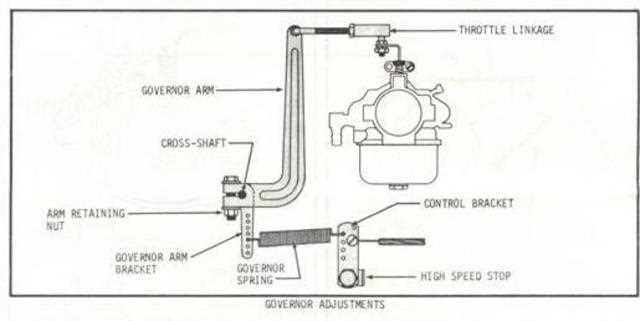

Delving into the intricacies of a visual representation that maps out the inner workings of an essential mechanical element reveals a detailed narrative of interconnected parts. This graphical portrayal, akin to a technical map, offers a visual blueprint that elucidates the intricate connections and functionalities of each constituent segment. Within this structured illustration, each component assumes a role akin to a specialized cog in a complex machinery, contributing harmoniously to the overall operational dynamics.

Unveiling the interplay between various sections within this graphical representation, one discovers a meticulous portrayal where each component emerges as a vital entity in the grander narrative of mechanical function. Each line and marking within this delineation serves not merely as a demarcation but as a traceable path that delineates the intricate dance of mechanical choreography.

The detailed contours depicted within this visual schema transcend mere lines and figures, offering an encapsulated story that narrates the essential linkages and interactions among its myriad elements. This illustration becomes a window into the structured symphony of mechanical ballet, where each notation and marking tells a tale of function and form.

