Understanding the layout and structure of individual elements is key to maintaining and repairing complex machinery. In this section, we will delve into the organization and purpose of various mechanisms, shedding light on how they function together to ensure optimal performance.

Each piece plays a vital role in the system’s overall functionality. By recognizing the interplay of these elements, one can easily identify potential issues and carry out effective maintenance. This guide will provide a clear understanding of how different units are interconnected, ensuring smooth and reliable operation.

Through detailed analysis and comprehensive descriptions, we will walk you through the intricacies of these essential components, highlighting their significance and the steps required for accurate identification and handling. Our goal

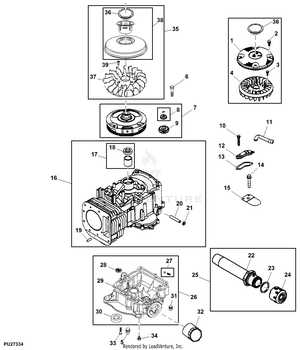

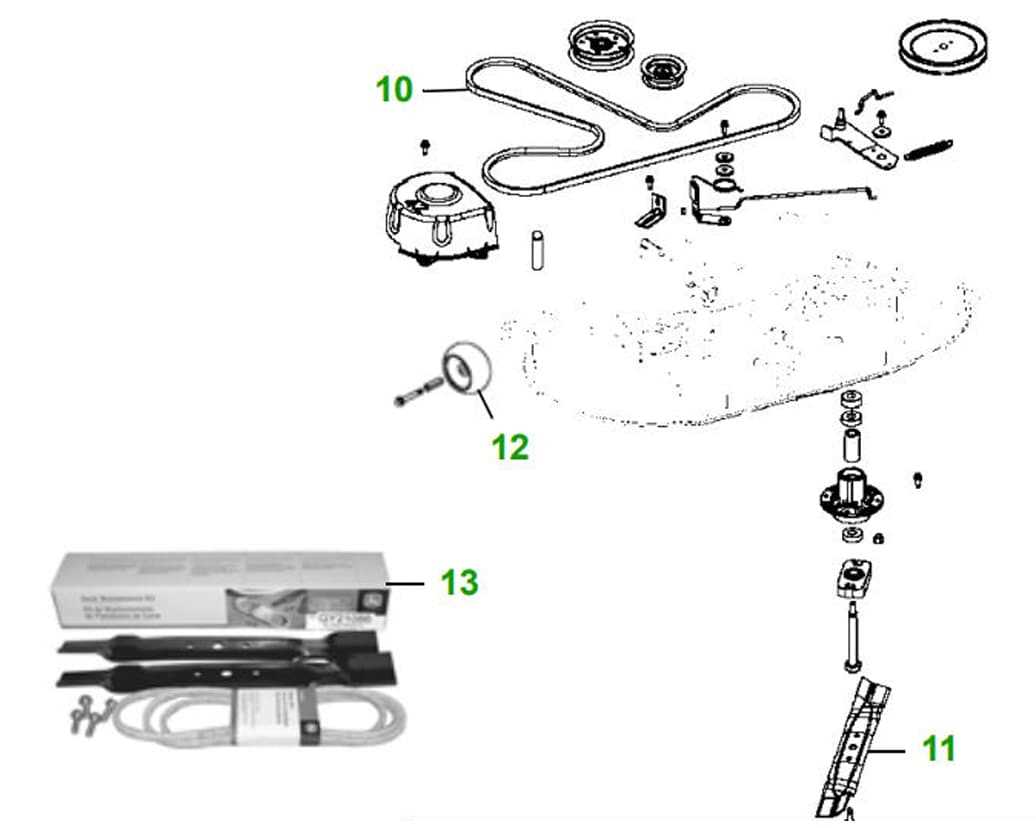

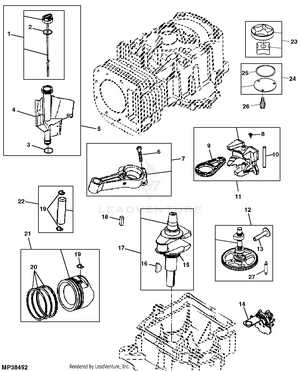

Overview of the LA110 System Components

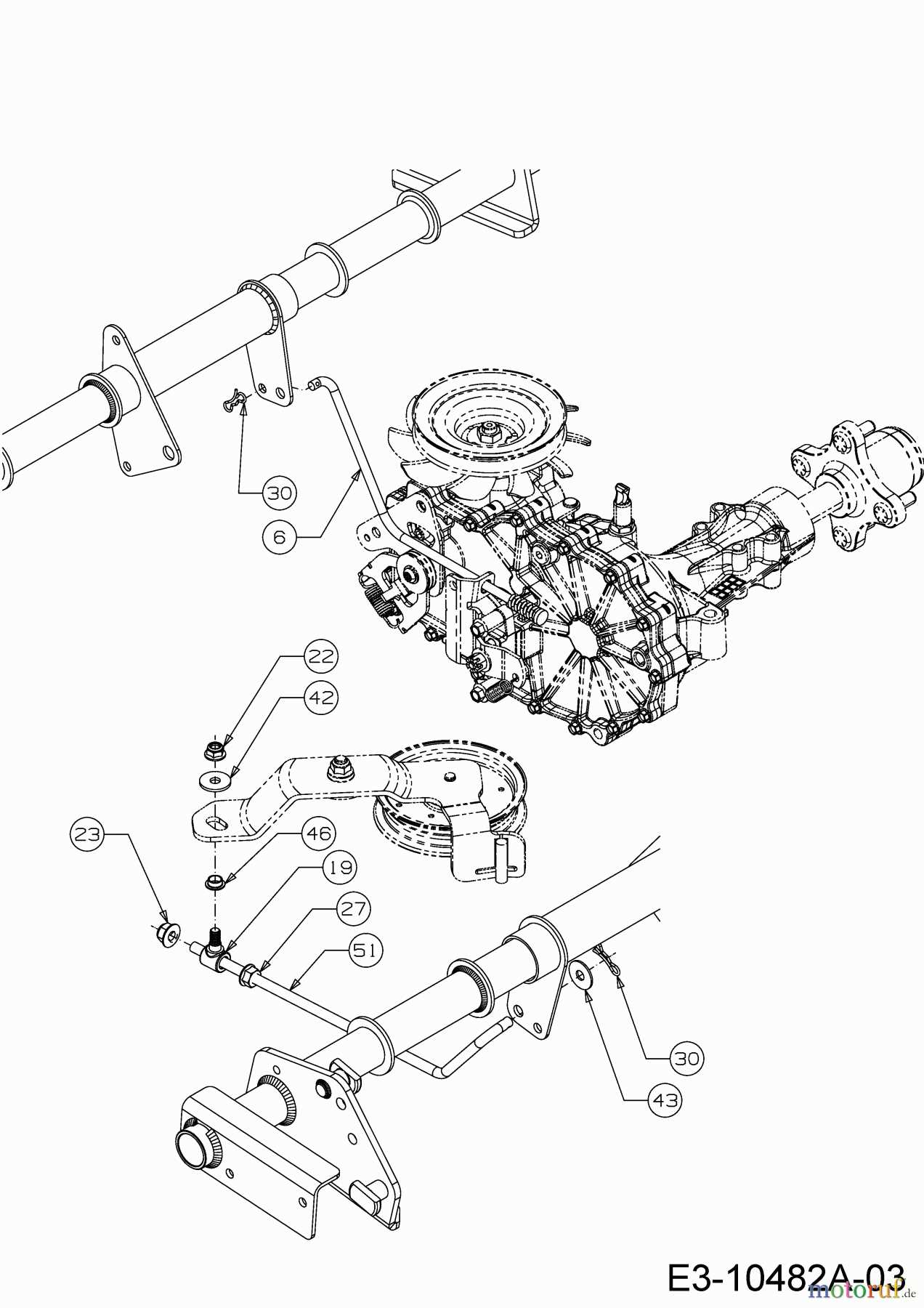

This section provides a detailed examination of the various elements that make up the core structure of the system. Each element plays a crucial role in ensuring optimal performance and efficient functionality, working in harmony with other components to create a cohesive and reliable setup. Understanding the interactions between these parts allows for better management and maintenance of the system, contributing to its overall efficiency and longevity.

