In this section, we will explore the key elements of a widely used lawn care machine, focusing on the specific arrangements and functionalities of various mechanical elements. By understanding how these components are organized and their roles, you’ll be better equipped to maintain and troubleshoot your equipment.

Each element plays a crucial part in ensuring the overall performance of the machinery. From cutting mechanisms to support structures, recognizing the importance of every part helps in both repair and efficient use. Identifying potential issues early can also prolong the lifespan of your equipment.

Whether you are performing routine maintenance or replacing damaged elements, having a clear understanding of how the mechanical system is structured will assist you in achieving the best results. This guide aims to provide clear insights into the structure and operation of key components.

Essential Components of X320 Mower Deck

The efficient operation of a mowing machine relies on several critical components that work together to ensure smooth and precise cutting performance. Each part contributes to the overall functionality, from cutting the grass to maintaining balance and support during operation.

| Component | Function |

|---|---|

| Blades | Responsible for cutting grass efficiently and evenly. |

| Belt | Transfers power from the engine to the blades, ensuring they rotate at the necessary speed. |

| Spindles | Hold the blades in place and allow for smooth rotation during operation. |

| Pulleys | Help guide the belt and maintain the correct tension for effective power transfer. |

| Anti-scalp Wheels | Prevent the cutting unit from scraping or damaging uneven terrain. |

Blade Types and Functions Overview

Understanding the variety of cutting blades is essential for ensuring optimal performance in different lawn maintenance tasks. Blades come in various shapes and designs, each suited to specific cutting needs and conditions. Below is an overview of the most common blade types and their functions.

Standard Blades

Standard blades, often referred to as straight blades, are the most common type. They are designed for efficient grass cutting and are suited for general-purpose use on well-maintained lawns. These blades ensure a clean cut and are easy to sharpen when needed.

Mulching Blades

Mulching blades have a curved design that allows them to finely chop grass clippings into small pieces. This design helps distribute clippings evenly across the lawn, acting as natural fertilizer and promoting healthy grass growth.

| Blade Type | Key Function |

|---|---|

| Standard Blade | Efficient for regular grass cutting |

| Mulching Blade | Designed for recycling grass into fine clippings |

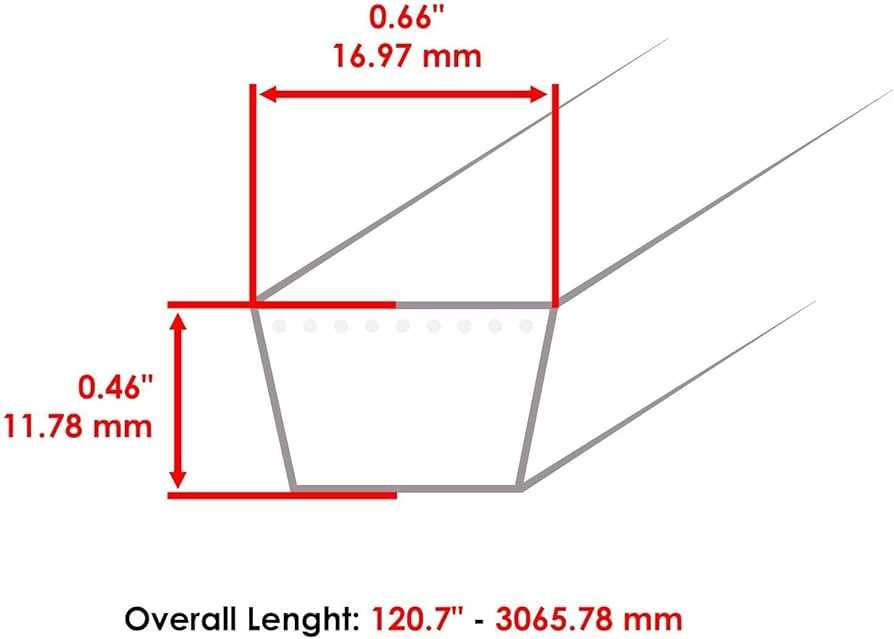

Belt System and Tension Mechanism

The belt system plays a critical role in transferring power efficiently between various components of the machine. Understanding how this system operates and ensuring proper alignment is essential for smooth functionality and extended equipment lifespan.

Structure of the Belt

The belt, designed to handle high levels of stress, connects vital rotating parts, ensuring synchronized movement. It must be robust enough to withstand friction and varying loads while maintaining flexibility.

Tension Adjustment

A properly adjusted tension mechanism is crucial for optimal belt performance. Too much tension can lead to premature wear, while insufficient tension may result in slipping. Regular inspection and adjustment of the tensioner ensure long-term efficiency and reduce the likelihood of breakdowns.

Spindle Assemblies and Maintenance Tips

Spindle assemblies play a crucial role in ensuring efficient operation and overall performance of mowing equipment. Proper upkeep and timely replacements are essential for maintaining smooth functionality, avoiding breakdowns, and extending the machine’s lifespan.

Key Components of Spindle Assemblies

The spindle assembly consists of several vital elements that work together to enable rotation and cutting action. Regular inspection of these parts helps identify any wear or damage early on.

- Bearing housing – supports the spindle shaft and ensures smooth rotation.

- Spindle shaft – connects to the cutting blade and transfers rotational force.

- Mounting bolts – secure the assembly to the cutting unit, ensuring stability.

Maintenance Tips for Longevity

- Regularly lubricate bearings to prevent friction and overheating.

- Check for loose or damaged bolts and tighten or replace them as necessary.

- Inspect blades for signs of wear and sharpen or

Deck Lift Mechanism Explained

The lifting mechanism is a crucial component that enables the elevation and lowering of the cutting platform for achieving the desired grass height. This system ensures that the user can easily adjust the positioning to match varying terrain conditions, providing flexibility in operation.

