When working with outdoor machinery, it’s essential to be familiar with the various mechanical elements that contribute to its operation. Knowing where each element is located and how it connects with others can be incredibly helpful for both routine upkeep and troubleshooting. Recognizing the physical arrangement of these mechanisms ensures smoother operation and a longer lifespan for the equipment.

Each section of this equipment has its own unique function, from propulsion systems to mechanisms that ensure a seamless power transfer. Gaining a clear perspective on how these interact allows users to quickly address any wear or malfunction. This knowledge not only aids in basic maintenance but also makes replacing components a more straightforward process.

Additionally, an accurate understanding of the layout can simplify the process of acquiring new elements. Being able to identify the right replacements for different segments can save time and prevent compatibility issues, ensuring that all components work together as intended. With this in mind, a detailed overview becomes an invaluable resource for any owner or technician.

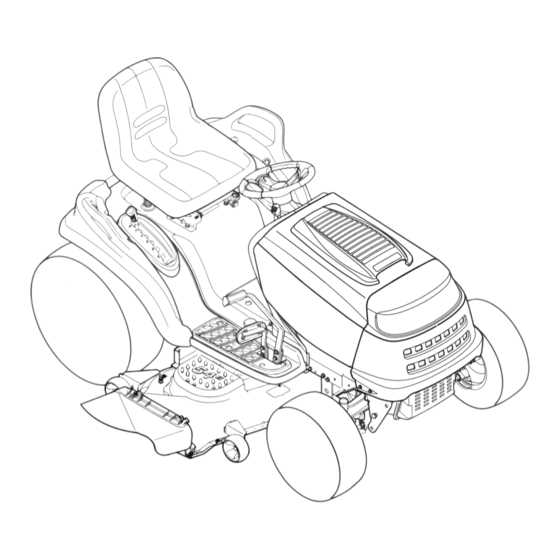

Understanding MTD Lawn Tractor Components

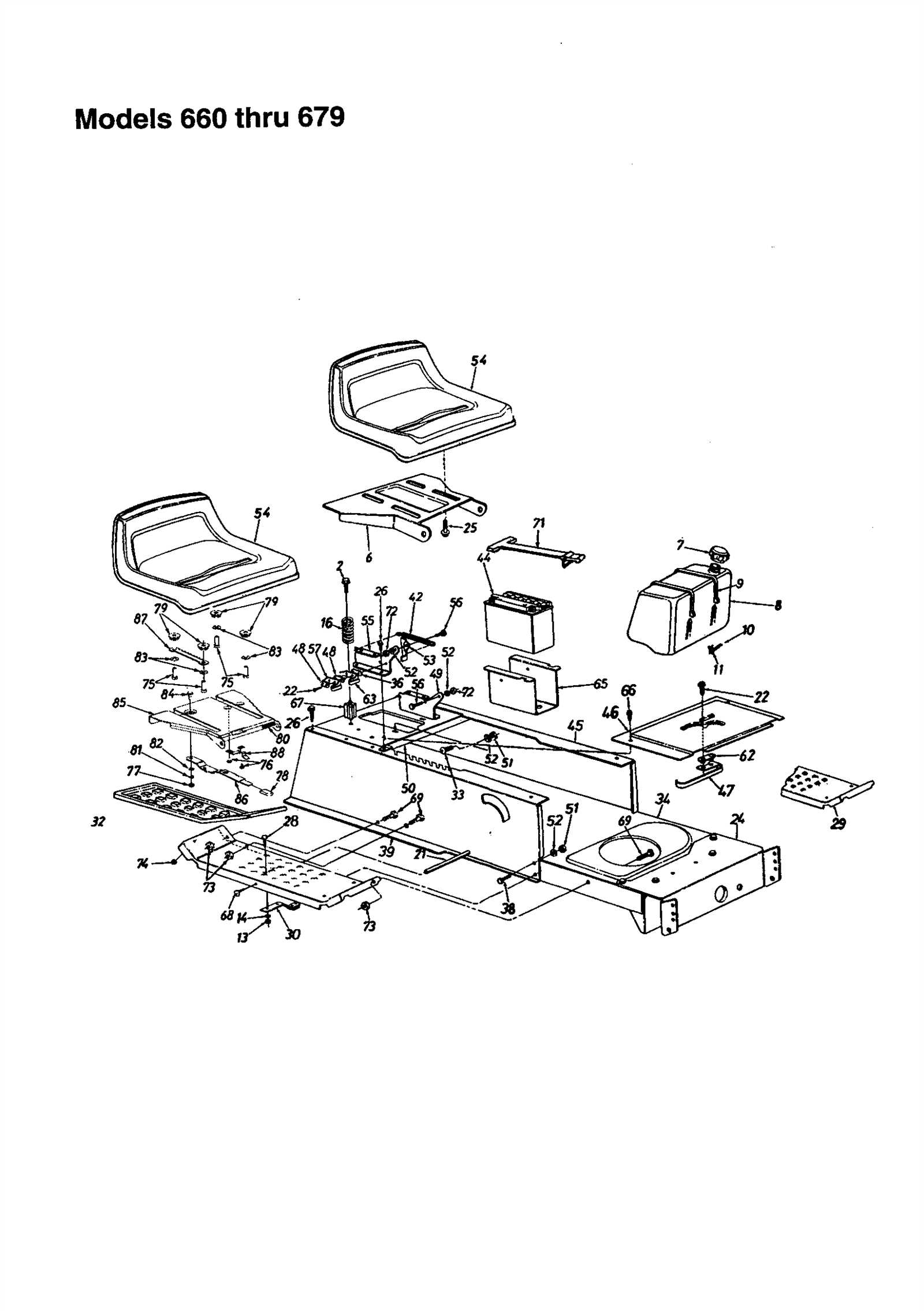

Exploring the various elements that contribute to the functionality of a lawn maintenance vehicle can be vital for effective upkeep. Each component works in harmony to ensure smooth operation, from the mechanisms that drive motion to those that manage cutting efficiency. A deeper understanding of these elements can help in diagnosing issues, performing repairs, and maintaining optimal performance.

Engine System: The core of any outdoor equipment, the engine drives the primary operations, providing the necessary power for movement and cutting. It is essential to maintain this part to ensure reliability and longevity of the machine.

Transmission Mechanism: Responsible for translating engine power into movement, this system allows control over speed and direction. It ensures the equipment can handle various terrains and workloads smoothly, adapting to different conditions.

