During the colder months, maintaining the functionality of your outdoor equipment is essential for efficient snow management. Whether you’re a professional landscaper or a homeowner, knowing the intricate details of your device can greatly enhance its performance and longevity. This section aims to provide insights into the various elements that make up your winter apparatus, helping you to grasp their roles and interconnections.

Identifying and understanding the specific components involved can streamline repairs and replacements when necessary. By familiarizing yourself with the layout and function of each segment, you can ensure that your equipment operates at its best, even in the harshest weather conditions. This knowledge empowers you to tackle challenges more effectively, saving both time and resources in the process.

Explore the various features and mechanisms that contribute to the overall efficiency of your winter machinery. Gaining a clearer perspective on these essential elements will not only enhance your understanding but also bolster your confidence when it comes to maintenance and troubleshooting tasks.

Toro 524 Snowblower Overview

This powerful outdoor equipment is designed for efficient snow removal during harsh winter conditions. Its robust construction and reliable performance make it an essential tool for homeowners facing heavy snowfall. The machine’s engineering allows for optimal maneuverability, ensuring users can navigate various terrains with ease.

Equipped with advanced features, this device offers a seamless operation that meets the demands of clearing snow quickly and effectively. Users can appreciate the thoughtful design that enhances both functionality and comfort, making it suitable for extended use.

| Feature | Description |

|---|---|

| Engine | Powerful motor for enhanced performance. |

| Width | Optimal clearing width for efficient snow removal. |

| Auger | Durable mechanism for effective snow breaking. |

| Chute Control | Easy adjustment for directing snow output. |

| Handles | Comfortable grips for improved handling. |

Understanding Snowblower Components

Winter machines designed for removing accumulated precipitation from various surfaces consist of several key elements, each playing a critical role in their overall functionality. Familiarizing oneself with these components can enhance maintenance practices and improve performance during operations. This section aims to elucidate the different features that contribute to the efficient performance of these devices.

Key Features of Winter Equipment

The various features of these machines can be categorized into essential assemblies that work together seamlessly. Understanding these assemblies helps in troubleshooting and optimizing usage. Here is a breakdown of the main components:

| Component | Function |

|---|---|

| Engine | Drives the entire mechanism, providing power to move and operate the unit. |

| Auger | Collects and breaks up the snow, enabling it to be discharged effectively. |

| Chute | Directs the flow of cleared material to the desired location. |

| Skids | Supports the machine, allowing it to glide over surfaces without damaging them. |

| Controls | Enable the operator to adjust speed and direction, ensuring precise handling. |

Importance of Regular Maintenance

Routine care of these components is crucial for maintaining optimal performance and extending the lifespan of the equipment. Regular inspections and timely replacements of worn parts can prevent unexpected breakdowns and enhance operational efficiency, ensuring that the machine is ready for use whenever needed.