Key Components of the Lifting System include levers and cables that work together to smoothly raise and lower the cutting platform. These elements are engineered for durability and precision, ensuring a consistent and even cut.

Additionally, the linkage system plays a significant role by transferring the force applied through the control lever to the platform, ensuring stability and balance throughout the process. This ensures that the cutting height remains consistent even on uneven surfaces.

Idler Pulley and Adjustment Guide

The idler pulley plays a crucial role in the functioning of various lawn care equipment by helping maintain proper tension on the drive belt. This guide provides essential insights into the maintenance and adjustment of the idler pulley to ensure optimal performance and longevity of your machinery.

Proper adjustment of the idler pulley can prevent unnecessary wear on the belt and components, reducing the risk of breakdowns. Regular checks and timely adjustments will help maintain the efficiency of the entire system, leading to a smoother operation.

Adjustment Steps

To achieve the best performance from the idler pulley, follow these steps:

Step Description 1 Inspect the idler pulley for wear and damage. 2 Loosen the mounting bolts to adjust the tension. 3 Align the pulley with the drive belt. 4 Tighten the bolts securely after adjustment. 5 Test the system to ensure proper tension and operation. Regular maintenance of the idler pulley is vital for the overall health of your equipment. By adhering to the adjustment guidelines, users can significantly enhance performance and extend the lifespan of their machinery.

Discharge Chute and Its Role

The discharge chute is a crucial component in lawn maintenance equipment, designed to effectively direct clippings away from the cutting area. This mechanism plays an essential role in ensuring a clean and efficient mowing process, promoting an even distribution of grass trimmings across the lawn. Understanding its function and importance can enhance the overall performance of the equipment.

Functionality of the Discharge Chute

The primary purpose of the discharge chute is to channel grass clippings away from the mower. This prevents clogs and maintains optimal airflow within the cutting deck, allowing for a consistent cut. Additionally, the chute helps minimize the accumulation of debris, which can hinder the mower’s efficiency and lead to uneven cutting results.

Maintenance Considerations

Regular inspection and maintenance of the discharge chute are vital for ensuring its longevity and functionality. Debris buildup can obstruct the chute, affecting its performance. Keeping it clean and free of obstructions will help maintain the efficiency of the mowing process.

Maintenance Task Frequency Inspect for Debris After Each Use Clean Chute Interior Weekly Check for Wear Monthly Deck Shell Structure and Materials

The shell structure of a lawn maintenance machine plays a vital role in its overall performance and durability. It serves as the outer casing that protects internal components while providing structural integrity. Understanding the materials and design features used in this assembly is essential for optimal maintenance and functionality.

Material Composition

Typically, the outer shell is constructed from robust materials such as high-strength steel or durable polymers. These materials are selected for their resistance to wear and impact, ensuring longevity under various operating conditions. The use of advanced composites can also enhance weight efficiency while maintaining strength.

Structural Design Features

The design of the shell includes features that promote airflow and cooling during operation, which is crucial for preventing overheating. Additionally, various reinforcements may be integrated into the structure to withstand stress and enhance rigidity. Proper drainage channels are often included to prevent water accumulation, further protecting the inner components.

Anti-Scalp Wheels: Function and Care

Anti-scalp wheels play a crucial role in maintaining the quality of lawn mowing. These components are designed to prevent the cutting unit from scalping the grass, ensuring an even and healthy lawn surface. By keeping the mower at the correct height, they help in avoiding damage to the turf, promoting overall lawn health.

To ensure optimal performance, it is important to regularly inspect and maintain these wheels. Cleaning them after each use can prevent the buildup of grass clippings and debris. Additionally, checking for any signs of wear or damage will help in prolonging their lifespan. Proper adjustment is also key; ensuring that the wheels are positioned correctly can significantly enhance mowing efficiency.

In summary, anti-scalp wheels are essential for achieving a well-manicured lawn. Regular maintenance and proper care not only improve their functionality but also contribute to a better mowing experience.

Cleaning and Lubrication of Deck Parts

Regular maintenance is essential for ensuring optimal performance and longevity of the mowing mechanism. This section emphasizes the importance of keeping components clean and well-lubricated to prevent wear and ensure efficient operation.

Cleaning should be performed after each use, especially in areas that accumulate grass and debris. Follow these steps for effective maintenance:

- Turn off the engine and disconnect the spark plug to ensure safety.

- Use a scraper or brush to remove any clippings or dirt from the surfaces.

- Rinse with water if necessary, allowing it to dry completely before further steps.

Lubrication is equally crucial to maintain smooth operation. Consider the following points:

- Identify all moving elements that require lubrication.

- Apply a suitable lubricant to each specified area, ensuring not to over-lubricate.

- Regularly check for any signs of rust or damage and address them promptly.

By adhering to these maintenance practices, the functionality and efficiency of the mowing equipment can be significantly enhanced, leading to a better overall experience.

Safety Features on Mower Deck

Modern lawn care equipment incorporates various protective elements designed to ensure user safety and minimize the risk of accidents. These features play a crucial role in enhancing operational security during maintenance tasks.

One essential aspect of safety is the presence of automatic shut-off mechanisms that engage when the operator leaves the designated area. This prevents unintended operation and protects users from potential hazards.

Additionally, many models are equipped with blade guards that shield the cutting elements from accidental contact, further reducing the risk of injury. The ergonomic design of controls also contributes to safety by allowing operators to maintain a secure grip while managing the machine.

Regular inspections and maintenance of these safety features are vital to ensuring their effectiveness. By prioritizing safety in design and operation, manufacturers help users enjoy a secure mowing experience.