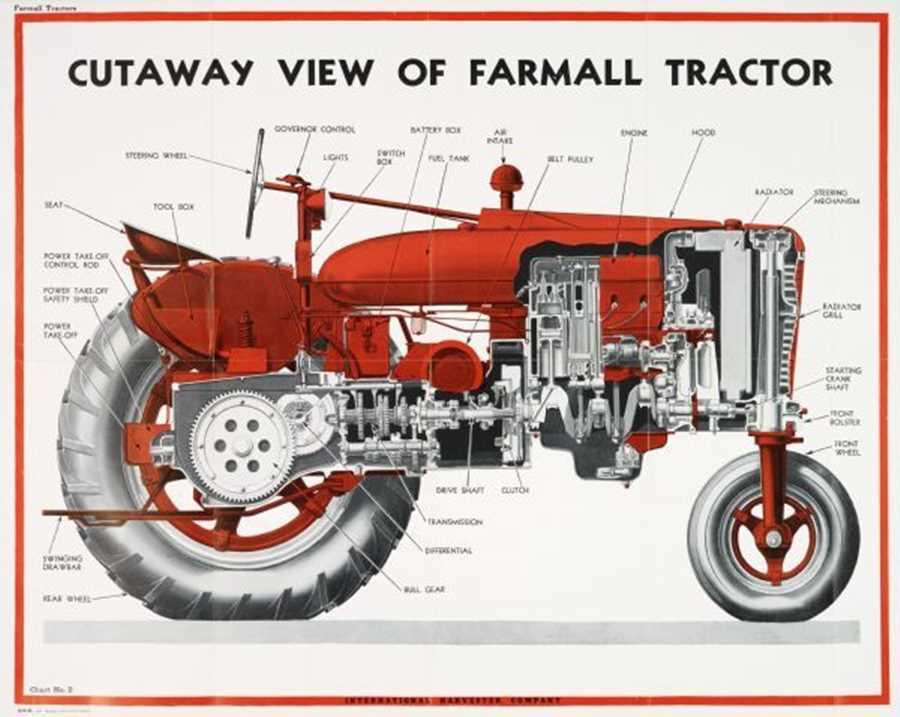

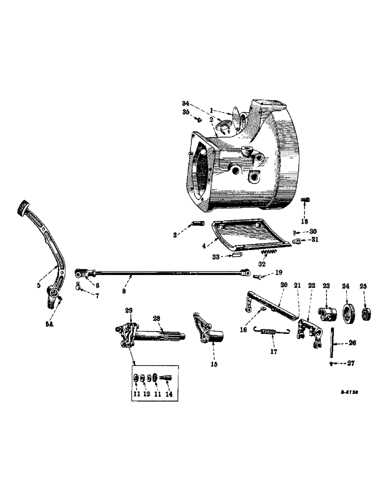

The efficient functioning of agricultural equipment relies heavily on the intricate assembly of its various elements. Each section serves a specific purpose, contributing to the overall performance and productivity of the machine. A clear representation of these components can aid users in identifying and understanding the relationships between different parts, facilitating maintenance and repairs.

In the realm of farm machinery, visual guides play a crucial role in helping operators and technicians navigate the complexities of these devices. By examining the layout of essential sections, one can gain insight into the structure and functionality of the equipment. This knowledge is invaluable for both troubleshooting issues and enhancing operational efficiency.

Moreover, familiarity with the individual elements not only empowers users to carry out effective repairs but also enhances their ability to make informed decisions regarding upgrades and replacements. A thorough grasp of how each component interacts within the broader system ensures that the machinery continues to perform optimally, ultimately supporting agricultural productivity.

Understanding the Farmall M Parts Diagram

This section aims to clarify the various components and their relationships within a specific agricultural machine, providing insights into its structure and functionality. By exploring these elements, one can appreciate how they work together to enhance performance and efficiency.

To effectively grasp the assembly of this machinery, it’s essential to break down its individual segments. The following table outlines key components and their respective functions:

| Component | Description |

|---|---|

| Engine | Drives the machine and provides power for various tasks. |

| Transmission | Facilitates the transfer of power from the engine to the wheels. |

| Chassis | Serves as the framework that supports all other elements. |

| Hydraulics | Controls various attachments and improves maneuverability. |

| Steering System | Enables direction control and navigation of the vehicle. |

Understanding these components allows users to delve deeper into maintenance and troubleshooting, ultimately ensuring optimal operation of their machinery.

Key Components of the Farmall M

This section explores the essential elements that contribute to the functionality and efficiency of a classic agricultural machine. Understanding these core components is crucial for maintenance and operation.

- Engine: The heart of the machine, providing power and performance.

- Transmission: Facilitates the transfer of power to the wheels, allowing for varied speeds.

- Hydraulic System: Enables lifting and lowering of attachments, enhancing versatility.

- Chassis: The structural frame supporting all components and ensuring stability.

- Wheels and Tires: Provide traction and mobility across different terrains.

Each of these elements plays a pivotal role in the overall operation, ensuring the machine can effectively tackle various tasks in the field.