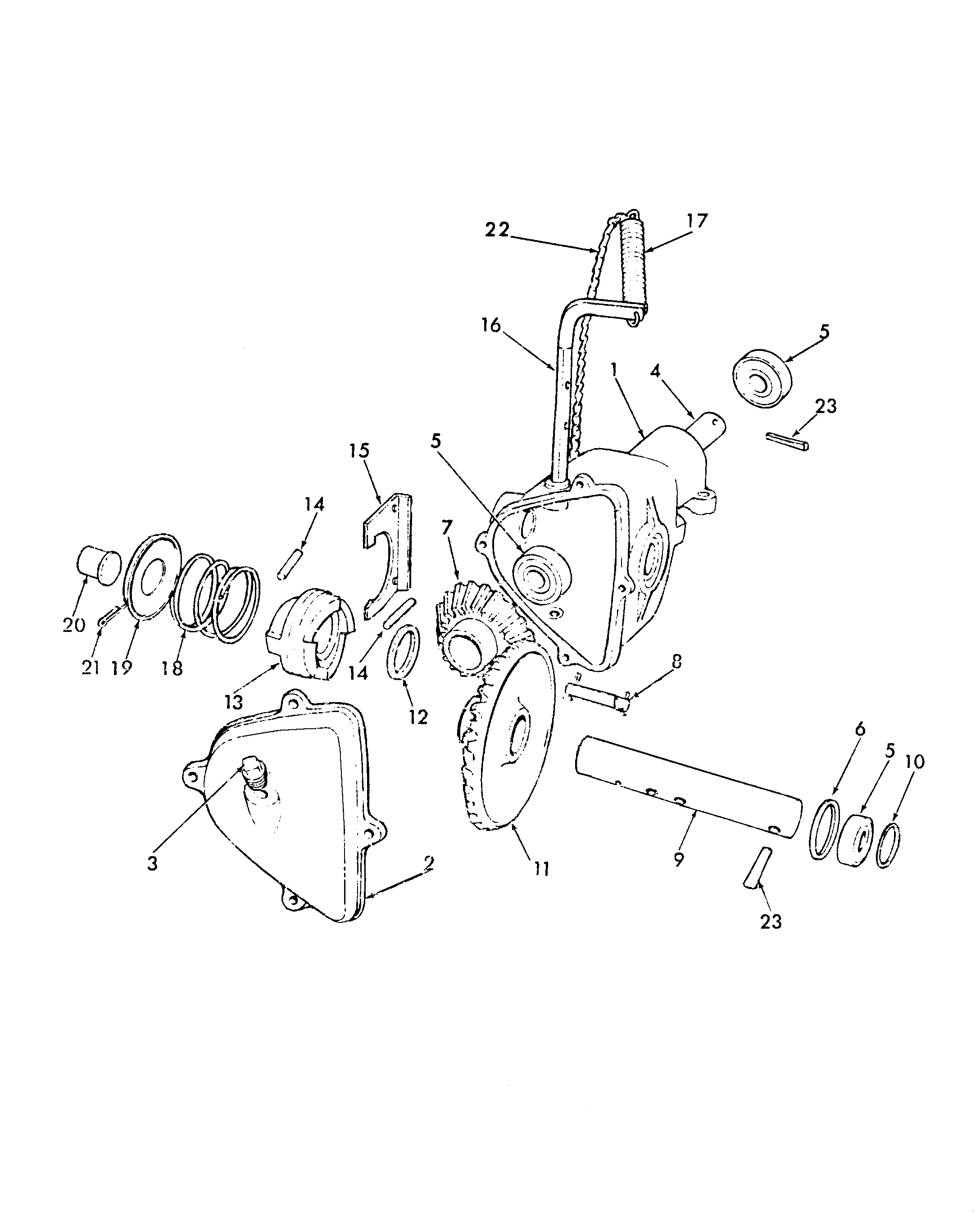

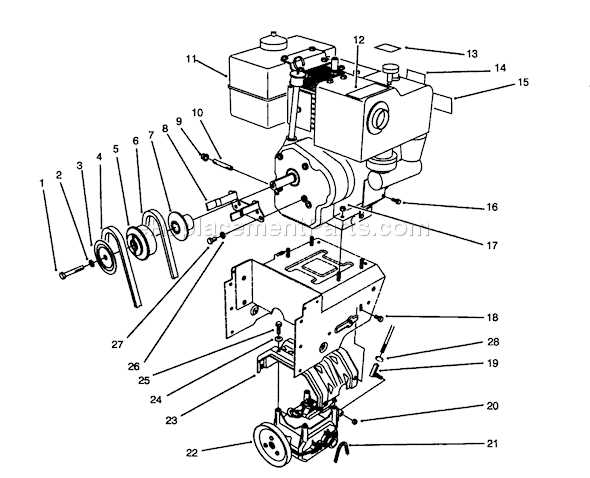

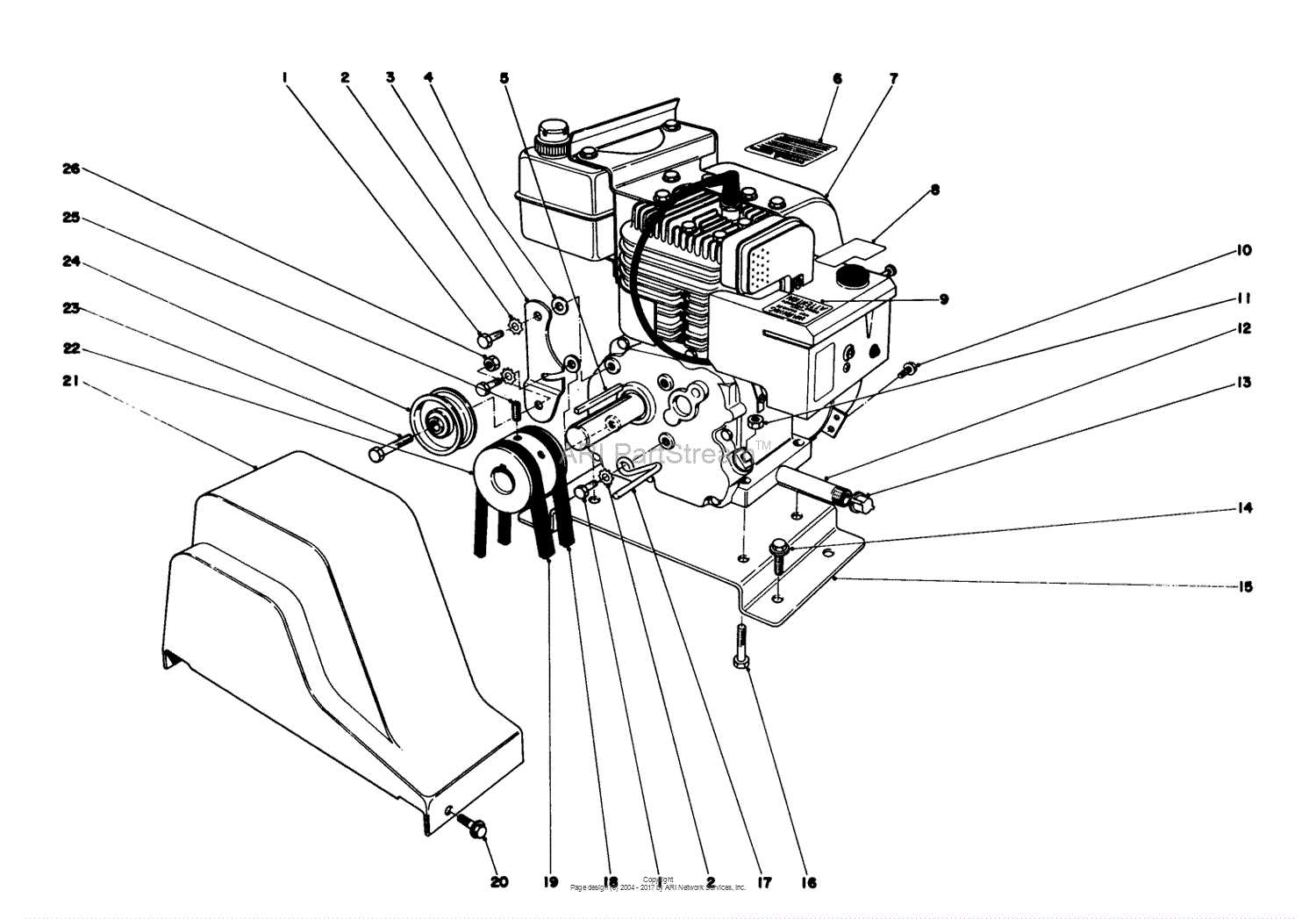

Importance of Parts Diagrams

Visual representations of components play a crucial role in understanding and maintaining machinery. These illustrations offer a clear overview of individual elements and their arrangement, facilitating easier repairs and replacements.

Utilizing these visual guides provides several advantages:

- Enhanced understanding of the assembly, allowing users to quickly identify specific pieces and their functions.

