The efficient operation of a widely used outdoor tool relies heavily on its intricate components and their seamless interaction. Knowledge of these elements is crucial for users who seek to maintain or repair their equipment effectively. Familiarity with the specific pieces that make up this machinery enhances its longevity and performance.

For those looking to delve deeper into the structure of their equipment, examining the assembly of various parts can be immensely beneficial. By identifying each section and understanding its function, users can troubleshoot issues and optimize the tool’s functionality. This exploration not only aids in maintenance but also fosters a greater appreciation for the craftsmanship involved in its design.

In this guide, we will provide a detailed overview of the essential components and their configurations. This resource will serve as a valuable reference for both novice and experienced operators alike, facilitating a deeper understanding of their equipment’s inner workings.

Proper upkeep is essential for ensuring the extended life and optimal performance of any outdoor power equipment. By following some simple maintenance practices, users can significantly enhance the durability of their tools and reduce the likelihood of repairs.

Regular inspections and cleaning are crucial. Keeping the equipment free from debris and dirt helps prevent wear and tear on components. Additionally, timely replacement of worn parts can prevent further damage and ensure smooth operation.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Inspect air filter | Every 25 hours | Clean or replace as needed to maintain airflow. |

| Check spark plug | Every 50 hours | Replace if worn to ensure efficient ignition. |

| Sharpen cutting blades | Every 10 hours of use | Sharp blades improve cutting performance and reduce engine strain. |

| Lubricate moving parts | Every 50 hours | Use appropriate lubricant to minimize friction. |

| Clean exterior | After each use | Remove dirt and debris to prevent corrosion. |

By adhering to these maintenance guidelines, users can ensure their equipment remains reliable and effective for many years. A proactive approach to care not only enhances performance but also provides peace of mind during operation.

Common Issues and Solutions

Every machine has its quirks and may encounter challenges during operation. Understanding these common problems and their respective solutions can enhance performance and prolong the lifespan of the equipment. Below are some frequently observed issues and practical remedies.

Frequent Problems

- Difficulty starting the engine

- Overheating during use

- Unusual noises while operating

- Fuel leaks

Possible Solutions

- Engine Starting Issues:

- Check the fuel level and ensure it is fresh.

- Inspect the spark plug for wear and replace if necessary.

- Examine the air filter and clean or replace it if clogged.

- Overheating:

- Ensure that the cooling fins are free of debris.

- Check for proper lubrication and add oil if levels are low.

- Reduce workload to prevent overheating.

- Unusual Noises:

- Inspect for loose or damaged components.

- Ensure that all fasteners are securely tightened.

- Listen for signs of wear in moving parts and address them promptly.

- Fuel Leaks:

- Examine fuel lines for cracks or damage.

- Ensure connections are tight and secure.

- Replace any faulty gaskets or seals.

Ordering Replacement Parts Effectively

When it comes to maintaining your equipment, acquiring the right components is crucial for ensuring optimal performance. Understanding the best practices for procuring these items can save time, reduce costs, and enhance the longevity of your machinery.