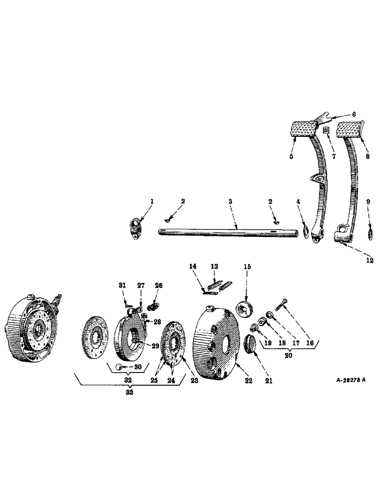

How to Read Parts Diagrams

Understanding visual representations of machinery components is essential for effective maintenance and repairs. These illustrations help users identify various elements, ensuring they can locate and replace specific items with ease.

To effectively interpret these visuals, follow these key steps:

| Step | Description |

|---|---|

| 1 | Familiarize yourself with the layout, noting the arrangement and connections between different parts. |

| 2 | Identify any labels or codes that correspond to components, which often provide additional information. |

| 3 | Refer to the accompanying legend, as it explains symbols or color coding used in the representation. |

| 4 | Cross-reference with a list of components to ensure accurate identification and selection. |

By following these steps, users can delve into the details and gain a clearer understanding of the machinery’s inner workings.

Common Issues with Farmall M Parts

When dealing with vintage machinery, various complications may arise that affect performance and longevity. These challenges can stem from wear and tear, outdated components, or even environmental factors. Understanding these common concerns can help owners maintain their equipment more effectively and ensure smoother operation.

Wear and Tear

Over time, mechanical elements can degrade due to constant use and exposure to harsh conditions. Common issues include leaking seals, worn bearings, and corroded connections. Regular inspection and timely replacement of these components are crucial to prevent more significant damage and costly repairs.

Compatibility Problems

Finding the right replacements for older models can be challenging, as some items may no longer be manufactured. This can lead to compatibility issues when sourcing alternatives. It’s essential to consult manuals or expert resources to ensure that the chosen replacements will fit correctly and function as intended.

Where to Find Replacement Parts

Locating the right components for your machinery can be crucial for maintaining optimal performance. Here are some effective avenues to explore when searching for high-quality replacements:

- Authorized Dealers: Check with local authorized sellers who specialize in equipment maintenance.

- Online Marketplaces: Websites like eBay and Amazon often have a wide selection of components available for purchase.

- Salvage Yards: Visit local salvage yards that may have used machinery and parts at a lower cost.

- Manufacturer’s Website: Many manufacturers provide catalogs and ordering options directly on their websites.

- Forums and Online Communities: Engage with enthusiasts who may have recommendations or be willing to sell parts.

Exploring these options can help you find the ultimate solution for your replacement needs.

Maintaining Your Farmall M Tractor

Proper upkeep of your vintage agricultural vehicle is essential for its longevity and efficiency. Regular checks and maintenance can prevent larger issues, ensuring that your machinery remains reliable during critical tasks.

Routine Inspections: Conduct frequent examinations of fluid levels, tire pressure, and overall condition. Addressing minor issues promptly can save time and resources.

Engine Care: Keep the engine well-maintained by changing oil and filters regularly. This practice enhances performance and prolongs its lifespan.

Electrical System: Regularly inspect the electrical components for wear or corrosion. Maintaining connections and replacing faulty parts can avoid unexpected breakdowns.

Cleaning: Remove dirt and debris from the exterior and undercarriage to prevent rust and damage. A clean machine operates more efficiently and looks better.

Storage: When not in use, store the vehicle in a dry, sheltered environment to protect it from the elements. This habit minimizes deterioration and preserves functionality.

By following these guidelines, you can ensure your tractor remains a dependable ally for years to come.

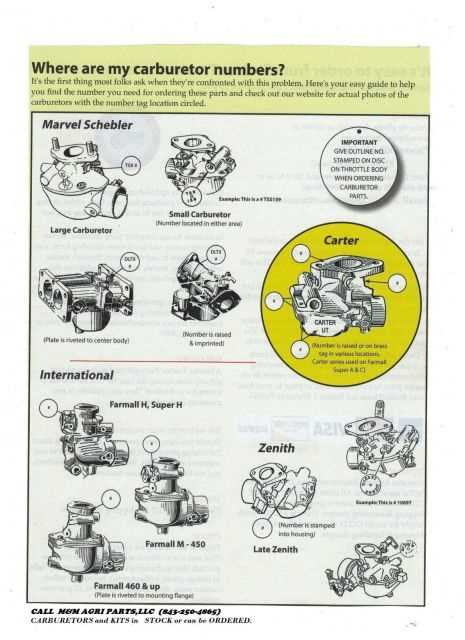

Upgrading Farmall M Components

Enhancing the functionality and performance of vintage machinery can breathe new life into your equipment. Upgrading various elements not only improves efficiency but also contributes to the longevity of your machinery. This section will explore key components that can benefit from modern upgrades, ensuring your equipment remains reliable and effective.

- Engine Modifications:

- Installing a new carburetor for improved fuel efficiency.