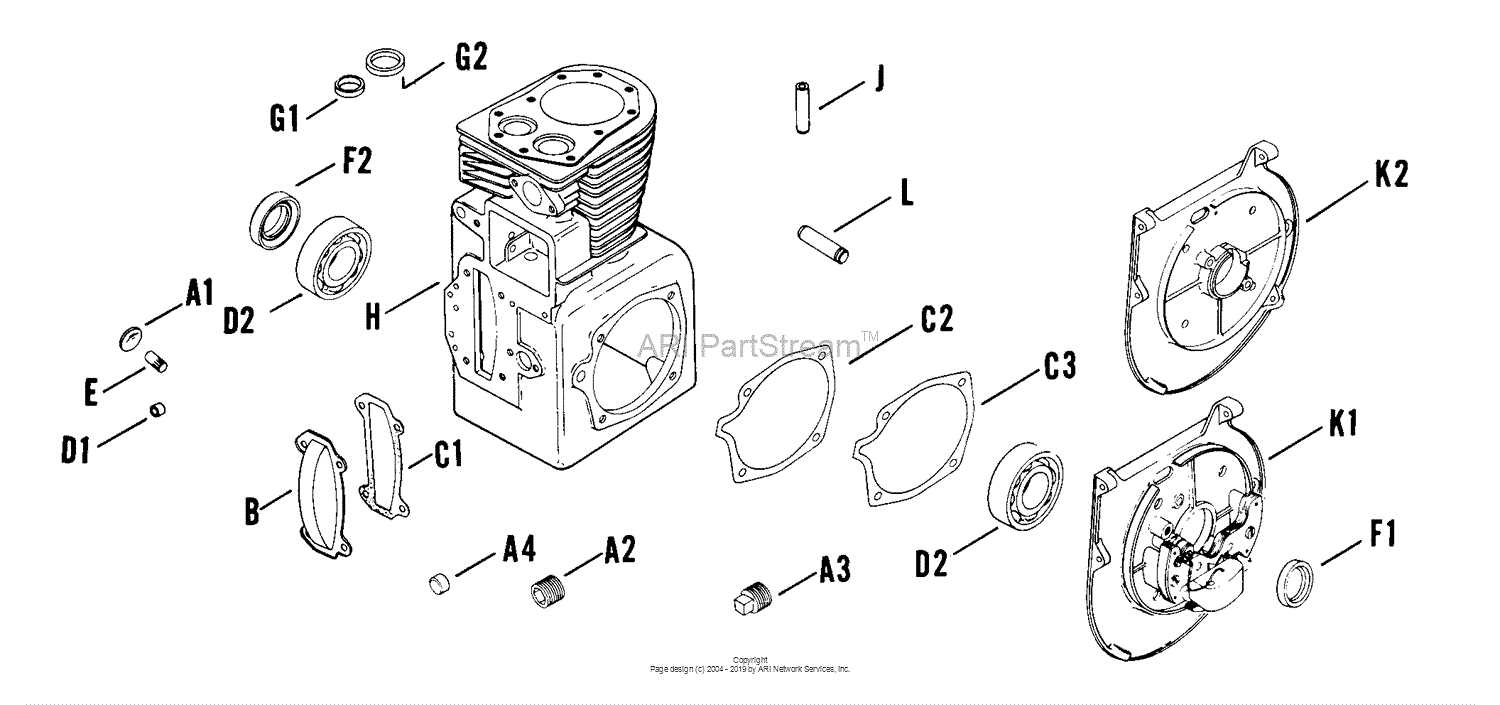

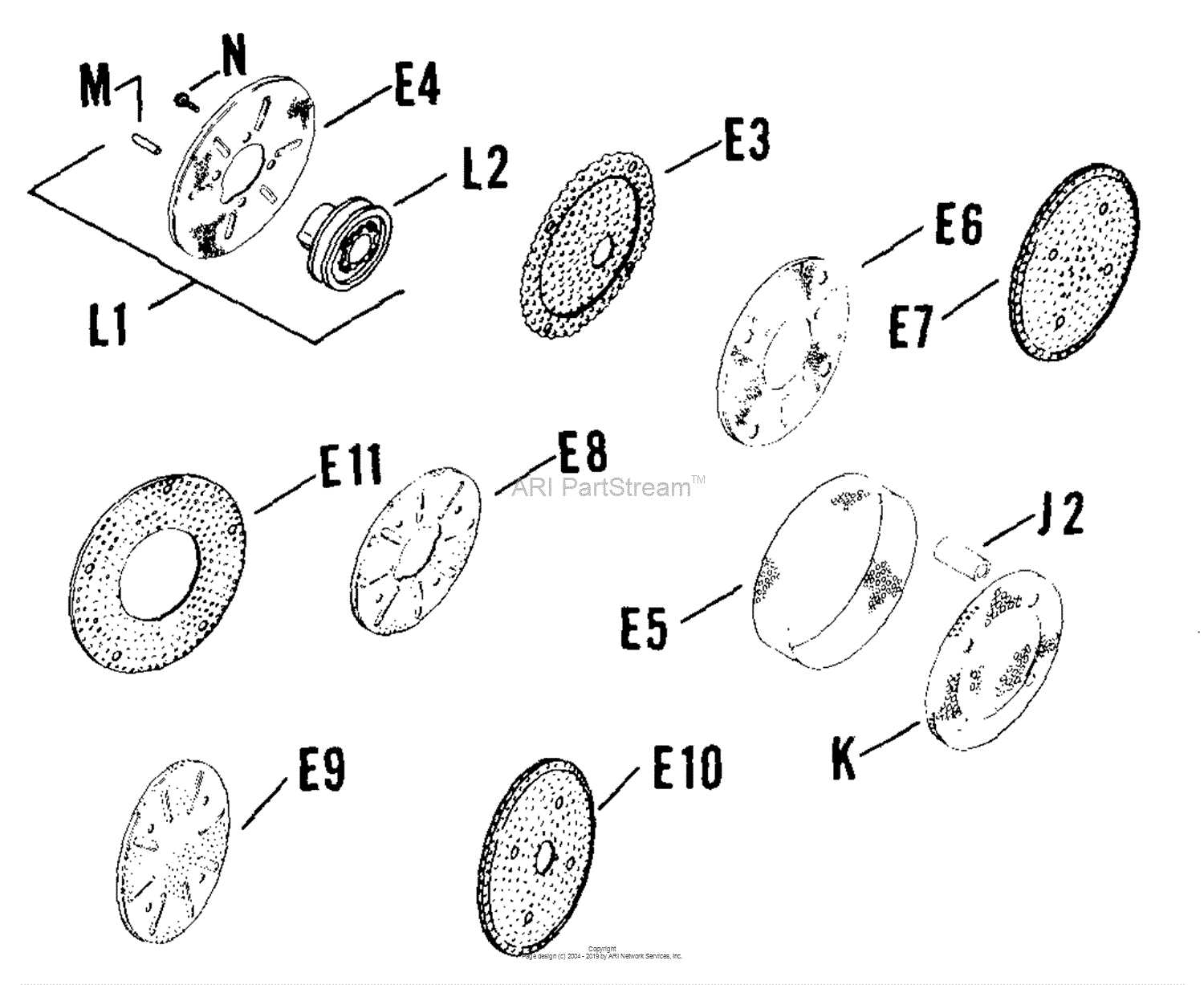

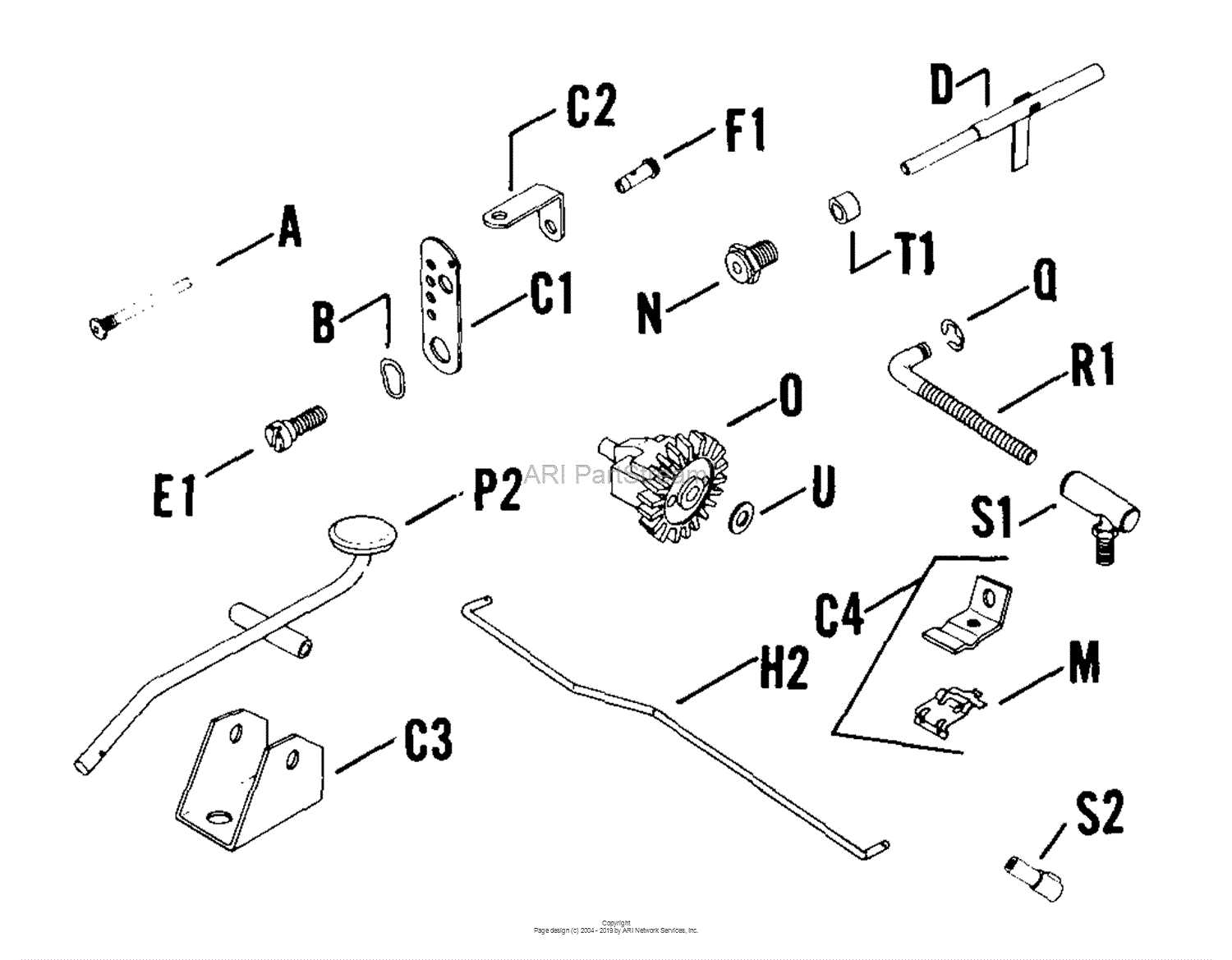

Engine Component Breakdown: Understanding the Inner Workings

In this section, we delve into the intricate anatomy of the powerful machine that drives your equipment. Explore the detailed breakdown of essential components, uncovering their roles and interactions within the engine system. Gain a deeper insight into the functional units that collectively ensure optimal performance and reliability, without which the entire mechanism would cease to function effectively.

Exploring the Kohler k241 Engine Model

This section delves into the intricacies of a specific power unit renowned for its reliability and efficiency. Designed for a variety of applications, this engine has garnered a loyal following among enthusiasts and professionals alike. Understanding its components and functionality can enhance maintenance and performance outcomes.

Key Features

- Robust construction for durability

- Compact design suitable for various machinery

