The intricate design of a pneumatic mechanism is essential for its optimal performance. Each component plays a vital role, contributing to the overall functionality and efficiency. Understanding how these elements interact can greatly enhance user experience and maintenance.

Detailed exploration of this assembly allows enthusiasts and technicians alike to gain insight into the operational dynamics. By familiarizing oneself with the configuration and roles of each piece, one can identify potential issues and implement effective solutions.

In this section, we will delve into the configuration of a specific model, providing a visual reference that highlights the arrangement and relationship of the essential components. This knowledge serves not only to inform but also to empower users in their hands-on engagements.

Understanding the Umarex Hammer Design

This section delves into the intricate construction and functionality of a specific pneumatic device, focusing on its core components and their interactions. The design principles underlying this mechanism are crucial for its performance and reliability.

At the heart of this system lies a robust assembly that facilitates the propulsion of projectiles. Each element is engineered to optimize energy transfer, ensuring precision and power. Material selection plays a vital role in enhancing durability, while mechanical design ensures smooth operation under varying conditions.

The integration of various components must be understood to appreciate how they contribute to overall efficiency. Key features, such as the triggering mechanism and energy storage, work in harmony to deliver consistent results. Analyzing these aspects reveals the engineering prowess involved in crafting a reliable tool for enthusiasts.

Key Components of the Umarex Hammer

This section delves into the essential elements that constitute a particular air-powered device designed for precision shooting. Understanding these fundamental components is crucial for enthusiasts and users aiming to enhance their experience and performance. Each element plays a significant role in the functionality and reliability of the mechanism, ensuring optimal operation during use.

Essential Mechanisms

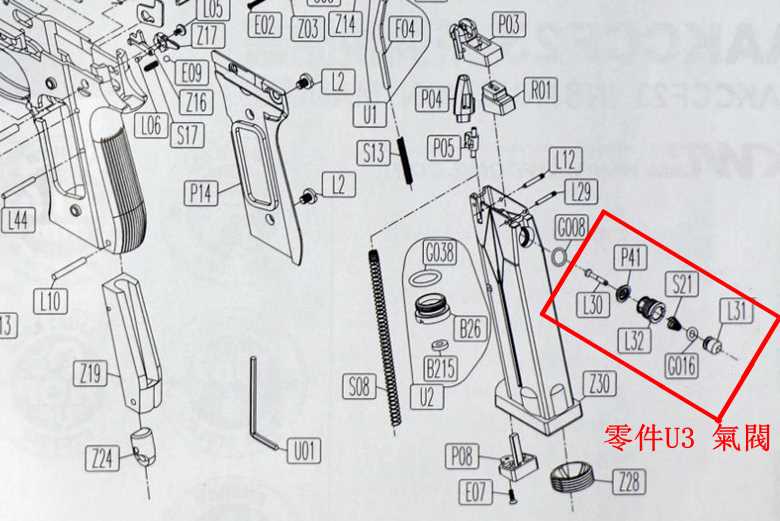

At the heart of this device are the critical mechanisms that facilitate its functionality. The trigger assembly is a vital part, providing the user with the means to initiate the firing sequence. Additionally, the valve system governs the release of air pressure, which propels the projectile with accuracy. These mechanisms work in harmony to deliver a seamless shooting experience.

Supporting Elements

In addition to the core mechanisms, various supporting elements contribute to the overall efficiency and performance. The barrel, crafted from high-quality materials, ensures that the projectile travels smoothly and maintains its trajectory. Furthermore, the stock not only provides stability but also enhances user comfort during operation. Each of these components is designed to optimize the device’s performance and durability.

