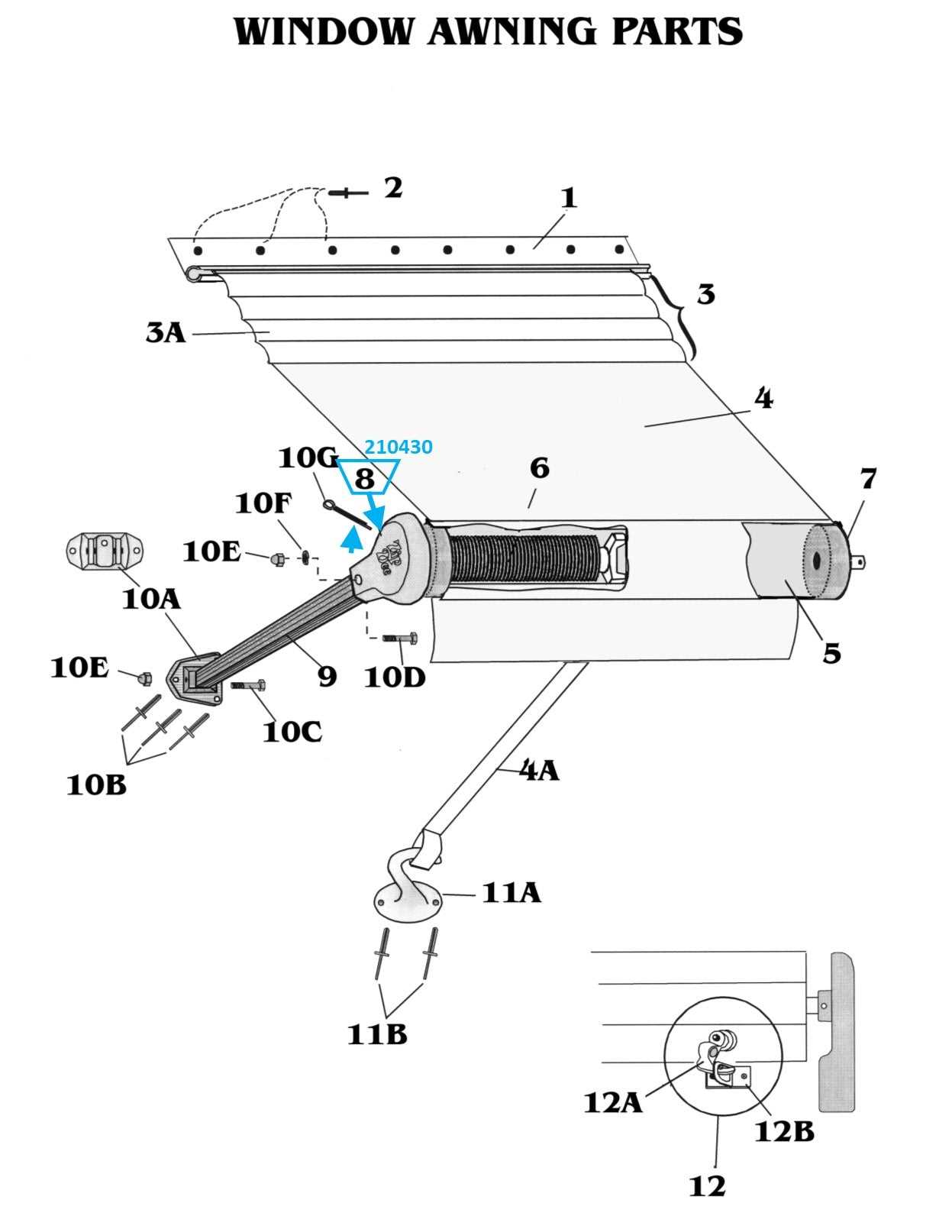

In this guide, we will explore the various elements that make up a commonly used fixture designed to allow ventilation while maintaining protection from outdoor elements. These structures are known for their efficiency in enabling airflow while keeping rain and other external factors out. Their design is simple yet effective, ensuring functionality in diverse environments.

