When it comes to maintaining or repairing a vehicle, having access to accurate and clear visual representations of its structure is crucial. These visual aids can simplify the process of identifying specific connections, hardware, and configurations, ensuring a smoother workflow for mechanics and car enthusiasts alike. The detailed schematics offer a breakdown of essential elements, making it easier to pinpoint what is needed during repair or assembly.

Each component within the system plays a vital role in the overall functionality of the vehicle. By examining these layouts, users can better comprehend how various elements work together, ensuring that each section operates efficiently. This type of resource is invaluable for those seeking to enhance their understanding of the intricate design and functionality behind modern automotive systems.

Understanding Original Manufacturer Components

When selecting components for your vehicle, it’s crucial to understand the benefits of using products created by the original producer. These items are crafted to meet the exact standards of the vehicle’s initial build, ensuring precise compatibility and reliable performance.

Quality assurance is one of the primary reasons to opt for such components. Each part is specifically engineered to maintain the integrity of the overall system, avoiding the potential issues that can arise from non-authentic alternatives.

Additionally, using components from the original manufacturer guarantees longer-lasting durability, as they are designed to work in harmony with the vehicle’s original specifications. This ensures a seamless fit and enhances the overall lifespan of the vehicle’s systems.

Exploring Compatibility Across Mercedes Models

When examining the interconnectivity of components across various vehicle models, understanding how different designs share common elements becomes crucial. This cross-platform compatibility ensures that certain elements can be used efficiently between models, enhancing the flexibility of maintenance and repair tasks.

Shared engineering principles often lead to standardized elements that can fit seamlessly into multiple designs. However, variations in year, design updates, and regional regulations can influence whether certain components will integrate smoothly. Thorough research is essential to ensure that replacements or upgrades match the specifications required by the vehicle’s system.

By analyzing structural similarities and key technical details, one can determine the best approach for achieving optimal performance across different models, while reducing the need for customizations.

How to Identify Genuine Replacement Parts

When searching for authentic components to replace worn or damaged elements, it’s important to ensure that you’re choosing high-quality items that meet the original standards. Identifying these can sometimes be challenging, but there are a few key methods to help verify their authenticity.

- Check the product code or serial number: Every original item typically has a unique identifier. Confirm this with the manufacturer’s specifications to ensure compatibility.

- Inspect the packaging: Genuine components often come in specific, high-quality packaging with logos, barcodes, and clear labeling that differentiate them from counterfeit products.

- Compare material quality: Authentic items are made with precise materials and finishes. Look out for inferior textures, incorrect colors, or poorly made parts.

- Verify with an official distributor: Always purchase from certified dealers or authorized sellers to minimize the risk of receiving counterfeit goods.

- Check for warranties: Original products are often backed by a warranty, which guarantees their performance and quality.

By following these steps, you can feel confident that the replacement component you choose will maintain the integrity and performance of your equipment.