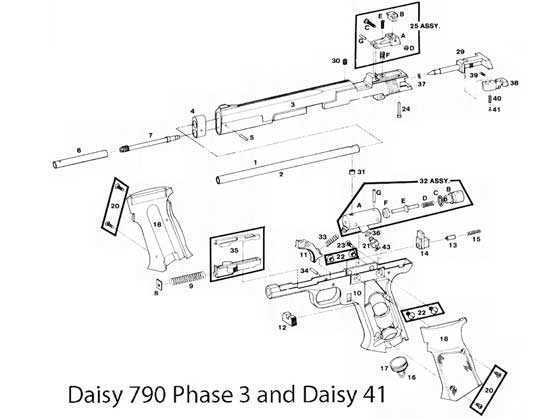

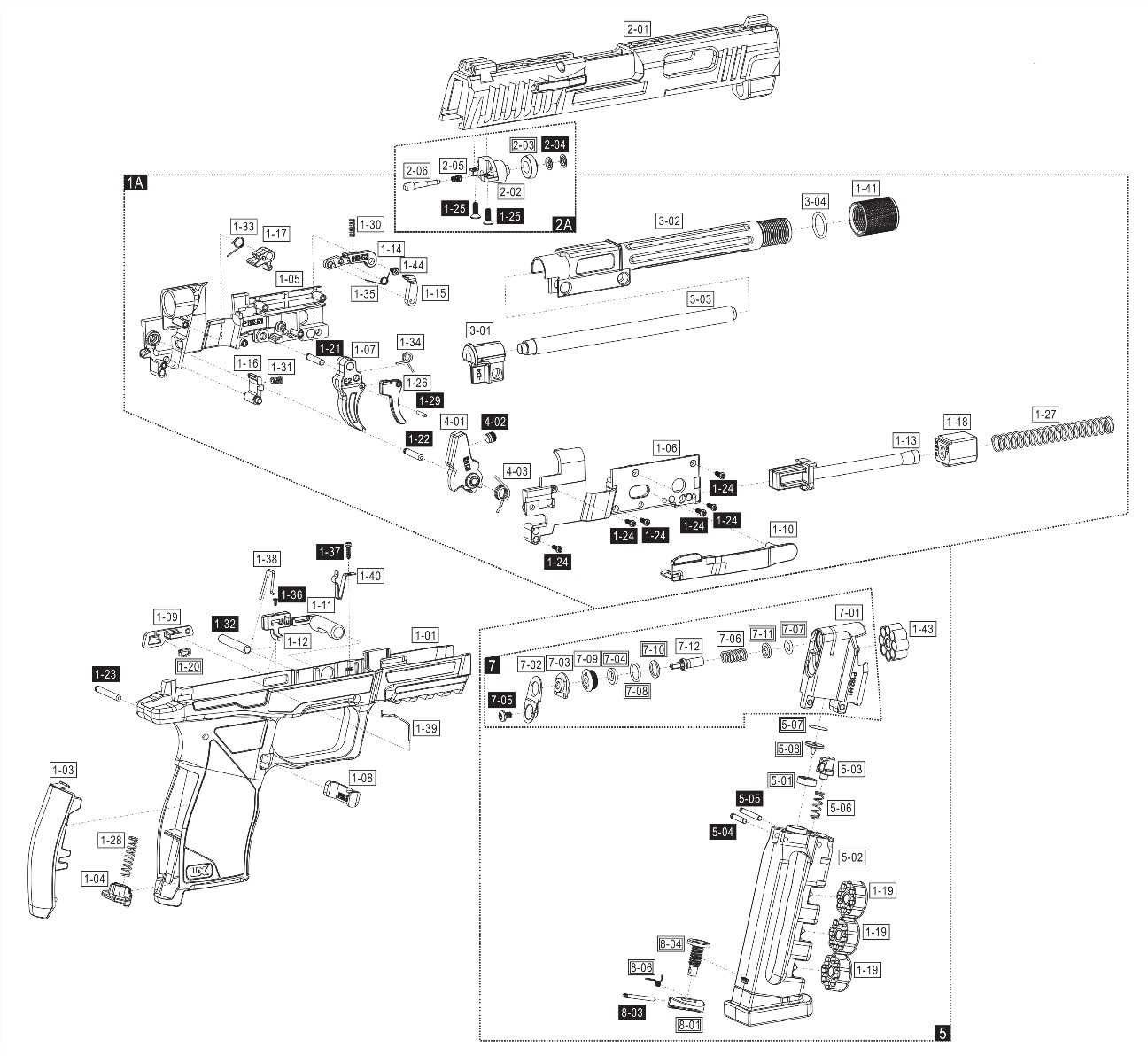

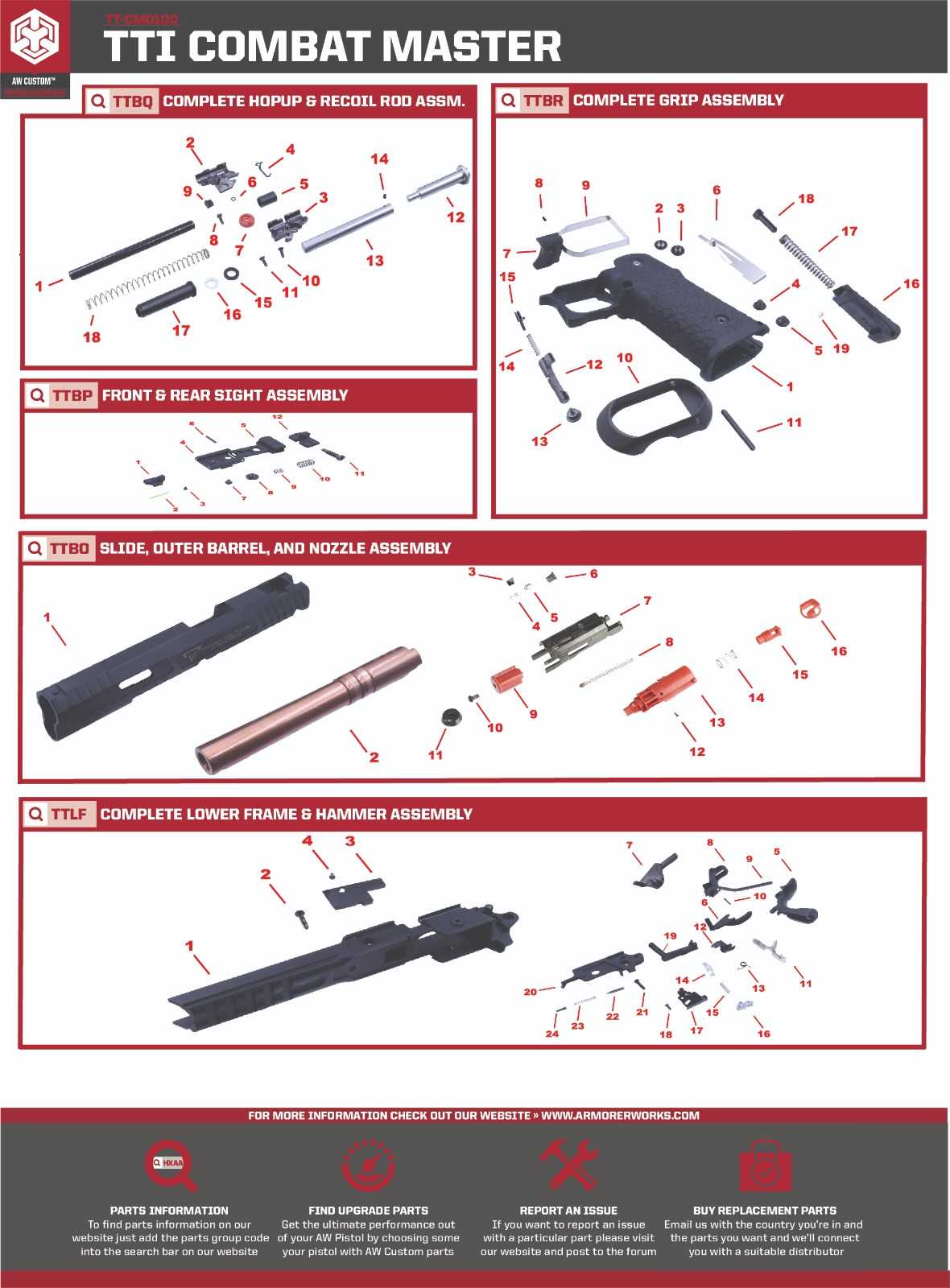