- Streamlined troubleshooting processes by enabling users to locate damaged or worn-out elements effectively.

- Time-saving benefits, as a comprehensive visual can reduce the need for extensive manuals or lengthy searches for information.

In addition, having a clear depiction of components can significantly assist in communication between technicians and customers, ensuring that everyone is on the same page regarding repairs and maintenance.

Ultimately, these visual aids are invaluable tools that not only improve efficiency but also enhance the overall user experience when dealing with mechanical systems.

Identifying Key Assembly Areas

Understanding the critical components of machinery is essential for effective maintenance and repair. This section focuses on recognizing the primary sections that contribute to optimal functionality. Familiarity with these segments will aid in troubleshooting and enhancing performance.

Core Components

The foundational elements of the equipment play a significant role in its operation. Each section serves a unique purpose, ensuring that the overall mechanism works seamlessly. Proper identification of these areas can streamline repair processes and reduce downtime.

Maintenance Focus

Regular upkeep of specific assemblies is vital for longevity. Paying attention to wear and tear in crucial regions will help prevent major failures. Knowing which parts require more frequent checks empowers users to take proactive measures and maintain efficiency.

Common Replacement Parts Explained

Maintaining outdoor equipment often requires an understanding of various components that may need to be replaced over time. Familiarity with these essential elements can ensure optimal performance and longevity. This section delves into the most frequently substituted items, highlighting their roles and significance in the overall functionality of your machine.

Key Components Overview

Several crucial elements play a vital role in the operation of your equipment. Knowing when and how to replace them can save you time and enhance your experience. Below is a table summarizing some of the most common components that may require replacement.

| Component | Description | Signs of Wear |

|---|---|---|

| Belts | Transmits power from the engine to the working mechanisms. | Cracks, fraying, or excessive slack. |

| Shear Pins | Designed to break under excessive load to protect the machinery. | Visible breakage or deformation. |

| Auger Blades | Cut and move material through the system. | Dull edges or significant wear. |

| Scraper Bars | Assist in clearing surfaces efficiently. | Warping or missing sections. |

Conclusion on Maintenance

Regularly inspecting and replacing these critical components can significantly enhance the reliability and effectiveness of your equipment. Understanding the signs of wear and knowing when to act will ensure that you are always ready for the challenges of winter.

Maintenance Tips for Toro Snowblowers

Regular upkeep is essential for ensuring the longevity and efficient performance of your winter equipment. By adhering to simple maintenance practices, you can prevent potential issues and enhance the functionality of your machine. This section outlines vital suggestions to keep your winter machinery in optimal condition.

One of the most important aspects of care involves routine inspections. Regularly check for signs of wear and tear, ensuring that all components are in good working order. Pay attention to the following elements:

| Component | Maintenance Action |

|---|---|

| Fuel System | Inspect and replace fuel as necessary to prevent engine issues. |

| Blades | Sharpen or replace worn blades to maintain efficient snow clearing. |

| Belts | Check for fraying or damage; replace if needed to ensure proper operation. |

| Lubrication | Apply appropriate lubricants to moving parts to minimize friction and wear. |

| Batteries | Test battery performance and replace if it shows signs of weakness. |

Implementing these measures will not only extend the lifespan of your equipment but also enhance its overall effectiveness during challenging winter conditions. Regular maintenance ensures that your machinery is always ready for action when you need it most.

How to Read a Parts Diagram

Understanding the layout of a component schematic is essential for anyone involved in maintenance or repair tasks. These visuals serve as a map, guiding users through the intricate arrangement of various elements, showcasing their interconnections and functions. Grasping how to interpret these illustrations can significantly enhance efficiency in identifying and sourcing replacement items.

Decoding the Symbols

Each element within the illustration is represented by specific symbols or notations. Familiarizing yourself with these representations is crucial. Often, the key to understanding lies in recognizing these graphical representations and knowing what each signifies. Look for labels and legends that provide context and clarity about each component’s role.

