Understanding the structure of key elements within an automobile is essential for ensuring smooth operation and maintaining its functionality. When working with certain mechanisms, having a clear view of how different sections connect and interact can make repairs or replacements far easier.

Exploring the internal configuration of various systems allows drivers and technicians to identify specific elements that may require attention. With a detailed schematic in hand, one can address issues more efficiently, minimizing downtime and ensuring the vehicle runs optimally.

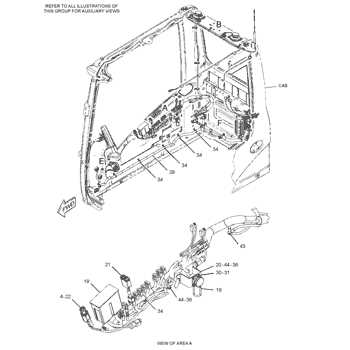

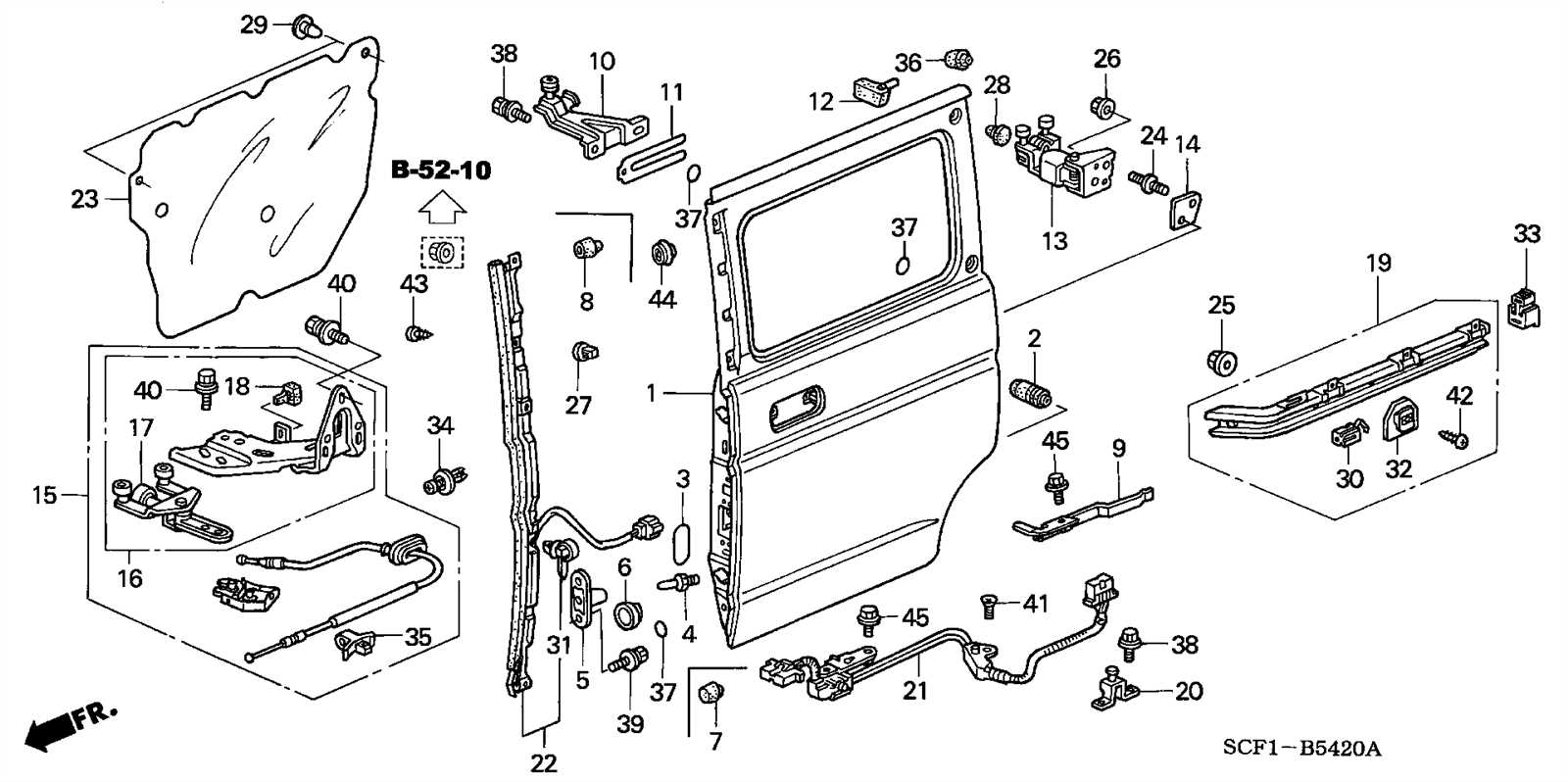

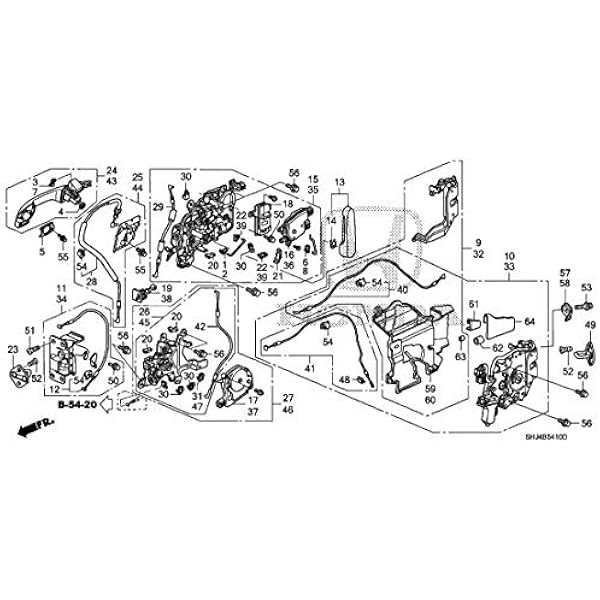

Overview of Sliding Door Components

The system designed for easy access and smooth operation involves various interconnected elements that ensure reliable functionality and user convenience. These components work together to allow seamless entry and exit while maintaining safety and durability over time. Understanding how each part contributes to the mechanism is essential for proper maintenance and troubleshooting.

- Track Assembly: Provides a pathway for movement, guiding the mechanism efficiently during operation.

- Rollers: Enable smooth gliding by reducing friction, ensuring minimal effort during use.

- Locking Mechanism: Ensures secure closure when the system is not in use, offering both safety and reliability.

- Motor and Cables: These elements power

Key Mechanisms for Door Functionality

Understanding the essential components involved in the movement and operation of a vehicle’s side entry system is crucial for maintaining smooth and reliable performance. Various elements work together to ensure seamless opening and closing actions, contributing to both the safety and convenience of the vehicle.

Main Components of the Operating System

The smooth operation relies on multiple interconnected elements that control motion, alignment, and securing. These parts are designed to handle the constant use and wear over time while maintaining efficiency and precision.

Additional Supporting Elements

Aside from the primary mechanisms, other components play a supporting role in enhancing durability and functionality. These include smaller, often overlooked parts that ensure everything works harmoniously.