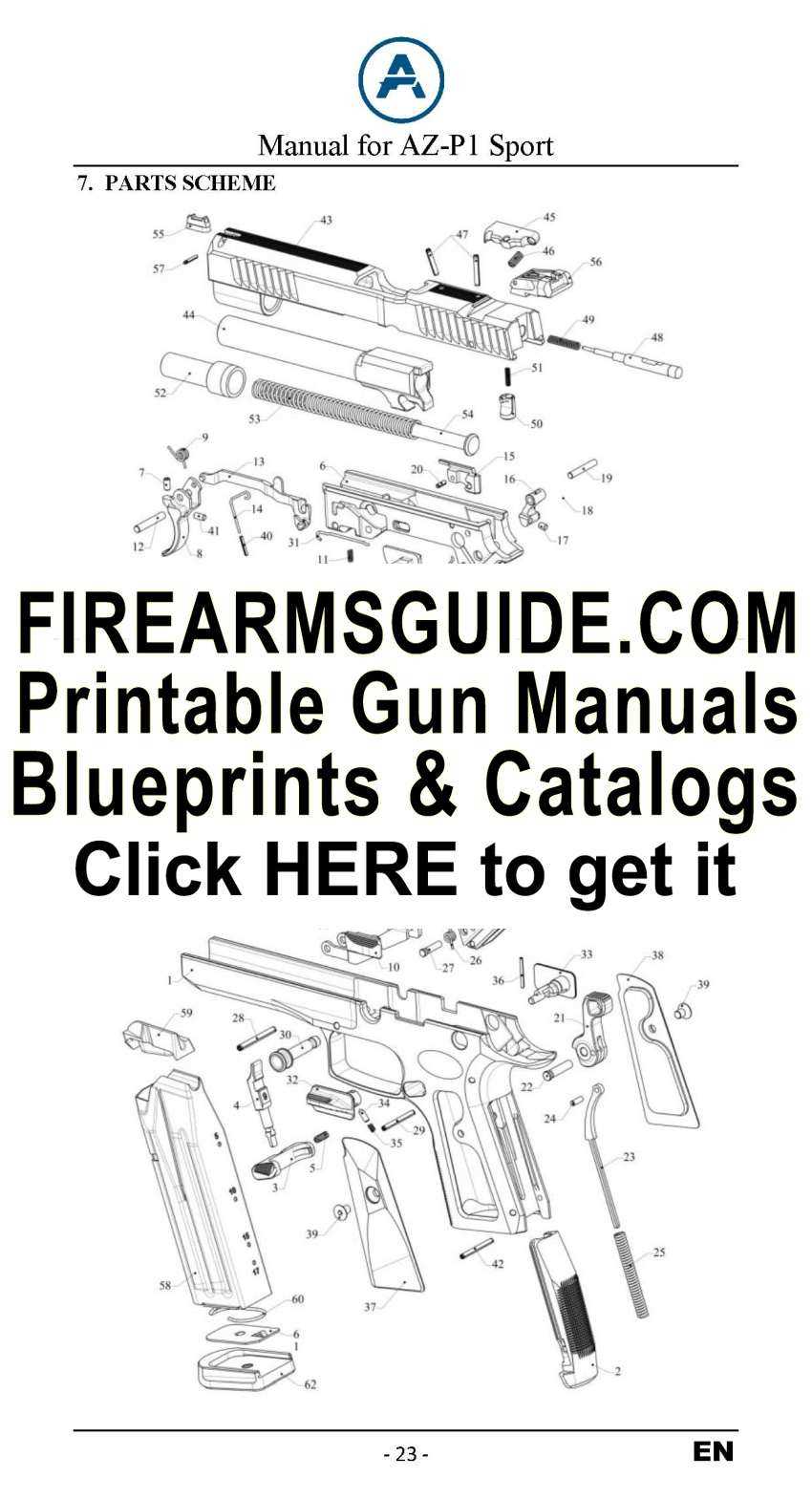

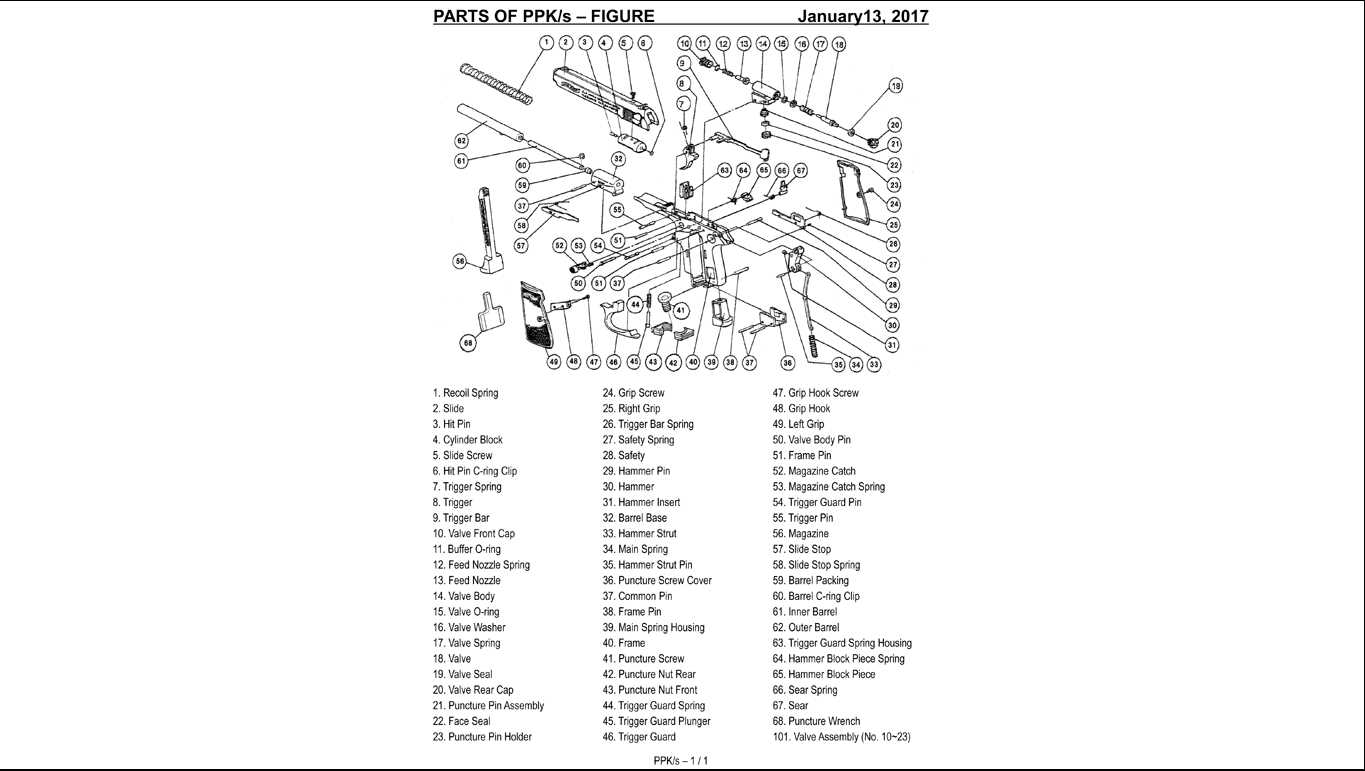

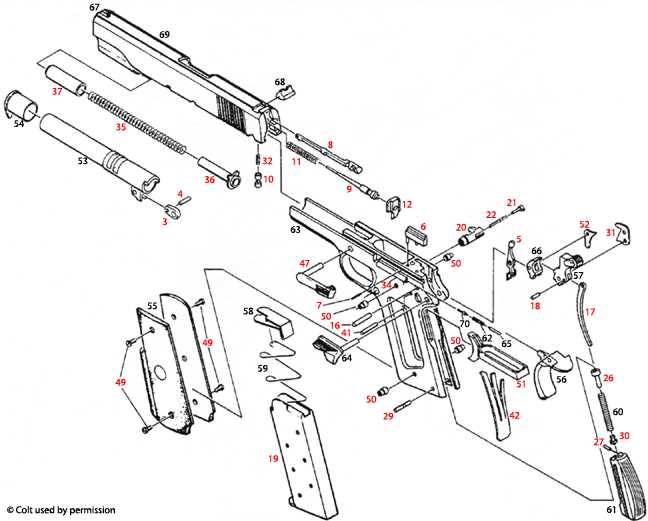

