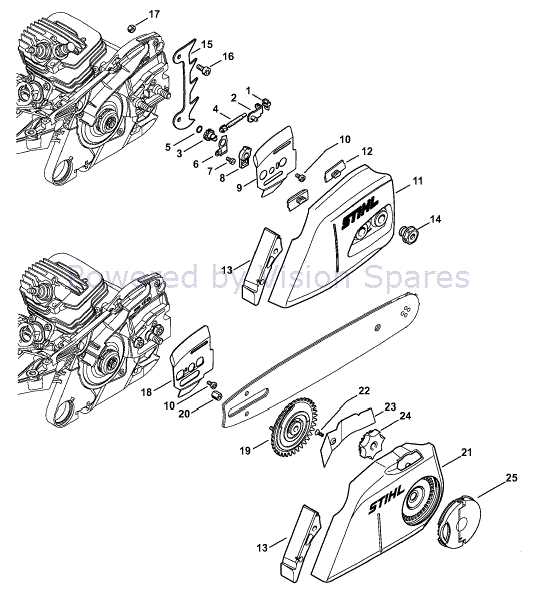

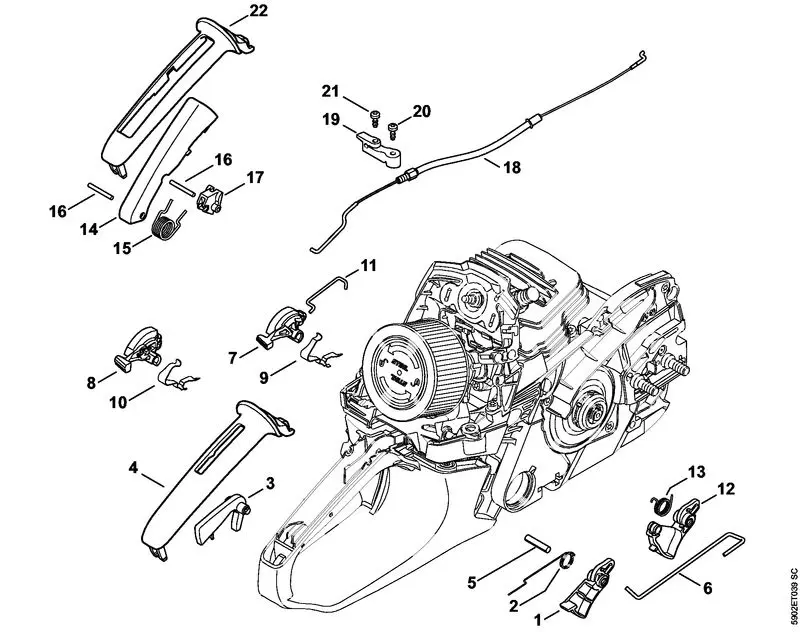

Importance of Parts Diagrams

Understanding the layout and function of various components within machinery is crucial for maintenance and repair tasks. Visual representations serve as essential tools for technicians and enthusiasts alike, aiding in the identification and replacement of individual elements. These illustrations facilitate a clearer understanding of how each piece interacts within the overall system, promoting efficiency and accuracy during servicing.

Enhancing Repair Efficiency

One of the primary advantages of utilizing visual guides is the significant boost in repair speed. By having a detailed reference, users can:

- Quickly locate specific components without unnecessary disassembly.

- Identify the correct replacement parts needed for repairs.

- Reduce the likelihood of errors during reassembly.

Facilitating Troubleshooting

Another key aspect of these visual resources is their role in troubleshooting. Users can:

- Trace the function of each element to identify faults.

- Understand the relationships between different components.

- Develop systematic approaches to problem-solving.

Understanding the Components List

Every mechanical system comprises various essential elements that work together to ensure optimal performance. Recognizing these components is crucial for anyone involved in maintenance, repair, or enhancement of machinery. A well-structured list of these elements aids in identifying specific parts, facilitating easier troubleshooting and replacement.

When examining the list of elements, it’s helpful to categorize them based on their functions. Below are some common categories:

- Engine Components:

- Cylinder

- Piston

- Crankshaft

- Fuel System:

- Carburetor

- Fuel Tank

- Fuel Lines

- Electrical System:

- Ignition Coil

- Starter Motor

- Battery

- Cutting Mechanism:

- Guide Bar

- Chain

- Chain Brake

Understanding each component’s role not only enhances your knowledge of the machinery but also empowers you to perform necessary repairs or upgrades effectively. Familiarity with these elements allows users to make informed decisions regarding maintenance schedules and potential replacements.