- Efficient fuel consumption, promoting sustainability

- Simple maintenance protocols for user convenience

Common Applications

- Lawn mowers

- Garden tractors

- Small construction equipment

- Generators

By exploring these aspects, users can appreciate the engine’s design and operational effectiveness, ensuring it remains a staple in diverse mechanical environments.

An Overview of Engine Parts and Components

Engines are complex systems composed of various mechanical elements working together to convert energy into motion. Each component within the engine plays a vital role in ensuring efficiency, performance, and durability. Understanding these key components is essential for maintaining and troubleshooting the system.

Main Structural Components

The engine’s core includes several essential structures that support its operation. The cylinder block serves as the foundation, housing the cylinders where combustion occurs. The crankshaft is responsible for converting the linear motion of the pistons into rotational motion, driving the machinery. Additionally, the camshaft controls the opening and closing of valves, coordinating the air-fuel mixture intake and exhaust gas release.

Additional Mechanisms

Several other mechanisms ensure smooth functioning. Pistons move up and down within the cylinders, powered by fuel combustion, while the connecting rods link the pistons to the cranks

Understanding the Function of Each Part

Every mechanical system relies on the coordinated operation of its components. Each individual element plays a crucial role in ensuring smooth performance and overall reliability. Understanding how these components work together helps to troubleshoot issues and maintain the system efficiently.

Key Elements and Their Roles

The core elements of the system are designed to interact with one another, transferring energy and motion. For example, the central power source drives a series of connected components, which in turn enable the movement of other crucial mechanisms. Without these interactions, the system would not function properly.