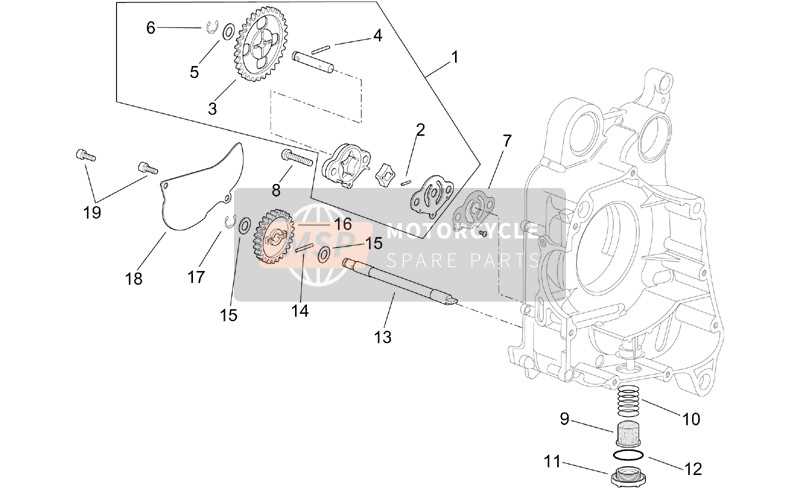

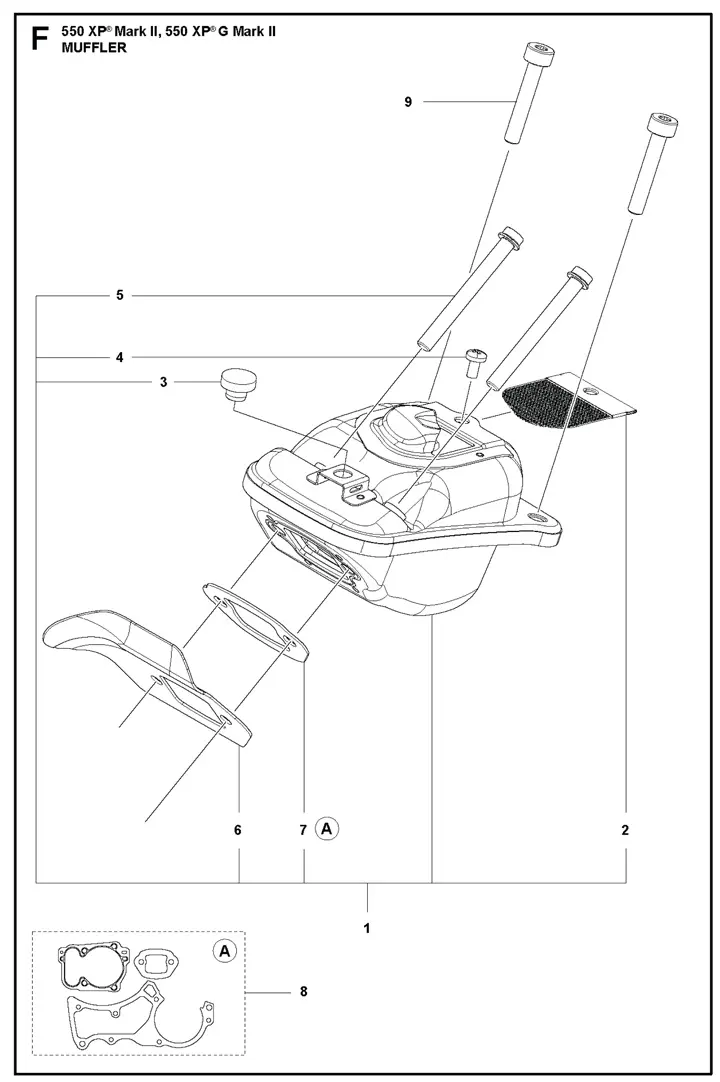

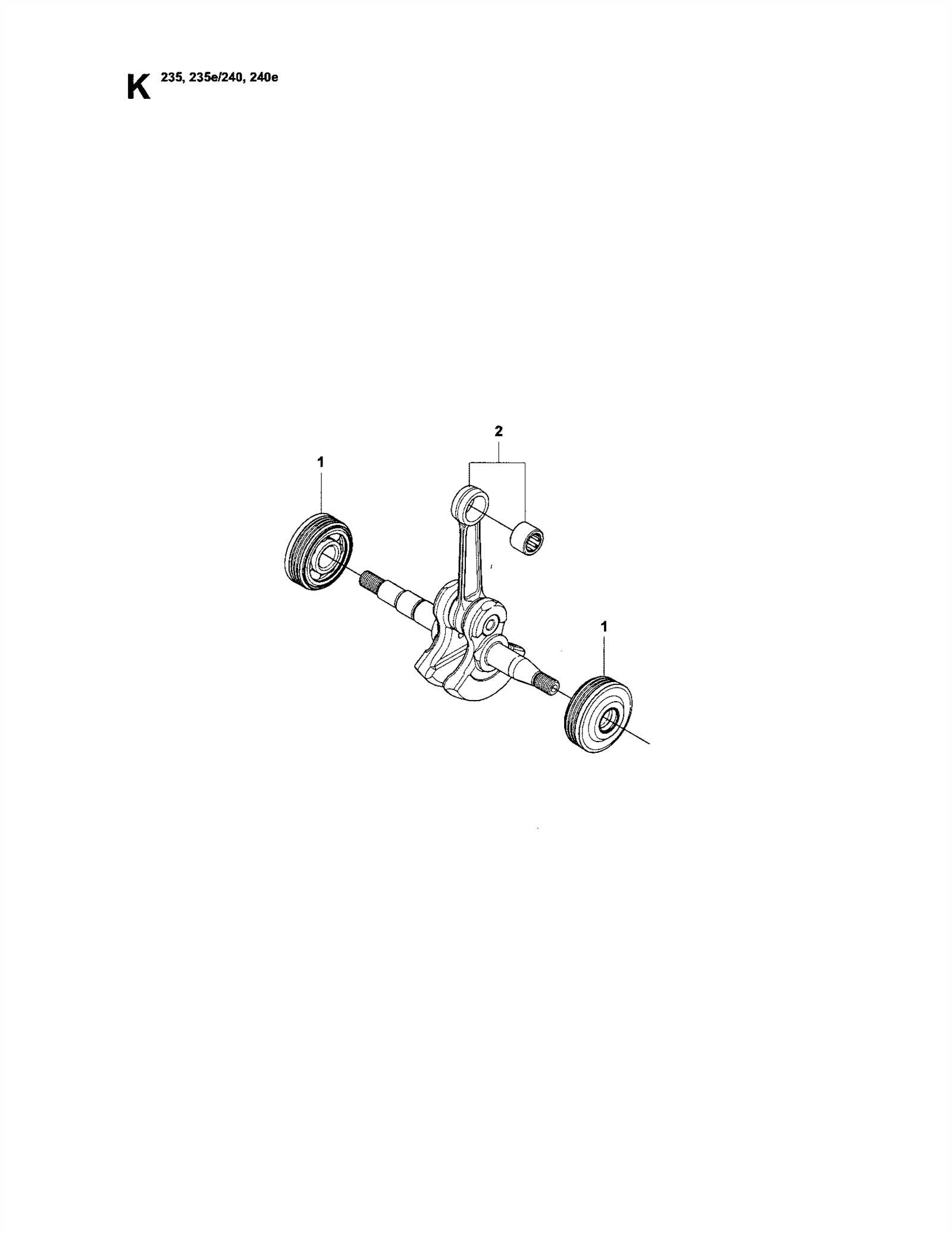

Start by identifying the specific components you need. Referencing a detailed breakdown of your equipment will help in pinpointing the exact items required. This initial step is essential for avoiding mistakes and ensuring that you order precisely what is necessary.

| Step | Action | Description |

|---|---|---|

| 1 | Identify Components | Use a breakdown to determine which items are required for your equipment. |

| 2 | Research Suppliers | Look for reputable suppliers who offer quality replacements. |

| 3 | Check Compatibility | Ensure the selected items are compatible with your specific model. |

| 4 | Compare Prices | Evaluate prices from different suppliers to find the best deal. |

| 5 | Order with Confidence | Place your order once you have verified all details. |

By following these steps, you can effectively navigate the process of obtaining replacement items, leading to improved functionality and durability of your tools.

Tools Needed for Disassembly

When undertaking the process of disassembling your equipment, having the right tools is essential for efficiency and safety. Proper tools ensure that each component can be removed without damage, facilitating a smooth reassembly later. Below is a list of commonly required implements that will aid in the disassembly process.

| Tool | Description |

|---|---|

| Socket Wrench | Useful for loosening bolts and nuts, providing leverage and reducing the risk of stripping. |

| Screwdriver Set | A variety of flathead and Phillips screwdrivers is necessary to handle different types of screws. |

| Torque Wrench | Ensures bolts are tightened to the manufacturer’s specifications during reassembly. |

| Pliers | Ideal for gripping and twisting components, especially in tight spaces. |