Primary Functional Units

The core framework consists of essential units that are responsible for handling specific tasks. These units are interconnected and designed to work seamlessly, ensuring the system performs its intended operations with precision. Whether it involves managing external inputs or controlling internal processes, each unit is optimized for its respective function.

Supporting Elements

Main Functions of Each Key Part

The design of this system relies on the precise interaction between multiple components, each serving a unique role. By understanding the purpose of these elements, it becomes easier to grasp the overall functionality and ensure efficient performance. Below is an overview of how these essential elements contribute to the system’s operation.

Core Components Overview

Several critical elements form the backbone of the system, and each plays a significant part in maintaining optimal function. Whether focusing on managing flow, regulating activity, or ensuring stability, every element works in tandem to achieve balanced performance.

| Component | Main Function |

|---|

| Component | Location | Fitment Notes |

|---|---|---|

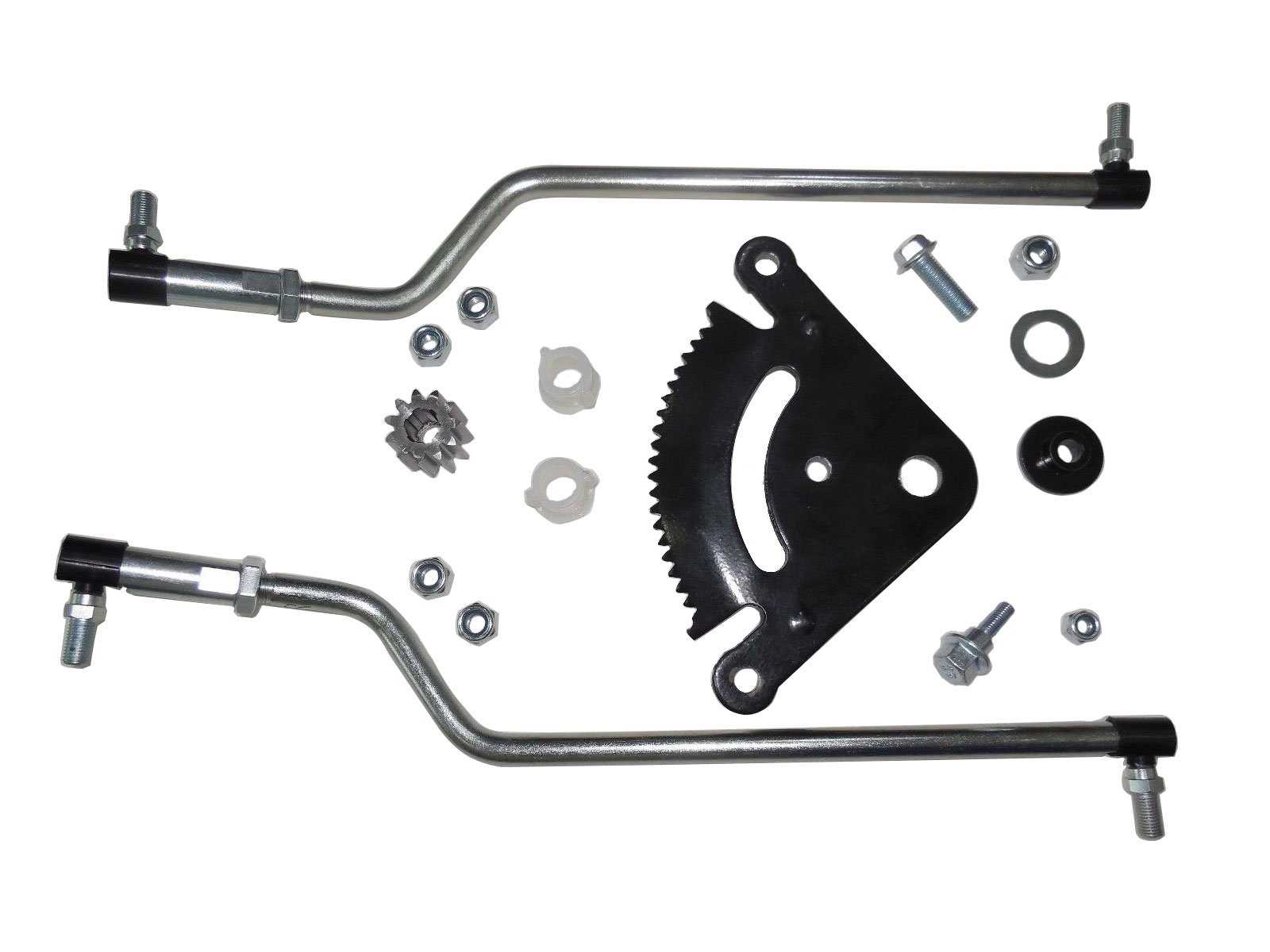

| Engine Assembly | Central Frame | Ensure secure mounting to minimize vibration. |

| Transmission Unit | Rear of Engine | Align with dowel pins for precise fitting. |