Cutting Deck Assembly: This section includes the blade mechanism and housing, crucial for achieving a precise trim. Proper alignment and maintenance of this part are key to ensuring an even and clean result across the area being worked on.

Control Interface: The steering, pedals, and levers form the interface through which the operator manages the vehicle’s actions. Understanding how to use these controls effectively can significantly enhance maneuverability and control during operation.

Safety Systems: Several built-in safety features protect the operator and the machine during use. Regular inspection and understanding of these safeguards ensure that they function properly, providing a secure working environment.

Essential Parts for MTD Mowers

Proper maintenance and care ensure long-lasting performance of outdoor equipment. This section highlights the key elements that keep these machines running smoothly, covering both vital mechanisms and frequently replaced components. Understanding these crucial elements can assist in diagnosing issues and maintaining peak efficiency.

| Component | Function | ||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Engine | Powers the entire system, providing the necessary drive to operate various mechanisms. | ||||||||||||||||||||||||||||||||||||||||||

| Transmission | Regulates the speed and direction, allowing smooth transitions between different movement ranges. | ||||||||||||||||||||||||||||||||||||||||||

| Cutting Blades | Ensures precise trimming and offers a clean finish on surfaces, adaptable for various grass heights. | ||||||||||||||||||||||||||||||||||||||||||

| Deck Assembly | Houses the blades and is designed to channel cuttings away, optimizing the cutting process. | ||||||||||||||||||||||||||||||||||||||||||

| Battery | Provides the initial power boost for starting the engine and supports electronic components. | ||||||||||||||||||||||||||||||||||||||||||

| Wheels and Tires | Ensure smooth navigation across different terrains, offering stability and traction. | ||||||||||||||||||||||||||||||||||||||||||