| Hex Key Set | Required for fasteners with hexagonal sockets, often found in various assemblies. |

| Cleaning Cloths | Essential for wiping off grease and debris to maintain a clean workspace. |

Step-by-Step Assembly Guide

This guide provides a comprehensive overview of the assembly process for your chainsaw, ensuring that each component is properly installed for optimal performance. Following these steps carefully will help you understand the assembly order and the function of each part, leading to a well-functioning tool that meets your cutting needs.

Necessary Tools and Components

Before starting the assembly, gather all the necessary tools and components. This preparation will streamline the process and minimize disruptions. Below is a table outlining the required items:

| Tool/Component | Purpose |

|---|---|

| Wrench Set | To tighten and loosen bolts and nuts. |

| Screwdriver | For securing various screws in place. |

| Assembly Manual | To reference specific instructions and diagrams. |

| Safety Goggles | To protect eyes during assembly. |

Assembly Steps

Follow these steps to assemble your chainsaw effectively:

- Begin by laying out all components on a clean surface to ensure easy access.

- Refer to the manual for the correct sequence of assembly.

- Start with the main body, attaching any necessary mounts and securing them tightly.

- Install the chain and bar, ensuring they are positioned correctly according to the specifications.

- Attach the handle, making sure all screws are tightened securely for safety.

- Finally, perform a thorough check of all connections before using the equipment.

Importance of Genuine Components

Utilizing authentic parts in machinery maintenance is crucial for ensuring optimal performance and longevity. These components are designed to meet specific standards, providing reliability and consistency that imitation items often cannot match.

