During the cold months, maintaining optimal performance of your outdoor machinery is crucial for efficient operation. Familiarity with the various components of your equipment not only enhances its functionality but also extends its lifespan. Knowing how each piece interacts with the others is essential for troubleshooting and repairs.

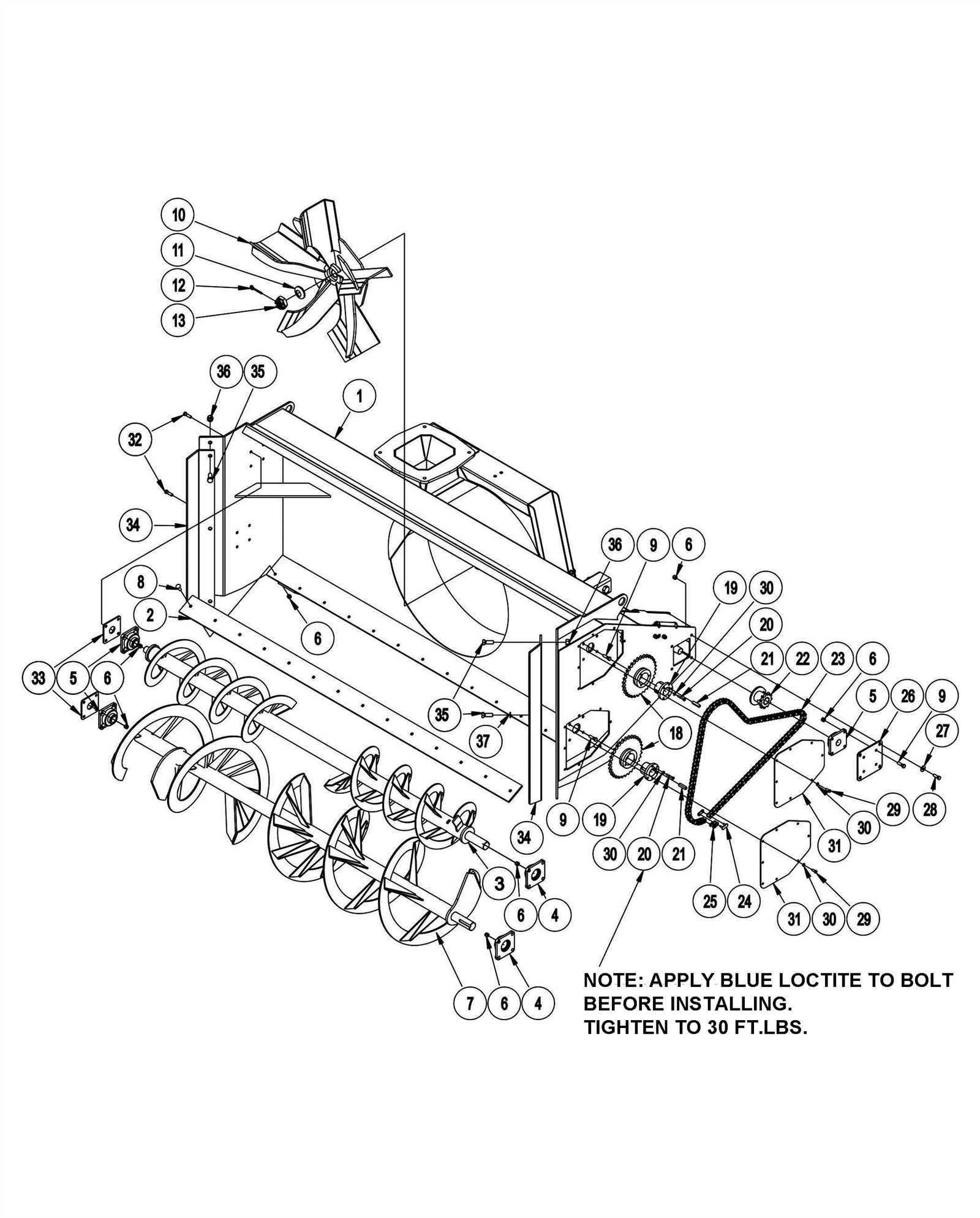

In this section, we will explore the intricate relationships among different elements that make up your winter tools. By dissecting the assembly and understanding the role of each segment, users can ensure smooth operation and effective service. A clear representation of these components serves as an invaluable resource for both novice users and experienced operators alike.