Common Issues with Sliding Doors

Many vehicles experience challenges with their lateral entry systems over time. These challenges can lead to difficulties in proper operation, reducing convenience and safety. Identifying and addressing the underlying problems early can help extend the longevity of these systems.

- Track obstruction: Accumulation of debris in the pathway can hinder smooth movement, causing jams or stuttering motion.

- Worn components: Over time, various mechanisms such as rollers or cables may wear down, leading to malfunction or inconsistent performance.

- Electrical malfunctions: Automatic systems can face issues with wiring, motors, or sensors, preventing efficient operation or leading to unresponsive controls.

- Weather-related effects: Extreme temperatures, moisture, or rust can compromise the system’s ability to function smoothly, requiring regular maintenance.

- Alignment problems: Misalignment due to physical impact or gradual wear

Replacement Options for Worn Parts

Over time, various components of any vehicle’s system may experience wear and tear, leading to the need for replacements. It’s important to identify the right alternatives to ensure smooth operation and prevent further damage. High-quality replacements can extend the lifespan of your vehicle and improve its overall performance.

Choosing the Right Components

When selecting replacement pieces, consider the material quality and compatibility with your vehicle. Opting for trusted suppliers and manufacturers ensures that the new parts will fit properly and function efficiently, minimizing the risk of future breakdowns.

Professional Assistance vs. DIY

While many owners prefer to replace worn components themselves, seeking professional help can guarantee a more precise installation. Experts can offer guidance on selecting the best replacement options and ensure the process is completed with accuracy.

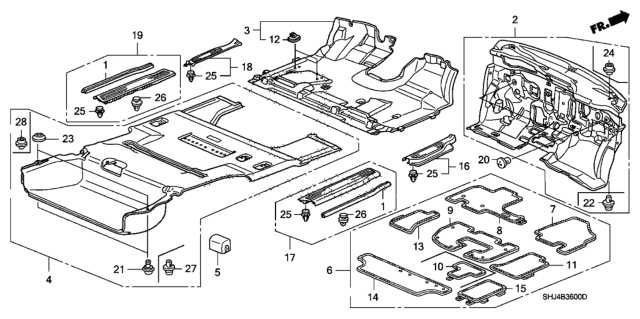

Maintaining the Door Track System

Regular upkeep of the track mechanism ensures smooth and efficient movement, preventing unnecessary strain on the components. By paying attention to cleanliness and addressing any minor issues early on, you can prolong the system’s lifespan and reduce the need for repairs.