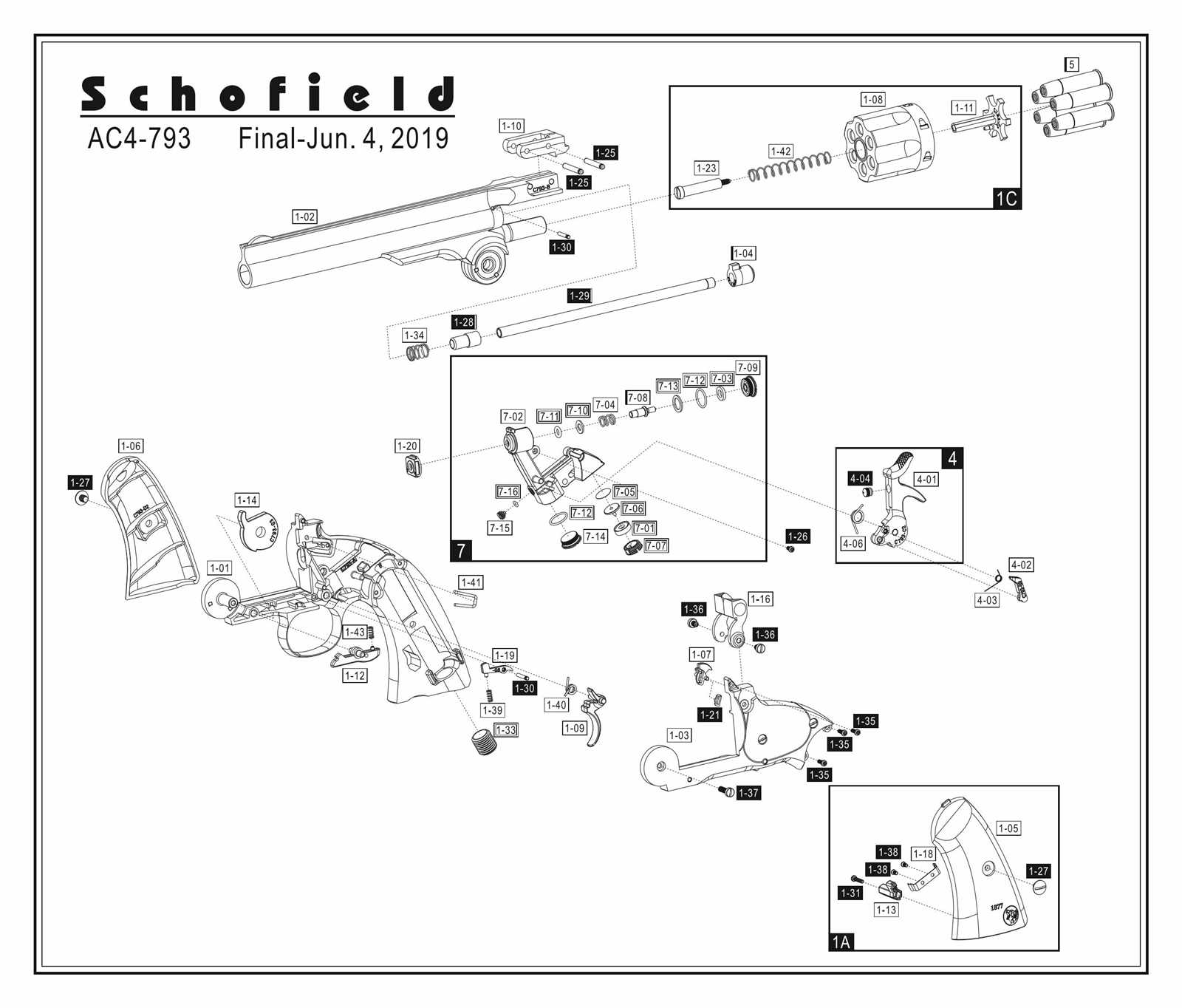

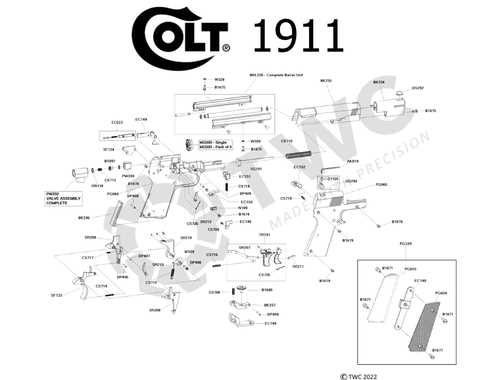

Visual Representation of Parts Layout

This section aims to provide a detailed overview of the configuration and arrangement of components within the mechanism. A clear visual outline allows users to understand the structure and interrelationships between various elements, enhancing their comprehension of functionality.