Whether you are looking to replace a worn-out component or simply wish to gain insight into the mechanics of your machinery, grasping the layout and function of individual elements is key. This knowledge empowers users to make informed decisions regarding maintenance and repairs, leading to a more productive experience during the snowy season.

Understanding the critical components of these machines is essential for effective operation and maintenance. Each element plays a significant role in the overall performance, ensuring efficiency and reliability during winter conditions. Below, we explore the fundamental elements that contribute to the functionality of these devices.

Main Components

- Engine: The heart of the machine, responsible for providing the necessary power to operate.

- Auger: The rotating blade system that collects and moves the snow toward the discharge chute.

- Chassis: The framework that supports all other components, ensuring stability and durability.

- Discharge Chute: Directs the expelled snow away from the unit, allowing for efficient clearing of pathways.

- Controls: The user interface that allows operators to manage speed, direction, and other functions.

Additional Features

- Skids: Adjustable feet that help maintain optimal height and prevent damage to surfaces.

- Headlights: Improve visibility during nighttime or low-light conditions, enhancing safety.

- Traction Tires: Specially designed to provide grip on icy or snowy surfaces, ensuring stability.

- Heated Hand Grips: Increase comfort for the operator during prolonged use in cold weather.

Visual Representation of Key Components

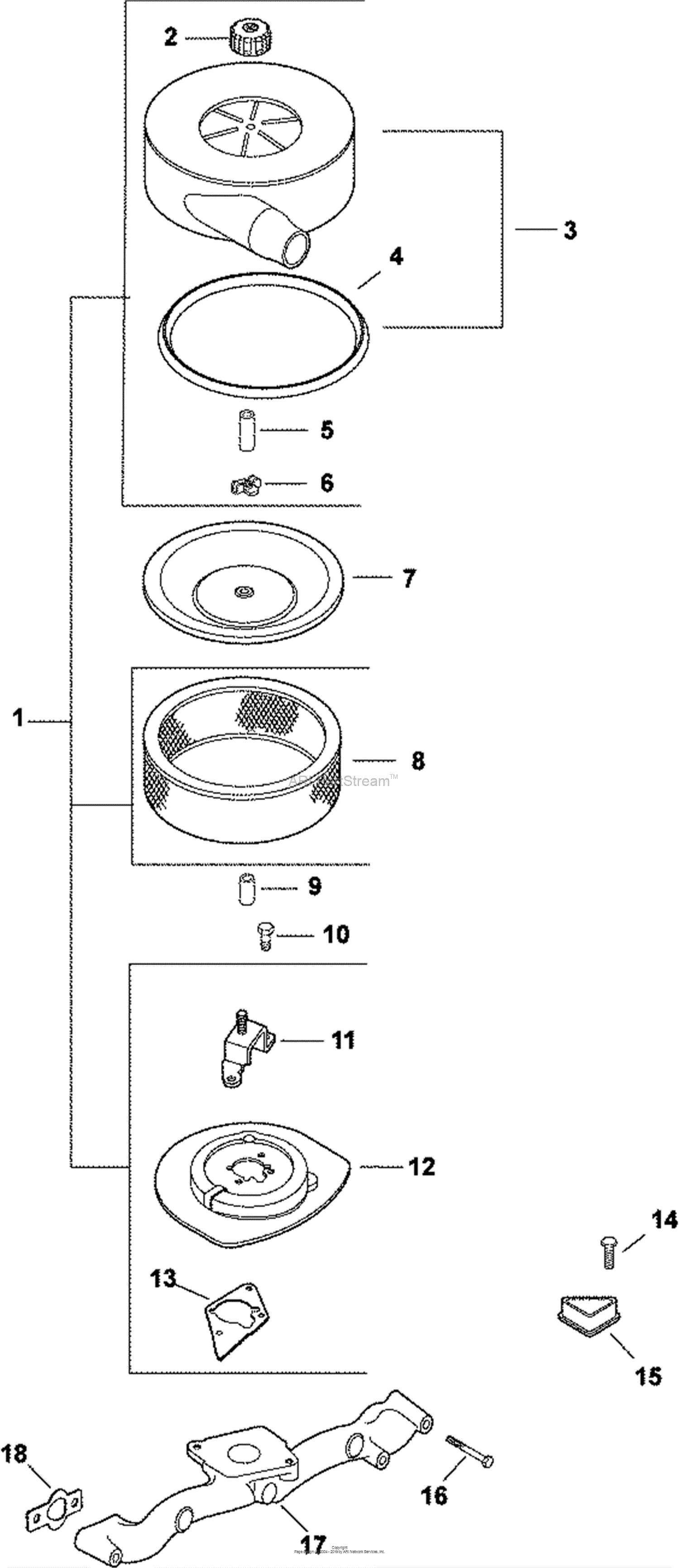

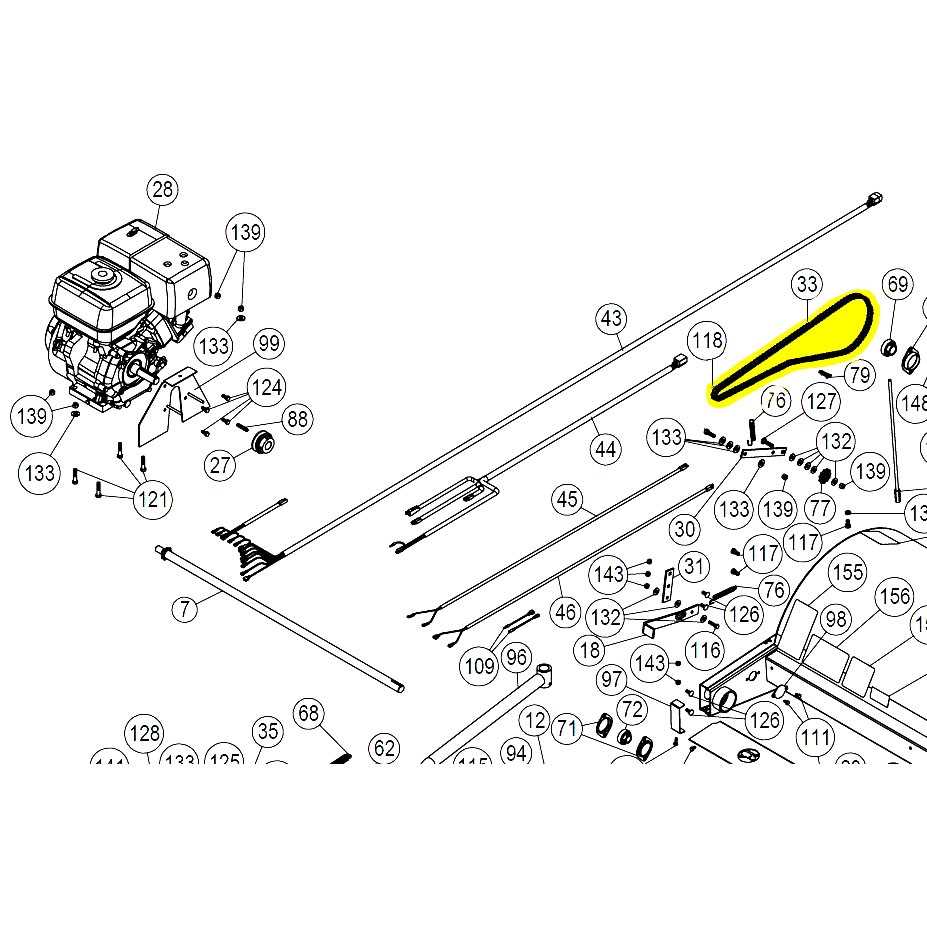

The visualization of essential elements plays a crucial role in understanding the functionality and assembly of any mechanical device. By examining illustrations and layouts, users can gain insights into how various components interact and contribute to overall performance. This knowledge not only aids in maintenance but also enhances the user’s ability to troubleshoot issues effectively.