Cleaning and Lubrication: It’s essential to keep the rails free from dirt and debris. Routine cleaning with a soft brush or cloth, followed by applying a light lubricant, will minimize friction and improve operation. Avoid using heavy oils that can attract dust.

Inspecting for Wear: Over time, parts of the system can wear down. Regularly inspect for any signs of damage, such as cracks or excessive wear. Early identification of worn elements can prevent more serious issues down the line.

Adjustments: If the system starts to operate unevenly, minor adjustments may be necessary. This can involve tightening loose screws or realignin

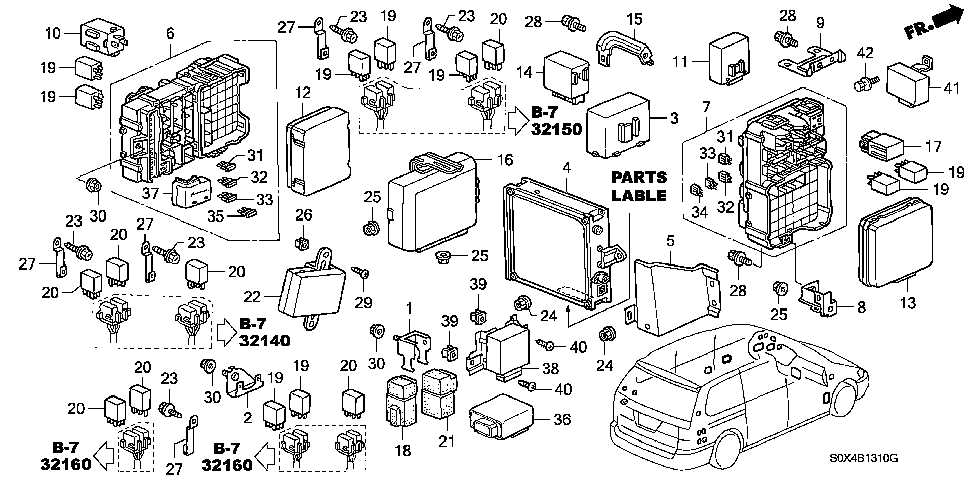

Identifying Problems in the Motor Assembly

The motor assembly plays a crucial role in ensuring the smooth operation of the system. Over time, wear and tear or other external factors can lead to issues that affect its functionality. Recognizing early signs of malfunction can help prevent further complications and extend the overall lifespan of the mechanism. Below are common indicators that can point to issues within the motor assembly.

Symptom Possible Cause Unusual noises Loose components or damaged gears Intermittent operation Worn-out electrical connections or failing motor Complete malfunction Burned-out motor or power supply issues Slow movement Debris build-up Fixing the Door Lock Mechanism

The lock mechanism can sometimes malfunction, leading to difficulty in securing the vehicle. This issue may stem from wear and tear or minor damage to internal components. Addressing these problems promptly is crucial to ensure the security of the vehicle and its occupants.

Step 1: Begin by inspecting the locking mechanism for any visible damage or debris that may obstruct its function. Check all moving parts to ensure they operate smoothly and are free from obstruction.

Step 2: Lubricate the moving components with a suitable lubricant. This will help reduce friction and prevent any further wear. Make sure to use a lubricant specifically designed for mechanical parts.

Step 3: If the lock remains unresponsive, disassemble the mechanism to access the internal parts. Look for signs of wear or breakage, such as worn-out springs or damaged connectors. Replace any faulty components with new ones to restore full functionality.

Understanding the Sensor System

The sensor system plays a crucial role in ensuring the smooth operation of vehicle components. By detecting various environmental conditions and providing real-time data, it enhances safety and convenience for users. Understanding how these sensors function can help in diagnosing issues and maintaining optimal performance.

Components of the Sensor System

The sensor assembly consists of several key elements that work together to monitor and regulate the functionality of the mechanisms involved. Here are the primary components:

- Proximity Sensors: These devices detect obstacles and prevent collisions.

- Position Sensors: They determine the exact location of moving parts, ensuring they are in the correct alignment.

- Temperature Sensors: These measure the temperature within the system to prevent overheating.

- Pressure Sensors: They monitor hydraulic or air pressure, which is essential for proper operation.

