In the world of textile creation, the intricacies of historical crafting devices reveal a rich tapestry of artistry and engineering. These remarkable instruments have stood the test of time, showcasing both function and aesthetic appeal. By exploring their individual elements, we gain insight into the craftsmanship that has shaped our approach to fiber manipulation over centuries.

The harmonious interplay between various sections of these implements is crucial for achieving optimal performance. Each component plays a specific role, contributing to the overall efficiency and effectiveness of the crafting process. Understanding these features not only enhances our appreciation for these tools but also informs modern practices in textile arts.

Through a detailed examination of these integral elements, we can uncover the secrets behind their operation. This exploration invites both enthusiasts and newcomers alike to engage with the historical significance and practical applications of these devices, bridging the gap between past and present in the world of fiber arts.

Understanding Antique Spinning Wheels

The exploration of traditional textile tools unveils a fascinating journey into craftsmanship and history. These devices, once central to fabric creation, embody a rich heritage of artistry and innovation. Each component plays a vital role in transforming raw materials into usable fibers, showcasing the intricate relationship between function and design.

Key Elements: Grasping the fundamentals of these implements involves recognizing their essential features. The mechanism consists of several interconnected sections, each contributing uniquely to the overall operation. Understanding how these segments work together allows enthusiasts to appreciate the sophistication behind their construction.

Historical Significance: These devices not only served practical purposes but also reflected cultural practices and technological advancements of their time. Studying their evolution reveals insights into societal changes and the artistry of previous generations.

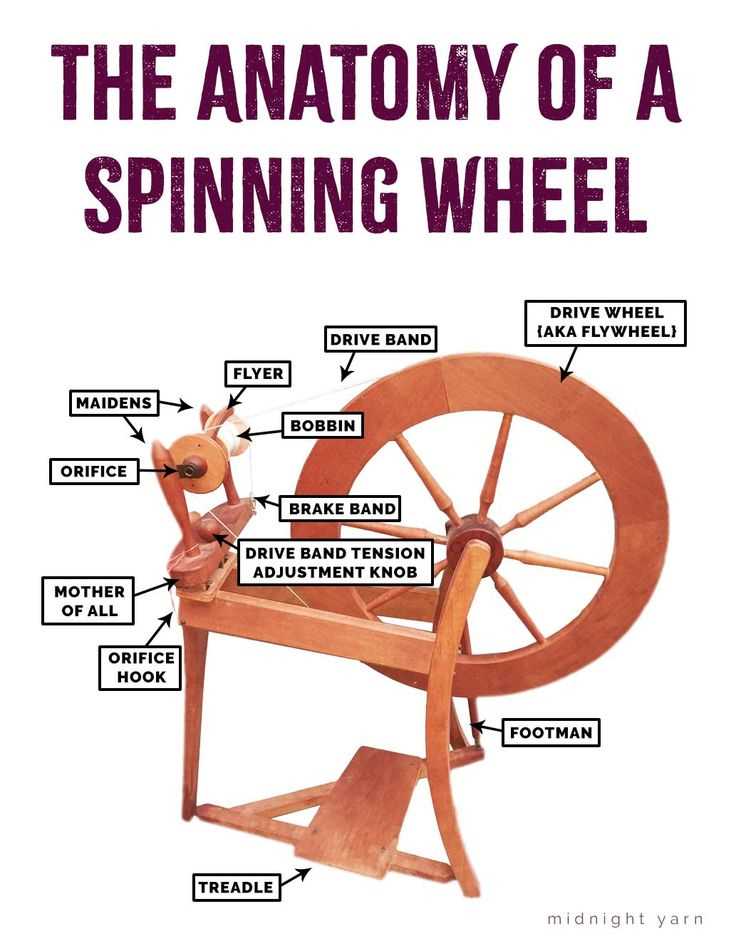

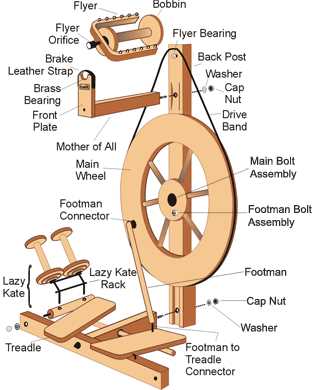

Essential Components of Spinning Wheels

Understanding the key elements that make up the crafting device is crucial for both novices and experienced artisans. Each segment plays a unique role in transforming fibers into yarn, allowing for creativity and innovation in textile production.