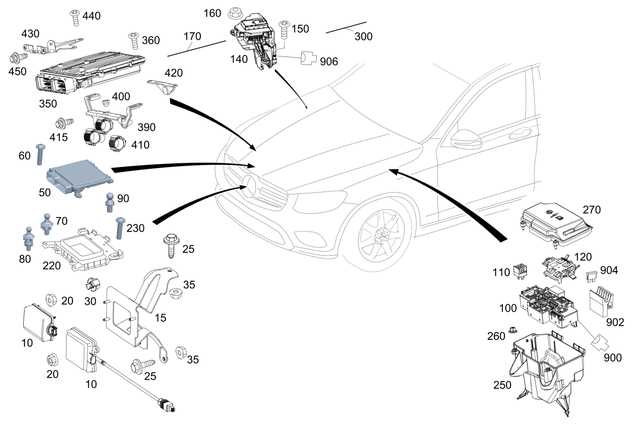

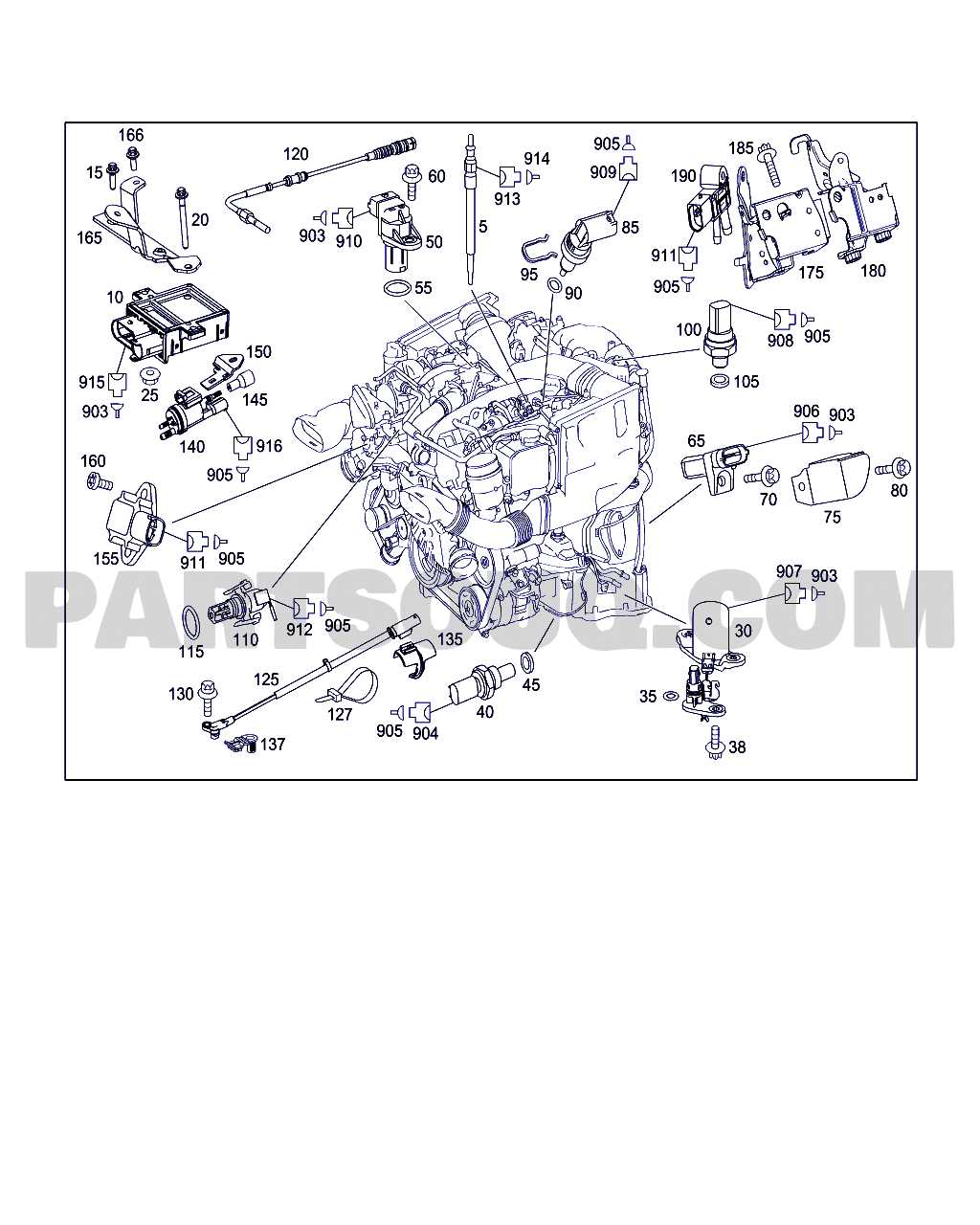

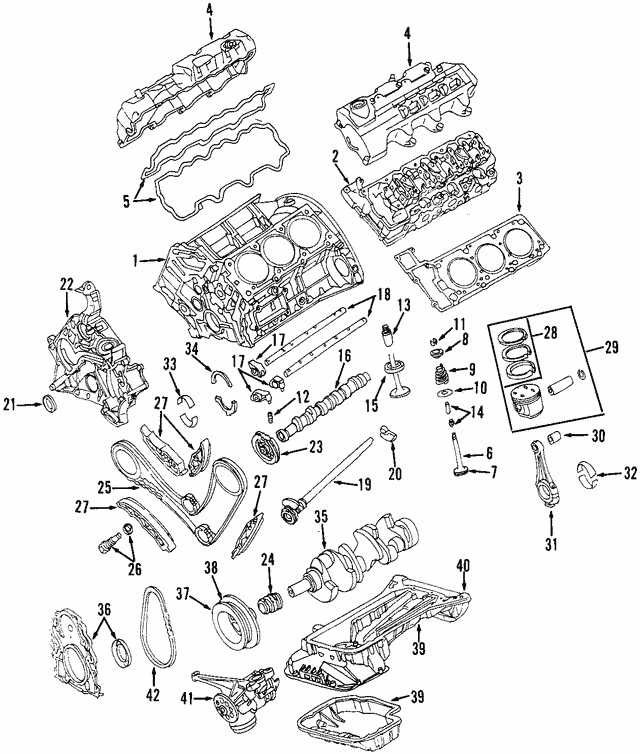

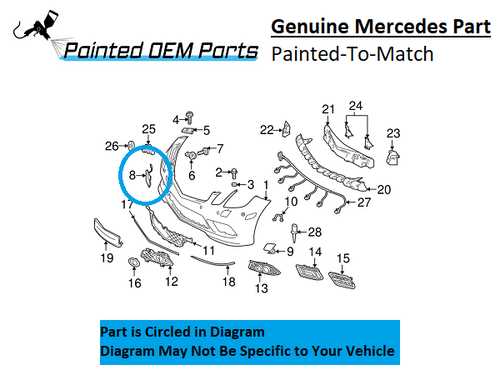

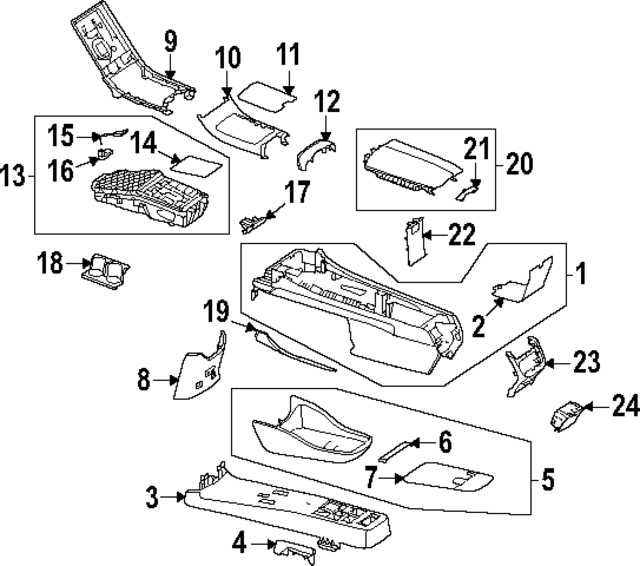

Reading and Analyzing Parts Schematics

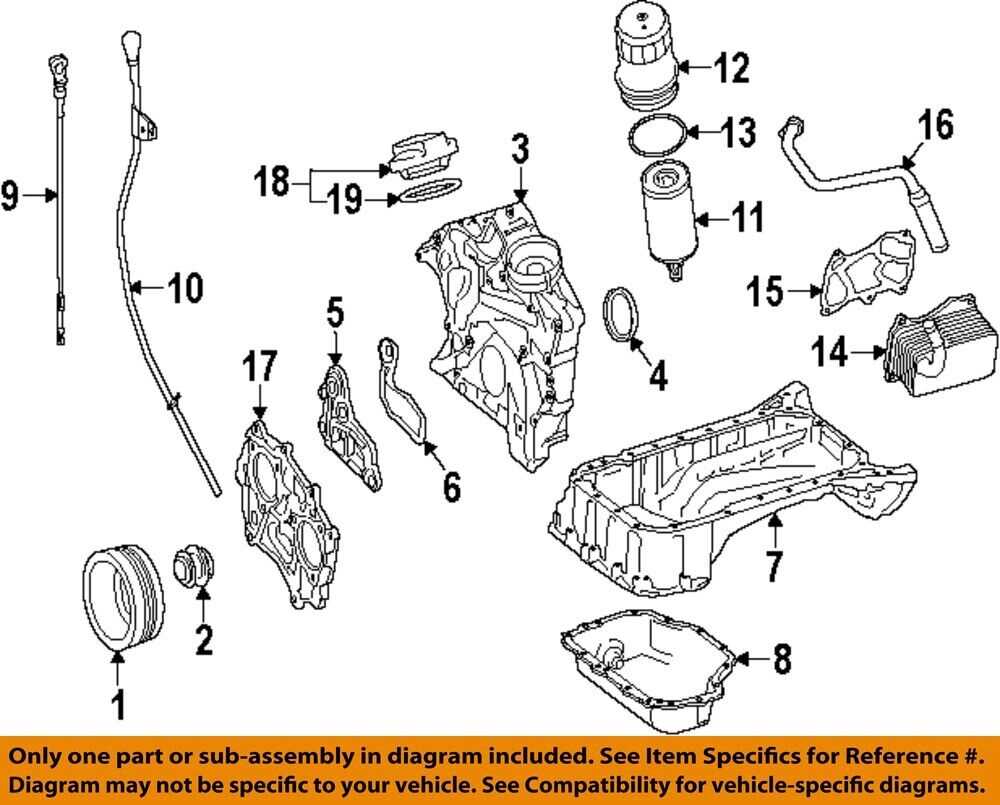

Understanding technical schematics is a crucial skill when dealing with mechanical assemblies. These detailed drawings provide a clear view of how various elements are interconnected and allow for efficient maintenance or upgrades. Proper interpretation of these diagrams can significantly simplify troubleshooting or component replacement.

When approaching a schematic, it’s important to break down the information into manageable sections:

- Identifying Components: Focus on recognizing individual elements in the layout. Each element is typically labeled with a reference number or symbol, which corresponds to a specific component in the list.

- Examining Connections: Study the pathways between elements to understand how they interact. This helps to visualize the flow of electrical signals, fluid, or mechanical forces.

- Interpreting Annotations: Schematics often include notes or symbols that provide additional details. These annotations may clarify technical specifications or special instructions for installation and usage.

By systematically analyzing each section, it becomes easier to diagnose issues or plan modifications based on the diagram’s structure. Attention to detail and careful study are key to mastering the reading of such technical illustrations.

Key Benefits of Using Authentic Components

Choosing original components for any vehicle or equipment ensures optimal performance, longevity, and reliability. By opting for certified elements, you maintain the integrity of the entire system, avoiding compatibility issues and potential failures. It is essential to consider the advantages of such selections to maximize the functionality of your asset.

Enhanced Durability and Reliability

Genuine elements are manufactured to meet strict quality standards, which guarantees that they last longer and perform better under various conditions. This durability minimizes the need for frequent replacements, saving you time and money in the long run.

Perfect Fit and Performance

Authentic components are designed to seamlessly integrate with the rest of your vehicle or equipment, ensuring that every part works in harmony. This precise fit improves efficiency and reduces the risk of malfunctions caused by improper installations or mismatched pieces.