Importance of Regular Maintenance

To ensure the effectiveness of the sensor system, regular checks and maintenance are vital. Neglecting this can lead to operational failures and safety hazards. Consider these maintenance tips:

- Inspect sensors for any signs of wear or damage.

- Clean sensor surfaces to prevent interference with readings.

- Test the system regularly to ensure all components are functioning correctly.

- Replace faulty sensors promptly to avoid complications.

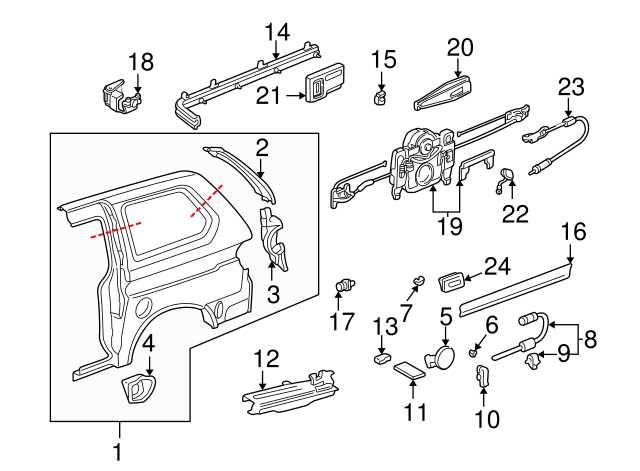

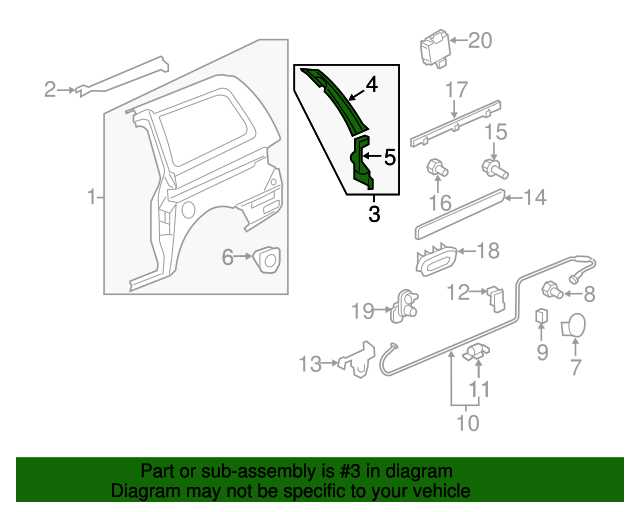

Adjusting the Door Alignment Properly

Ensuring the correct alignment of the access panels is crucial for optimal functionality and longevity. Misalignment can lead to various issues, including increased wear on components, difficulty in opening or closing, and compromised security. This section will guide you through the steps necessary to achieve proper alignment, enhancing the overall performance of your vehicle.

Common Signs of Misalignment

- Uneven gaps between the access panel and the body

- Difficulty in latching or unlatching

- Excessive noise during operation

- Visible wear on hinges and other mechanisms

Steps for Adjustment

- Inspect the hinges and latching mechanisms for any signs of wear or damage.

- Loosen the mounting bolts that secure the access panel to the frame.

- Gently reposition the panel to achieve an even gap around its perimeter.

- Tighten the mounting bolts while holding the panel in the adjusted position.

- Test the functionality by opening and closing the panel several times.

Regular maintenance and timely adjustments can prevent future complications and ensure smooth operation. Taking the time to align the access panels correctly can significantly enhance the user experience and vehicle reliability.

Lubrication Techniques for Smooth Operation

Ensuring optimal functionality of mechanisms is crucial for longevity and performance. Proper lubrication techniques play a significant role in reducing friction, preventing wear, and enhancing the overall efficiency of moving components. This section outlines effective methods for applying lubricants to achieve seamless operation.

Choosing the Right Lubricant is essential for effective maintenance. Selecting a high-quality lubricant suited for specific materials and operating conditions can significantly impact performance. Different lubricants, such as grease or oil, serve various purposes, providing unique benefits in diverse scenarios.

Application Methods are vital for achieving comprehensive coverage. Techniques such as spraying, brushing, or using a syringe ensure that lubricant reaches all necessary areas. Regularly inspecting components and applying lubricant to high-friction zones can prevent issues and maintain smooth functionality.

Frequency of Lubrication should not be overlooked. Establishing a routine schedule for lubrication can help prevent deterioration and ensure ongoing efficiency. Factors such as environmental conditions and usage frequency should guide the determination of how often lubricants should be reapplied.

Monitoring Performance after lubrication is crucial. Observing changes in operation can indicate the effectiveness of the applied techniques. If issues persist, it may be necessary to reassess the chosen lubricant or application method to ensure the best results.