Critical Elements Overview

In any machinery, certain critical elements are pivotal for optimal operation. These include the propulsion mechanism, cutting tools, and control systems. Understanding their arrangement and connection points is vital for both assembly and repair. Each component has a specific role, and recognizing these can lead to improved efficiency and longevity of the equipment.

Understanding Component Interaction

Analyzing how different elements work together is essential for effective operation. For instance, the connection between the drive system and the cutting mechanism illustrates the importance of synchronization. A visual layout can clarify how power is transferred and highlight potential areas for wear and tear, making it easier to identify maintenance needs.

Common Issues with Snowblower Parts

In cold weather, equipment designed for clearing snow can face several challenges that affect performance and efficiency. Understanding frequent problems that arise with various components can aid in timely maintenance and repairs, ensuring smooth operation during harsh conditions.

Below are some typical challenges encountered with essential components:

| Component | Issue | Possible Solution |

|---|---|---|

| Drive Belt | Worn or frayed, causing slippage | Inspect regularly and replace if damaged |

| Auger | Obstruction or bending, affecting movement | Clear debris and realign if necessary |

| Engine | Hard starting or stalling | Check fuel levels and clean spark plug |

| Chassis | Corrosion or wear from harsh conditions | Apply protective coatings and store properly |

Regular inspection and proactive maintenance of these key components can significantly enhance the longevity and effectiveness of the equipment, ensuring it is ready for use when needed the most.

Maintenance Tips for Snowblower Efficiency

Regular upkeep of your winter equipment is essential for optimal performance and longevity. Implementing a few simple maintenance strategies can enhance efficiency and ensure smooth operation during harsh conditions.

Essential Maintenance Practices

- Inspect the Fuel System: Ensure that the fuel tank is clean and free from contaminants. Use fresh fuel and consider adding a fuel stabilizer to prevent degradation.

- Check the Oil Level: Regularly examine the oil level and replace it as needed. Clean oil improves engine performance and reduces wear.

- Sharpen the Blades: Dull blades can hinder effectiveness. Regularly sharpen or replace the cutting components to maintain optimal performance.

- Clean the Exterior: Remove snow, ice, and debris from the exterior to prevent corrosion and enhance airflow.

Seasonal Preparations

- Pre-Season Check: Before the winter season, perform a thorough inspection of all components to ensure everything is functioning correctly.

- Post-Season Care: After the winter, clean and store the equipment in a dry place to prevent rust and damage.

- Lubricate Moving Parts: Apply lubricant to all moving parts to minimize friction and wear during operation.

How to Identify Part Numbers

Understanding how to pinpoint component identifiers is essential for effective maintenance and repair of machinery. Accurate identification ensures that the correct elements are sourced, facilitating seamless functionality and extending the lifespan of equipment.

To accurately recognize these identifiers, follow these steps:

- Refer to the Owner’s Manual: Most equipment manuals contain a detailed list of component identifiers, making them an invaluable resource.

- Examine the Equipment: Check the actual machine for labels or tags that may indicate the identifiers for various components.

- Online Resources: Manufacturer websites often provide extensive catalogs and databases that can help locate the necessary identifiers.

- Consult with Experts: Reach out to professionals or forums specializing in your machinery for assistance in identifying specific elements.

By utilizing these strategies, you can efficiently find the necessary component identifiers, ensuring proper repairs and maintenance.

Ordering Replacement Parts Online

When it comes to maintaining your equipment, sourcing components through online platforms offers a convenient solution. This approach allows users to quickly locate the necessary elements without the hassle of visiting multiple physical stores. Whether you’re looking for a specific item or exploring compatible alternatives, the internet provides a vast array of options tailored to your needs.

Finding Reliable Suppliers

Identifying trustworthy vendors is crucial when purchasing components online. Start by researching reputable websites that specialize in outdoor machinery and accessories. Look for customer reviews, ratings, and any warranty information that can provide insight into the quality and reliability of the products offered. Additionally, ensuring that the supplier has a clear return policy can save you from potential issues down the line.