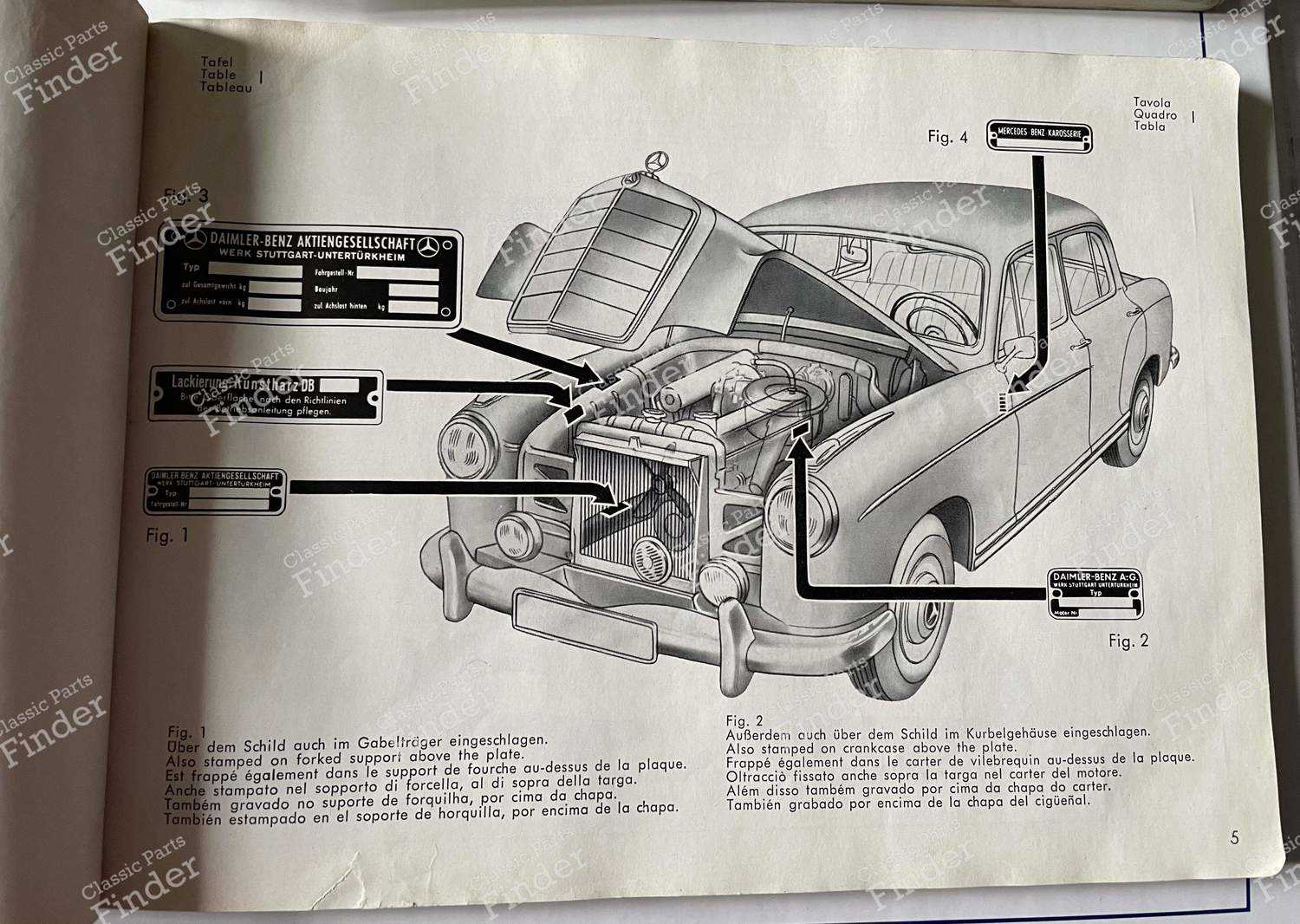

Decoding Part Numbers and Labels

Understanding the structure of identification codes and markings is essential for accurate sourcing and replacement of components. These alphanumeric sequences convey vital information regarding the specifications, compatibility, and manufacturing details of each item. Proper interpretation of these codes ensures that you obtain the correct component for your vehicle’s requirements.

Structure of Identification Codes

Typically, identification codes consist of a combination of letters and numbers that indicate various attributes. The initial segments may refer to the category or type of the item, while subsequent numbers often denote specific variations or revisions. Familiarity with these conventions enables enthusiasts and professionals to navigate catalogs and databases more effectively.

Labeling Standards and Interpretation

Labels on components may include additional information such as manufacturing dates, geographic origins, and compliance certifications. These details help to verify the authenticity and quality of the items. By learning how to read and interpret these labels, users can make informed decisions about the products they are considering for installation or replacement.

Installation Tips for Factory-Approved Parts

When upgrading or replacing components in your vehicle, ensuring that you follow the correct installation procedures is essential for optimal performance and longevity. Utilizing factory-certified items can greatly enhance reliability and maintain the integrity of your machine.

1. Verify Compatibility: Before beginning the installation, confirm that the selected components match the specifications required for your model. Consult the manufacturer’s guidelines to ensure proper fitment.

2. Gather Necessary Tools: Having the right tools on hand can streamline the installation process. Ensure you have all essential equipment ready, such as wrenches, screwdrivers, and any specialized tools recommended by the manufacturer.

3. Follow Manufacturer Instructions: Always adhere to the provided installation instructions closely. These guidelines are designed to help you achieve a successful installation while minimizing the risk of damage or malfunction.

4. Inspect Existing Components: Before installation, examine any related components for wear or damage. Addressing these issues beforehand can prevent further complications and ensure that the new items function correctly.