Following the Connections

Beyond identifying individual pieces, it’s important to observe how they interact with one another. Pay attention to lines and arrows that indicate connections, dependencies, or flows. This insight into how components work together will not only aid in repairs but also deepen your comprehension of the overall system’s functionality.

Finding Genuine Toro Parts

When it comes to maintaining outdoor equipment, sourcing authentic components is essential for optimal performance and longevity. Genuine items are specifically designed to fit perfectly and function effectively, ensuring your machinery runs smoothly. By choosing original replacements, users can avoid potential issues that arise from substandard alternatives.

To locate these authentic components, start by consulting the manufacturer’s website or authorized dealers. They provide detailed catalogs and online resources that can help identify the correct items needed for repairs or maintenance. Additionally, exploring specialized retailers and online marketplaces can yield a wide selection of genuine options, complete with descriptions and compatibility information.

Another valuable strategy is to connect with local repair shops or service centers. These professionals often have access to a network of suppliers and can recommend the best sources for acquiring legitimate items. Furthermore, engaging with online forums and communities dedicated to outdoor equipment can offer insights and tips from fellow enthusiasts who have navigated similar searches.

Steps for Disassembling Your Snowblower

When maintenance or repair is required, knowing how to take apart your machine is essential. This process allows for thorough cleaning, examination of components, and replacement of any worn parts. Following a systematic approach will ensure that the disassembly is smooth and efficient, enabling you to address any issues effectively.

Preparation and Safety Measures

Before starting, gather all necessary tools, including wrenches, screwdrivers, and pliers. Make sure to wear protective gloves and eyewear to ensure your safety throughout the procedure. Disconnect the power source to prevent accidental start-ups and clear the workspace to provide ample room for maneuvering the unit.

Step-by-Step Disassembly

Begin by removing the housing covers. This usually involves unscrewing several bolts. Once the exterior is off, carefully detach the auger and impeller assembly, ensuring to note the position of any clips or connectors. Next, remove the drive belt and check for wear, as this may require replacement. As you proceed, organize the fasteners and parts to facilitate reassembly. Documenting each step with notes or photographs can also prove beneficial for putting everything back together later.

Troubleshooting Common Issues

When operating winter equipment, encountering obstacles is common. Recognizing potential problems early can prevent larger failures and enhance efficiency. This section highlights frequent challenges and their solutions, allowing users to maintain optimal functionality.

Below is a summary of typical issues and recommended fixes:

| Issue | Possible Cause | Solution |

|---|---|---|

| Equipment not starting | Insufficient fuel or battery issues | Check fuel levels and battery connections; recharge or replace if necessary. |

| Ineffective snow clearing | Clogged chute or dull blades | Inspect and clear any blockages; sharpen or replace blades as needed. |

| Excessive vibration | Loose components or misaligned parts | Tighten all bolts and ensure parts are correctly aligned. |

| Engine overheating | Blocked air intake or low oil levels | Clean air intake and check oil levels; add oil if required. |

By identifying and addressing these common complications, users can ensure reliable operation and prolong the lifespan of their equipment.

Upgrading Your Toro Snowblower

Enhancing the performance and efficiency of your winter machinery can significantly improve its usability and effectiveness. By incorporating various upgrades, you can ensure your equipment operates at peak performance, making your winter tasks much easier. This section will explore the benefits of upgrading key components and how they can contribute to a more efficient operation.

Benefits of Upgrading

Investing in enhancements not only boosts the functionality of your machine but also extends its lifespan. Improved features may include better snow clearing capabilities, enhanced durability, and increased ease of use. These upgrades often translate to reduced maintenance costs and a more enjoyable experience during harsh weather conditions.

Key Components for Improvement

| Component | Upgrade Options | Benefits |

|---|---|---|

| Engine | Higher horsepower options | Increased power and efficiency |

| Auger | Reinforced materials | Improved durability and snow cutting |

| Control System | Electronic start and throttle controls | Enhanced user convenience and response time |

| Tires | All-terrain options | Better traction and stability on slippery surfaces |