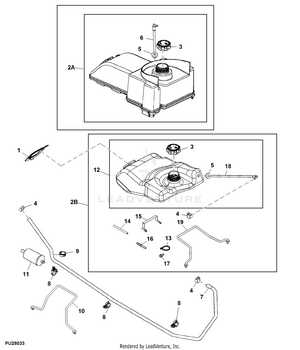

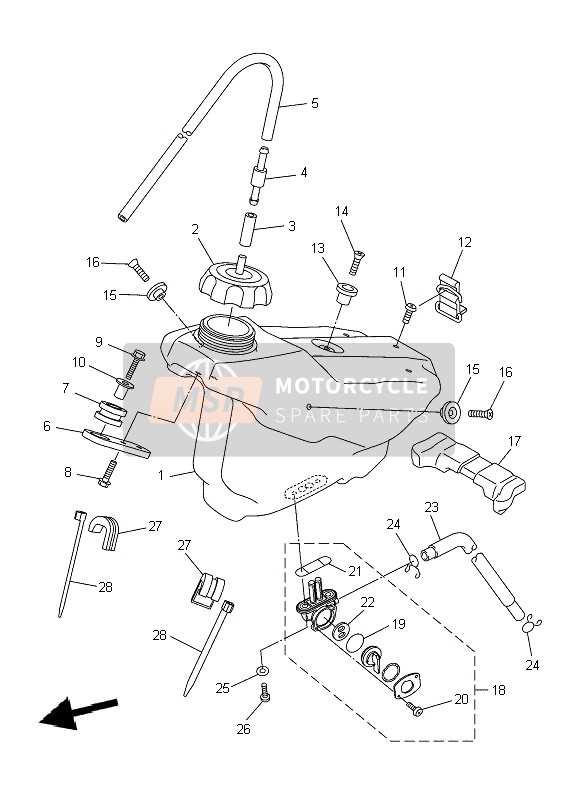

| Fuel System | Side Compartment | Check for leaks post-installation. |

| Cooling System | Front Assembly | Verify airflow and access to radiator. |

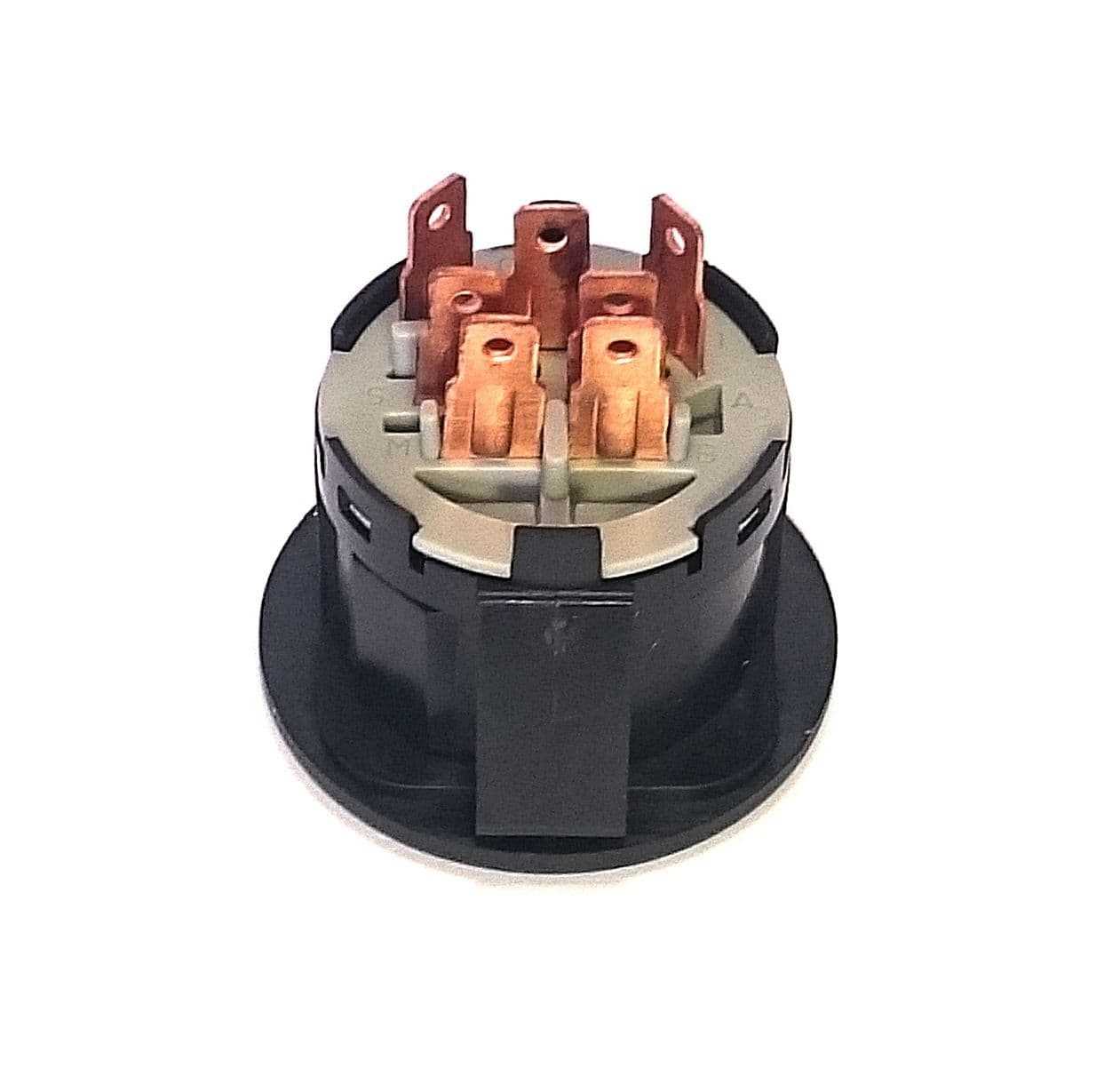

| Electrical Components | Under Dashboard | Ensure all connections are secure and insulated. |

How Parts Align Within the System

Understanding the arrangement and interaction of components within a system is crucial for its overall functionality. Each element plays a specific role, contributing to the seamless operation and efficiency of the entire assembly. By examining how these units connect and cooperate, we can appreciate the intricacies of their design and the importance of each part in achieving optimal performance.

| Component | Function | Connection Type |

|---|---|---|

| Unit A | Initiates process | Direct link |

| Unit B | Regulates flow | Indirect connection |

| Unit C | Processes data | Integrated circuit |

| Unit D | Outputs results | Wireless transmission |

By mapping out these connections, we gain insights into the systematic dependencies that exist. Recognizing the alignment of these units helps in troubleshooting and enhancing the overall structure, ensuring that each element can be accessed and modified when necessary.