Interconnected Operations

The interconnected nature of the system means that each element is dependent on the others. When one component fails, it can cause a ripple effect, impacting other elements. This highlights the importance of regular maintenance and understanding how each part contributes to the ove

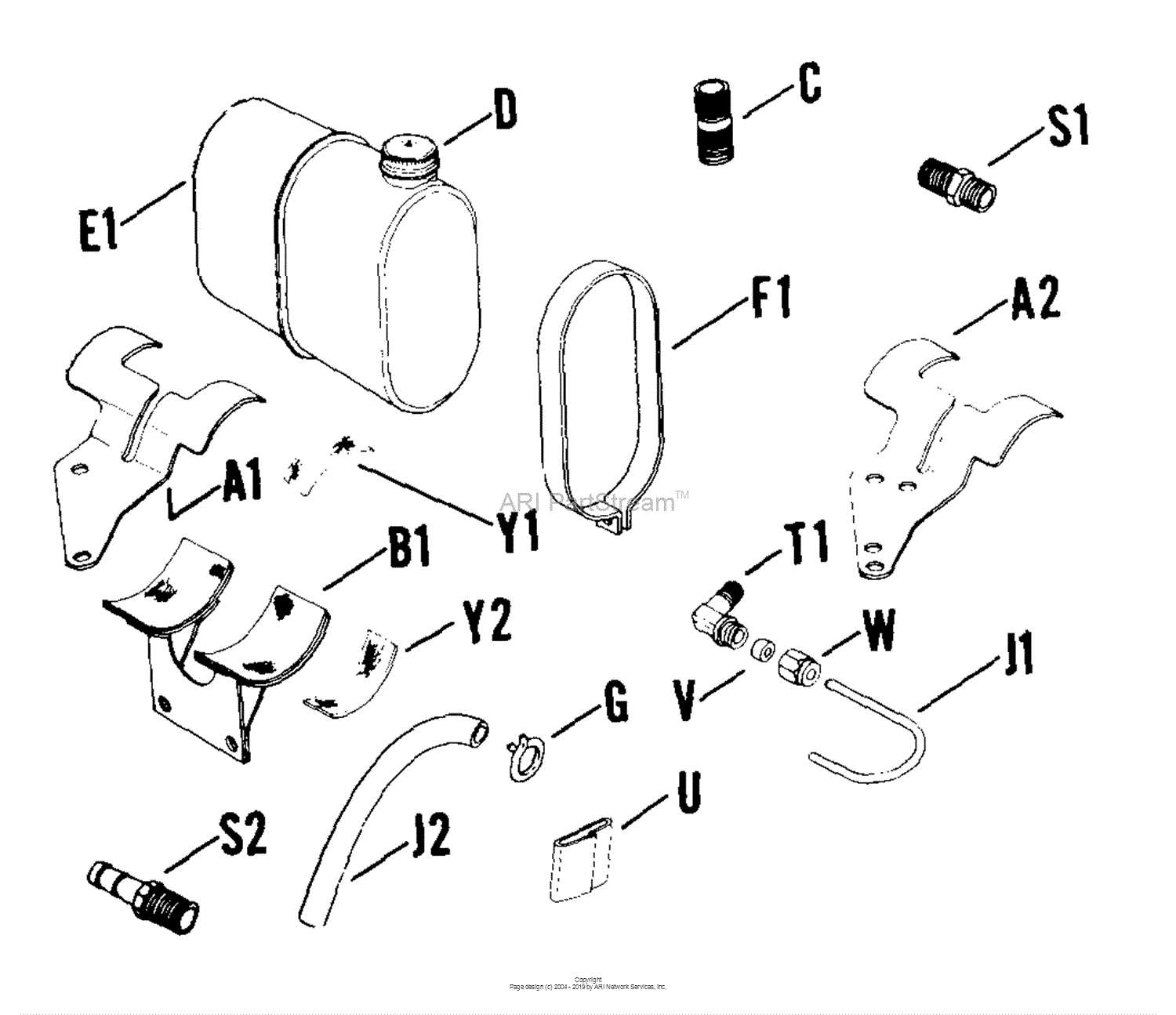

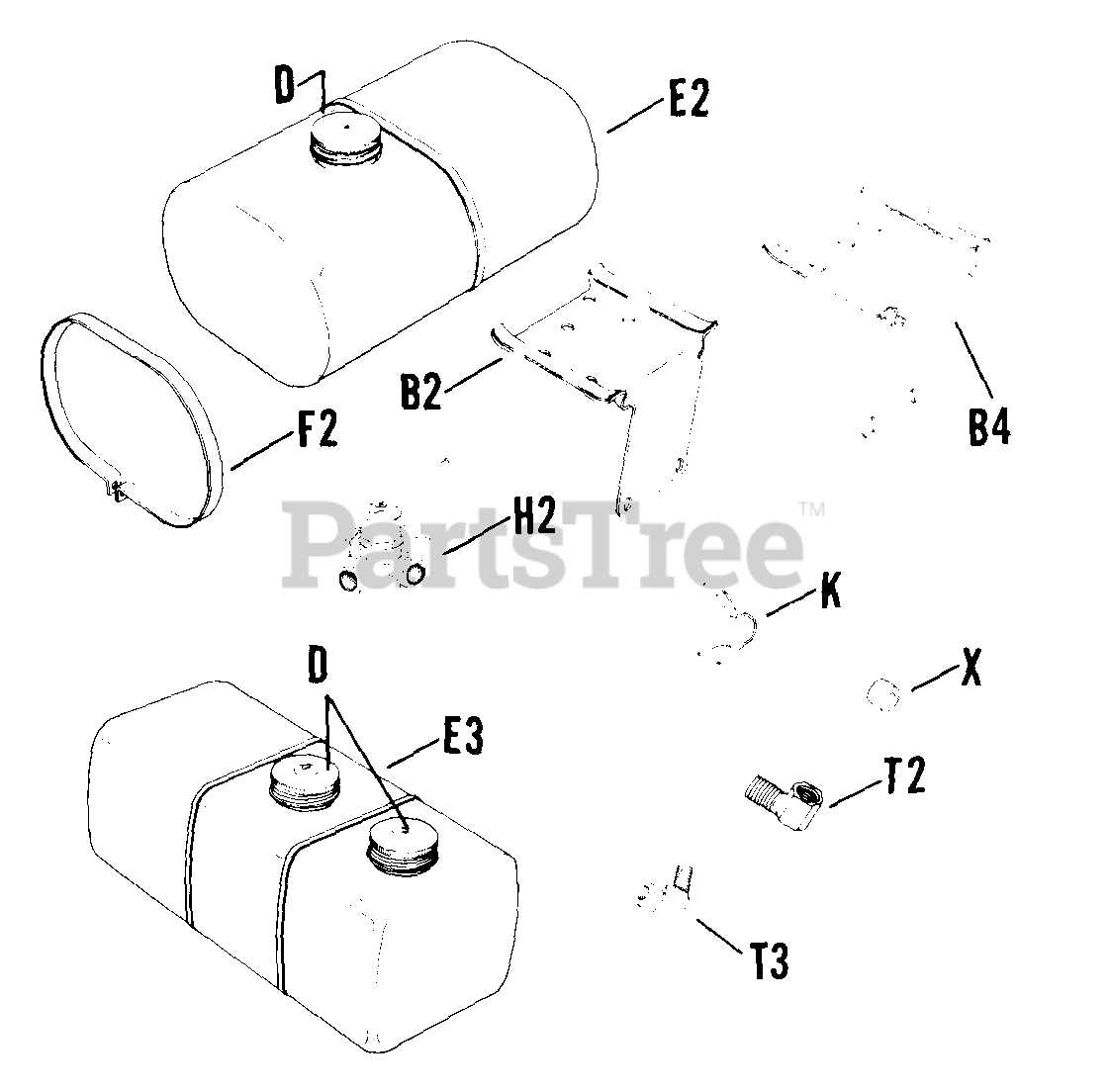

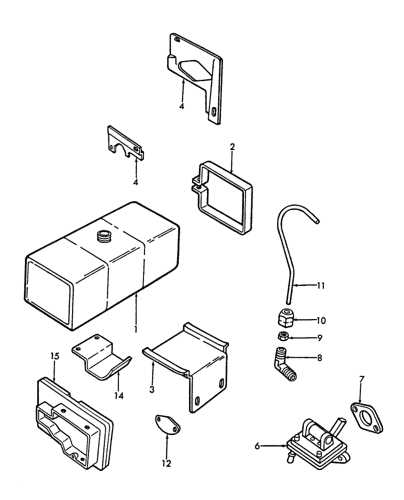

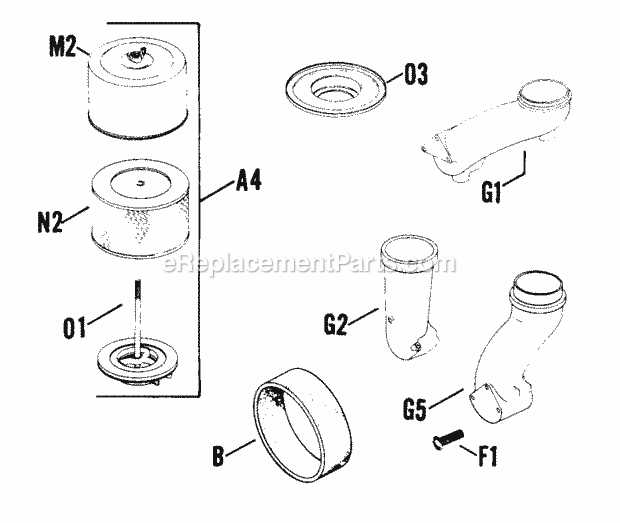

Identifying Key Components in the Diagram

Understanding the visual layout of mechanical systems requires recognizing various essential elements. Each component in a schematic plays a crucial role in ensuring the smooth operation and functionality of the system.

| Component | Function | Location in Diagram |

|---|---|---|

| Engine Block | Forms the main structure, housing internal mechanisms. | Central area |

| Crankshaft | Converts linear motion into rotational power. | Connected to the bottom section |

| Cylinder Head | How to Interpret the Parts Identification Numbers