Common Replacement Parts Explained

Understanding the essential components of a chainsaw is crucial for effective maintenance and repairs. Over time, certain elements may wear out or become damaged due to regular use, necessitating their replacement. Familiarity with these key components can help ensure your equipment operates smoothly and efficiently.

Guide Bar and Chain

The guide bar and chain are fundamental to the chainsaw’s cutting mechanism. The guide bar provides a stable platform for the chain to rotate around, while the chain itself is responsible for the cutting action. Regular inspection for wear and tension is essential, as a dull or damaged chain can hinder performance and increase the risk of accidents.

Air Filter and Spark Plug

The air filter and spark plug play vital roles in engine efficiency. The air filter prevents dust and debris from entering the engine, ensuring optimal airflow and performance. Meanwhile, the spark plug ignites the fuel-air mixture, facilitating engine operation. Replacing these components at regular intervals helps maintain peak performance and prolongs the lifespan of the machinery.

Identifying OEM vs Aftermarket Parts

When it comes to maintaining and repairing outdoor power equipment, understanding the difference between original equipment manufacturer (OEM) components and aftermarket alternatives is crucial. This knowledge helps ensure that your machinery operates efficiently and safely while potentially saving you money and time in the long run.

What are OEM Components?

OEM components are parts produced by the same manufacturer that made the original item. These parts are designed specifically for a particular model, ensuring compatibility and performance.

- High-quality manufacturing standards

- Exact specifications for fit and function

- Usually come with a warranty

Understanding Aftermarket Alternatives

Aftermarket alternatives are produced by third-party companies and may offer various benefits. However, their quality and compatibility can vary significantly.

- Potentially lower cost

- Wider variety of options

- Quality can be inconsistent

In summary, recognizing the differences between these two types of components allows you to make informed decisions, ensuring the longevity and reliability of your equipment.

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the durability and performance of your equipment. Implementing simple maintenance practices can greatly extend its lifespan, ensuring it operates efficiently and reliably for years to come. Here are some crucial tips to keep in mind.

Routine Inspection

- Check all components for wear and tear before each use.

- Inspect the cutting mechanism for damage or dullness.

- Examine fuel lines and filters for clogs or leaks.

Proper Cleaning

- Clean the exterior regularly to prevent dirt and debris buildup.

- Remove any residue from the cutting parts after each use.

- Use compressed air to blow out any dust from hard-to-reach areas.

Regular Lubrication

- Lubricate moving parts to reduce friction and wear.

- Follow the manufacturer’s guidelines for recommended lubricants.

- Ensure proper oil levels in the engine for optimal performance.

By following these maintenance strategies, you can ensure your machinery remains in excellent condition, ultimately enhancing its functionality and prolonging its life span.

Troubleshooting Common Issues

When operating a power tool, encountering problems can be frustrating. Understanding how to identify and resolve common malfunctions can enhance the performance and lifespan of your equipment. This section provides guidance on addressing typical issues that users may face, ensuring a smooth and efficient operation.

Identifying Common Problems

Several factors can lead to operational difficulties. Here are some prevalent issues and their potential causes:

| Issue | Possible Cause | Recommended Solution |

|---|---|---|

| Engine won’t start | Fuel blockage or stale fuel | Check fuel lines and replace old fuel with fresh. |

| Loss of power | Clogged air filter or spark plug failure | Clean or replace the air filter and spark plug. |

| Excessive vibration | Loose components or worn parts | Tighten loose screws and inspect for wear. |

| Fuel leakage | Damaged fuel lines or connections | Inspect for damage and replace faulty lines. |

Preventive Measures

Regular maintenance is crucial to avoid issues. Ensure routine checks and cleanings are performed to keep your equipment in optimal condition. Following the manufacturer’s guidelines for care will significantly reduce the likelihood of encountering problems.

Where to Find Replacement Parts

Finding components for your outdoor power equipment can be a straightforward process if you know where to look. Various resources are available to help you obtain the necessary items for repairs or maintenance, ensuring your machinery runs smoothly. Whether you prefer shopping online or visiting local retailers, there are multiple options to suit your needs.

