In the realm of modern household technology, understanding the essential elements of your robotic cleaning device can enhance its performance and longevity. Familiarity with these components enables users to troubleshoot issues effectively and ensure optimal functionality.

Recognizing the different sections of the appliance plays a crucial role in maintaining its efficiency. Each element is designed to work harmoniously, contributing to the overall cleaning process and ensuring that your space remains tidy.

By examining the intricate layout of the various segments, users can identify potential wear and tear, facilitating timely replacements. This knowledge empowers users to take control of their cleaning experience, leading to a more effective and satisfying use of their device.

Roomba i7 Parts Overview

This section provides an overview of the various components that make up the robotic cleaner. Understanding these elements can enhance user knowledge and facilitate better maintenance and troubleshooting. Each part plays a crucial role in ensuring optimal performance and efficiency, allowing the device to navigate and clean effectively.

| Component | Description |

|---|---|

| Brush Assembly | Includes rotating brushes designed to capture dirt and debris from various surfaces. |

| Dustbin | A removable container that collects dust and debris, ensuring easy disposal and cleaning. |

| Navigation Sensors | Help the unit detect obstacles and navigate around rooms efficiently. |

| Battery | Powers the device, enabling it to operate without being plugged in. |

| Charging Dock | Allows the cleaner to recharge when not in use, ensuring it’s always ready for the next cleaning session. |

Understanding the Main Components

This section provides insight into the essential elements that contribute to the functionality and efficiency of robotic cleaning devices. Each component plays a vital role in ensuring that the unit operates seamlessly, allowing for optimal performance in various environments. Understanding these elements is crucial for effective maintenance and troubleshooting.

Key Functional Elements

The primary functional elements include sensors, brushes, and the power system. Each component works in conjunction with the others to facilitate cleaning tasks, navigation, and overall efficiency.

| Component | Function |

|---|---|

| Sensors | Detect obstacles and navigate the surroundings. |

| Brushes | Remove dirt and debris from surfaces. |

| Power System | Supplies energy for operation and recharging. |

Importance of Maintenance

Regular upkeep of these essential elements is crucial for sustained performance. Ensuring that each component is functioning properly can extend the lifespan of the unit and enhance its cleaning efficiency.

Detailed Look at the Brush System

The cleaning mechanism of robotic vacuums plays a crucial role in their effectiveness. This section delves into the intricacies of the brush assembly, focusing on its design and functionality. Understanding how these components work together can enhance maintenance and performance.

Primary Brush Roll is the main component responsible for agitating dirt and debris from various surfaces. Its unique bristle configuration allows it to reach deep into carpets and across hard floors, ensuring thorough cleaning.

Side Brushes complement the primary brush by targeting edges and corners. These smaller, rotating brushes sweep debris toward the center, allowing the main roller to pick it up effectively. Their placement is strategically designed to maximize coverage in tight spaces.

Brush Housing protects the internal mechanisms while providing easy access for cleaning. Regularly inspecting this area helps prevent clogs and ensures the brushes remain functional. Proper care can significantly extend the lifespan of the cleaning system.

Understanding the components of the brushing mechanism can lead to better upkeep and improved cleaning performance, making it an essential aspect for users seeking to maintain optimal functionality.

Battery Specifications and Features

The power source is a critical component in robotic cleaning devices, ensuring optimal performance and longevity. Understanding the specifications and features of the energy unit can enhance the user’s experience and facilitate better maintenance.

Specifications

This energy unit typically has a voltage rating of 14.4V, providing a reliable output for consistent operation. It usually features a lithium-ion design, known for its efficient energy density and reduced weight. The capacity often ranges from 3000 to 4000 mAh, enabling extended cleaning sessions without frequent recharges.

Features

Many energy units are equipped with advanced technology, such as smart charge capabilities that prolong battery life by preventing overcharging. Additionally, some models include built-in protection mechanisms against overheating and short circuits, ensuring safe and reliable usage. Furthermore, the lightweight construction contributes to the overall efficiency and maneuverability of the cleaning device.

Navigation System Explained

The navigation system is a critical component in robotic cleaners, allowing them to move efficiently through various environments. This sophisticated technology enables these devices to map their surroundings, recognize obstacles, and plan effective cleaning paths. Understanding how this system works can provide insights into its performance and capabilities.

Key Components of Navigation

The navigation mechanism typically includes sensors, cameras, and advanced algorithms. Sensors detect obstacles, while cameras capture visual data to help the device understand its environment. Advanced algorithms process this information, enabling the cleaner to make real-time decisions about its movement and cleaning strategy.