Main Functional Elements

The primary components include a framework that supports the entire mechanism, along with a drive system that facilitates motion. These elements work in unison to create the necessary tension and rotation, ensuring that the fiber is adequately processed. The drum and distaff are integral in holding and feeding the material, while the spindle plays a pivotal role in twisting the fibers together.

Additional Accessories

Various accessories enhance the overall functionality and ease of use. Tools such as bobbin holders and guide hooks assist in managing the yarn’s flow, while adjustable tension knobs allow for customization based on the type of fiber being used. Together, these features contribute to a seamless crafting experience, promoting efficiency and creativity.

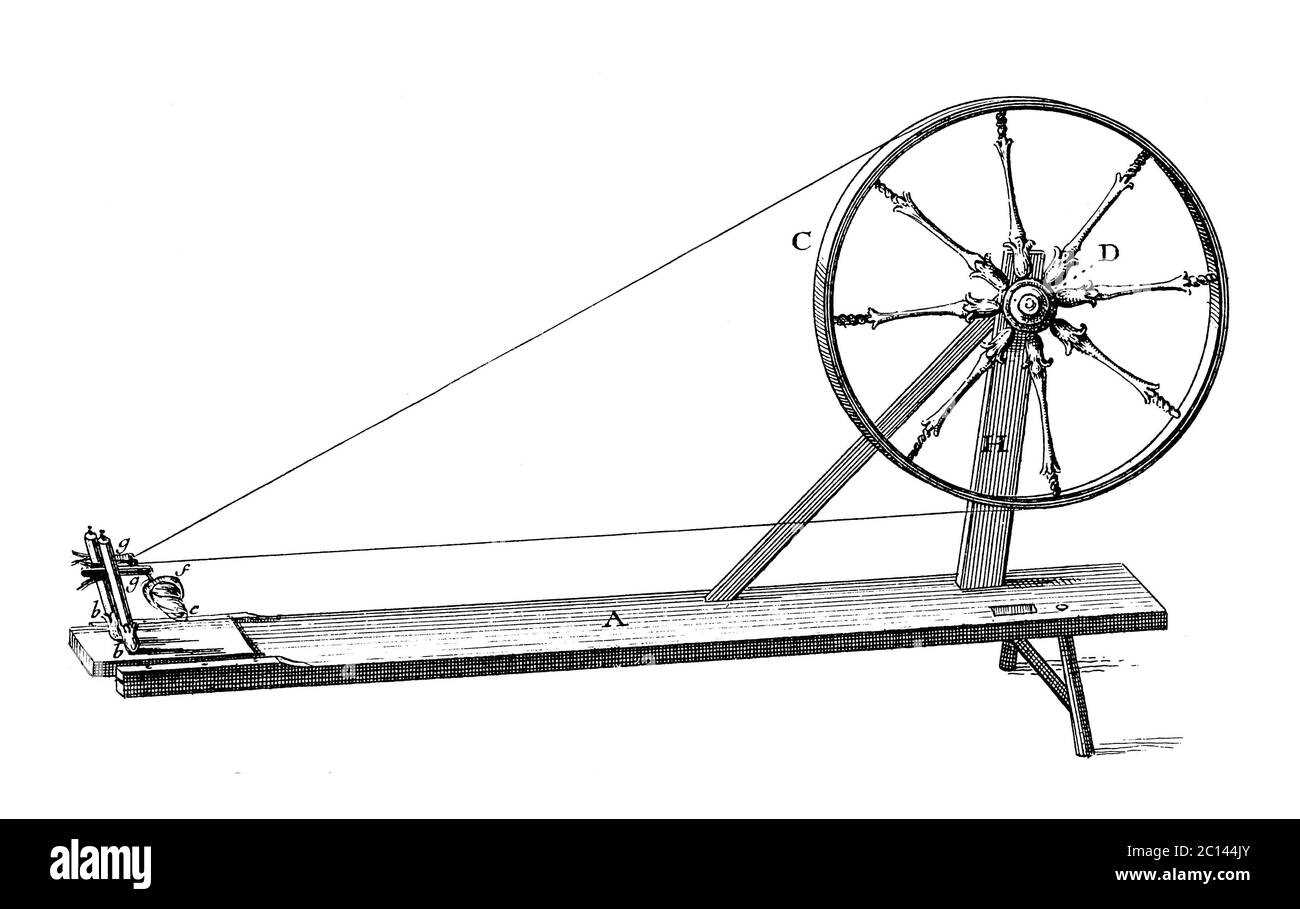

Historical Context of Spinning Wheels

The evolution of fiber processing tools has significantly shaped textile production throughout history. These devices have played a crucial role in transforming raw materials into usable fabric, influencing both economic structures and cultural practices.