Ensuring Compatibility

Before finalizing your order, verify that the selected component matches your model specifications. Many online retailers provide detailed descriptions and compatibility charts, making it easier to confirm that the item will function as intended. Taking the time to double-check these details can prevent unnecessary delays and expenses, ensuring a seamless maintenance experience.

Installation Guide for New Parts

Ensuring the proper installation of new components is crucial for the effective operation of your equipment. This guide outlines the steps necessary to seamlessly integrate new elements into your machine, enhancing its performance and longevity.

Before starting the installation, gather the required tools and components. Here’s a brief checklist:

- Replacement components

- Basic hand tools (screwdrivers, wrenches, etc.)

- Protective gloves and eyewear

- Owner’s manual for reference

Follow these steps for a successful installation:

- Safety First: Disconnect any power sources to avoid accidents.

- Remove Old Components: Carefully detach the existing elements by following the instructions in the owner’s manual.

- Inspect the Area: Check for any damage or debris that may affect the new component’s installation.

- Install the New Component: Position the new part in place, ensuring a secure fit. Refer to the manual for specific orientation and alignment details.

- Secure Connections: Tighten any fasteners or connections to prevent loosening during operation.

- Test Functionality: Reconnect the power source and perform a functionality check to ensure everything operates smoothly.

By following this guide, you can confidently replace components and maintain the efficiency of your machine.

Safety Precautions During Repairs

When undertaking maintenance or fixing equipment, ensuring safety is paramount. Proper precautions not only protect the individual performing the task but also help prevent damage to the machinery. Following specific guidelines can mitigate risks and create a safer work environment.

Here are essential safety measures to keep in mind:

- Wear Personal Protective Equipment (PPE): Always don safety goggles, gloves, and sturdy footwear to shield against potential hazards.

- Disconnect Power Sources: Before starting any work, ensure that the equipment is unplugged or disconnected from its power source to prevent accidental activation.

- Work in a Well-Ventilated Area: Adequate airflow is crucial when handling chemicals or performing tasks that generate fumes.

- Use Proper Tools: Employ the correct tools for each job to avoid injuries and ensure efficient repairs.

- Read the Manual: Familiarize yourself with the equipment’s manual to understand specific safety instructions and warnings.

By adhering to these guidelines, individuals can significantly reduce the risk of accidents and enhance the overall safety of repair activities.

Upgrading Your Snowblower Features

Enhancing your machine’s capabilities can significantly improve its performance during winter tasks. By incorporating advanced components, you can achieve greater efficiency and versatility, making your work easier and more enjoyable.

When considering enhancements, it’s essential to evaluate which features will provide the most benefit for your specific needs. Below is a comparison of common upgrades that can enhance functionality:

| Upgrade Type | Description | Benefits |

|---|---|---|

| Power Kit | Increase engine horsepower or torque. | Improved snow clearing ability, especially in heavy accumulations. |

| Control System | Upgrade to electronic or joystick controls. | Smoother operation and enhanced maneuverability. |

| Auger Enhancements | Install advanced augers for better snow handling. | More efficient snow chopping and throwing distance. |

| Additional Accessories | Add items like LED lights or heated grips. | Improved visibility and comfort during operation. |

Investing in these upgrades not only boosts performance but can also extend the lifespan of your equipment. By selecting the right enhancements, you ensure that your machine is ready to tackle any winter challenge with ease.

Resources for Snowblower Troubleshooting

When facing issues with your outdoor equipment, having the right resources can make a significant difference in effectively diagnosing and resolving problems. Utilizing various materials and tools can help streamline the troubleshooting process, ensuring that your machinery operates smoothly and efficiently.

Manuals and Documentation

User manuals are invaluable resources that provide detailed information on operational guidelines, maintenance schedules, and troubleshooting steps. Additionally, technical documentation can offer insights into specific components and their functions, helping you identify potential issues more accurately.

Online Communities and Forums

Engaging with online communities dedicated to outdoor equipment can be incredibly beneficial. These platforms allow users to share experiences, tips, and solutions for common issues. Furthermore, forums often feature discussions that can provide practical advice and troubleshooting techniques from experienced users.