Quality Assurance: Genuine components undergo rigorous testing to verify their durability and effectiveness. This quality assurance minimizes the risk of breakdowns and enhances overall efficiency.

Compatibility: Original items are engineered to fit seamlessly with your equipment, reducing the likelihood of complications during installation. This compatibility ensures that the machinery operates smoothly without any operational issues.

Safety: Employing non-genuine parts can compromise the safety of the equipment. Authentic components are manufactured with safety protocols in mind, reducing the risk of accidents and injuries.

Warranty Protection: Many manufacturers stipulate that the use of genuine parts is necessary to maintain warranties. Using imitation parts could void warranties, resulting in costly repairs or replacements.

In conclusion, investing in original components is essential for preserving the integrity and performance of machinery. It ensures that equipment runs efficiently, safely, and reliably over time.

Safety Precautions While Repairing

When engaging in maintenance and repair tasks, it is crucial to prioritize safety to prevent accidents and ensure effective work. Adhering to specific guidelines can greatly reduce the risk of injury while enhancing the overall repair experience.

Essential Safety Guidelines

- Always wear appropriate personal protective equipment, including gloves, goggles, and sturdy footwear.

- Ensure the workspace is well-lit and free from clutter to minimize hazards.

- Familiarize yourself with the equipment and tools being used to understand their functions and potential risks.

- Disconnect the power source or remove the fuel before starting any repairs to prevent accidental activation.

Working Safely with Tools

- Inspect tools before use to ensure they are in good condition and properly maintained.

- Use the right tool for the job to avoid damage and reduce the risk of injury.

- Handle sharp or heavy tools with care, storing them securely when not in use.

- Keep your work area organized to prevent tripping hazards and misplaced tools.

Comparison with Other Husqvarna Models

When evaluating the performance and features of various chainsaw models from the same manufacturer, it’s essential to consider their specifications, applications, and user preferences. This analysis provides insight into how different machines stack up against one another, offering a clearer understanding of which model may suit particular needs best.

Key aspects to consider in the comparison include:

- Engine Power: The output of the engine significantly affects cutting efficiency. Higher power often translates to better performance in demanding tasks.

- Weight: The weight of the saw can influence maneuverability and ease of use. Lighter models are preferable for extended use, while heavier units may offer more stability during operation.

- Cutting Length: Different models accommodate varying bar lengths, impacting the thickness of material that can be tackled.

- Features: Innovations such as anti-vibration systems, easy-start mechanisms, and fuel efficiency can enhance user experience and operational comfort.

In a side-by-side evaluation, users often find that some models are better suited for professional logging, while others are more appropriate for casual use or homeowner tasks. Additionally, preferences in ergonomics and handle design can lead to a different experience even among similarly powered machines.

Ultimately, understanding these distinctions can guide potential buyers in selecting the right equipment tailored to their specific requirements and applications.

Customer Reviews on Parts Performance

This section provides an overview of user experiences regarding the functionality and durability of components for specific outdoor equipment. Feedback from consumers can significantly influence the decision-making process when selecting replacements, as it highlights both strengths and weaknesses based on real-life usage.

Positive Feedback

Many users have expressed satisfaction with the reliability of the components, noting their effectiveness in enhancing the overall performance of their equipment. Customers have reported fewer breakdowns and increased efficiency after replacing worn-out pieces, indicating a solid return on investment.

Areas for Improvement

While the majority of reviews are positive, some users have mentioned issues such as compatibility and longevity. A few individuals experienced difficulties during installation, leading to concerns about the fit of certain items. Additionally, there are reports of some components wearing out quicker than expected, prompting users to seek alternatives.

| Review Aspect | Positive Comments | Negative Comments |

|---|---|---|

| Reliability | Improved performance and fewer breakdowns | Occasional compatibility issues |

| Durability | Long-lasting under normal use | Some wear out sooner than expected |

| Installation | Easy to install for most users | Challenges reported by a few |

Where to Find Reliable Resources

Finding dependable sources for information and components is essential for anyone looking to maintain or repair their equipment. Quality resources can provide insights into the specifications, compatibility, and installation processes, ensuring that users make informed decisions.

Online Platforms

Numerous websites specialize in offering manuals, schematics, and user forums where individuals can share their experiences. These platforms often feature a wealth of knowledge that can guide users through troubleshooting and component selection.

Local Retailers and Workshops

Visiting local retailers or workshops can also yield valuable information. Experienced staff can offer personalized advice and may have access to exclusive resources that are not available online. Building relationships with local experts can be a great asset for ongoing support and guidance.