Understanding identification numbers is essential when working with equipment or machinery. These codes provide a methodical way to recognize different components and ensure accurate replacement or repair. By breaking down these numeric or alphanumeric codes, users can decipher key information such as size, type, and compatibility of a specific component. First, focus on the structure of the number. It often consists of various sections, each representing a different aspect of the component’s specifications. Whether it be dimensions, material, or production details, each section serves a purpose. Next, familiarize yourself with any prefixes or suffixes, as these can indicate modifications or specific versions of the component. This attention to detail is crucial when ensuring you have the right match for your equipment. Lastly, cross-referenc Common Maintenance and Replacement Parts

Regular upkeep of any mechanical engine ensures its longevity and reliable performance. Over time, certain components naturally wear out and require substitution to maintain smooth operation. Performing timely inspections and replacements of essential elements can prevent unexpected breakdowns. Oil Filters are one of the key elements that should be changed periodically. They help ensure that the engine runs efficiently by filtering contaminants from the lubricant. Neglecting this can lead to reduced efficiency and engine wear. Another critical element to monitor is the spark plug. Over time, this component may corrode or become fouled, leading to issues with starting or poor performance. Replacing it as part of routine maintenance can help maintain optimal ignition. Air filters also play a significant role in maintaining engine performance by ensuring clean air intake. A clogged filter reduces airflow, which can cause the engine to run inefficiently or even overheat. Regular Importance of Using Genuine Kohler PartsChoosing original components for machinery maintenance plays a vital role in ensuring the longevity and efficiency of your equipment. Authentic elements are specifically designed to meet the performance standards, providing reliability and durability. Ensuring Optimal PerformanceOriginal elements are engineered to fit seamlessly with your machine, which reduces wear and tear and minimizes potential issues. This compatibility ensures that your equipment runs smoothly, helping prevent costly breakdowns.