Each part of this operable structure works in unison to provide smooth operation and long-term durability. Understanding how these elements fit together can be essential for maintenance or repair. Whether you’re looking to replace a single piece or curious about the mechanics behind its movement, grasping the role of individual components will help you make informed decisions.

We will walk through each element of this system, explaining its purpose and how it interacts with the others. By the end of this guide, you will have a clear understanding of how this structure operates and what to look for when servicing or upgrading it.

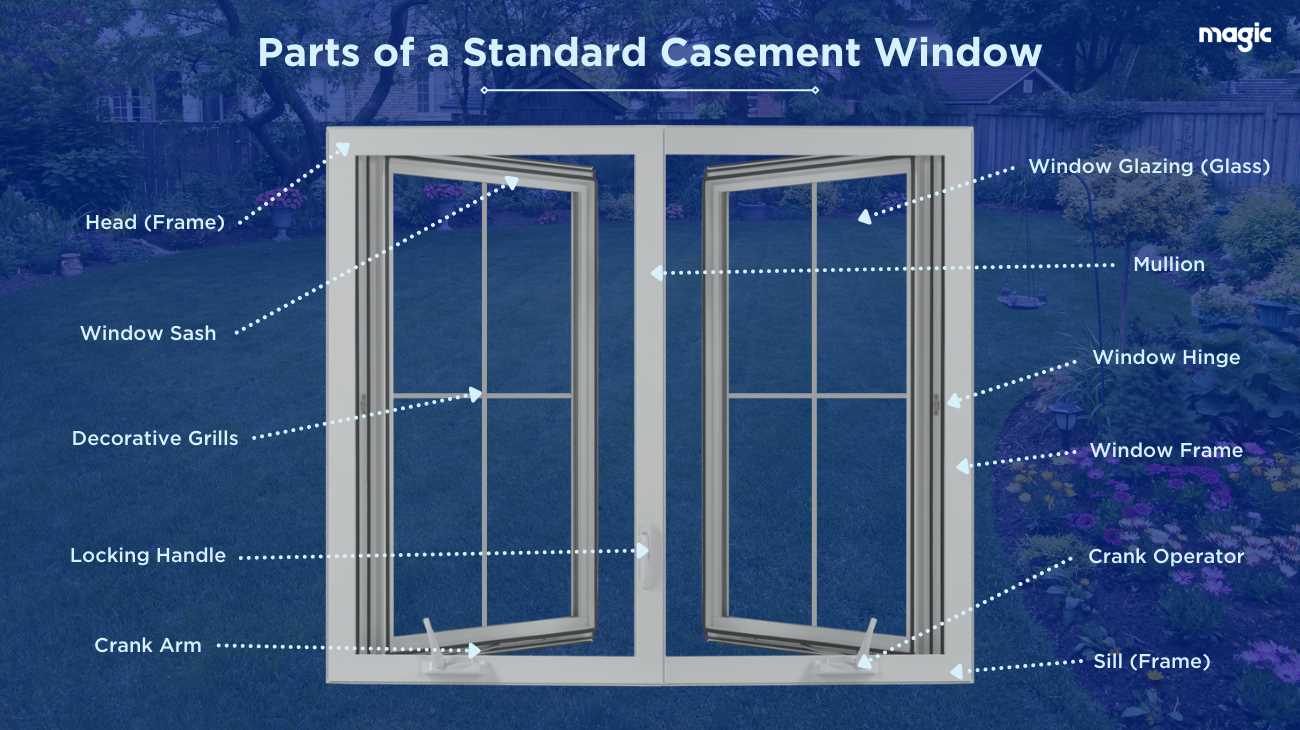

Awning Window Components Overview

In this section, we will explore the individual elements that come together to form a specific type of operable frame often seen in homes and buildings. These components are essential for proper functioning, providing durability, ease of use, and seamless operation.