Diagnostic Guide for LA110 Parts

This section provides a comprehensive overview aimed at helping users identify and troubleshoot components within the specified model. Understanding the arrangement and functionality of each element is essential for effective maintenance and repair, ensuring optimal performance and longevity.

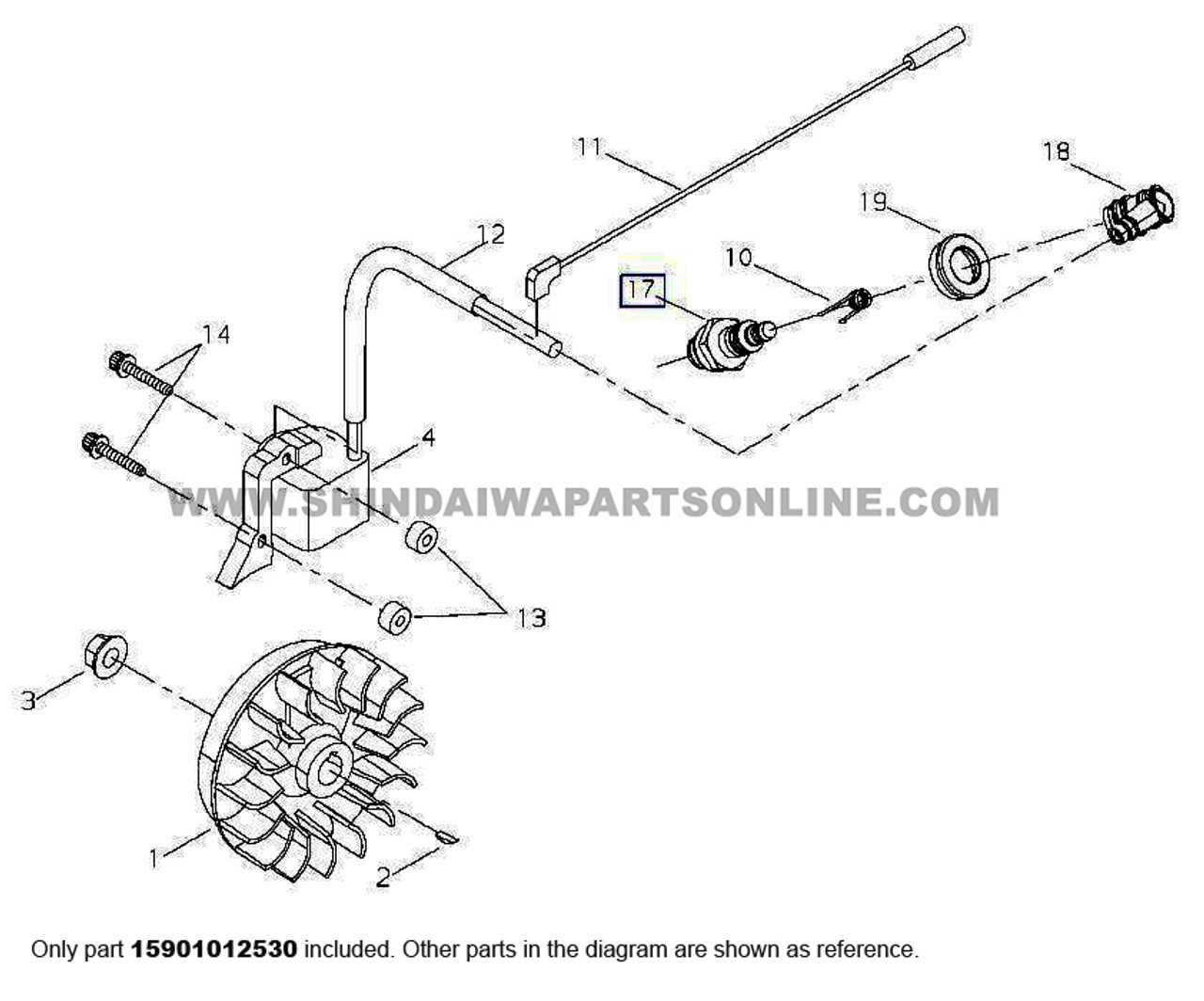

Identifying Components

Familiarizing yourself with the various components is crucial. Each element serves a specific role, and recognizing their locations and functions can simplify the troubleshooting