Avoiding Inferior AlternativesNon-authentic replacements might seem like a cost-saving option but can lead to frequent malfunctions. Using unapproved components increases the risk of poor performance and can even void warranties, leading to more expensive repairs in the long run.

Troubleshooting Tips Based on the DiagramUnderstanding the visual breakdown of components can greatly assist in identifying potential issues and resolving them effectively. By following the structured illustration, one can trace the source of mechanical problems and address them with precision. Check for Misalignments: One common issue involves components not being properly aligned. By reviewing the positions indicated in the schematic, you can ensure each element is situated correctly, preventing further malfunctions. Inspect for Wear and Tear: Visual representations often highlight areas prone to wear. Examine these sections closely, as excessive friction or erosion could lead to breakdowns. Properly maintaining these areas will extend the machine’s lifespan. Identify Blockages: In systems where flow or movement is crucial, blockages can disrupt function. Use the layout to pinpoint possible choke points and clear them to restore Upgrading or Modifying Your Engine PartsEnhancing or customizing your engine components can significantly improve performance and efficiency. Whether you’re looking to increase power output, enhance fuel efficiency, or improve reliability, various modifications can help you achieve these goals. Understanding the options available and their implications is crucial for making informed decisions that align with your needs. Benefits of Engine ModificationsModifying engine components can lead to numerous advantages. Upgrades can result in better acceleration, smoother operation, and a more enjoyable driving experience. Additionally, certain modifications can enhance the lifespan of your engine by reducing wear and tear on critical parts. Careful consideration of compatible upgrades ensures optimal performance without compromising durability. Considerations Before UpgradingBefore proceeding with any enhancements, it’s important to evaluate your specific requirements and the compatibility of new components with your existing setup. Consult with experts or conduct thorough research to determine the best modifications for your engine type. Additionally, consider any potential warranty implications or legal regulations regarding emissions and modifications in your area. Safety Precautions When Handling Engine Components

When working with mechanical parts of an engine, it is essential to adhere to specific safety measures to prevent accidents and injuries. Understanding these precautions ensures that the handling of components is performed safely and effectively, promoting a secure working environment. Personal Protective Equipment (PPE)Utilizing the appropriate personal protective equipment is crucial when engaging with engine components. This equipment includes:

Proper Handling Techniques

Adopting correct handling techniques can significantly reduce the risk of accidents. Consider the following guidelines:

By following these safety measures, individuals can effectively manage engine components while minimizing risks associated with their handling. Where to Find and Access a Kohler k241 Parts Diagram

Locating detailed visual references for engine components can significantly enhance maintenance and repair efforts. Various resources are available that provide comprehensive breakdowns of engine assemblies, enabling users to identify necessary elements quickly and accurately. Online Resources

Printed Manuals and Guides

Resources for Further Information and Support

Accessing reliable resources is crucial for those seeking guidance and assistance related to engine components and maintenance. Whether you are a hobbyist or a professional, having a variety of support options at your disposal can enhance your understanding and troubleshooting capabilities. One of the most valuable resources is the official manufacturer’s website, where you can find comprehensive manuals, FAQs, and troubleshooting tips. Additionally, online forums and community groups dedicated to engine enthusiasts offer a platform for sharing experiences, asking questions, and obtaining advice from knowledgeable members. Another beneficial option is video tutorials available on platforms like YouTube, where you can watch step-by-step guides on repairs and maintenance. Local repair shops and specialty retailers also serve as great resources, as their staff often possess extensive knowledge and can provide personalized assistance. Lastly, consider consulting books or guides dedicated to engine maintenance and repair, as these can offer in-depth insights and techniques. Utilizing these various resources will empower you to tackle any challenges you may face effectively. |