| Fuel System | Includes a tank, filter, and

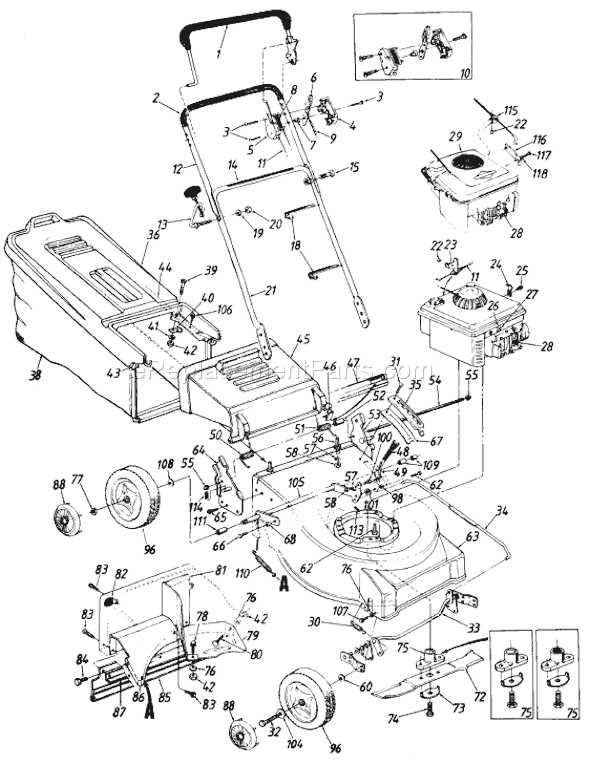

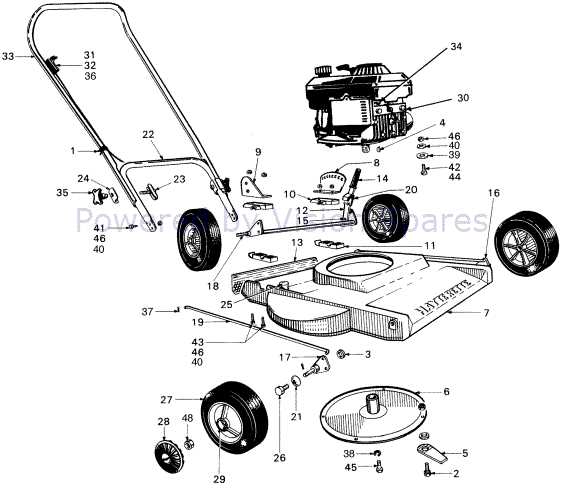

Guide to Blade ReplacementChanging the cutting component is essential for maintaining efficient grass trimming performance. Over time, this part can become dull or damaged, leading to uneven cuts and potential strain on the machine. A timely replacement ensures a smoother operation and a cleaner trim, extending the lifespan of your equipment. Preparation Steps: Before beginning, ensure that the machine is powered off and positioned on a flat surface. It’s crucial to secure it properly, using blocks or a sturdy lift, to prevent any accidental movement during the process. Wear protective gloves to avoid injury when handling sharp edges. Removing the Old Component: Use a wrench or socket tool to loosen the bolts holding the old cutting piece in place. Carefully remove the fasteners and note their positions for reassembly. Gently take off the worn-out part, being mindful of its orientation, as this will guide the placement of the new piece. Installing the New Blade: Align the fresh cutting edge in the same direction as the previous one, ensuring it fits snugly onto the spindle. Reattach the bolts, tightening them securely but without over-tightening, to avoid damaging the assembly. Double-check the alignment to ensure a balanced rotation during use. Final Inspection: After installation, manually rotate the newly Deciphering Engine LayoutUnderstanding the organization of various components within a small engine can simplify maintenance and troubleshooting. The structure involves several interconnected elements that play specific roles in ensuring smooth operation and performance.