Mapping and Path Planning

Mapping involves creating a digital layout of the area, which is essential for effective path planning. The system uses collected data to generate a map, allowing the cleaner to identify the most efficient routes while avoiding areas that have already been cleaned or obstacles. This capability enhances both the efficiency and effectiveness of the cleaning process.

Filter Types and Maintenance

Understanding the different types of filtration systems and their upkeep is essential for optimal performance of cleaning devices. These systems play a crucial role in trapping dust, allergens, and debris, ensuring a cleaner environment. Proper maintenance extends the lifespan of these components, enhancing efficiency and effectiveness.

Types of Filters

Various filtration systems are utilized in cleaning machines, each designed to cater to specific needs:

| Filter Type | Description | Recommended Maintenance |

|---|---|---|

| High-Efficiency Filter | Designed to capture fine particles, including allergens. | Wash every month and replace every 6 months. |

| Standard Filter | Basic filtration that traps larger debris. | Clean weekly and replace every 3-4 months. |

| Washable Filter | Reusable filter that can be cleaned with water. | Rinse every month and air dry thoroughly. |

Maintenance Tips

Regular upkeep of filtration components is vital for maintaining performance. Cleaning or replacing filters as recommended ensures optimal airflow and suction power. Additionally, checking for blockages and ensuring proper installation can prevent operational issues.

Charging Dock Functionality

The charging dock serves as an essential component for maintaining the operational efficiency of robotic vacuums. This unit not only provides a designated area for the device to recharge but also ensures it is ready for its next cleaning cycle. Understanding its role helps users appreciate how these machines function autonomously.

Power Supply Management

The primary purpose of the docking station is to supply power. When the cleaning unit returns to the dock, it connects to the power source, allowing it to recharge its batteries. This seamless process guarantees that the device remains charged and can operate without interruption.

Navigation and Communication

Additionally, the charging dock plays a crucial role in navigation. It emits signals that help the cleaning unit locate it, ensuring accurate docking. This functionality allows for effective communication between the two components, enabling the device to understand when to return for a recharge.

Software and Firmware Components

The effectiveness of robotic cleaning devices relies heavily on their software and firmware. These integral elements work together to manage the operations, ensuring the device performs optimally in various environments. This section will delve into the critical software functions and firmware aspects that enhance the user experience and improve overall performance.

Software Functionality

Advanced algorithms govern the cleaning patterns, navigation, and obstacle detection of these machines. By utilizing sophisticated software, the device can learn the layout of a space, adapt to changes, and optimize cleaning routes. Regular updates to the software ensure the latest features and improvements are available to users, enhancing functionality and usability.

Firmware Updates

Firmware is essential for the basic operation of the device, bridging the gap between hardware and software. It controls various components, from sensors to motors, ensuring seamless communication between them. Periodic firmware updates are crucial, as they can fix bugs, improve performance, and introduce new capabilities, allowing the device to function more efficiently and effectively.