Origins and Development

Initially crafted from simple materials, these tools have undergone numerous modifications over centuries:

- Early devices were hand-powered and often unique to local cultures.

- With advancements in technology, mechanisms became more complex and efficient.

- The introduction of machinery during the Industrial Revolution revolutionized production on a larger scale.

Cultural Significance

Beyond their practical use, these tools have held symbolic meaning across different societies:

- In many cultures, the act of creating textiles is associated with community and tradition.

- They often serve as a rite of passage, marking important life events.

- Artisanship in textile creation has fostered unique regional identities.

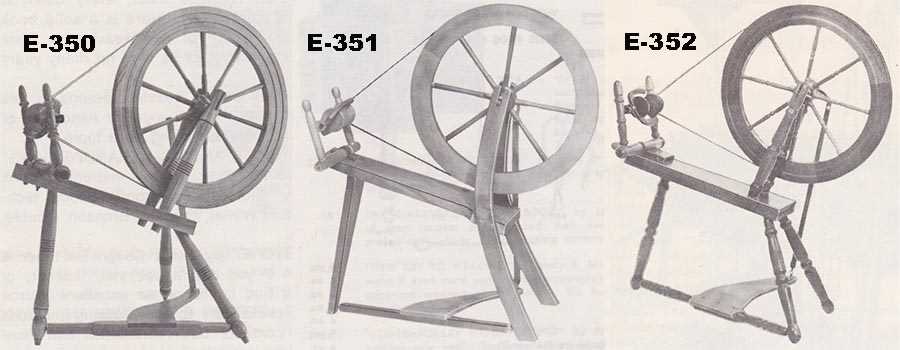

How to Identify Antique Models

Recognizing vintage craftsmanship requires a keen eye and knowledge of specific characteristics. This guide provides insights into distinguishing features that can help enthusiasts identify these unique creations from the past.

- Materials Used: Examine the substances. Early creations often utilized natural resources like wood, metal, or textiles.

- Construction Techniques: Look for signs of handwork, such as visible tool marks or irregularities, which indicate craftsmanship rather than mass production.

- Design Elements: Study the aesthetics. Traditional designs may feature intricate carvings, unique shapes, or distinctive embellishments.

In addition to physical attributes, consider the following:

- Provenance: Research the history. Documentation or family lore can provide context and authenticity.

- Patina: Observe the surface finish. Age often contributes to a rich patina that enhances character.

- Functionality: Assess how the item operates. Many earlier models were designed with practicality in mind, reflecting their purpose and use.

By focusing on these elements, collectors can better appreciate and identify these cherished artifacts, ensuring their historical significance is recognized and preserved.

Common Issues with Spinning Wheel Parts

Many enthusiasts encounter various challenges when working with traditional fiber tools. Understanding these common difficulties can enhance the experience and longevity of these cherished instruments.

Wear and Tear

Over time, components may suffer from degradation, leading to decreased efficiency. Regular maintenance is essential to prevent friction and ensure smooth operation.

Alignment Problems

Misalignment can result in uneven tension and hinder functionality. It’s crucial to periodically check the positioning of the elements to maintain optimal performance.

Maintenance Tips for Spinning Wheels

Regular care and attention are essential for ensuring the longevity and efficiency of your crafting equipment. By implementing a few simple practices, you can enhance performance and enjoy a smoother experience in your creative endeavors.

Cleaning and Lubrication

- Dust and debris can accumulate; regularly wipe down surfaces with a soft cloth.

- Use appropriate oils for moving components to minimize friction and wear.

- Check for buildup in any crevices and clear them to prevent obstruction.

Inspection and Adjustment

- Periodically inspect all elements for signs of damage or wear.

- Make necessary adjustments to ensure optimal tension and alignment.

- Replace any worn components promptly to maintain functionality.

Restoration Techniques for Antique Wheels

Reviving historical textile tools requires a blend of care, knowledge, and precision. Proper techniques ensure not only functionality but also preserve the charm and character of these remarkable creations.

Initial Assessment

Begin with a thorough evaluation to determine the condition and necessary repairs. Consider the following:

- Examine for structural integrity.