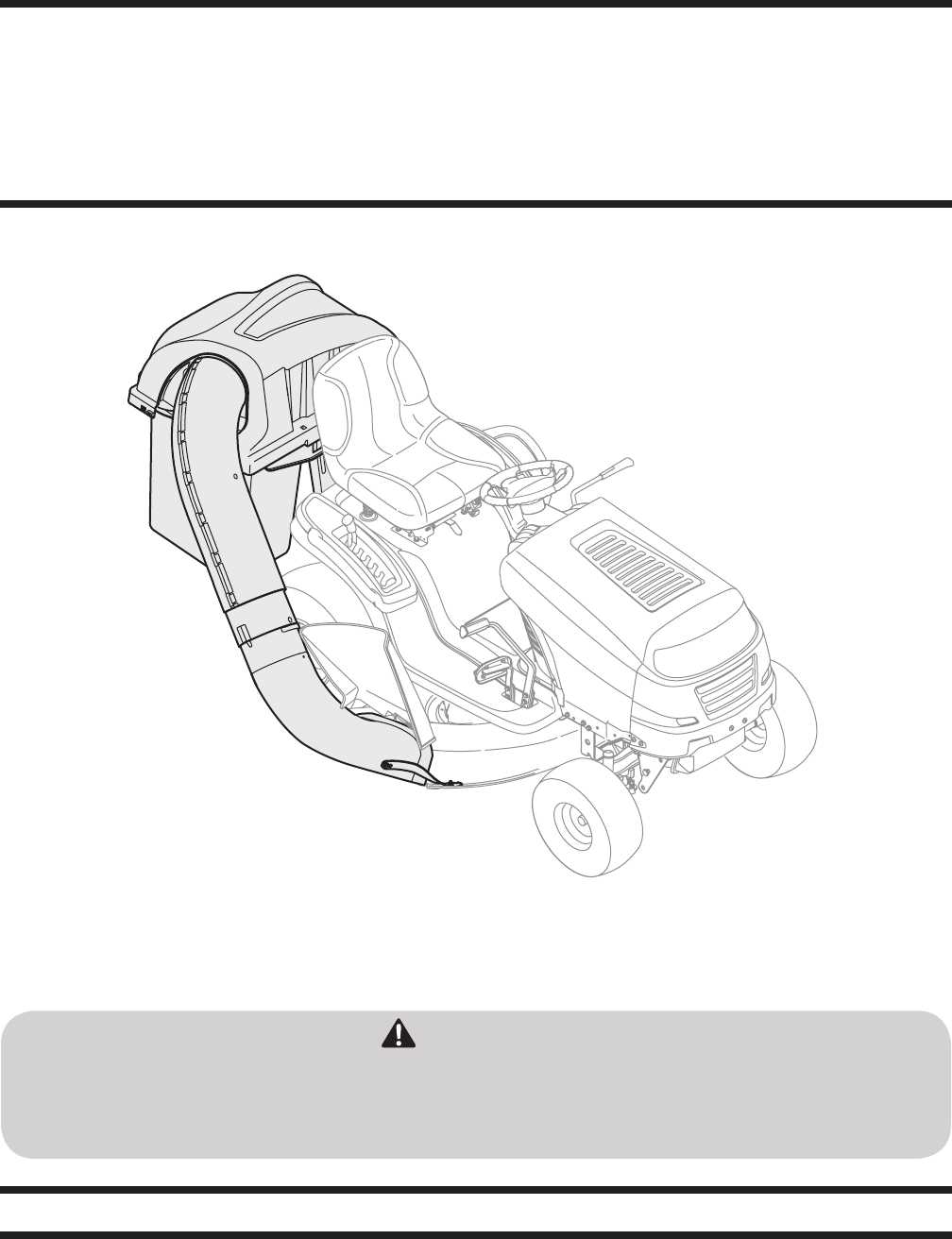

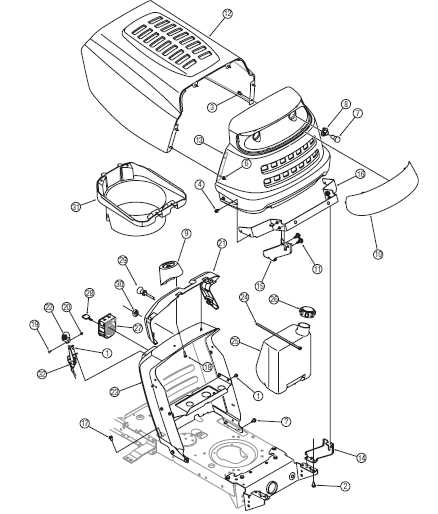

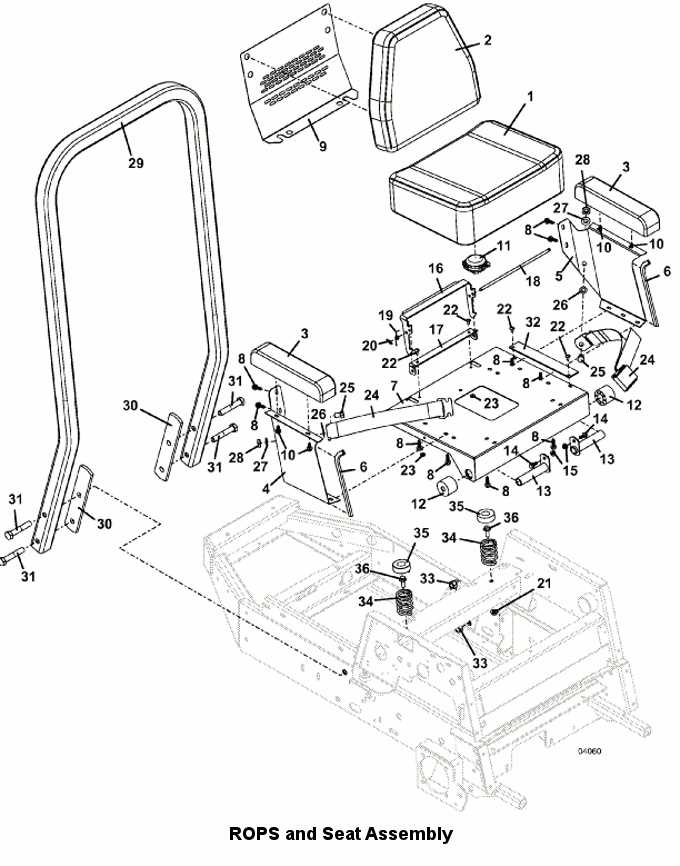

By identifying these sections and th Deck Assembly BreakdownThe deck assembly is a crucial component that significantly influences the performance and efficiency of outdoor lawn equipment. This section delves into the various elements that constitute this assembly, providing insight into their functions and how they contribute to the overall operation. Key Components of the Deck Assembly

Assembly Process

Understanding the intricate details of the deck assembly can enhance maintenance practices, prolonging the life of the equipment while optimizing its performance. Wiring Schematics for MTD ModelsUnderstanding the electrical configurations of various outdoor machinery can significantly enhance maintenance and troubleshooting efforts. Detailed diagrams serve as essential tools for visualizing the connections between components, ensuring that users can effectively manage their equipment. This section delves into the intricacies of wiring setups, helping users grasp how each element interacts within the system. These electrical layouts typically include key elements such as power sources, switches, and connectors, all clearly labeled for ease of reference. By following these schematics, users can identify the correct pathways for electricity, diagnose potential issues, and execute repairs with confidence. Moreover, familiarity with these diagrams fosters a better understanding of overall functionality, paving the way for more efficient operation. Additionally, each model may have unique configurations that require careful attention to detail. Whether dealing with ignition systems, lighting, or starter circuits, accurate interpretations of these diagrams are crucial. Users should prioritize studying these layouts to ensure they have a solid foundation for any maintenance or modifications they intend to perform. Transmission Components OverviewThe efficiency of a machine largely depends on its transmission system, which plays a crucial role in transferring power from the engine to the wheels. Understanding the various elements within this system is essential for optimal performance and maintenance.