process. Start by examining the assembly layout to gain insight into how each part interacts with others, which can lead to quicker diagnostics and repairs.

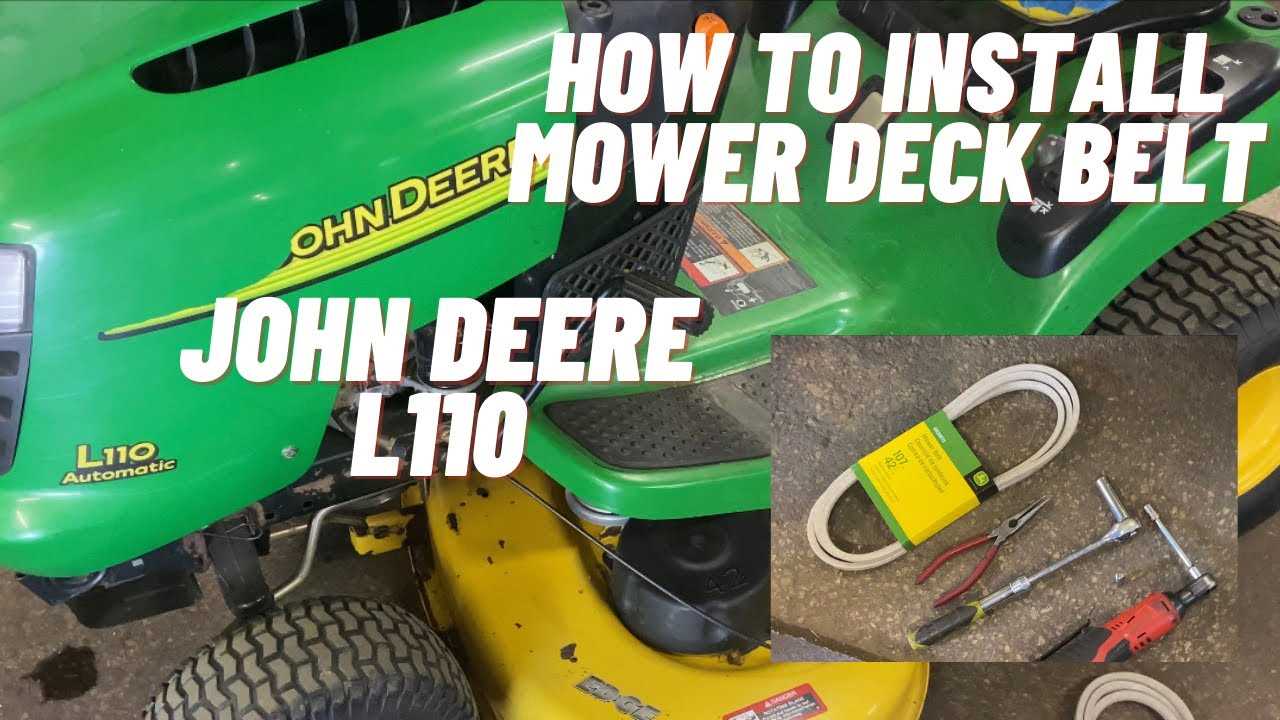

Troubleshooting Techniques

Utilize systematic methods for diagnosing issues. Begin with visual inspections to detect any obvious signs of wear or damage. If problems persist, employ testing tools to assess functionality. This approach not only helps pinpoint failures but also aids in determining whether a component requires replacement or if adjustments can resolve the issue.