5. Test After Installation: Once everything is in place, conduct thorough testing to confirm that the new components operate as expected. Pay attention to any unusual sounds or behaviors that may indicate improper installation.

Tracking Updates and Revisions in Diagrams

Maintaining the accuracy of technical representations is essential for ensuring effective communication and understanding among users. Regular updates and revisions help reflect changes in specifications, enhance clarity, and improve usability. Establishing a systematic approach to track these modifications ensures that all stakeholders are informed and can make the best use of the available information.

Importance of Regular Updates

Periodic updates to technical illustrations provide numerous benefits, including:

- Accuracy: Ensures that the information is current and correct.

- Compliance: Adapts to regulatory changes or industry standards.

- User Experience: Enhances clarity, making it easier for users to interpret the information.

Best Practices for Tracking Changes

To effectively monitor modifications, consider the following strategies:

- Version Control: Implement a versioning system to document updates chronologically.

- Change Logs: Maintain detailed records of what changes were made, why, and by whom.

- User Feedback: Incorporate feedback from users to identify areas needing clarification or correction.

- Consistent Review: Schedule regular audits of the information to ensure it remains relevant and accurate.

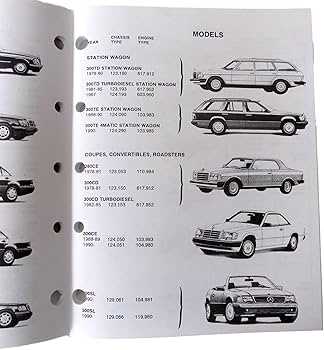

Finding the Right Diagram for Your Vehicle

Locating the appropriate visual representation for your automobile is essential for effective maintenance and repairs. Understanding the layout and components of your vehicle can significantly simplify the troubleshooting process and enhance your overall experience.

When searching for the correct illustration, consider the following steps:

- Identify Your Vehicle’s Model and Year: Accurate identification ensures you find the specific representation tailored for your automobile.

- Consult Official Resources: Utilize manufacturer websites or authorized service manuals to obtain reliable visuals.

- Explore Online Forums: Engage with community groups where enthusiasts share valuable insights and resources.

- Check Parts Retailers: Many reputable suppliers provide detailed visuals alongside their offerings, which can assist in your search.

By following these guidelines, you can enhance your understanding of your vehicle’s structure and components, leading to more informed decisions during maintenance and repairs.

Commonly Replaced Components and Their Locations

When maintaining a vehicle, certain components tend to wear out more frequently than others. Identifying these elements and their positions within the assembly can enhance the efficiency of repairs and replacements, ultimately improving the vehicle’s overall performance.

Among the most frequently substituted components are filters, such as oil, air, and fuel filters, which are typically situated near the engine or fuel tank. Additionally, batteries are often located in the engine bay, where they are easily accessible for replacement. Other commonly replaced elements include wipers, which can be found on the exterior of the windshield, and brake pads, typically positioned near the wheel assemblies.

Moreover, belts and hoses play a crucial role in the functioning of various systems and are generally routed throughout the engine compartment. Understanding the location of these essential components aids in performing timely maintenance, ensuring that the vehicle remains in optimal condition.

Avoiding Counterfeit Parts in the Market

In today’s automotive landscape, the proliferation of imitation components poses significant risks to vehicle owners. These unauthorized replicas can compromise not only performance but also safety. It is crucial to recognize how to identify and avoid these fraudulent offerings to ensure that your vehicle operates optimally and remains reliable.

Understanding the Risks

The use of non-genuine replacements can lead to various issues, from decreased efficiency to complete system failures. Additionally, counterfeit items often lack the durability and reliability of authentic equivalents, leading to more frequent replacements and increased costs over time.

Key Strategies for Identification

To protect your investment, consider implementing the following strategies:

| Strategy | Description |

|---|---|

| Verify Sources | Purchase from reputable dealers and authorized retailers to ensure authenticity. |

| Check Packaging | Examine the packaging for signs of tampering or poor quality, which may indicate a counterfeit item. |

| Look for Certifications | Authentic components often come with certifications or warranties; verify these before purchasing. |

| Research Part Numbers | Always cross-reference part numbers with official manufacturer databases to confirm legitimacy. |