Each of these elements works together to create a cohesive system, enhancing overall functionality and reliability. Regular inspection and maintenance of these components can significantly improve the lifespan and performance of the entire mechanism. MTD Steering Mechanism ExplainedThe steering system of a garden vehicle plays a crucial role in ensuring precise navigation and control. Understanding its components and functioning can enhance the user’s experience and maintenance practices. This mechanism typically comprises several key elements that work together to facilitate smooth movement and responsive handling. At the core of this system is the steering wheel, which translates the operator’s movements into directional changes. Connected to the wheel are various linkages and rods that transmit force to the front wheels. These components must be properly aligned to ensure optimal performance. Any misalignment can lead to difficulty in maneuvering and can cause excessive wear over time. Furthermore, the mechanism often includes a set of bearings and bushings that reduce friction and allow for smoother operation. Regular inspection of these parts is essential, as worn-out bearings can impact responsiveness and lead to steering instability. Keeping the steering assembly clean and lubricated will also extend its lifespan and enhance functionality. In summary, a well-maintained steering mechanism is vital for achieving effective control and handling in a garden vehicle. Understanding its components and their roles can help operators ensure a more enjoyable and efficient operation. Fuel System Parts IdentificationUnderstanding the components of a fuel delivery system is crucial for maintaining optimal performance. This section provides an overview of the essential elements involved in the operation of the system, ensuring that fuel is delivered efficiently to the engine. The assembly typically includes a tank, which stores the fuel; a pump that moves the fuel from the tank to the engine; and a filter that ensures contaminants do not enter the system. Additionally, various hoses connect these components, allowing for a smooth flow of fuel. The carburetor or fuel injector plays a vital role in mixing fuel with air, facilitating combustion. Recognizing each of these elements is essential for troubleshooting and repairs. Proper maintenance of the fuel system can prevent issues such as poor performance or starting difficulties. Regular inspection of the tank for leaks, the condition of the hoses, and the efficiency of the pump can contribute to the longevity of the equipment. Understanding the role of each component aids in effective management and ensures reliability during operation. Commonly Replaced Belts and Pulleys

In the maintenance of outdoor equipment, certain components often require attention due to wear and tear. Among these, flexible bands and circular mechanisms play a crucial role in the functionality of machinery. Understanding their importance can help in timely replacements, ensuring optimal performance and longevity of the equipment. Types of Belts

Flexible bands serve to transfer power between different parts, and their durability is vital for smooth operation. The following table outlines the most frequently replaced bands:

Pulley Overview

Circular mechanisms guide the flexible bands and help maintain tension. Regular checks can prevent issues that may disrupt operation. Below is a table detailing the key components:

How to Maintain Safety Switches

Proper upkeep of safety mechanisms is essential for ensuring optimal functionality and preventing accidents. These devices play a crucial role in providing protection while operating machinery, and regular maintenance can prolong their lifespan and effectiveness. Follow these guidelines to keep safety features in top condition:

By adhering to these maintenance practices, users can significantly enhance the reliability and safety of their equipment. Regular inspections and prompt repairs not only protect the operator but also improve the overall performance of the machine. Troubleshooting Electrical Components

Addressing issues within the electrical systems of machinery can often be a complex process, requiring a systematic approach to identify and rectify faults. Understanding the fundamental components and their functions is crucial for effective troubleshooting. Begin by examining the battery, as it serves as the primary power source. Ensure that the terminals are clean and securely connected. A multimeter can help verify voltage levels; a reading below the specified range may indicate a need for replacement. Next, inspect the wiring harness for signs of wear or damage. Frayed wires or loose connections can disrupt the flow of electricity, leading to operational failures. Carefully trace each wire to its connection points, looking for any signs of corrosion or breaks. Additionally, consider the functionality of the fuses. These protective devices can blow due to overloads or short circuits, preventing power from reaching essential components. Replace any blown fuses with ones of the same rating to restore functionality. Lastly, evaluate the switches and relays within the electrical system. Malfunctioning switches can prevent circuits from completing, while faulty relays may fail to activate necessary components. Testing these elements for continuity can help determine if they are operational or in need of replacement. Maintaining MTD Wheel and Tire Assemblies

Proper care of wheel and tire assemblies is crucial for optimal performance and longevity of any lawn equipment. Regular maintenance not only enhances the efficiency of operation but also ensures safety during use. By paying attention to specific components, owners can prevent common issues that arise from neglect. Routine InspectionConducting routine checks is essential for identifying wear and tear early. Look for signs of damage, such as cracks or bulges on the tire surface, which can indicate a need for replacement. Ensure that the wheels are securely fastened and free from rust or corrosion. Regularly inspecting the pressure levels is also vital, as improper inflation can lead to decreased traction and increased wear. Cleaning and Lubrication

Keeping the assemblies clean contributes to their performance and durability. Remove any debris or dirt that accumulates around the tires and wheels. Additionally, lubricating moving parts, such as wheel bearings, helps to reduce friction and prevent seizing. Using a suitable lubricant will ensure smooth rotation and enhance the overall functionality of the equipment. In summary, maintaining the wheel and tire assemblies involves regular inspections, cleaning, and appropriate lubrication. By following these practices, users can enhance the performance and lifespan of their outdoor machinery. |