Identifying Common Issues and Solutions

When working with complex mechanical systems, it’s essential to recognize typical challenges that may arise during operation. Understanding these problems can facilitate timely interventions and minimize downtime. This section outlines frequent malfunctions, their symptoms, and practical remedies to ensure optimal functionality.

Frequent Malfunctions

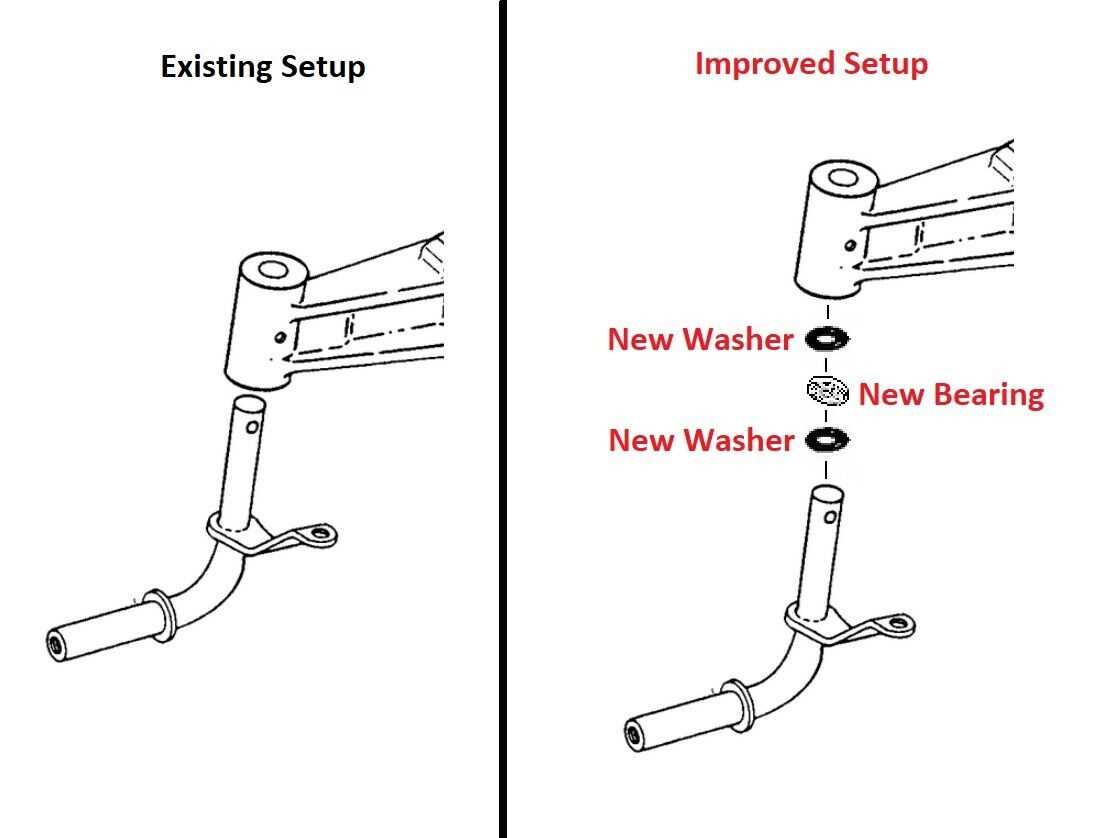

Common issues may include irregular performance, mechanical failures, and improper alignments. These problems can manifest in various ways, affecting overall efficiency and reliability. Awareness of these symptoms is crucial for prompt identification and resolution.

Troubleshooting and Remedies

Below is a summary of prevalent issues along with potential solutions:

| Issue | Symptoms | Recommended Solution |

|---|---|---|

| Overheating | Excessive heat generation, unusual noises | Check for blockages in airflow; ensure proper lubrication |

| Inconsistent Operation | Erratic movements, failure to start | Inspect electrical connections; test for power supply issues |

| Wear and Tear | Visible damage, decreased efficiency | Replace worn components; conduct regular maintenance checks |