One of the most convenient methods is to explore online marketplaces, which often have a wide selection of components from different brands. This approach allows you to compare prices and read customer reviews before making a purchase. Alternatively, local authorized dealers can provide genuine items and expert advice on compatibility and installation.

| Source | Description | Advantages |

|---|---|---|

| Online Retailers | Websites that specialize in outdoor equipment components. | Convenient shopping, wide variety, user reviews. |

| Local Dealers | Authorized retailers that sell genuine equipment components. | Expert assistance, quality assurance, immediate availability. |

| Salvage Yards | Facilities that sell used parts from decommissioned machines. | Cost-effective options, unique finds, sustainable practices. |

| Manufacturer’s Website | Official site offering direct sales of components. | Reliable source, warranty options, latest items. |

By exploring these resources, you can effectively locate the necessary components to keep your machinery in optimal condition. Remember to verify the compatibility of each item with your specific equipment to ensure a successful repair.

Online Resources for Diagrams

Accessing accurate illustrations and technical drawings is crucial for anyone involved in maintenance or repair tasks. Numerous online platforms provide comprehensive visual aids that can significantly enhance understanding of machinery components. These resources not only facilitate quick reference but also ensure that users can perform repairs with greater confidence.

Manufacturer Websites: Many manufacturers host detailed resources on their official sites. Here, you can often find specific schematics that cover a range of models, making it easy to identify individual elements and their relationships.

Forums and Community Groups: Online forums dedicated to machinery and equipment often feature discussions where enthusiasts share their insights. Members frequently upload useful visuals, making these platforms a treasure trove of information for DIYers and professionals alike.

Video Tutorials: Platforms like YouTube host numerous channels that provide step-by-step guides, often accompanied by visual representations. These videos can clarify complex assemblies and demonstrate proper procedures effectively.

Technical Manuals: Various online libraries offer access to technical manuals in PDF format. These documents typically include high-quality visuals and detailed descriptions, making them indispensable for anyone looking to gain a deeper understanding of their equipment.

Utilizing these resources can make a significant difference in your ability to maintain and repair machinery efficiently. By taking advantage of the wealth of information available online, users can ensure they are well-equipped to handle any task that comes their way.

Benefits of Using Genuine Parts

Opting for original components when maintaining your equipment can significantly enhance performance and longevity. These high-quality items are specifically designed to fit perfectly and work seamlessly with your machine, ensuring optimal functionality. Using authentic replacements not only guarantees superior performance but also helps prevent potential issues that may arise from using substandard alternatives.

- Enhanced Durability: Authentic components are manufactured with high-quality materials, leading to a longer lifespan compared to counterfeit versions.

- Optimal Performance: Genuine items are engineered to the exact specifications of the equipment, providing superior performance and reliability.

- Improved Safety: Using original replacements reduces the risk of malfunctions, which can pose safety hazards during operation.

- Warranty Protection: Many manufacturers offer warranties on their equipment when genuine items are used, providing peace of mind and financial protection.

- Better Resale Value: Maintaining your machine with authentic components can help preserve its value, making it more attractive to potential buyers in the future.

In conclusion, choosing original replacements is a wise investment that can lead to better performance, increased safety, and overall satisfaction with your equipment.

Safety Considerations When Repairing

When undertaking maintenance or repair work on machinery, it is crucial to prioritize safety to prevent injuries and ensure effective operation. Proper precautions not only protect the individual performing the repairs but also prolong the lifespan of the equipment.

Essential Safety Gear

- Eye Protection: Always wear safety glasses or goggles to shield your eyes from flying debris.

- Hand Protection: Use gloves that provide a firm grip while also being resistant to cuts and abrasions.

- Footwear: Steel-toed boots can prevent injuries from heavy components.

- Hearing Protection: Consider earplugs or earmuffs if working in a noisy environment.

Work Area Safety

- Ensure the workspace is clean and well-lit to avoid accidents.

- Keep tools organized and within reach to minimize movement.

- Be aware of your surroundings and ensure no one is in the danger zone when operating machinery.

Following these safety guidelines will help create a secure environment for maintenance tasks and ensure the longevity of the machinery involved.