- Frame Structure: This forms the foundation, holding everything in place and ensuring stability for the entire unit.

- Glazing Panels: The transparent sections that allow light to enter while protecting against external conditions.

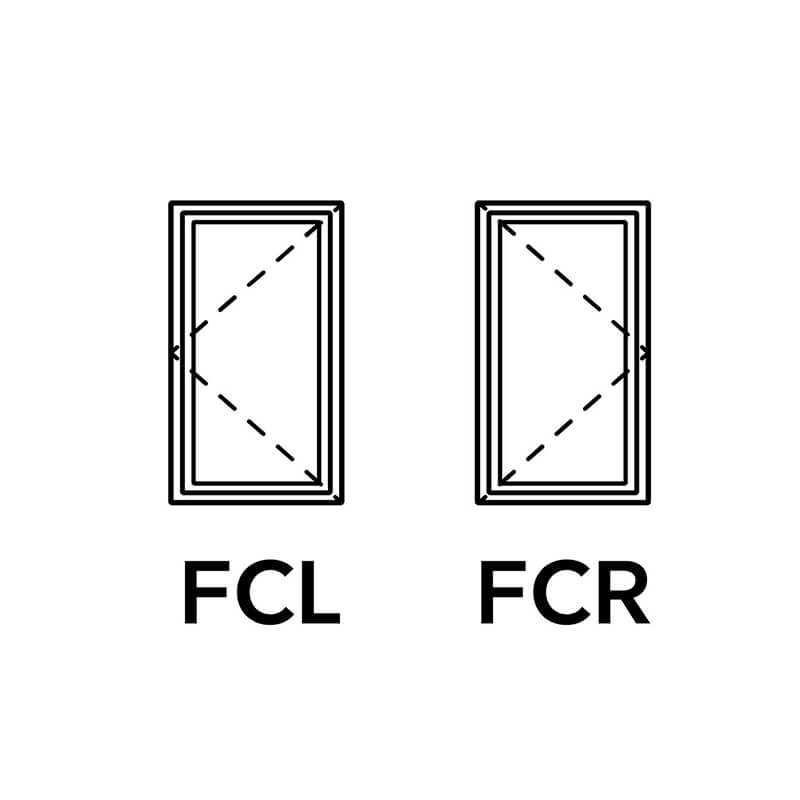

- Hinges: Mechanical devices that facilitate movement, allowing the user to open and close the assembly smoothly.