Utilizing illustrations can significantly aid in identifying each segment and its role. These representations not only simplify the learning process but also serve as a valuable reference for maintenance and assembly tasks. With a precise layout, enthusiasts can better appreciate the intricate design and engineering behind the system.

Moreover, visual aids contribute to a more effective troubleshooting process, enabling users to quickly locate potential issues. By examining the schematic layout, individuals can follow logical pathways and make informed decisions regarding repairs or modifications.

In conclusion, a well-crafted visual representation acts as an essential tool for anyone seeking to deepen their understanding of the internal workings and improve their interaction with the device.

Functionality of Each Hammer Part

This section explores the individual components involved in the striking mechanism of a firearm and their specific roles in ensuring proper operation. Understanding these elements is essential for maintenance and troubleshooting.

Striker: The striker is the primary element responsible for initiating the firing sequence. When engaged, it delivers a forceful impact to the primer, igniting the cartridge.

Spring: This elastic component stores energy and facilitates the rapid return of the striker to its resting position after activation. Its tension is crucial for reliable performance.

Sear: Acting as a safety mechanism, the sear holds the striker in place until the trigger is pulled. Once the trigger is engaged, the sear releases the striker, allowing it to move forward.

Trigger: The trigger serves as the user interface, enabling the shooter to control the firing action. Its design influences the pull weight and overall shooting experience.

Safety Mechanism: This feature prevents accidental discharges by blocking the striker’s movement unless the trigger is intentionally pulled, enhancing user safety.

Common Issues with Umarex Hammer

In the realm of high-performance air-powered devices, several challenges may arise that affect functionality and user experience. Understanding these frequent complications can aid in maintaining optimal performance and prolonging the lifespan of your equipment.

Frequent Problems Encountered

Users often report a variety of issues ranging from operational inconsistencies to mechanical failures. These complications can stem from improper handling, lack of maintenance, or inherent design flaws.

| Issue | Description | Possible Solutions |

|---|---|---|

| Leakage | Air leaks can occur at various junctions, leading to decreased efficiency. | Inspect seals and connections; replace worn components. |

| Inconsistent Power | Variable performance may affect accuracy and range. | Check for obstructions; ensure proper maintenance routines are followed. |

| Difficulty in Operation | Resistance during use may indicate mechanical wear or obstruction. | Lubricate moving parts; conduct thorough cleaning. |

Maintenance Recommendations

Regular upkeep is crucial to prevent many of these issues. Adhering to a structured maintenance schedule will not only enhance performance but also help identify potential problems before they escalate.

Maintenance Tips for Longevity

Ensuring the durability and optimal performance of your equipment requires regular upkeep and attention to detail. By following specific maintenance practices, you can significantly extend its lifespan and maintain its efficiency. This section provides essential guidelines to help you keep your device in excellent condition.

Routine Cleaning

Regular cleaning is crucial to prevent the accumulation of dirt and debris, which can affect functionality. Use a soft cloth and appropriate cleaning solutions to gently wipe down surfaces. Pay special attention to moving components and crevices where dust may settle.

Lubrication

Applying the right lubricant can reduce friction and wear on internal mechanisms. Ensure you choose a high-quality product designed for your device’s specific materials. Regularly check lubrication points and reapply as needed to maintain smooth operation.

| Maintenance Task | Frequency |

|---|---|

| Clean surfaces | Weekly |

| Check and apply lubricant | Monthly |

| Inspect components for wear | Quarterly |

| Full disassembly and deep clean | Annually |

Upgrading Components for Enhanced Performance

Improving the efficiency and overall functionality of your equipment can significantly elevate your shooting experience. By selecting high-quality upgrades, enthusiasts can enhance accuracy, reliability, and overall performance. This section delves into various components that can be optimized to achieve superior results.

One of the primary areas to consider is the firing mechanism. Upgrading to precision-engineered components can lead to more consistent shots and reduced trigger pull weight. This change not only improves user comfort but also enhances accuracy during use.

Another critical aspect is the air supply system. Opting for high-performance valves and seals can enhance air pressure consistency, allowing for greater velocity and more stable projectile trajectories. Such enhancements ensure that each shot is delivered with precision and power.