- Identify missing or damaged components.

- Assess the finish and surface wear.

Repair and Maintenance

Once assessed, follow these steps to restore:

- Clean all surfaces gently using appropriate solvents.

- Replace or repair broken elements, ensuring compatibility.

- Refinish surfaces with suitable products to enhance appearance.

These techniques provide the ultimate path to revitalize cherished pieces while honoring their rich history.

Where to Find Replacement Parts

Locating components for classic textile machinery can be a rewarding endeavor. Many enthusiasts seek to restore their equipment to optimal condition, and knowing where to look for necessary elements is crucial.

Online Marketplaces

- eBay – A vast selection of both new and used items.

- Amazon – Various sellers offer a range of components.

- Etsy – Unique and handcrafted options from individual artisans.

Local Resources

- Antique shops – Often carry a selection of older machinery and accessories.

- Flea markets – A treasure trove for rare finds.

- Specialty craft stores – May stock supplies tailored for restoration projects.

Exploring these avenues can help enthusiasts find the ultimate components for their cherished machinery.

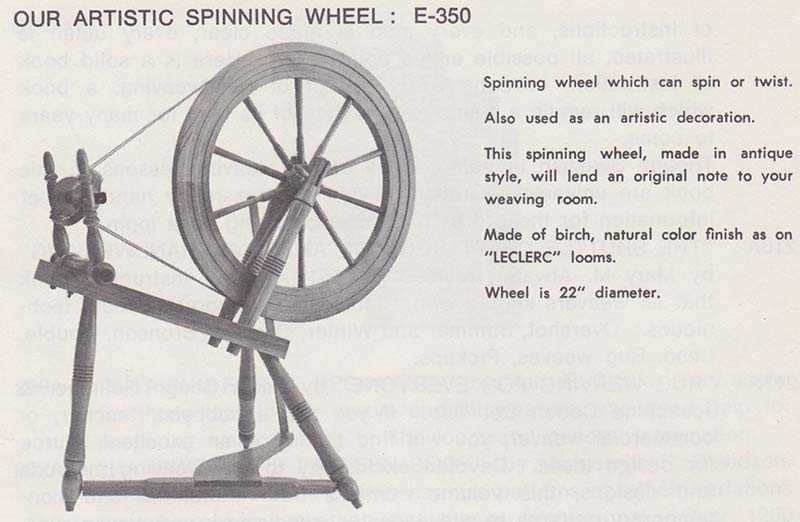

Significance of Wheel Design Variations

The diverse configurations of circular mechanisms play a crucial role in the efficiency and aesthetic appeal of textile production tools. These variations not only reflect the ingenuity of their makers but also cater to specific functional requirements across different cultures and time periods.

Understanding the significance of these designs involves several key aspects:

- Functionality: Different shapes and sizes can enhance performance and adaptability for various materials.

- Aesthetics: Unique designs often showcase the artistic skills of craftsmen, adding cultural value.

- Historical Context: Variations provide insights into technological advancements and societal needs of the time.

- Material Use: The choice of materials influences durability and usability, reflecting available resources.

Exploring these factors allows us to delve into the ultimate relationship between design and utility, enriching our understanding of historical craftsmanship.