- Upgrading the ignition system to enhance starting reliability.

- Transmission Enhancements:

- Rebuilding the transmission for smoother shifting and better power delivery.

- Adding a modern clutch for improved responsiveness.

- Electrical System Upgrades:

- Replacing outdated wiring with new, durable materials to reduce electrical failures.

- Integrating LED lighting for better visibility and lower power consumption.

- Hydraulic Improvements:

- Upgrading hoses and fittings to prevent leaks and ensure efficient operation.

- Installing a more powerful hydraulic pump for enhanced lifting capabilities.

By focusing on these critical areas, you can significantly improve the performance of your machinery, making it more effective for various tasks while preserving its classic charm.

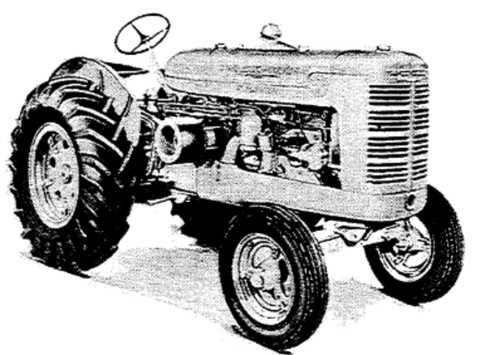

Historical Context of Farmall M Design

The evolution of agricultural machinery during the mid-20th century marked a significant transformation in farming practices. This particular model emerged as a response to the changing needs of farmers, emphasizing efficiency, versatility, and reliability. Its design reflects the technological advancements of the era and the growing demand for equipment that could handle various tasks on the farm.

Influences on Design

Several factors influenced the development of this machine. Economic pressures, advances in engineering, and the increasing scale of agricultural operations all played critical roles. Manufacturers sought to create a product that not only met the immediate demands of the market but also anticipated future trends in farming technology.

Technical Specifications

The following table outlines some of the key specifications and features that characterized this model, showcasing its innovative design elements:

| Feature | Description |

|---|---|

| Engine Type | Four-cylinder, providing ample power for various tasks. |

| Transmission | Standard gear system, enhancing operational control. |

| Weight | Approximately 3,000 lbs, allowing for stability and traction. |

| Versatility | Compatible with numerous attachments for diverse farming activities. |

In conclusion, the design of this model not only revolutionized farming techniques but also laid the groundwork for future innovations in agricultural machinery.

Popular Modifications for Performance

Enhancing the efficiency and capabilities of agricultural machinery can lead to significant improvements in productivity. Various upgrades can optimize engine output, increase fuel efficiency, and enhance overall operational effectiveness. Below are some widely adopted modifications that can elevate performance levels.

Engine Upgrades

One of the most effective ways to boost performance is through engine modifications. Installing a high-performance air filter can improve airflow, while a tuned exhaust system enhances exhaust flow. Turbocharging can also significantly increase power output, providing a notable advantage in demanding tasks.

Transmission Enhancements

Upgrading the transmission system is another popular approach. Implementing a higher gear ratio can improve torque and speed, allowing for more efficient work. Additionally, a hydraulic system overhaul can enhance responsiveness and control during operation, ultimately leading to smoother handling and better overall performance.

Comparing Farmall M with Other Models

This section explores the differences and similarities between a specific vintage tractor and its contemporaries. By analyzing key features, performance, and design, we gain insights into how this model stands out or aligns with others in its category. Understanding these comparisons helps enthusiasts and potential owners make informed decisions based on their specific needs.

| Feature | Farmall M | Competitor A | Competitor B |

|---|---|---|---|

| Engine Type | 4-cylinder gasoline | 6-cylinder diesel | 4-cylinder gasoline |

| Horsepower | 48 HP | 60 HP | 45 HP |

| Weight | 3,600 lbs | 4,200 lbs | 3,400 lbs |

| Production Years | 1939-1954 | 1940-1955 | 1938-1952 |

| Transmission | 5-speed | 4-speed | 5-speed |

The table above summarizes essential specifications, allowing for a straightforward comparison. The distinct characteristics of each model can significantly influence usability, efficiency, and user preference, illustrating the diversity within this segment of agricultural machinery.

Tips for First-Time Farmall Owners

Owning a vintage agricultural machine can be an exciting yet challenging experience. For newcomers, understanding the intricacies of these classic machines is crucial to ensuring their longevity and performance. Here are some valuable tips to help you navigate your journey as a first-time owner.

Understand Maintenance Needs

Regular upkeep is essential for optimal functionality. Familiarize yourself with the routine tasks required to keep your equipment running smoothly. This includes checking fluid levels, inspecting belts and hoses, and cleaning air filters. Keeping a maintenance log can help you track what has been done and when.

Join a Community

Connecting with other enthusiasts can be incredibly beneficial. Look for local clubs or online forums dedicated to vintage machinery. These communities can provide support, share valuable resources, and offer advice on repairs and restoration. Engaging with fellow owners can also lead to friendships and a deeper appreciation for your new acquisition.

Investing time in learning about your machine will not only enhance your ownership experience but also empower you to tackle challenges with confidence.