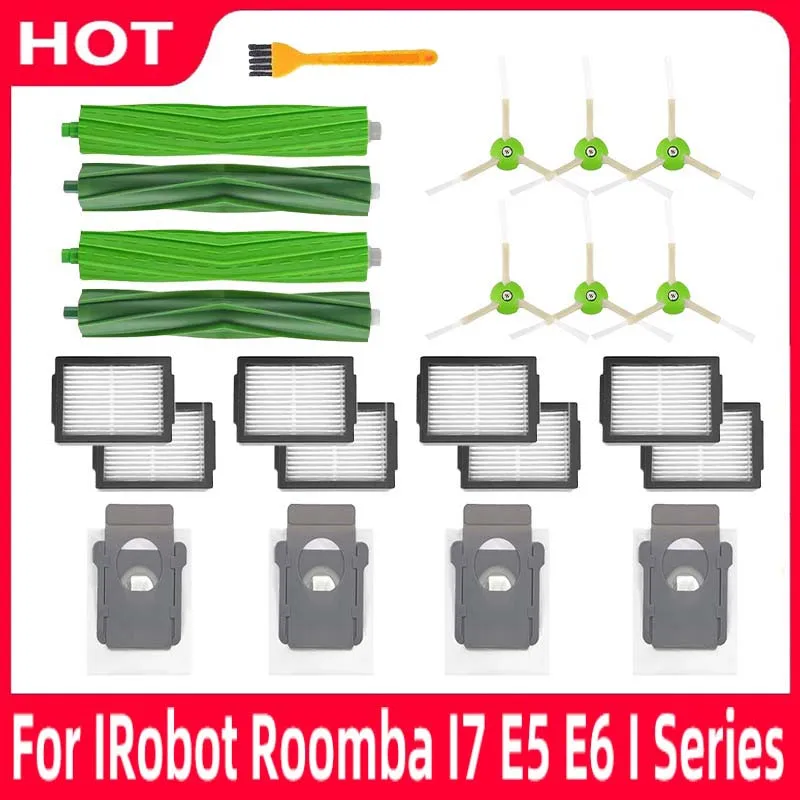

Replacement Parts Availability

Ensuring the longevity and optimal performance of your robotic vacuum cleaner often requires access to essential components. The availability of these elements is crucial for maintaining functionality and efficiency. Users should be aware of where to find reliable replacements that fit their specific device model.

Where to Find Components

Authorized retailers and online platforms provide a wide array of options for securing necessary items. Websites specializing in home appliances frequently stock these essentials, while local stores may also offer a selection of compatible alternatives. When purchasing, it is advisable to verify compatibility to avoid any performance issues.

Quality Considerations

Choosing high-quality replacements is vital for sustaining the effectiveness of your device. Opting for genuine replacements ensures optimal compatibility and performance. However, many third-party options are available that can serve as cost-effective alternatives. Always check reviews and product ratings to make an informed decision.

Common Issues with Parts

Understanding the typical challenges that arise with components in robotic cleaning devices can enhance their longevity and performance. These challenges often manifest as reduced efficiency or unexpected malfunctions, prompting users to seek solutions. By identifying and addressing these issues promptly, users can maintain optimal functionality and extend the lifespan of their devices.

Wear and Tear

Wear and tear is an inevitable part of using any robotic cleaner over time. Components such as brushes and filters can degrade, leading to decreased cleaning performance. Regular inspection and timely replacement of these items are essential to ensure the unit operates effectively.

Clogs and Obstructions

Another frequent problem involves clogs and obstructions that can hinder performance. Debris accumulation in the intake or around the wheels can prevent smooth operation. Regular maintenance, including clearing any blockages, is crucial for keeping the unit running efficiently.

Comparing i7 with Other Models

This section provides a comparative analysis of the i7 model alongside various other robotic cleaning devices. By examining their features, functionality, and performance, we aim to highlight the strengths and weaknesses of each, assisting potential buyers in making an informed decision.

| Feature | i7 | Model A | Model B |

|---|---|---|---|

| Navigation Technology | Smart mapping | Random navigation | Gyro navigation |

| Battery Life | 75 minutes | 60 minutes | 90 minutes |

| Dustbin Capacity | 0.4 liters | 0.3 liters | 0.5 liters |

| Smart Home Integration | Yes | No | Yes |

| Self-Cleaning Feature | Yes | No | No |

When comparing the i7 with other models, it becomes evident that its advanced navigation and cleaning capabilities set it apart. While some alternatives may excel in battery life or dustbin capacity, the overall performance of the i7 offers a unique balance of efficiency and technology, appealing to users seeking a reliable cleaning solution.

Tips for Proper Care

Maintaining your robotic cleaning device in optimal condition is essential for its longevity and performance. Regular attention to specific components can significantly enhance efficiency and ensure a clean environment. Here are some essential tips to help you take care of your cleaning appliance.

Regular Cleaning

- Remove hair and debris from the brushes and wheels after each use to prevent clogs.

- Wipe down the sensors and charging contacts regularly to ensure proper functionality.

- Empty the dustbin frequently to maintain suction power.

Battery Maintenance

- Charge the device fully before its first use to optimize battery life.

- Avoid leaving it on the charger for extended periods to prevent battery degradation.

- Store the unit in a cool, dry place when not in use for extended periods.

By following these guidelines, you can extend the life of your robotic cleaning device and ensure it operates at peak performance for years to come.

Assembly Instructions for Parts

This section provides detailed guidance on the assembly of various components of your cleaning device. Proper installation is crucial for optimal performance and longevity. Follow these steps carefully to ensure that everything fits together seamlessly.

Step-by-Step Assembly

Begin by gathering all necessary components. Lay them out in a clear workspace to facilitate the assembly process. Start with the base unit, ensuring it is stable and positioned correctly. Next, attach the first component, aligning it with the designated slots. Press down firmly until you hear a click, indicating that it is securely in place.

Final Adjustments

After all components are assembled, check for any misalignments. Adjust them as needed, ensuring everything is flush and secure. It is advisable to perform a quick test to confirm that the assembly functions as intended. Regular checks will help maintain efficiency and prevent issues in the future.