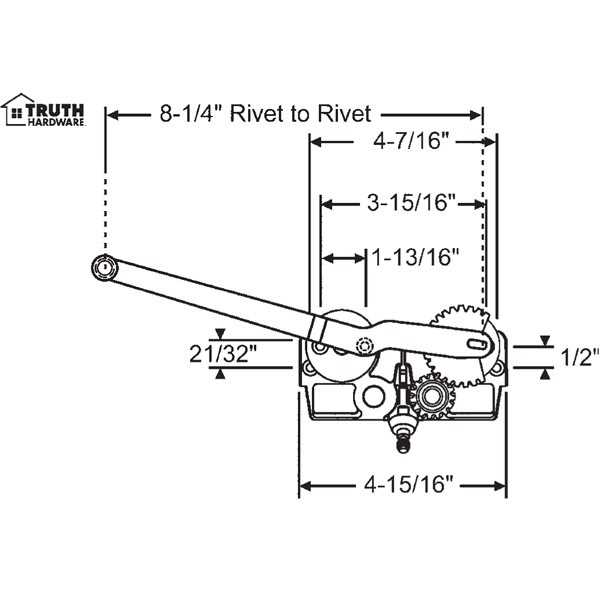

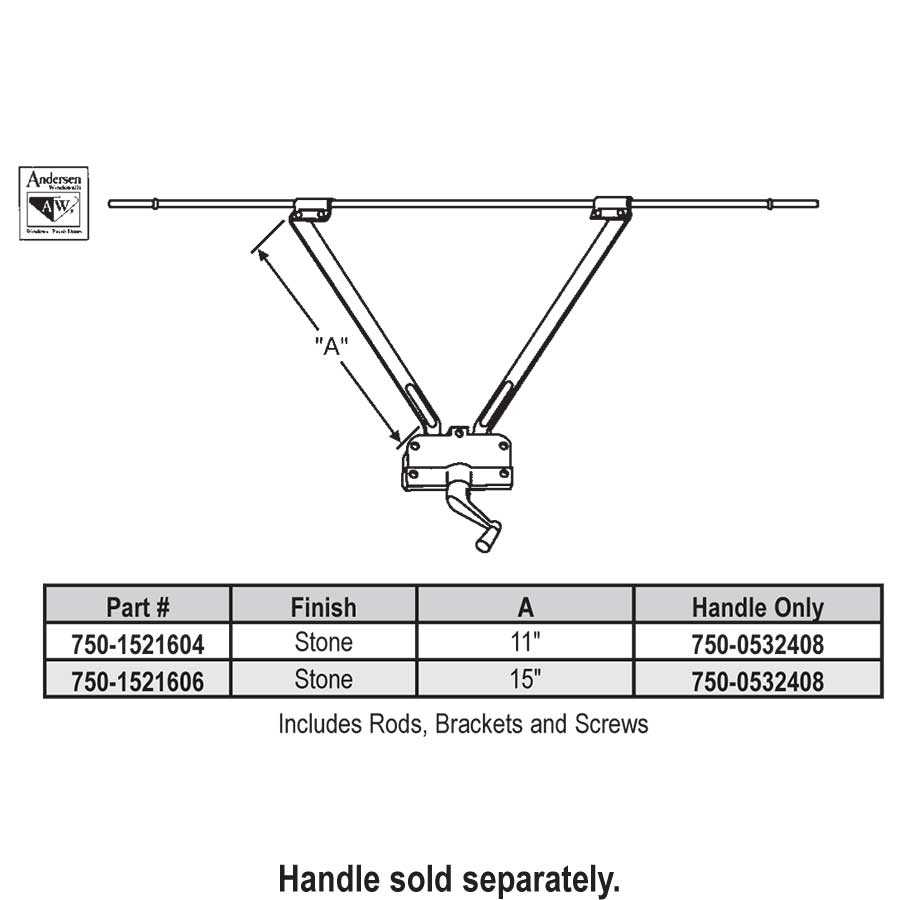

- Crank Mechanism: A rotating handle system that controls the opening and closing with precision.

- Seals and Weatherstripping: These components are crucial for ensuring the structure remains airtight, keeping drafts and moisture out.

- Locks and Fasteners: Devices installed to secure the unit, providing both safety and ease of access when needed.

Each of these parts works together,

Main Frame Construction and Materials

The structural foundation of the outer casing plays a crucial role in ensuring stability, durability, and long-lasting performance. It serves as the core element that holds various components together, providing the necessary support for a range of functions. Understanding the materials and design of this key structure helps to improve its efficiency and lifespan.

- Aluminum: Known for its lightweight nature and resistance to corrosion, aluminum is a popular choice in many structural designs. It offers a sleek appearance and is easy to maintain.

- Vinyl: Vinyl offers high insulation properties, making it a suitable material for energy efficiency. It is also weather-resistant and requires minimal upkeep.

- Wood: Traditional yet robust, wood provides excellent insulation and a natural aesthetic. However, it requires proper treatment to protect against environmental elements.

- Fiberglass: This material is highly durable and offers superior strength. Fiberglass also resists warping and is known for its low-maintenance qualities.

The design and material selection of the main casing directly affect factors such as thermal insulation, weather resistance, and overall structural integrity, making them critical considerations in any architectural project.