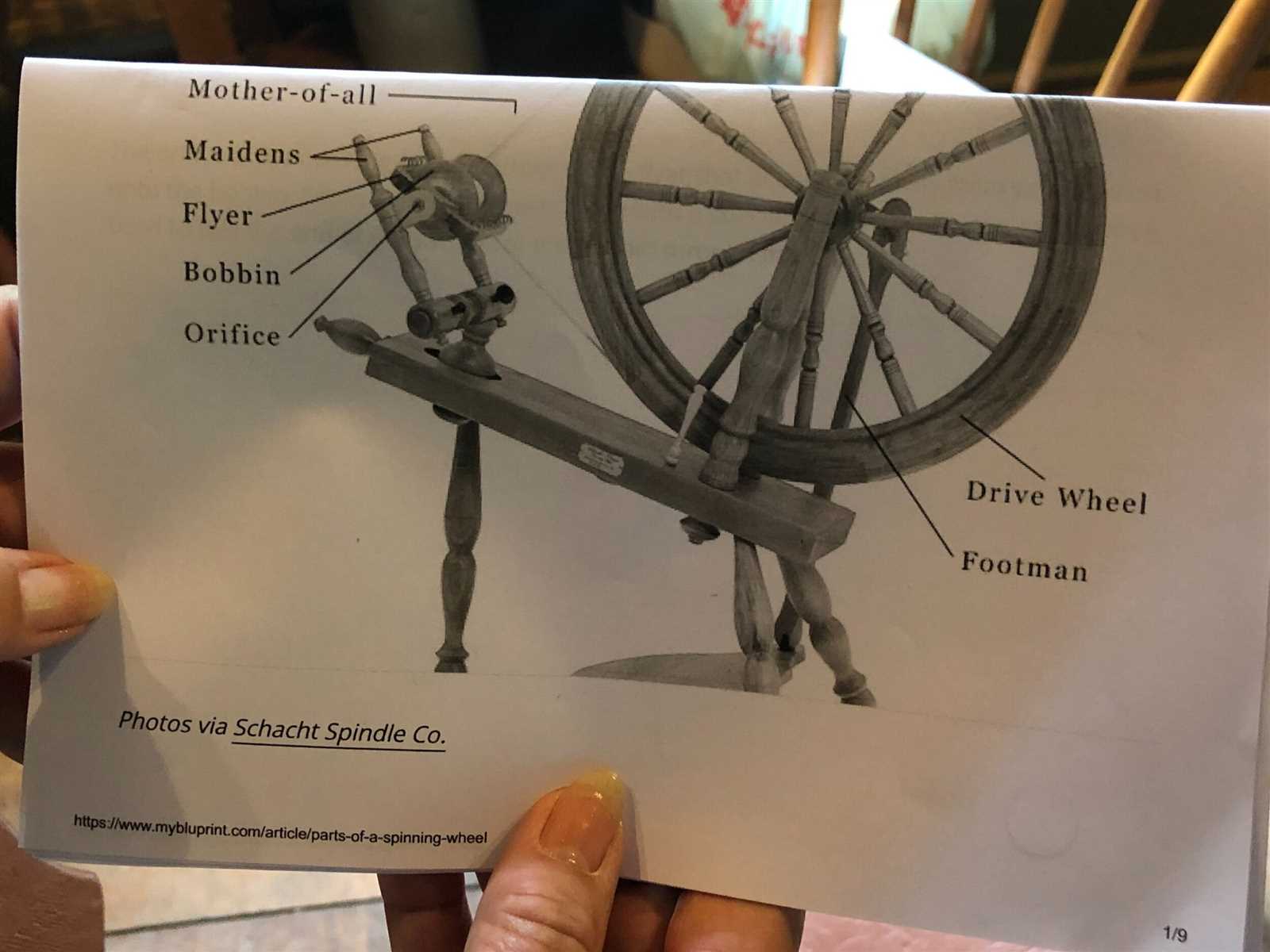

Using Diagrams for Repair Guidance

Visual representations can significantly enhance the process of understanding and fixing intricate machinery. These illustrations serve as essential tools, enabling users to grasp the structure and function of components effectively. By translating complex mechanisms into clear visuals, they simplify troubleshooting and restoration tasks.

Clarity and Precision

When engaging with technical challenges, clarity is paramount. Diagrams provide a precise outline of elements, making it easier to identify issues and locate specific areas needing attention. This clarity minimizes confusion and aids in achieving successful repairs.

Step-by-Step Instructions

Detailed visuals often accompany instructions, guiding users through each phase of the repair. These sequential illustrations foster confidence, allowing individuals to delve into the restoration process with assurance. Proper use of these resources can lead to ultimate success in maintaining and reviving valuable items.

Collecting Antique Spinning Wheel Insights

Delving into the world of historical textile equipment offers a fascinating glimpse into craftsmanship and culture. Enthusiasts often find joy in exploring the intricacies of these unique creations, appreciating their artistry and the stories they carry. Each piece serves as a testament to the skills of its maker and the era it represents.

When embarking on this collecting journey, it is crucial to develop a keen eye for detail. Understanding the materials and techniques used in the construction of these items can greatly enhance one’s appreciation. Research is essential; familiarize yourself with various styles, regional differences, and the evolution of designs over time.

Moreover, connecting with fellow collectors and joining local groups or online forums can provide invaluable insights. Sharing knowledge and experiences fosters a deeper understanding of the historical significance and the nuances that make each item special. Networking not only broadens your horizons but also opens doors to acquiring rare finds and preserving the heritage of this remarkable craft.