Finally, don’t overlook the benefits of a high-quality barrel. Upgrading to a match-grade barrel can significantly improve shot grouping and overall accuracy. The right barrel can reduce friction and improve airflow, making each shot smoother and more reliable.

Investing in these key upgrades can transform the performance of your gear, making it not only more enjoyable to use but also more effective in various shooting scenarios.

Tools Needed for Disassembly

Proper disassembly of the mechanism requires specific instruments to ensure a smooth and safe process. Having the right tools not only facilitates the task but also minimizes the risk of damage to components. Below is a list of essential items that will aid in the process.

Essential Tools

- Wrenches: Various sizes for loosening screws and bolts.

- Screwdrivers: Both flathead and Phillips types are necessary for different fasteners.

- Allen Keys: Often required for hex screws.

- Pliers: Useful for gripping and twisting smaller parts.

- Tweezers: Ideal for handling small components delicately.

Additional Equipment

- Work Gloves: To protect hands during handling.

- Magnetic Tray: Keeps small screws and parts organized and prevents loss.

- Flashlight: Provides better visibility in tight spaces.

- Soft Cloth: Helps in cleaning and protecting surfaces from scratches.

Reassembly Process Explained

Reassembling your device requires careful attention to detail and a systematic approach. This ensures that each component is correctly positioned, maintaining the functionality and safety of the mechanism. Following a structured process can simplify the task and prevent potential issues during operation.

Step-by-Step Guidelines

Begin by organizing all components in a logical order. This can aid in understanding how each piece fits together. Always refer to the manufacturer’s instructions if available, as they provide crucial insights into the specific assembly requirements.

Final Checks and Testing

Once everything is reassembled, perform a thorough inspection to confirm that all components are secured properly. It is essential to test the functionality before full use, ensuring that the mechanism operates smoothly and safely. Regular maintenance after reassembly will enhance the longevity of the equipment.

Comparing Models: Features and Parts

When examining various designs, it’s essential to understand the distinctive characteristics and components that set each version apart. Each model presents unique attributes that cater to different preferences and needs.

Design Variations: The aesthetics and ergonomics of each iteration can significantly influence user experience. Some versions prioritize a sleek appearance, while others focus on functionality and durability.

Component Quality: The materials and manufacturing processes used in crafting different elements can affect overall performance. High-quality components often enhance reliability and longevity, ensuring consistent operation.

Performance Features: Variations in trigger sensitivity, firing mechanisms, and safety measures contribute to the operational experience. Users may find that certain models offer enhanced precision or ease of use based on these design choices.

Ultimately, a thorough comparison of these features allows potential users to select a model that aligns with their specific requirements and expectations.

Safety Precautions During Repairs

When undertaking maintenance or repairs on equipment, it is essential to prioritize safety to prevent accidents and ensure a smooth process. Adhering to specific guidelines can significantly reduce risks associated with handling tools and mechanical components.

Essential Safety Measures

- Always wear appropriate personal protective equipment (PPE), such as gloves and safety goggles, to safeguard against injuries.

- Ensure that the work area is clean and organized to minimize hazards, such as tripping over tools or components.

- Disconnect power sources or any pressurized systems before starting any repair work to prevent unexpected activation.

Handling Tools and Components

- Use tools specifically designed for the job to avoid damage to parts or personal injury.

- Be cautious of sharp edges and small components, as these can pose risks when mishandled.

- Store tools properly when not in use to prevent accidents and ensure they are easily accessible when needed.

By implementing these safety precautions, you can create a safer working environment and enhance the efficiency of your repair tasks.

Where to Find Replacement Parts

Finding components for your equipment can be a straightforward task if you know where to look. There are various reliable sources that cater to enthusiasts and hobbyists seeking specific items to maintain or upgrade their devices.

Online Retailers

- Visit specialized e-commerce websites that focus on outdoor and sporting goods.

- Check major online marketplaces for user-reviewed options.

- Search for dedicated parts suppliers that offer a wide range of products.

Local Shops and Workshops

- Explore local sporting goods stores that may stock relevant accessories.

- Inquire at repair shops that specialize in similar devices for availability.

- Attend community events or expos where vendors might sell components directly.

By utilizing these resources, you can easily locate the necessary items to keep your equipment functioning optimally.