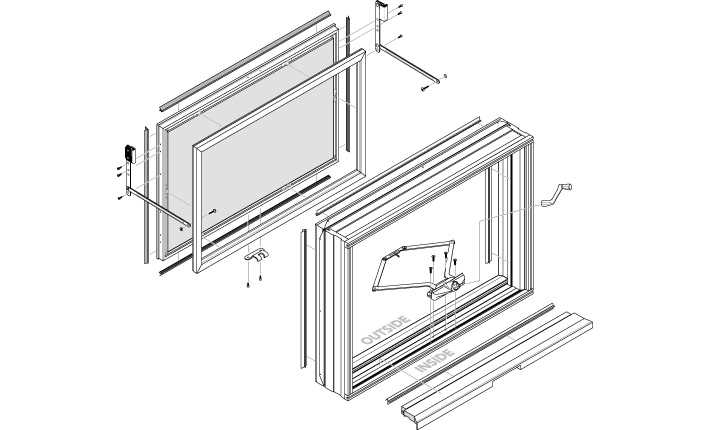

Operating Mechanism and Its Role

The functioning system plays a crucial role in controlling the opening and closing of the unit. It ensures smooth operation and allows the user to easily adjust the ventilation and security levels. The mechanism typically involves various components working in harmony to achieve precise movements, which contribute to the overall performance of the structure.

| Component | Function |

|---|---|

| Handle | Enables manual control over the opening and closing process. |

| Hinges | Supports the structure while allowing it to pivot during operation. |

| Linkage | Connects moving parts, ensuring synchronized movement and stability. |

| Locking Mechanism | Secures the unit in place, preventing unintended movements or drafts. |

Handle Types and Functions

Handles play a crucial role in providing ease of operation, comfort, and control. They are designed to fit different operational mechanisms and vary in appearance, style, and function, catering to specific user needs. This section explores the most common handle types and their respective functions, helping users choose the most suitable option for their system.

Common Handle Designs

There are several popular handle designs that differ in functionality and appearance. These designs can include options such as cranks, levers, and folding handles, each offering unique advantages. The choice of handle can impact both the efficiency and the aesthetic appeal of the system.

| Handle Type | Function | ||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Crank Handle | Provides precise control and requires less effort to operate, often used in systems where smooth and steady movement is required. | ||||||||||||||||||||

| Lever Handle | Allows for quick and easy operation with a simple push or pull motion, ideal for systems that need to be opened or closed

Locks and Security FeaturesEnsuring the safety of your living space is a top priority, and selecting the right locking mechanisms plays a vital role in achieving this goal. The variety of options available today provides both convenience and enhanced protection against unauthorized access. Key-operated locks offer a simple yet effective solution for securing your home, allowing only those with the right key to operate the mechanism. These systems come in various designs, providing flexibility for different types of installations. For those seeking additional peace of mind, multi-point locking systems distribute the locking force across several points, making it significantly harder to bypass. This advanced technology not only enhances security but also improves the durability of the entire setup. Modern digital and smart locks take security to a new level, allowing users to control and monitor access remotely. These innovative systems integrate seamlessly with home automation setups, offering both convenience and robust protection. Seals and Weatherproofing Elements

Maintaining a proper barrier against moisture and drafts is essential for ensuring long-lasting performance and protection from environmental factors. These components play a key role in preserving the structural integrity and energy efficiency of any enclosure, preventing unwanted infiltration. Types of Sealing MaterialsVarious sealing materials are used depending on the environment and the specific requirements. Common options include rubber gaskets, foam strips, and silicone-based compounds, each offering unique benefits in terms of durability, flexibility, and resistance to wear and weather conditions. Installation and Maintenance Tips

Proper installation of weatherproofing elements is crucial for their effectiveness. Regular inspection and timely replacement of worn-out components will ensure that they continue to provide optimal performance. Careful application of sealants and alignment of gaskets can greatly improve protection against the elements.

|